Beruflich Dokumente

Kultur Dokumente

The New Tecsys SMD Line: COMPANY REPORT Professional Equipment Manufacturer Tecsys, Brazil

Hochgeladen von

Alexander WieseOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The New Tecsys SMD Line: COMPANY REPORT Professional Equipment Manufacturer Tecsys, Brazil

Hochgeladen von

Alexander WieseCopyright:

Verfügbare Formate

COMPANY REPORT

Professional Equipment Manufacturer Tecsys, Brazil

The New Tecsys SMD Line

Tecsys Production

Manager Adilson da Silva holding a circuit board produced by their new SMD machine.

Very good operational organization Concentration on professional satellite reception products In-house development department IRD is their success product

164 TELE-audiovision International The Worlds Largest Digital TV Trade Magazine 03-04/2013 www.TELE-audiovision.com

www.TELE-audiovision.com 03-04/2013 TELE-audiovision International

165

COMPANY REPORT

Professional Equipment Manufacturer Tecsys, Brazil

With a new SMD line that has been in operation since June 2012, the Brazilian manufacturer Tecsys can further increase their quality and improve their reaction time to incoming orders. Tecsys produces everything themselves. Tecsys was founded in 2000 by three partners who were all involved for many years in the TV reception industry. Today the three founders wear different hats at Tecsys: CEO is Jose Marcos Freire Martins, CCO is Jorge Alberto Ganuza and CTO is Rodolfo Vidal. CEO Jose Marcos Freire Martins explains to us how it all started: Tecsys began as a manufacturer of SMATV products. We had seven employees and produced,

Jose Marcos

Freire Martins is one of the founders of Tecsys and is CEO of the company

So Jos dos Campos

Jorge Alberto

Ganuza is also one of the three founders and is CCO

for example, head ends. The company grew very quickly. Today we have 97 employees of which 28 of them are engineers. Tecsys produces everything that can be found in head ends, from IRDs (the companys success product) to modulators and decoders. Tecsys ships primarily to the domestic Brazilian market; many of the larger TV organizations utilize Tecsys products. Business is so good that, according to CCO Jorge Alberto Ganuza, Tecsys is planning on moving into a much larger building. A highlight at Tecsys is their SMD line. This work was previously outsourced to another company but by installing their own production line, Tecsys is now not only much more flexible when it comes to the customers requirements, but they can also react more quickly to changes in their own products. The entire production operation at Tecsys is

166 TELE-audiovision International The Worlds Largest Digital TV Trade Magazine 03-04/2013 www.TELE-audiovision.com

unusually well organized: Lean Production is the keyword from Production Manager Adilson da Silva, who showed us the details of the operation (see pictures). By concentrating on reception technology primarily that of satellite TV, Tecsys has created an interesting niche for themselves. With their modern production system and their highly professional operational organization, Tecsys is poised to become a stronger force on the world market.

168 TELE-audiovision International The Worlds Largest Digital TV Trade Magazine 03-04/2013 www.TELE-audiovision.com

1. Bruno Renato is responsible for incoming inspection. All deliveries are sorted into three categories and color coded: red is for products that dont meet the requirements, yellow (as shown in the picture) is for those products that still need to be checked and green indicates that the products can be released to the stockroom. 2. Warehouse Supervisor is Helbert Lopes Silva. He shows us how the system functions: Each delivery has its own barcode label. 3. A look in the stockroom with the rolls of surface mount components for the SMD machine. 4. All products are given a code that identifies its location in the stockroom. This makes it easy to find a missing production component. 5. Rodrigo Rosa is the SMD machine technician. He explains to us the production process with the SMD machine. 6. The empty circuit boards are fed into the machine. 7. Components are now placed on the board.

www.TELE-audiovision.com 03-04/2013 TELE-audiovision International

169

10

8. Then the stuffed circuit board is placed in an oven. The circuit board is then heated to a specific temperature depending on the number of components and the size of the board. We use software to calculate the necessary temperature that can be anywhere from 108C to 260C, explains Rodrigo Rosa. 9. Each circuit board is checked with a microscope. 10. The last step is the solder bath. The internal temperature reaches 246C. 11. Multiple circuit boards are needed for a complete Tecsys IRD, plus theres also a power supply circuit board. 12. A detailed functionality check is performed before final assembly.

170 TELE-audiovision International The Worlds Largest Digital TV Trade Magazine 03-04/2013 www.TELE-audiovision.com

11

12

172 TELE-audiovision International The Worlds Largest Digital TV Trade Magazine 03-04/2013 www.TELE-audiovision.com

Finally, theres the burn-in process.

The devices are run for two days.

174 TELE-audiovision International The Worlds Largest Digital TV Trade Magazine 03-04/2013 www.TELE-audiovision.com

Das könnte Ihnen auch gefallen

- Devise RDokument10 SeitenDevise RAlexander WieseNoch keine Bewertungen

- GoosatDokument10 SeitenGoosatAlexander WieseNoch keine Bewertungen

- Tele SystemDokument6 SeitenTele SystemAlexander WieseNoch keine Bewertungen

- Eldtec For Brazil Only: COMPANY REPORT Dish, Antenna and Cable Manufacturer ELDTEC, BrazilDokument9 SeitenEldtec For Brazil Only: COMPANY REPORT Dish, Antenna and Cable Manufacturer ELDTEC, BrazilAlexander WieseNoch keine Bewertungen

- HisiliconDokument7 SeitenHisiliconAlexander WieseNoch keine Bewertungen

- Sumavision PDFDokument10 SeitenSumavision PDFAlexander WieseNoch keine Bewertungen

- Video Controls LimitedDokument6 SeitenVideo Controls LimitedLeonardLapatratNoch keine Bewertungen

- Wadt BrazilDokument4 SeitenWadt BrazilAlexander WieseNoch keine Bewertungen

- Speedcast: Satellite Uplink Speedcast, Barueri, SP, Brazilia Raport de FirmăDokument8 SeitenSpeedcast: Satellite Uplink Speedcast, Barueri, SP, Brazilia Raport de FirmăAlexander WieseNoch keine Bewertungen

- Спутниковый Восходящий Канал Speedcast, Баруэри, Сп, Бразилия Отчет КомпанииDokument8 SeitenСпутниковый Восходящий Канал Speedcast, Баруэри, Сп, Бразилия Отчет КомпанииAlexander WieseNoch keine Bewertungen

- Speedcast: Satelitski Uplink Operater Speedcast, Barueri, SP, Brazil Company ReportDokument8 SeitenSpeedcast: Satelitski Uplink Operater Speedcast, Barueri, SP, Brazil Company ReportAlexander WieseNoch keine Bewertungen

- Term End Project: Ashish Sharma (167) & Ghanshyam Sinh JadejaDokument28 SeitenTerm End Project: Ashish Sharma (167) & Ghanshyam Sinh JadejaAshish SharmaNoch keine Bewertungen

- Speedcast: Satelliet Uplink Speedcast, Barueri, SP, Brazilië BedrijfsrapportDokument8 SeitenSpeedcast: Satelliet Uplink Speedcast, Barueri, SP, Brazilië BedrijfsrapportAlexander WieseNoch keine Bewertungen

- Tornos Deco Mag 35 UkDokument45 SeitenTornos Deco Mag 35 UkGuillermo RamirezNoch keine Bewertungen

- Feasibility Study of Pritel Expansion For TV Speaker Receiver 20170228Dokument8 SeitenFeasibility Study of Pritel Expansion For TV Speaker Receiver 20170228Rediet Feleke100% (1)

- Speedcast: Speedcast Enlace de Subida de Satelite, Barueri, SP, Brasil Informe de CompañíaDokument8 SeitenSpeedcast: Speedcast Enlace de Subida de Satelite, Barueri, SP, Brasil Informe de CompañíaAlexander WieseNoch keine Bewertungen

- Speed CastDokument8 SeitenSpeed CasttelesatellitefrenchNoch keine Bewertungen

- Creowave BrochureDokument4 SeitenCreowave BrochureFuad RahimovNoch keine Bewertungen

- Company Profile: Today The Group Operates Through Six Key SectorsDokument14 SeitenCompany Profile: Today The Group Operates Through Six Key Sectorsbetu8137Noch keine Bewertungen

- 1.1 Introduction To VideoconDokument24 Seiten1.1 Introduction To VideoconsabijagdishNoch keine Bewertungen

- Minilec CatalougeDokument64 SeitenMinilec CatalougePrajin KundoorNoch keine Bewertungen

- bHUSHAN rEPORTDokument87 SeitenbHUSHAN rEPORTParveen ManglaNoch keine Bewertungen

- Speedcast: A Speedcast Műholdas Felküldő Állomás, Brazilia, Sao Pauló, Barueri Vállalati BeszámolóDokument8 SeitenSpeedcast: A Speedcast Műholdas Felküldő Állomás, Brazilia, Sao Pauló, Barueri Vállalati BeszámolóAlexander WieseNoch keine Bewertungen

- COMPANY REPORT Digital TV Head-End Manufacturer DEXIN, ChinaDokument7 SeitenCOMPANY REPORT Digital TV Head-End Manufacturer DEXIN, ChinaAlexander WieseNoch keine Bewertungen

- Microcontroller Used To Improve Performance in A Foam Sensing and Control SystemDokument21 SeitenMicrocontroller Used To Improve Performance in A Foam Sensing and Control SystemtesfaNoch keine Bewertungen

- CATALOGO 2019 Rev C Francés PDFDokument124 SeitenCATALOGO 2019 Rev C Francés PDFPepe PinNoch keine Bewertungen

- Speedcast: Uydu Uplink Speedcast, Barueri, SP, Brezilya Şirket RaporuDokument8 SeitenSpeedcast: Uydu Uplink Speedcast, Barueri, SP, Brezilya Şirket RaporuAlexander WieseNoch keine Bewertungen

- TELE-audiovision International - The World‘s Largest Digital TV Trade Magazine TELE-audiovision International - 全球发行量最大的数字电视杂志Dokument8 SeitenTELE-audiovision International - The World‘s Largest Digital TV Trade Magazine TELE-audiovision International - 全球发行量最大的数字电视杂志Alexander WieseNoch keine Bewertungen

- Catalogue RittalDokument648 SeitenCatalogue RittalFelicia MarceanNoch keine Bewertungen

- Quality Antennas For The Global Market: COMPANY REPORT Antenna Manufacturer Tianditong, ChinaDokument10 SeitenQuality Antennas For The Global Market: COMPANY REPORT Antenna Manufacturer Tianditong, ChinaAlexander WieseNoch keine Bewertungen

- Axiomtek Catalog V217Dokument76 SeitenAxiomtek Catalog V217Hendra PutraNoch keine Bewertungen

- EuroWire July 2021Dokument68 SeitenEuroWire July 2021Tien Dung PhanNoch keine Bewertungen

- Ikanos Communications: (Nasdaq: Ikan) January 16, 2013Dokument26 SeitenIkanos Communications: (Nasdaq: Ikan) January 16, 2013Stephen ChenNoch keine Bewertungen

- Company Profile of VideoconDokument32 SeitenCompany Profile of Videoconamit85tewariNoch keine Bewertungen

- Tesco tcm6-2083Dokument4 SeitenTesco tcm6-2083HEART_GIFT4UNoch keine Bewertungen

- Ci-Turbo Brochure-PtDokument8 SeitenCi-Turbo Brochure-PtAmazonas ManutençãoNoch keine Bewertungen

- D It Ron Precision Company OverviewDokument22 SeitenD It Ron Precision Company OverviewVishal Singh JaswalNoch keine Bewertungen

- CATALOG STAHLWILLE - SculegeroDokument347 SeitenCATALOG STAHLWILLE - SculegeroSculegeroNoch keine Bewertungen

- CISCO - Industrial IoT PDFDokument13 SeitenCISCO - Industrial IoT PDFEgle FitneNoch keine Bewertungen

- Video Conferencing (TandbergDokument2 SeitenVideo Conferencing (TandbergFarhan KhanNoch keine Bewertungen

- Security & Communications: Residential and Commercial Products and ServicesDokument172 SeitenSecurity & Communications: Residential and Commercial Products and ServicesCeyhun_Seran_3143Noch keine Bewertungen

- Managing It in Business: Group 4 Mayank Agrawal Raghu Khanna Rupika S K Vijaya P Shankar Abhishek KandeyDokument23 SeitenManaging It in Business: Group 4 Mayank Agrawal Raghu Khanna Rupika S K Vijaya P Shankar Abhishek KandeyAbhishek KandeyNoch keine Bewertungen

- Turbosat IcecryptDokument5 SeitenTurbosat IcecryptAlexander WieseNoch keine Bewertungen

- General Brochure IsomecDokument80 SeitenGeneral Brochure IsomecEmil GabrielNoch keine Bewertungen

- Telit2market No 6-11 EnglishDokument132 SeitenTelit2market No 6-11 Englishbrentd91Noch keine Bewertungen

- FOOD Cat enDokument106 SeitenFOOD Cat enMargo SmithNoch keine Bewertungen

- Pricing Strategy Project VideoconDokument21 SeitenPricing Strategy Project VideoconGaurav Singh RanaNoch keine Bewertungen

- SICC Progetti Speciali 2015 PDFDokument15 SeitenSICC Progetti Speciali 2015 PDFeldidiNoch keine Bewertungen

- Iti Bangalore Report AbstractDokument9 SeitenIti Bangalore Report AbstractSagar NagarajNoch keine Bewertungen

- 18 How To Write A SummaryDokument7 Seiten18 How To Write A SummaryNano1028Noch keine Bewertungen

- Conax Company BrochureDokument12 SeitenConax Company BrochureTechy Guy100% (1)

- Valvetech Industries: Materials That Create SolutionsDokument1 SeiteValvetech Industries: Materials That Create SolutionsShankey JAlanNoch keine Bewertungen

- 2I Company ProfileDokument10 Seiten2I Company ProfileShahid KhanNoch keine Bewertungen

- 655f3dbd 8Dokument62 Seiten655f3dbd 8Ignacio MarínNoch keine Bewertungen

- Di Jantung Negeri Jerman: Business VoucherDokument7 SeitenDi Jantung Negeri Jerman: Business VoucherAlexander WieseNoch keine Bewertungen

- Hospitality Tvs 3 5982Dokument56 SeitenHospitality Tvs 3 5982abdulmohsin abdulazizNoch keine Bewertungen

- De-Generation World: Revolutionary ParadiseDokument18 SeitenDe-Generation World: Revolutionary ParadiseUtkarsh SoniNoch keine Bewertungen

- TeleEye Product Cat 2012Dokument44 SeitenTeleEye Product Cat 2012pretkovNoch keine Bewertungen

- VideoconDokument80 SeitenVideoconNishant NamdeoNoch keine Bewertungen

- Tracing The Advance Of Technology And Delving Into Technical ThingsVon EverandTracing The Advance Of Technology And Delving Into Technical ThingsNoch keine Bewertungen

- Satbeams PDFDokument4 SeitenSatbeams PDFAlexander WieseNoch keine Bewertungen

- Tekniksat PDFDokument4 SeitenTekniksat PDFAlexander WieseNoch keine Bewertungen

- Haenlein: PVR Software For Digital TV ReceiversDokument4 SeitenHaenlein: PVR Software For Digital TV ReceiversAlexander WieseNoch keine Bewertungen

- Sparos PDFDokument17 SeitenSparos PDFAlexander WieseNoch keine Bewertungen

- Editorial PDFDokument1 SeiteEditorial PDFAlexander WieseNoch keine Bewertungen

- Alpsat PDFDokument5 SeitenAlpsat PDFAlexander WieseNoch keine Bewertungen

- Mktech PDFDokument7 SeitenMktech PDFAlexander WieseNoch keine Bewertungen

- Formuler PDFDokument9 SeitenFormuler PDFAlexander WieseNoch keine Bewertungen

- Feature Dongle PDFDokument6 SeitenFeature Dongle PDFAlexander WieseNoch keine Bewertungen

- Sumavision PDFDokument10 SeitenSumavision PDFAlexander WieseNoch keine Bewertungen

- EICO On Top of The WorldDokument5 SeitenEICO On Top of The WorldAlexander WieseNoch keine Bewertungen

- DVR Studio PDFDokument2 SeitenDVR Studio PDFAlexander WieseNoch keine Bewertungen

- Cableworld PDFDokument13 SeitenCableworld PDFAlexander WieseNoch keine Bewertungen

- Editorial PDFDokument1 SeiteEditorial PDFAlexander WieseNoch keine Bewertungen

- Eng TELE-audiovision 1411Dokument164 SeitenEng TELE-audiovision 1411Alexander WieseNoch keine Bewertungen

- Chinasatcom PDFDokument6 SeitenChinasatcom PDFAlexander WieseNoch keine Bewertungen

- Jonsa Antennas: COMPANY REPORT Satellite Dish Manufacturer Jonsa, TaiwanDokument10 SeitenJonsa Antennas: COMPANY REPORT Satellite Dish Manufacturer Jonsa, TaiwanAlexander WieseNoch keine Bewertungen

- Titanium Asc1: TEST REPORT Positioner For Big Satellite DishDokument11 SeitenTitanium Asc1: TEST REPORT Positioner For Big Satellite DishAlexander WieseNoch keine Bewertungen

- By Perfectvision: Product Report Coax Cable DispenserDokument9 SeitenBy Perfectvision: Product Report Coax Cable DispenserAlexander WieseNoch keine Bewertungen

- Maxing Electronic Technology MX Lnbs Of: Test Report Ku Band LnbsDokument3 SeitenMaxing Electronic Technology MX Lnbs Of: Test Report Ku Band LnbsAlexander WieseNoch keine Bewertungen

- The IMC Group Acquires Horizon: COMPANY REPORT Signal Meter Manufacturer, HORIZON, UKDokument2 SeitenThe IMC Group Acquires Horizon: COMPANY REPORT Signal Meter Manufacturer, HORIZON, UKAlexander WieseNoch keine Bewertungen

- Bank Statement - Feb.2020Dokument5 SeitenBank Statement - Feb.2020TRIVEDI ANILNoch keine Bewertungen

- Brochure A35g A40g t4f en 22 20050840 DDokument20 SeitenBrochure A35g A40g t4f en 22 20050840 DRengga PratamaNoch keine Bewertungen

- Radios of America in EnglishDokument3 SeitenRadios of America in Englishvitor_pedroNoch keine Bewertungen

- Prof. Herkutanto-JKN - Patient Safety Dan Etika 2016Dokument30 SeitenProf. Herkutanto-JKN - Patient Safety Dan Etika 2016galih wicaksonoNoch keine Bewertungen

- MultiplexersDokument23 SeitenMultiplexersAsim WarisNoch keine Bewertungen

- EP T8 Diesel ForkliftsDokument7 SeitenEP T8 Diesel ForkliftsHein Sithu KyawNoch keine Bewertungen

- ECSS E ST 50 03C (31july2008)Dokument43 SeitenECSS E ST 50 03C (31july2008)jsadachiNoch keine Bewertungen

- SKANDIX - Order EditDokument2 SeitenSKANDIX - Order EditmehNoch keine Bewertungen

- Engg Prospect1usDokument20 SeitenEngg Prospect1usArun KumarNoch keine Bewertungen

- Serial NumberDokument3 SeitenSerial NumberNidal Nakhalah67% (3)

- Unit 4 SoftwareDokument16 SeitenUnit 4 Softwareapi-293630155Noch keine Bewertungen

- Kv2ci Oi PDFDokument142 SeitenKv2ci Oi PDFJethro AbanadorNoch keine Bewertungen

- 1 Complete Weaving MillDokument6 Seiten1 Complete Weaving MillKomol KabirNoch keine Bewertungen

- 2016 HSC Engineering StudiesDokument40 Seiten2016 HSC Engineering StudiesR MathewNoch keine Bewertungen

- Characteristics of Responsible Users and Competent Producers of Media and InformationDokument83 SeitenCharacteristics of Responsible Users and Competent Producers of Media and InformationMarson B. GranaNoch keine Bewertungen

- Blank Irf - 2023-03-22T001455.667Dokument2 SeitenBlank Irf - 2023-03-22T001455.667mar asepmalNoch keine Bewertungen

- Process Simulation in Refineries SamplerDokument30 SeitenProcess Simulation in Refineries SamplerNagendra HNoch keine Bewertungen

- Capitulo 9 - Flujo de DatosDokument24 SeitenCapitulo 9 - Flujo de DatosOrlando Espinoza ZevallosNoch keine Bewertungen

- IET Membership Guidance NotesDokument4 SeitenIET Membership Guidance NotesKingsley InbasinghNoch keine Bewertungen

- E85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFDokument8 SeitenE85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFLuis TovarNoch keine Bewertungen

- Voltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFDokument58 SeitenVoltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFHoward KnopfNoch keine Bewertungen

- Gym Mega ForceDokument3 SeitenGym Mega ForceAnonymous iKb87OINoch keine Bewertungen

- Track 3 Tuesday MobilarisDokument15 SeitenTrack 3 Tuesday Mobilarissaleema2010Noch keine Bewertungen

- Forensics Plastics and Burn TestsDokument2 SeitenForensics Plastics and Burn TestsTrishaNoch keine Bewertungen

- 中国铁路客运枢纽发展回顾与展望 王昊Dokument9 Seiten中国铁路客运枢纽发展回顾与展望 王昊qiqiaorongNoch keine Bewertungen

- Guidelines For Performance Task - LIVING MUSEUM PDFDokument2 SeitenGuidelines For Performance Task - LIVING MUSEUM PDFJoserie Barioga HernaneNoch keine Bewertungen

- TPMS - A Learning GuideDokument14 SeitenTPMS - A Learning GuideOrangeElectronicUsaNoch keine Bewertungen

- MCSL-045 Solved Assignments 2014-15Dokument6 SeitenMCSL-045 Solved Assignments 2014-15manishNoch keine Bewertungen

- DD The Superior College Lahore: Bscs 5CDokument15 SeitenDD The Superior College Lahore: Bscs 5CLukeNoch keine Bewertungen

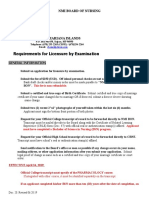

- 20 and 21. Requirements For Licensure by Examination Nclex. Revised 06.20.19 1Dokument2 Seiten20 and 21. Requirements For Licensure by Examination Nclex. Revised 06.20.19 1Glennah Marie Avenido RamosNoch keine Bewertungen