Beruflich Dokumente

Kultur Dokumente

What's New @: A Hundred Uses With Over A Hundred Thousand Channels in Use!

Hochgeladen von

cumtjerryOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

What's New @: A Hundred Uses With Over A Hundred Thousand Channels in Use!

Hochgeladen von

cumtjerryCopyright:

Verfügbare Formate

5/7/2013

A Look Into HBMs Somat Product Line..

A Hundred uses with over a Hundred Thousand channels in use!

The eDAQ and eDAQ Lite have accumulated over 100,000 channels produced in the past handful of years!

Whats new @

The smallest system may only have a handful of channels, the largest systems have hundreds, hundreds sometimes thousands!

2013

A Hundred uses with over a Hundred Thousand channels in use!

A typical single system of eDAQ is about 100 channels, a typical Lite system is only about 30!

Wireless Communications

Adding the ability to distance yourself from the scenario..!

The new SO-WIFI-2 provides a truly plug and play approach to connecting to your eDAQ system.. With an 80211 54Mbps connection it is almost like being directly connected but now without a cable you could be 1,000 feet (300 meters) away or more! An Android APP is now available and can be used on any portable device that supports Android OS 3+, but even if you are an Apple user, you can still use the built in web server on the eDAQ to control your test.

The largest number of systems networked together was eleven, which was used for a missile test! The systems were over a mile away from the operators! It had to be perfect, a single test was estimated at $1,000,000 per launch!

5/7/2013

Video Layer Integration (Lite & Plus)

Integrated plug and play video integration

Ruggedized enclosures with everything that you need to capture fully synchronized video streamed directly into your data stream. Up to 30fps at 1megapixel with selectable compression rates the video layer offers a guaranteed synchronized video stream in motion jpeg format that can be manipulated directly with your data, you can even export the images directly to Excel along with the referenced data.

Powering your eDAQ

Whenever the need arises to have that extra autonomy..

The eDAQ Lite has been able to operate from a battery pack located in the base (illustrated below), but the eDAQ Plus being of much greater channel densities has always been overwhelmed by the size of batteries that could be used. All of that has changed and as the battery technologies improve, we are taking advantage of the enhanced longevity, power and capacity that they offer. The new Plus battery layer integrates a power solution that could operate an average sized eDAQ for up to five hours of continual testing, add this to the ability to operate in a lower power mode (awaiting a programmable trigger) and the system could literally be stationed for days on a single charge!

Switch (integrated POE) DC-DC converter

PLUS battery

encoders

Lite battery

Simply fixes to the base of your system

4 camera PLUS type

5 6

Software Enhancements

Reacting to the needs and desires of the user..

TCE (Test Control Environment) has been a mainstay for the eDAQ for many years, it is both proven and reliable yet there is always something new that can be added! In 2012 we added the power save mode, this was specifically for railroad applications that were unattended for may months and even years! It provided the user with the ability to cut all power to transducers and place the eDAQ into a latent state until a specific event occurs. We added this into TCE as a free enhancement late last year. In 2013 we added enhanced and expanded CAN capabilities, most notably the ability to import a CCP file in either A2L (ATI) or ROB (ETAS) formats then derive the CAN database for use on the eDAQ. This included the support of the seed key requirements for much of the CCP implementations. We also added larger CAN signal handling capabilities that increased the total signal capability of the COM layer to more than th a thousand th d (1,000) (1 000) filt filtered d CAN messages as well ll as enhanced h d filt filtering! i !

SomatCR Thermocouple Solution using CAN

The all new large scale temperature measurement solution..

Temperature measurement is actually the most common measurement made! Often times the number of thermal monitoring channels exceed all other channel types by a factor of 5 to 10! As part of our ongoing efforts to simplify the testing process, especially the preparation, we have introduced the SomatCR CAN thermocouple measurement system. This compact and robust device provides 16 channels of K, J or T type thermocouples per unit and up to 16 units could be daisy chained together into each COM port of the eCOM and/or eLCOM unit! This means that with a single layer on your eDAQ Lite you could be measuring over 1,000 temperatures!

Power save option A2L file import

5/7/2013

A Look Into HBMs Somat Product Line..

Brake Testing using eDAQ

The eDAQ has proven to be an excellent choice for brake test applications..

The quote is from a test Engineer at the NTRC(Braking systems and Safety in Ohio) and is based on a series of first time uses where the eDAQ Lite has been implemented for brake performance testing. The eDAQ Lite can be used as a brake performance test tool by simply knowing that many of the features that would be required for the test are inherently available in the system itself. For example, the ability to know when the event started is of paramount importance, or the ability to only perform certain functions during the event and of course the knowing when the event ended! Derived information is as much a part of the test as actual acquired information, this all has to happen very quickly, be repeatable and representative.

Brake Testing Using eDAQ & eDAQ Lite

Test requirements are, simply put, knowing how long from the command to stop it took to actually stop, what force was required, how the mass behaved and how effective the entire operation was, thermally as well as cohesively.

10

Brake Testing using eDAQ

What is required for the targeted standard?

No test has validity unless a specific objective is defined, in the case of brake testing the requirements can be broken down and defined into specific steps/stages, the user, of course, would need to have all of this work taken care of for them! This can be easily achieved using the eDAQ Field Computer in conjunction with some very simple and straightforward calculations, and a user interface..

Brake Testing using eDAQ

Providing the information at this point will save time later!

These tests are typically based on Govt. requirements, there is extensive documentation available and the nice thing is that they dont change that often! The advantage is continuity..

The user may want to print the test sequence instructions out, they may want to review or even reorder, the operator will need to have a quick reference when they are running.

11

12

5/7/2013

Brake Testing using eDAQ

Some thoughts about starting the test..

When the test starts, there are certain criteria that have to be satisfied for the test start to be valid! The actual application of the brakes may actually be the end of a prior sequence such as developing the correct speed, ascertaining the correct thermal component, such as rotor or material temperatures or placing the vehicle into a specific attitude to obtain the inertial effects of a shifting load?

Brake Testing using eDAQ

Actually interfacing with the operator

The operator should not be distracted at any point during the test! On eDAQ this is actually very simple and easy to achieve, the system can provide audible feedback if the operator doesnt want to lose concentration for even a moment!

The data acquisition system must be able to provide some feedback to the operator possibly without the interference of visual distractions or operator intervention!

Since eDAQ can deal equally as well with digital outputs, the digital output could be used in conjunction with alarms, buzzers, tone indicators or even the vehicle horn!

That isnt to say that visual feedback isnt possible, in fact this can all be achieved hand in hand..

Of course the other thing that the data acquisition system mustnt do is interfere with the test in respect of influencing the performance of any safety system involved!

13

14

Brake Testing using eDAQ

Simple yet capable operation..

The basic requirements for brake testing are: Speed. Brake operation. Brake pressure/loads associated with operation. Temperatures various. More detail: as well as some expansion on additional parameters. Speed Wheel speed sensors (all contacting wheels). Sometimes extracted directly from ABS sensors. Road speed non contact or fifth wheel. Also often derived from GPS data. Brake Operation Directly from related and associated activation switches, also from ancillary switches such plate additions for pedals or levers. Pressure switches (also used to track latency in pressure based systems very important for pneumatic assisted systems). Brake Pressure/Loads Typically in-line pressure sensors that have zero or absolute minimal implication to operational performance of systems. Load cells or pedal/lever assemblies that have been prepared/converted into load cells. Temperatures Rotor/drum skin temperature. Pressure equipment, lines, cylinders, pumps valves (largely depends on preference). Proximity, proximity implication, material and dissipation proximities.

Brake Testing using eDAQ

The Nuts & Bolts

The nuts and bolts of brake testing (generalized) amounts to knowing some key pieces of information, the predominant one is of course the speed. This is where the initial test criteria is defined, is the vehicle (specimen) traveling at the correct speed to commence the actual braking activity? The definition of stopping distance is simply the perceived distance from the start point to the point at which the vehicle/specimen has come to a complete stop. The problem is that this is very relative, that is to say that forward motion may have been halted, but the vehicle/specimen itself is still in some sort of motion! This is especially apparent when dealing with test vehicles/specimens such as tracked ones. In the case of a tank for example, while forward motion has seemingly ended, the vehicle may be in a severe pitching condition, this of course means that there could be a loss of control as the mass from fore to aft, in some cases the center of gravity is so influenced by factors almost unique to the test vehicle, that motion actually ceases some moments after the actual f d motion, ti h as ended! d d! forward as such,

FUEL TANK

Compensating for the mass movement must be a consideration in some tests. GPS on iPhone

15

worksheet

16

5/7/2013

Brake Testing using eDAQ

The Nuts & Bolts

Actual criteria discussed.. Additional parameters may be that the thermal considerations are in place as well, in eDAQ surmising these is incredibly simple, you merely look at the transducer values using some very simple Boolean logic;

Brake Testing using eDAQ

The Nuts & Bolts

Where parameters such as the brake temperatures are concerned, the eDAQ makes adding and modifying these very simple, you can also integrate these with the API (Application Programming Interface) of the eDAQ and have feedback visually through customized API programs. Getting triggers accurately is of course very important, even in the case of something like a brake pedal where the braking event could be triggered from a load cell or pressure plate the eDAQ provides the user with advanced flexibility in respect of threshold and combination monitoring.

worksheet

The above simply shows the ease with which you could create the Boolean logic required for the speed trigger component. This could be combined with other parameters such as the temperature of the pad material.

worksheet

17

In the above example we have named the brake switch

18

Brake Testing using eDAQ

Going for the Distance!

In the below example one of the many canned calculation channels is used to get the distance component.

Brake Testing using eDAQ

The key components

The primary components to a successful test are; speed, brake event start, vehicle/specimen attitude (situation) and event conclusion.

From the speed, you can get the distance and deceleration rates as well as instantaneous values.

The derived information, such as distance is gathered from the speed and period information and can be processed and presented as live, available information. Note the way that the primary trigger, and a secondary trigger can be used to prevent integrating numbers when it is not appropriate to do so.

worksheet

19

worksheet

20

5/7/2013

Brake Testing using eDAQ

Stopping and confirming test success

The purpose of the test may be performance, behavior or even safety, but either way the test needs to be stopped and the success of the test is better evaluated sooner than later.

Brake Testing using eDAQ

Test Configuration

Below is an example of the computed channels involved..

OUTOFBOUNDS

WITHINBOUNDS

WITHINBOUNDS

For that reason, the actual or desired outcome requirement needs to be known prior to commencing the test itself!

21

What you see is: Time because an accurate representation of time is essential, the eDAQ has time derived from a 1Ghz clock! PrevSpeed a special lagging channel for comparison purposes, increasing, decreasing or constant. Stopped the criteria that actually indicates that a full stop has been achieved. LogNow the combined speed and control switches. Brake_Trip a combination of the master control and the brake application. TestActive this is actually just a method of turning a generically Boolean value into a numeric value. InProgress to track when a change occurs this is a lagged value of the TestActive channel. Last_Stopped again, a lagged version but this time of Stopped computed channel. End_Marker Checks for the change in the Stopped and Last_Stopped to determine that the criteria is correct. Last_Brake provides the lagged version of the brake application for comparison purposes. Start_Marker the Boolean output from the brake switch comparison. And so on..

22

Brake Testing using eDAQ

Visualizing the Test in a flowchart format..

Real & Derived

Brake Testing using eDAQ

Success or Failure?

Previous slides displayed the data visualization, this can be achieved using the built in API for eDAQ systems. There is NO intermediate program required, no DLL to interpret, the eDAQ utilizes a HTTP based API so it isnt even platform dependant! You could as easily produce an interface in Linux as IOS, Windows or Android! The two examples below simply start a test run and stream data at 20Hz. HTTP://192.168.100.100:2345/teststart HTTP://192.168.100.100:2345/realtime?Headers=0&Rate=20

SetHTTP GetIP & ":2345/teststart", 2345 Private Sub SetHTTP(ByVal SendSTRG As String, ByVal PortX As Integer) SendSTRG = "http://" & SendSTRG ss = "GET " & SendSTRG & " HTTP/1.1" & vbCrLf ss = ss & "Host: " & RCom.RemoteHostIP & vbCrLf ss = ss & "Connection: close" & vbCrLf ss = ss & "Accept: */*" & vbCrLf ss = ss & vbCrLf bC Lf SendTEXT PortX End Sub Private Sub Establish(ByVal WhichPORT As Integer) RCom.Close RCom.RemoteHost = eDAQ_SETUP.IPeDAQ.Text RCom.RemotePort = WhichPORT RCom.Connect If RCom.State = sckConnecting Then End If End Sub Private Sub SendTEXT(ByVal PortNUM As Integer) Establish PortNUM Do Until RCom.State = sckConnected DoEvents Loop If RCom.State = sckConnected Then RCom.SendData ss End If End Sub

23

'// ss is public

Note that in this example scale factors are corrected for the sample rate used.

24

5/7/2013

Brake Testing using eDAQ

Success or Failure?

sequence

Brake Testing using eDAQ

Diversity of Testing..

Since the eDAQ Lite has become more broadly known for brake testing the users have become as broadly spread across various industries, some are ones that you may never have even put any thought to, some you will be pleased to hear, take it as seriously as you would hope!

chose your test

connect your eDAQ

Ironically not as demanding as some of the testing requirements but equally as important are those related to the aerospace industry. In the case of the landing gear manufacturers the association with the performance of the tires under extreme temperature changes, means that these tests are joint exercises. Therefore the data that is required can be more diverse than some of the specific road vehicle applications!

assign your channels

define the variables

run your test see the outcome immediately

25

Parking Brake Test (Aerospace)

26

Any Testing using eDAQ

Simplify all of your testing..

Instrumentation requirements have a certain core set of components but these can be quite diverse! eDAQ works with almost every transducer on the market.. Consider the advantages that reducing data processing in real time can save you. Consider the advantages of a system that can function in any environment under almost any conditions.

www.hbm.com

Dave Gallop p Product Manager Ruggedized Acquisition Systems Champaign, IL USA 217 328 5359 dave.gallop@hbm.com

eDAQ & eDAQ Lite, as simple as you would like as capable as you could ever need.

27

measure and predict with confidence

Das könnte Ihnen auch gefallen

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- Key FeaturesDokument9 SeitenKey FeaturesDaud Simon ANoch keine Bewertungen

- Automotive Electronic Diagnostics (Course 2)Von EverandAutomotive Electronic Diagnostics (Course 2)Bewertung: 4 von 5 Sternen4/5 (2)

- Cutler-Hammer: Learning Module 26: DevicenetDokument41 SeitenCutler-Hammer: Learning Module 26: Devicenetksenthil77Noch keine Bewertungen

- Automatic Simulation Measurement and Verification of Inputs and Outputs of Body Control ModuleDokument4 SeitenAutomatic Simulation Measurement and Verification of Inputs and Outputs of Body Control ModuleInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Controller System For Industrial AutomatDokument27 SeitenController System For Industrial AutomatALI SABIRNoch keine Bewertungen

- Digital Bike Operating System Sans KeyDokument8 SeitenDigital Bike Operating System Sans KeyArjun AnduriNoch keine Bewertungen

- 01 02 Ethernet. Cables de Conexion EthernetpdfDokument9 Seiten01 02 Ethernet. Cables de Conexion EthernetpdfdimarclNoch keine Bewertungen

- Digital Bike Operating System Sans KeyDokument9 SeitenDigital Bike Operating System Sans KeyTejaswini KodaliNoch keine Bewertungen

- Transformer Monitoring Systems - MRDokument4 SeitenTransformer Monitoring Systems - MRKelly chatingNoch keine Bewertungen

- ETAP 12.5: New Features & CapabilitiesDokument115 SeitenETAP 12.5: New Features & CapabilitiestkhandelwalNoch keine Bewertungen

- ADL Seminar 2008Dokument102 SeitenADL Seminar 2008elimeir80Noch keine Bewertungen

- Module 26 DeviceNetDokument35 SeitenModule 26 DeviceNeteyd bartulabaNoch keine Bewertungen

- END End Testing: Rick G. Asche, PEDokument11 SeitenEND End Testing: Rick G. Asche, PEZokiNoch keine Bewertungen

- Lenze 8200vector BrochureDokument8 SeitenLenze 8200vector Brochuregeloram66Noch keine Bewertungen

- Report On PLC & ScadaDokument30 SeitenReport On PLC & ScadaRajmal Menariya60% (10)

- PLC & SCADA Training ReportDokument44 SeitenPLC & SCADA Training Reportneeraj meena100% (2)

- Controller System For Industrial Automation: Analogue Vs Digital ControllersDokument27 SeitenController System For Industrial Automation: Analogue Vs Digital ControllerstrlucNoch keine Bewertungen

- Ultrasonic TrainingDokument38 SeitenUltrasonic TrainingarmasciaNoch keine Bewertungen

- Data Acquisition Systems: Assignment EC375-Measurements and InstrumentationDokument10 SeitenData Acquisition Systems: Assignment EC375-Measurements and InstrumentationAfrasinei Sergiu VladNoch keine Bewertungen

- Gauge Programming FundamentalsDokument13 SeitenGauge Programming FundamentalsMarius MullerNoch keine Bewertungen

- TUGx-Abstracts 190702 PDFDokument15 SeitenTUGx-Abstracts 190702 PDFMahesh MahiNoch keine Bewertungen

- SCADA Interview Questions and AnswersDokument11 SeitenSCADA Interview Questions and AnswersShashikant PrasadNoch keine Bewertungen

- UCPDokument0 SeitenUCPcontact_egypt2Noch keine Bewertungen

- Powernet Data Acquisition and ControlDokument4 SeitenPowernet Data Acquisition and ControlErfan NugrohoNoch keine Bewertungen

- Vehicle Transmission and Brake TestingDokument2 SeitenVehicle Transmission and Brake TestingSahil KalaNoch keine Bewertungen

- TexRay Application Hand Book Ver1.02Dokument22 SeitenTexRay Application Hand Book Ver1.02kuwabbNoch keine Bewertungen

- RTC Based - Automatic College BellDokument53 SeitenRTC Based - Automatic College BellPgc VnbNoch keine Bewertungen

- Development of Scada Like Application Using Arduino WithDokument7 SeitenDevelopment of Scada Like Application Using Arduino WithInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Strategies For High Quality Low Cost Optical Sensors - Automotive v7Dokument11 SeitenStrategies For High Quality Low Cost Optical Sensors - Automotive v7Poovannan PrakashNoch keine Bewertungen

- Software DLB International Manual Del UsuarioDokument131 SeitenSoftware DLB International Manual Del UsuarioJuan Rivera100% (1)

- T-Dplat, TATA ELXSI Diagnostics Platform: Prem Mohan Nair & Sreeraj ADokument5 SeitenT-Dplat, TATA ELXSI Diagnostics Platform: Prem Mohan Nair & Sreeraj Acoolman729Noch keine Bewertungen

- PCB Diagnostic & Functional Test System: Qmax QT-200 QT-200Dokument6 SeitenPCB Diagnostic & Functional Test System: Qmax QT-200 QT-200Eslam SalahNoch keine Bewertungen

- Sppa T3000Dokument6 SeitenSppa T3000Dipti BhanjaNoch keine Bewertungen

- PLC Vs ControllerDokument4 SeitenPLC Vs ControllerththeeNoch keine Bewertungen

- 2015 Belt-Way Manual 2 1 WebDokument72 Seiten2015 Belt-Way Manual 2 1 WebanhNoch keine Bewertungen

- PipelineStudio Gas Simulator Module Excel - EnglishDokument19 SeitenPipelineStudio Gas Simulator Module Excel - Englishgcarreong100% (1)

- Siemens s7-300 ProgrammingDokument94 SeitenSiemens s7-300 ProgrammingPrittam Kumar Jena100% (6)

- SCADA Design Dec2001Dokument193 SeitenSCADA Design Dec2001arthur_52948949Noch keine Bewertungen

- What's The Difference Between Ethernet Types?Dokument4 SeitenWhat's The Difference Between Ethernet Types?leonardo_melo_costaNoch keine Bewertungen

- Sunset MTTDokument20 SeitenSunset MTTNdambuki DicksonNoch keine Bewertungen

- Introduction FormatDokument31 SeitenIntroduction Formatshashikumar_desaiNoch keine Bewertungen

- Report AcknowledgmentDokument45 SeitenReport Acknowledgmentrajubhati41Noch keine Bewertungen

- CANape Basics WhitePaper enDokument15 SeitenCANape Basics WhitePaper enwlidhaaa0% (1)

- Introduction To GENEX ProbeDokument46 SeitenIntroduction To GENEX ProbeTUYAMBAZE JEAN CLAUDENoch keine Bewertungen

- EPASurge Users GuideDokument27 SeitenEPASurge Users GuideNattasit JiraissarakornNoch keine Bewertungen

- Agilent E7495B Base Station Test Set Data SheetDokument16 SeitenAgilent E7495B Base Station Test Set Data SheetJamilAwanNoch keine Bewertungen

- Clap Switch: An Industry Oriented Main Project ReportDokument31 SeitenClap Switch: An Industry Oriented Main Project Reportanon_574219456Noch keine Bewertungen

- An Intelligent Architecture For Industrial Automation Using RTOS TechnologyDokument6 SeitenAn Intelligent Architecture For Industrial Automation Using RTOS TechnologyInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Through-Air Radar VEGAPULS Brochure 36705-EnDokument8 SeitenThrough-Air Radar VEGAPULS Brochure 36705-EnsayedmhNoch keine Bewertungen

- Jaguar 682 Adv Electrical 02-20-02Dokument246 SeitenJaguar 682 Adv Electrical 02-20-02Hector ArenasNoch keine Bewertungen

- PLC & Scada Summer Training ReportDokument48 SeitenPLC & Scada Summer Training ReportsubrampatiNoch keine Bewertungen

- Automation: Your Guide To Selecting The Right PLCDokument16 SeitenAutomation: Your Guide To Selecting The Right PLCasritaipNoch keine Bewertungen

- Project PLCDokument12 SeitenProject PLCmajumderabhijit85Noch keine Bewertungen

- Metro Train Prototype: A Summer Training Report OnDokument34 SeitenMetro Train Prototype: A Summer Training Report OnPooja SharmaNoch keine Bewertungen

- A G Readm e - FD .W PD O Ctober 6, 2014Dokument4 SeitenA G Readm e - FD .W PD O Ctober 6, 2014eduardoNoch keine Bewertungen

- Project Synopsis Digital Controller Using Matlab: Deptt. of Electronics and InstrumentationDokument9 SeitenProject Synopsis Digital Controller Using Matlab: Deptt. of Electronics and InstrumentationSaumya TripathiNoch keine Bewertungen

- SKF Mount - 6319 - Hot Mounting - Shaft PDFDokument5 SeitenSKF Mount - 6319 - Hot Mounting - Shaft PDFfantiniluanapaivaNoch keine Bewertungen

- SKF Mount - 22318 EJA - VA405 - Hot Mounting - HousingDokument3 SeitenSKF Mount - 22318 EJA - VA405 - Hot Mounting - HousingcumtjerryNoch keine Bewertungen

- SKF Mount - 6319 - Hot Mounting - Shaft PDFDokument5 SeitenSKF Mount - 6319 - Hot Mounting - Shaft PDFfantiniluanapaivaNoch keine Bewertungen

- Bearing Data - Permissible - Angular - MisalignmentDokument1 SeiteBearing Data - Permissible - Angular - MisalignmentcumtjerryNoch keine Bewertungen

- SKF Mount - 22318 EJA - VA405 - Hot Mounting - ShaftDokument4 SeitenSKF Mount - 22318 EJA - VA405 - Hot Mounting - ShaftcumtjerryNoch keine Bewertungen

- SKF Bearing MoutingDokument2 SeitenSKF Bearing MoutingcumtjerryNoch keine Bewertungen

- Bearing Data - Rotating Shaft DeflectionDokument1 SeiteBearing Data - Rotating Shaft DeflectioncumtjerryNoch keine Bewertungen

- Spherical Roller Bearings - 22318 EJA - VA405-2Dokument3 SeitenSpherical Roller Bearings - 22318 EJA - VA405-2cumtjerryNoch keine Bewertungen

- SKF Bearing MoutingDokument2 SeitenSKF Bearing MoutingcumtjerryNoch keine Bewertungen

- Bearing Data - Permissible - Angular - MisalignmentDokument1 SeiteBearing Data - Permissible - Angular - MisalignmentcumtjerryNoch keine Bewertungen

- Experimental Modal Analysis: A Simple Non-Mathematical PresentationDokument11 SeitenExperimental Modal Analysis: A Simple Non-Mathematical PresentationTuan Pham MinhNoch keine Bewertungen

- Taper Roller Bearing-1054142 PDFDokument5 SeitenTaper Roller Bearing-1054142 PDFcumtjerry100% (1)

- DFM Whitepaper 1 PDFDokument4 SeitenDFM Whitepaper 1 PDFcumtjerryNoch keine Bewertungen

- Sheet Metal Design-Handbook-Rev3 PDFDokument12 SeitenSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Vacuum Technology Book II Part 3 2 PDFDokument207 SeitenVacuum Technology Book II Part 3 2 PDFcumtjerryNoch keine Bewertungen

- Vacuum Technology Book II Part 3 3Dokument399 SeitenVacuum Technology Book II Part 3 3cumtjerryNoch keine Bewertungen

- Derivation of Endurance Curves From Fatigue Test Data, Including Run-OutsDokument39 SeitenDerivation of Endurance Curves From Fatigue Test Data, Including Run-OutscumtjerryNoch keine Bewertungen

- The Effect of Post-Weld Treatments On Fatigue at Fillet Welded AttachmentsDokument16 SeitenThe Effect of Post-Weld Treatments On Fatigue at Fillet Welded AttachmentscumtjerryNoch keine Bewertungen

- Derivation of Endurance Curves From Fatigue Test Data, Including Run-OutsDokument39 SeitenDerivation of Endurance Curves From Fatigue Test Data, Including Run-OutscumtjerryNoch keine Bewertungen

- Vacuum Technology Book II Part 3 2 PDFDokument207 SeitenVacuum Technology Book II Part 3 2 PDFcumtjerryNoch keine Bewertungen

- Vacuum Technology Book II Part 2Dokument140 SeitenVacuum Technology Book II Part 2bracio100% (1)

- Vacuum Technology Book II Part 2Dokument140 SeitenVacuum Technology Book II Part 2bracio100% (1)

- Vacuum Technology Book II Part 3 3Dokument399 SeitenVacuum Technology Book II Part 3 3cumtjerryNoch keine Bewertungen

- 2.75 GANTT TemplateDokument8 Seiten2.75 GANTT TemplatecumtjerryNoch keine Bewertungen

- Generalities On Welded - ConnectionsDokument12 SeitenGeneralities On Welded - ConnectionscumtjerryNoch keine Bewertungen

- Sutherland - Fatigue Analysis of Wind Turbines - 1999Dokument147 SeitenSutherland - Fatigue Analysis of Wind Turbines - 1999boulderrockNoch keine Bewertungen

- ConnectionsDokument13 SeitenConnectionscumtjerryNoch keine Bewertungen

- Unit 8 Loaders 装载机Dokument23 SeitenUnit 8 Loaders 装载机cumtjerryNoch keine Bewertungen

- MTAP Math ChallengeDokument5 SeitenMTAP Math ChallengeHaron Abedin100% (1)

- Class NotesDokument16 SeitenClass NotesAdam AnwarNoch keine Bewertungen

- Boden 2015 Mass Media Playground of StereotypingDokument16 SeitenBoden 2015 Mass Media Playground of StereotypingMiguel CuevaNoch keine Bewertungen

- Units 6-10 Review TestDokument20 SeitenUnits 6-10 Review TestCristian Patricio Torres Rojas86% (14)

- Who, Summary NotesDokument12 SeitenWho, Summary NotesIvan Lohr100% (2)

- Isc The Tempest Workbook Answers Act 1 Scene 2: Home Science Commerce Mathematics Language LiteratureDokument31 SeitenIsc The Tempest Workbook Answers Act 1 Scene 2: Home Science Commerce Mathematics Language LiteratureHarsh Ahirwar100% (1)

- Bug Tracking System AbstractDokument3 SeitenBug Tracking System AbstractTelika Ramu86% (7)

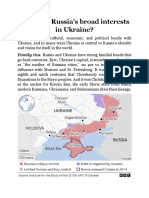

- What Are RussiaDokument3 SeitenWhat Are RussiaMuhammad SufyanNoch keine Bewertungen

- Full Moon RitualsDokument22 SeitenFull Moon RitualsJP83% (6)

- Registration - No Candidate Gender Category Rank/Percentage Allotment - Seat Base - Seat Course CollegeDokument166 SeitenRegistration - No Candidate Gender Category Rank/Percentage Allotment - Seat Base - Seat Course CollegeCyber ParkNoch keine Bewertungen

- Brain and LanguageDokument3 SeitenBrain and LanguageJasper AngelesNoch keine Bewertungen

- Context: Lesson Author Date of DemonstrationDokument4 SeitenContext: Lesson Author Date of DemonstrationAR ManNoch keine Bewertungen

- RF Design MCQ-1Dokument16 SeitenRF Design MCQ-1JeyavelNoch keine Bewertungen

- Cofee Table Book - Hayyan - Alef GroupDokument58 SeitenCofee Table Book - Hayyan - Alef GroupMustafa GelenovNoch keine Bewertungen

- Head InjuryDokument7 SeitenHead InjuryRoshan Ghimire100% (1)

- Professional Education Pre-Licensure Examination For TeachersDokument12 SeitenProfessional Education Pre-Licensure Examination For TeachersJudy Mae ManaloNoch keine Bewertungen

- Tamil Ilakkanam Books For TNPSCDokument113 SeitenTamil Ilakkanam Books For TNPSCkk_kamalakkannan100% (1)

- Paradigm Shift in Teaching: The Plight of Teachers, Coping Mechanisms and Productivity in The New Normal As Basis For Psychosocial SupportDokument5 SeitenParadigm Shift in Teaching: The Plight of Teachers, Coping Mechanisms and Productivity in The New Normal As Basis For Psychosocial SupportPsychology and Education: A Multidisciplinary JournalNoch keine Bewertungen

- Unit 2 Foundations of CurriculumDokument20 SeitenUnit 2 Foundations of CurriculumKainat BatoolNoch keine Bewertungen

- Parkinson DiseaseDokument49 SeitenParkinson Diseaseiqra100% (1)

- Mathematics - Grade 9 - First QuarterDokument9 SeitenMathematics - Grade 9 - First QuarterSanty Enril Belardo Jr.Noch keine Bewertungen

- Measure For Measure AngeloDokument1 SeiteMeasure For Measure AngeloRoger Knight100% (1)

- Week9 Phylum NemathelminthesDokument26 SeitenWeek9 Phylum NemathelminthesCzerinne Angela Justinne AlarillaNoch keine Bewertungen

- Bubble ColumnDokument34 SeitenBubble ColumnihsanNoch keine Bewertungen

- RA 9344 As Amended by RA 10630 - HandoutsDokument9 SeitenRA 9344 As Amended by RA 10630 - HandoutsJan Re Espina CadeleñaNoch keine Bewertungen

- Navamsa Karma and GodDokument9 SeitenNavamsa Karma and GodVisti Larsen50% (2)

- WWW - Ib.academy: Study GuideDokument122 SeitenWWW - Ib.academy: Study GuideHendrikEspinozaLoyola100% (2)

- Afia Rasheed Khan V. Mazharuddin Ali KhanDokument6 SeitenAfia Rasheed Khan V. Mazharuddin Ali KhanAbhay GuptaNoch keine Bewertungen

- 76 ECL GuideDokument45 Seiten76 ECL GuideOana SavulescuNoch keine Bewertungen

- The Role of Financial System in DevelopmentDokument5 SeitenThe Role of Financial System in DevelopmentCritical ThinkerNoch keine Bewertungen