Beruflich Dokumente

Kultur Dokumente

Aux Boiler - Karan REV.03

Hochgeladen von

sharif339Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aux Boiler - Karan REV.03

Hochgeladen von

sharif339Copyright:

Verfügbare Formate

`

MS-M-003 Rev. 03

METHOD STATEMENT

FOR

INSTALLATION OF AUXILIARY BOILER PAGKAGE

Contract No. JI-194 SAUDI ARAMCO OIL COMPANY

KARAN UTILITY AND COGENERATION PROJECT Khursaniyah, Saudi Arabia

Signature 03 Rev. 29-Dec-10 Print Name Date R.M.Serrano Prepared by MMG N. Umbal Checked by MMG R.A. Dimatatac Approved by MMG P. Ranzenbacher Approved by PSAL

Page 1 of 14

MS-M-003 Rev. 03 I. PURPOSE: To ensure that equipment installation is carried out safely, and in accordance with good working practice, as per PSAL/SAUDI ARAMCO Job Specification. The procedure is intended to provide recommended practices, general application guidance and establish controls during preparation and execution of equipment erection. II. SCOPE: This Method Statement is applicable for the installation of Auxiliary Boiler Package. Any single equipments with a weight of 40MT (Metric Tonne) and above is not part of scope. PSAL will provide lifting/Installation plan. Execution of work shall be carried out in accordance with the relevant project specifications. III. REFERENCES: PIP VEFV1100 : Process Industry Practices; Fabrication/ Installation Details Vessels / S&T Heat Exchanger Standard Details. : Typical Erection Procedure MVF boiler in Field. : Boiler Big Block Installation Procedure. : Preservation Procedure for Boiler Big Block. : Recommended Practices for Machinery Installation and Installation Design. : SAUDI ARAMCO CONSTRUCTION SAFETY MANUAL

P8926-F-004 1007-C-766 1007-Q-155 PIP REIE 686

SACSM

IV.

RESPONSIBILITIES: Mechanical Superintendent / Supervisor: Ensure full compliance by all millwrights, mechanical foremen and labour regarding execution of the work in accordance with PSAL/SAUDI ARAMCO project requirements and specifications. Confirm the availability of all materials, tools, equipment, and required personnel who will carry out the work. Quality Control Inspector: Conduct inspection in accordance with this procedure and approved Quality Inspection and Test Plan. Monitors daily mechanical activities and verify compliance to PSAL/SAUDI ARAMCO Specifications. Prepares quality records and final acceptance documentation where required.

Page 2 of 14

MS-M-003 Rev. 03 Safety Supervisor: Monitor the work is carried out in accordance with PSAL/SAUDI ARAMCO project safety procedures. Engineering Department: Prepare and submit method statement together with all related documents for engineered lift, such as crane capacity chart, spreader beam calculation, etc (which are specified in Saudi ARAMCO specification & safety requirement for PSAL/SAUDI ARAMCO review and approval. Provide latest revision of AFC drawings and technical support to MMG site operation group. V MANPOWER CATEGORY VI. Foreman Millwright Mechanical Fitter Fabricator Helper Scaffolder Surveyor Rigger Permit Coordinator and Other Involve Manpower

WORK SEQUENCE / PROCEDURE: A. Required Tools and Equipment: Appropriate Crane for Specified Lift Wire Slings / Nylon Web Sling / Soft Tag Lines Shackles / Beam Clamps / Blocks / Wrenches Spreader Bar or Frame / Chain Hoist Wrenches / Levelling Tools / Filler Gauge Welding Machine with Accessories Measuring Tools / Precision Scale Theodolite. Equipment shall be maintained & check prior to use for safe work insurance. Equipment shall be approved & certified by ARAMCO. For equipments: Mobile/Crawler crane, man-lifts, Certified Man-Basket etc.

B. Pre-Installation Work Activities: 1. Obtain the AFC Drawings. 2. Review construction drawings by identifying the following requirements.

Page 3 of 14

MS-M-003 Rev. 03 a. Prepare a specific heavy and multi-crane lift plan and procedure considering weight, size, and shape of the equipment to be installed, when required. Preparation of heavy and multi-crane lift plan / procedure. b. Arrangement of lifting, hoisting, and construction equipment during lift. c. Issue the correct AFC Drawings to all personnel associated with the work. d. Review the construction drawings and check availability of the following. e. Lifting, hoisting and construction equipment / tools. certification and inspections. Check validity of

f. Temporary facilities and consumables to be used for the installations. g. Visit the installation location and consider the following items. h. Feasibility of lifting plan/procedure and provision of access. i. Installation of safety equipment / facilities (scaffolding, safety nets and safety ropes) at strategic locations. Preparation for the provision of firefighting equipment.

j.

k. Removal of obstructions such as structural beams and braces (where necessary). l. Ensure appropriate protection for the equipment and its surrounding areas; i.e., pipe protection for the existing piping.

3. Visually check equipment / accessories are free from damage. 4. Obtain the necessary work permit before the commencement of work activities. 5. Install lifting brackets and temporary bracings / stops in accordance with specific drawings. 6. As a minimum, the following items shall be checked prior to installation of any mechanical equipment. After which raise RFI for QC Inspection. 7. Provide touch up to any damage paint. 9.1. Concrete Foundation: The following conditions of the concrete foundation shall be checked against the relevant drawings. a. Whether the centerline is marked.

Page 4 of 14

MS-M-003 Rev. 03

b. Accuracy of height and whether elevation line is marked. c. Dimensions d. curing time e. Ensure f. The top of the concrete foundation shall be lower than the finished height of the grout thickness indicated on the foundation drawings. 9.2. Anchor Bolts: The following conditions of the anchor bolts embedded in the foundation shall be checked against the drawings or with a steel template for major equipment a. Tolerance shall be in accordance with project specification b. Projection The projection of the bolts above the foundation surface shall be of a proper length relative to the final level of the foundation finish. c. Inclination There must be no inclination of the bolts which may prevent the equipment base plate from fitting accurately. d. Condition of the bolts and nuts Threaded parts shall be completely coated with grease or machine oil allowing the nuts is unscrewed smoothly. e. Anchor bolts with pipe sleeves to allow adjustment of the final bolt position shall be checked with the following. f. Sleeve as specified in the instruction manual. g. Inside Sleeve Inside space of sleeve should be free from sand, dust and debris. h. Unless otherwise specified in the Instruction manual, pipe sleeves shall be approximately 50 mm larger in diameter than the anchor bolts. i. When pockets are used for anchor bolts, these shall be installed in the pockets after the equipment is temporarily placed in the correct position.

Page 5 of 14

MS-M-003 Rev. 03 j. Unless otherwise specified in the Instruction manual, pipe sleeves shall be approximately 50 mm larger in diameter than the anchor bolts. k. When pockets are used for anchor bolts, these shall be installed in the pockets after the equipment is temporarily placed in the correct position. 8. After the grouted mortar has sufficiently hardened, leveling work shall commence. 9. Pockets shall be cleaned before the installation of equipment. 10. Ensure that equipment foundations should be released from civil QC department prior to installation of equipment. 11. Delivery of mechanical equipment to site shall be in accordance with Site Handling and Identification of Mechanical Materials. 12. Boiler package materials received shall be preserved in accordance with vendor Preservation Procedure and Project Material Preservation and Storage procedure. C. Installation Activities: 1. Installation of Boiler Big Block, PSAL 1.1 Installation of Boiler Big Block shall be carried out by Heavy Lift Contractor assigned by PSAL. 1.2 Boiler shall be installed lifting by crane and positioned on foundation pedestals P1 P10. 1.3 Before the lay-down of the boiler on the plinths, carry out the positioning and levelling of the slide base plates on the foundation P1 & P2 drum saddles and P3 to P10 for side walls with relevant Teflon pads according to drawing M-021 (SP No. PB-A-97039), M-025 (SP- No. PBB-97043). For the levelling operation, sheets of metal of various thickness to shim base plates must be used only. Do not use channels or beams. The shims shall be located in correspondence of the saddles stiffening. 1.4 Lay down boiler on P1 to P10. 1.5 Remove all temporary devices. Note: Anchor bolts for plinths P1 to P10 shall be located in position before final boiler block lay down onto foundation. Final Casting of the said anchor bolts shall be done after boiler positioning and levelling as stated on MACCHI drawing ref. 1007-M-021. In order

Page 6 of 14

MS-M-003 Rev. 03 to assure matching of said anchor bolts with boiler base-plates, a proper adjustment of anchor bolts shall be foreseen before final casting. 1.6 After the boiler lay-down of boiler on the plinths, check the level and the plumbing of the boiler. 1.7 Check if the slides pads are in perfect contact with the support saddles. If not shim the base plates up to the slide pads are in contact. 1.8 Carry out grouting for the plinths P1 to P10 as per drawing M-021 (SPNo. PB-A-97039). 1.9 Removing of the boiler transport structures and the transport stiffeners. 1.10 Positioning and welding of all plates and profiles on the base plates for boiler guides and fixing point as per drawing M-532 (SP No. PB-97180) 2. Positioning Air Ducts and Air Foil. 2.1 Ensure foundation of air ducts are inspected and approve. 2.2 Verify withdrawn material from warehouse against AFC drawing. 2.3 Plan the insertion of Air foil, AD3 and AD4 at the bottom of the boiler. See drawing M-400 (SP No. PC-A-97062). 2.4 Position AD1, AD2, AD3 and AD4 according to drawing M-400 (SP No. PC-A-97062). 2.5 Provide temporary support between AD2 and AD3 for the Air Foil, prior to positioning. 2.6 Prior to connecting the AD1, AD2, AD3, AD4 and Air Foil, check the X and Y alignment and elevation as per AFC drawing. 3. Erection of steel structures, stairs ladders and platforms with canopy for burners front according to drawing (M-701). 3.1 Receive the fabricated structural components and check all members of the structure to be erected. Damaged fabricated steel should be corrected or replaced prior to erection. 3.2 Deposit the material on wooden dunnage supports to clear steel surfaces from ground contact. 3.3 At all times protect structural components during handling and installation to prevent damage or deformation.

Page 7 of 14

MS-M-003 Rev. 03

3.4 Ensure that all temporary bolts and welds are of sufficient strength to withstand erection loads incidental to the construction operation. Foundation anchor bolts are to be set within specified tolerances, levelled and held firmly in position during all setting operations. 3.5 Ensure rigging is performed in accordance with the approved lifting plan/procedure. 3.6 For equipment platforms, check and secure that contact surfaces of supports have been painted accordingly prior to installation. 3.7 Install columns to their respective foundation as per AFC drawing. 3.8 Install supporting beams and other supports by means of welding or bolting. 3.9 Provide scaffolding if required. 3.10 Check for plumb and square of support against the columns. 3.11 Carry out QC inspection and obtain approval. 3.12 Fabricate all frames for gratings and platform near the erection area 3.13 Install frames and gratings, ladders, stairs and hand rails as per drawing. 3.14 Touch up if any paint damaged was found. 3.15 Carry out QC inspection and obtain approval. 4. Installation of economizer block as per AFC drawing. PSAL to erect economizer block. 5. Piping installation 5.1 Obtain the latest revision of AFC drawings / specifications and construction procedures and distribute to those personnel supervising the work. 5.2 Review AFC Drawings, confirm installation feasibility in the field and check availability of pertinent materials. 5.3 When discrepancies in the field exist relating to AFC drawings or field condition, raise technical queries and submit to the PSAL.

Page 8 of 14

MS-M-003 Rev. 03 5.4 Confirm procedures and AFC drawings are available to personnel associated with the work. 5.5 Check spool installation locations and determine the need for scaffolding / work platforms and rigging / lifting equipment. Co-ordinate with both scaffolding and rigging sections. 5.6 Install scaffolding where required. 5.7 Rigging shall be in accordance with approved rigging Instruction. Assign suitably qualified personnel to assist with the installation work. 5.8 Verify lifting procedures and tools are approved / certified in accordance with customer and MMG project safety regulations (recommended 1/3 rd rotation). 5.9 Review AFC drawing, determine spool and material availability. Determine sequence of spool installation based on construction schedules, availability of equipment / access and materials. 5.10 Ensure correct materials, tools and personnel are available to perform installation work. 5.11 Handling and transportation of pipes and components from the project warehouse and fabrication area to the work area. 5.12 To prevent damage to pipe spools which have been coated. Handling shall only be carried out with non-metallic slings following full curing of the coating system. Chains or wire ropes shall not be used. The manufacturers recommendations shall be followed for curing of coatings at all times. 5.13 Coated spools shall be stored on soft standings (wood dunnage, sand bags etc.). 5.14 Loading and handling of coated pipe spools shall be carried out in such a way that coating damage is kept to an absolute minimum. Soft lines shall be attached to spools, where necessary, to prevent swing and possible damage during loading / unloading. 5.15 During transportation, spools shall be adequately secured with soft lines to prevent movement and damage. Where practicable, end caps / bevel protectors shall be installed to prevent the ingress of foreign objects and damage to weld preps. 5.16 To prevent the entry of debris and damage to flange faces, flange covers shall be left in position on valves and spools until the time of installation.

Page 9 of 14

MS-M-003 Rev. 03

5.17 Obtain work permit (when required). 5.18 Prior to installation the following items shall be observed. a) Check the location and orientation of spools to plan north on AFC isometrics / plans b) Identify permanent supports (trunnions, guides, anchors, dummy supports and pipe shoes). 5.19 Install permanent pipe supports in accordance with the AFC isometric, support drawings or when practical, provide temporary supports of sufficient capability to withstand applied loads. 5.20 Establish good reference point and commence installation in a progressive manner. 5.21 Fit up and other installation activities shall be accordance to approved method statement of Piping Above Ground and Erection Procedure MVF Boiler in Site by MACCHI. 6. For NDE Requirements refer to: Approved QCIP 7. For Hydrotest Requirements refer to approved method statement for Hydrotest. 8. Erection of air windbox with relevant support structure and spring hangers according to drawing 1007-M-410 (SP No. PC-A-97064), 1007-M-414 (Macchi internal doc.) 9. Positioning of burners according to drawing 1007-M-200 (SP-No. PY-B-97150), 1007-M-201 (SP No. PY-B-97047), 1007-M-202 (SP No PY-B-9748) 10. Execution of refractory casting for burner throat by means of proper template according to drawing 1007-M-504 (Macchi InternDWal Doc.) 10.1 Positioning of refractory tiles in the furnace floor and the bricks in the inspection doors according to 1007-M-540 (SP-No. PC-A-97068). 11. Erection of the gas ducts from boiler to economizer according to drawing 1007M-400 and 1007-M420. 12. Erection of Gas ducts from economizer to stack according to drawing 1007-M400 and 1007-M420. 13. Erection of Stack 13.1. Review AFC drawing.

Page 10 of 14

MS-M-003 Rev. 03

13.2. Stack delivered in four parts ST1, ST2, ST3 and ST4. 13.3. Use suitable crane for pre-assembly. 13.4. Lay all stack sections ST1, ST2, ST3 and ST4 on the ground. Align and weld as per WPS and AFC drawings. Assemble all steel structure such as platforms, ladders, grating and hand rails, personal protection stackers etc., along with cable trays with cabling complete with painting on the ground. 13.5. Install in one piece as tandem lift by PSAL. 14. Positioning of F.D. fan drivers (electric motors or steam turbine) and silencer according to drawing 1007-M-211 (SP steam No. PC-A-97050), 1007-M-715 (SP No. PC-A-97195)). 15. Erection of sand filter for FD fan suction on relevant support structure according to drawing 1007-M-412 (SP No. PC-A-97063), 1007-M-700 (SP No. PC-A-97070).

16. Installation of insulation materials, fabrication and installation of lagging on the economizer casing on the ducts according to the drawing 1007-M-605 (Macchi internal documents). Moreover has to be carried out the completion of insulation on the lower parts of steam boiler after the removal of the shipping frame according to drawing 1007-M-600 (SP No. PC-A-97069), 1007-M-601 (macchi Internal doc.) 17. Erection of pressure safety valves according to drawing 1007-M-276 (SP No. PC-A-97069). Note: Check if the plugs for hydrostatic test are installed in the safety valves if yes, they must be removing before commissioning activities. 18. Positioning of sampling system according to the drawing n 1007-S-307 (SP No. PC-D-97108), 1007-M-021 (SP No. PB-A-97039). 19. Positioning of steam vent silencers on relevant support structures according to the drawing 1007-M-271 (SP No. PC-A-97051), 1007-M-272 (SP No. PC-A97052), 1007-M-700 (SP No. PC-A-97070). 20. Positioning, assembling and welding of non-boiler external piping, the related valves and supports up to battery limit. The piping with DN =< 2 will be supplied loose in commercial length and shall be pre-fabricated on site according to the routings shown on assembly dwg. 1007-M-300 (SP No. PB-A97054) and materials list 1007-M-326 (SP No. PA-E-97059).

Page 11 of 14

MS-M-003 Rev. 03 Note: that these routings are indicative and have to be verified on site before the erection to avoid interference. The piping erection shall be according to the following documents: P&ID 1007-S-002 (SP No. PD-A-97007), 1007-S-003 (SP No. PD-A-97008), 1007-S-006 (SP No. 23. PD-A-97009), 1007-S-007 (SP No. PD-A-97010), 1007-S-011 (SP No. PD-A-97073), 1007-S-019 (SP No. PD-A-97136) [1007-S018 (SP No. PD-A-97140) and 1007-S-019 (SP No. PD-A-97139) for boiler C]. Lines list 1007-M-001 (SP No. PD-A-97139) Valves list 1007-M-002 (SP No. PA-E-97038) Piping assembly and details dwg. n 1007-M-300 (SP N o. PB-A-97054), 1007M-316 (SP No. PAE-97055), 1007-M-321 (SP No. PA-E-97057), 1007-M-326 (SP No. PA-E-97059). Piping supports 1007-M-330 (SP No. PC-A-97060), 1007-M-350 (SP No. PC-A-97061) During the activities special care has to be taken to prevent that any foreign matters, shaping, dirty enter into the pipes/boiler. All pipe connections must be closed with temporary protections up to assembling and welding the joints. 21. Spreader bar will be used with nylon sling that shall carry Boiler Stacks as shown in the procedure plan drawing. 22. Carry out of N.D.E. on non-boiler external piping according to applicable codes and QCIP. 23. Installation of insulation material and lagging on piping and relevant auxiliaries up to battery. 24. Limits according to the dwg. 1007-M-610 (Macchi internal doc.), 1007-M-615 (Macchi internal doc.). 25. Installation of textile expansion joints between the air duct and the windbox, between the boiler. outlet connection and flue gas duct, between the F.D.FANS and the air duct according to dwg. 1007-M-410 (SP No. PC-A-97064), 1007-M420 (SP No. PB-B-97165) and the installation manuals provide by the expansion joint supplier (see Attachments 3 and 4). . VII. INSPECTION & / QUALITY RECORDS: 1. Inspection shall be conducted and recorded in accordance with the Job Specific Inspection and Test Plan, QC detail activities along with references for checklist according to SATIP-F-001-04 - BOILER - Packaged Type and Vendor approved ITP.

VIII.

SAFETY PRECAUTIONS: The work shall be executed in accordance with the approved job safety analysis (JSA). Permit shall be obtained prior to any commencement of the work when required

Page 12 of 14

MS-M-003 Rev. 03

IX.

ATTACHMENT:

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 1007-M-420 1007-M-431 1007-M-400 1007-M-410 1007-M-700 1007-M-701 1007-M-702 1007-M-703 1007-M-704 1007-M-705 1007-M-706 1007-M-707 1007-M-750 1007-M-751 1007-M-752 1007-M-753 1007-M-754 1007-M-755 1007-M-760 1007-M-761 1007-M-762 - Air Duct Assembly and Details. - Stack Details. - Air and Flue Gas Duct General Arrangement. - Air Duct Assembly Details. - Platform Stairs and Ladders General Arrangement Drawing. - Steel Structure Platform and Stairs /Ladders Assembly Mark STR1 - Steel Structure Platform and Stairs /Ladders Assembly Mark STR2 - Steel Structure Platform and Stairs /Ladders Assembly Mark STR3 - Steel Structure Platform and Stairs /Ladders Assembly Mark STR4 - Steel Structure Platform and Stairs /Ladders Assembly Mark STR5 - Steel Structure Platform and Stairs /Ladders Assembly Mark STR6 - Steel Structure Platform and Stairs /Ladders Assembly Mark STR7 - Hand Rail & Toe-Plate Plan elevation +104150 (TOS) - Hand Rail & Toe-Plate Plan elevation +106620 (TOS) - Hand Rail & Toe-Plate Plan elevation +11327 to 116670 (TOS) - Hand Rail & Toe-Plate Plan elevation +11327 to 116670 (TOS - Hand Rail & Toe-Plate Section Stair and Details - Hand Rail & Toe-Plate for Stack - Grating & Step Assembly Plan elevation + 104180 (TOG) - Grating & Step Assembly Plan elevation + 106650 (TOG) - Grating & Step Assembly Plan elevation form +108780 to +110880 (TOG) - Grating, Step Assembly Plan and Details elevation form +113000

22. 1007-M-763 to 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50.

+116700 (TOG) 1007-M-764 - Platform Stack Grating Assembly. JI194-OK030004-MR-C03-001-A - Piping Support Construction details. 1007-W-100 - Macchi Welding Book with Welding Map PQR Procedure. 1007-S-002 - V86-U-0501 (Train 1) Water Steam P & I Diagram. 1007-S-003 - V86-U-0501 (Train 1) Air-fuel Gas and P & I Diagram. 1007-S-006 - V86-U-0501 (Train 1) Fuel Supply System P & I Diagram. 1007-M-001 - Line List. 1007-M-002 - Valve list. 1007-M-020 - Boiler Foundation Assembly. 1007-M-300- Sh.1 - Boiler Piping Assembly Plan El. 0.00. 1007-M-300- Sh.2 - Boiler Piping Assembly Plan El. 4150. 1007-M-300- Sh.3 - Boiler Piping Assembly at elevation 6620. 1007-M-300-Sh.4 - Boiler Piping assembly Plan El. 10040. 1007-M-300-Sh.5 - Boiler Piping Assembly Plan El. 13270. 1007-M301-Sh.1 - Boiler Piping Assembly Right Side View. 1007-M-301 Sh.2 - Boiler Piping Assembly Left Side View. 1007-M-302 - Boiler Piping Assembly Front View. 1007-M-303 - Boiler Piping Assembly Rear View. 1007-M-316 - Steam Drum Instrument assembly. 1007-M-320 - Isometric Drawing Code Under Code Jurisdiction. 1007-M-321 - Isometric Drawing External Piping. 1007-M-330 Sh.1 - Boiler piping Assembly plan El. 0.00 support position. 1007-M_330 Sh.2 - Boiler Piping Assembly Plan elevation 4150 Support Position. 1007-M-330 Sh.3 - Boiler Piping Assembly Plan El. 6620 Support Position. 1007-M-330 sh.4 - Boiler Piping Assembly Plan 10040 supports position. 1007-M-330 Sh.5 - Boiler Piping Assembly Plan 13270 Supports Position. 1007-M-331-Sh.1 - Boiler Piping assembly Right Side View Support Position. 1007-M-331-Sh.2 - Boiler Piping Assembly Left Side View Supports Position. Page 13 of 14

MS-M-003 Rev. 03

51. 52. 53. 54. 55. 56. 1007-M-332 1007-M-333 1007-M-350 1007-M-325 1007-M-326 P8926-M-600 - Boiler piping Assembly Front View Supports Position. - Boiler Piping assembly Rear View support position. - Piping Supports Constructive Details. -Piping Under Code Jurisdiction Material List <= 1 . - External Piping Material List & Isometrics. - Boiler External Insulation assembly.

Note:

All font ,italicized and bold, are either Revisions / Additions -------------------

END

------------------

Page 14 of 14

Das könnte Ihnen auch gefallen

- Procedure For Installation of Steel Stair StructureDokument6 SeitenProcedure For Installation of Steel Stair StructureImamah AliNoch keine Bewertungen

- TFA Course For Foremen & QC TechnDokument39 SeitenTFA Course For Foremen & QC TechnPrabhu RajalingamNoch keine Bewertungen

- Method Statement For Hot Tapping Rev 0 PDFDokument9 SeitenMethod Statement For Hot Tapping Rev 0 PDFsharif339Noch keine Bewertungen

- Method Statement For Hot Tapping Rev 0 PDFDokument9 SeitenMethod Statement For Hot Tapping Rev 0 PDFsharif339Noch keine Bewertungen

- Florida's Construction Lien Law: Protect Yourself and Your InvestmentDokument2 SeitenFlorida's Construction Lien Law: Protect Yourself and Your InvestmentpeterNoch keine Bewertungen

- TR2222 - Pipeline Flooding, Cleaning, Gauging and Pressure TestingDokument20 SeitenTR2222 - Pipeline Flooding, Cleaning, Gauging and Pressure Testingmaximusala83Noch keine Bewertungen

- Boiler Drum Erection ProcedureDokument6 SeitenBoiler Drum Erection Procedureer_sanjaypatel100% (1)

- List of Nozzles List of Nozzles: T T 1 T T 1Dokument1 SeiteList of Nozzles List of Nozzles: T T 1 T T 1גרבר פליקס100% (1)

- NS1 Work Plan Procedure For Erection of Circulating Water Pump Rev.0 - Part 1 of 3Dokument53 SeitenNS1 Work Plan Procedure For Erection of Circulating Water Pump Rev.0 - Part 1 of 3namdq-1Noch keine Bewertungen

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Dokument22 SeitenTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117Noch keine Bewertungen

- Vessel Final BoxDokument14 SeitenVessel Final Boxmanoj thakkarNoch keine Bewertungen

- Safety Alert Space HeatersDokument2 SeitenSafety Alert Space HeatersRamadan KareemNoch keine Bewertungen

- FQP 16.11.18 Vol-I - BoilerDokument90 SeitenFQP 16.11.18 Vol-I - Boilerashis chatterjeeNoch keine Bewertungen

- Industrial TrainingDokument59 SeitenIndustrial TrainingSatnam SinghNoch keine Bewertungen

- Lift Plan FormDokument1 SeiteLift Plan Formخالد نسیمNoch keine Bewertungen

- Inspection and Test Plan For Water Tube BoilerDokument13 SeitenInspection and Test Plan For Water Tube BoilerVinh Do Thanh100% (1)

- Inspection and Test Plan For Storage TankDokument7 SeitenInspection and Test Plan For Storage TankABDELKADER BENABDALLAHNoch keine Bewertungen

- WeldingDokument13 SeitenWeldingAna Hidayah SyuhadaNoch keine Bewertungen

- 350 - Tray Installation Manual - EngDokument36 Seiten350 - Tray Installation Manual - EngRashid MadathilNoch keine Bewertungen

- API-1000-11 Rev 0Dokument3 SeitenAPI-1000-11 Rev 0Mahesh MishraNoch keine Bewertungen

- ITP Expoxy Bonded Pipeline TripatraDokument16 SeitenITP Expoxy Bonded Pipeline TripatraparwotoNoch keine Bewertungen

- 1365 PDFDokument221 Seiten1365 PDFSaad SarfarazNoch keine Bewertungen

- Shackle InspectionDokument3 SeitenShackle InspectionArfanAliNoch keine Bewertungen

- Lowering of PipelineDokument5 SeitenLowering of PipelineLarry Ubu100% (1)

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDokument18 Seiten4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNoch keine Bewertungen

- 1-Manual Horizontal Stand CTS670 ST7H PDFDokument121 Seiten1-Manual Horizontal Stand CTS670 ST7H PDFManikandaprabhu ManickamNoch keine Bewertungen

- Quality Control System in The Fabrication of Heat ExchangersDokument5 SeitenQuality Control System in The Fabrication of Heat ExchangersCorine CaracasNoch keine Bewertungen

- WPS Sa 517Dokument2 SeitenWPS Sa 517DHANANNJAI SINGH -Noch keine Bewertungen

- Work Instruction For Hydrostatic TestingDokument18 SeitenWork Instruction For Hydrostatic TestingAlok SinghNoch keine Bewertungen

- Pipe Instalation ChecklistDokument4 SeitenPipe Instalation ChecklistYuwantoniAlNoch keine Bewertungen

- CommissioningDokument4 SeitenCommissioningowaise007Noch keine Bewertungen

- Post Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2Dokument15 SeitenPost Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2williamsenNoch keine Bewertungen

- Tank Truck Equipment CatalogDokument133 SeitenTank Truck Equipment CatalogluisfernandoaliNoch keine Bewertungen

- Visual Inspection of Large Electric GeneratorsDokument28 SeitenVisual Inspection of Large Electric Generatorsemailsepamku gorgomNoch keine Bewertungen

- Structural Inspection Checklist For FactoryDokument1 SeiteStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- Clarkson C-Valve Iom ManualDokument102 SeitenClarkson C-Valve Iom Manualpca9750% (2)

- Stationary Equipment Procedure (Pack 1)Dokument5 SeitenStationary Equipment Procedure (Pack 1)Farhan SheikhNoch keine Bewertungen

- The NEW Company ProfileDokument26 SeitenThe NEW Company ProfilewisandhaNoch keine Bewertungen

- Neral Specification For Skid Mounting Assemblyt - 03-GTS-02 REV. 1Dokument10 SeitenNeral Specification For Skid Mounting Assemblyt - 03-GTS-02 REV. 1Ashok Kumar100% (1)

- Standard Erection Manual (Pressure Parts)Dokument138 SeitenStandard Erection Manual (Pressure Parts)rarundivya100% (1)

- SWPP ListDokument18 SeitenSWPP ListAnonymous hNpF6I0% (1)

- Procedure For Instalattion of VesselDokument6 SeitenProcedure For Instalattion of Vesselyayan hNoch keine Bewertungen

- Cold Forming and Heat Treatment Requirement of Austenitic Stainless Steel Tubes.Dokument5 SeitenCold Forming and Heat Treatment Requirement of Austenitic Stainless Steel Tubes.R kumarNoch keine Bewertungen

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDokument2 SeitenElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNoch keine Bewertungen

- Steam BoilerDokument3 SeitenSteam BoilerMohammad AzlanNoch keine Bewertungen

- Ipss Handbook PDFDokument45 SeitenIpss Handbook PDFSarbendu Paul100% (1)

- 1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceDokument11 Seiten1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceIstiQamahh MuhamadNoch keine Bewertungen

- Standard PracticeDokument14 SeitenStandard PracticeRomi Abdul RahmanNoch keine Bewertungen

- Bolting Program Info PDFDokument2 SeitenBolting Program Info PDFIrshad AhmadNoch keine Bewertungen

- Method Statement Pipe Handling and AssemblyDokument6 SeitenMethod Statement Pipe Handling and AssemblyDanny NguNoch keine Bewertungen

- Job Hazard Analysis: Generic Jha For Blasting & Painting WorksDokument7 SeitenJob Hazard Analysis: Generic Jha For Blasting & Painting WorksReynaldo PesqueraNoch keine Bewertungen

- Jacking Procedurefor Construction of Tanks OLDDokument10 SeitenJacking Procedurefor Construction of Tanks OLDVikram RangasamyNoch keine Bewertungen

- FMS Training M01Dokument14 SeitenFMS Training M01donyemjoroNoch keine Bewertungen

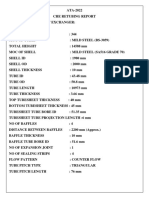

- CHE Retubing ReportDokument29 SeitenCHE Retubing ReportRajesh KtrNoch keine Bewertungen

- Visual Inspection Checklist For Flanges, Gaskets and Bolting Reinstatement of Sea Water Cooling Project Phase IiDokument1 SeiteVisual Inspection Checklist For Flanges, Gaskets and Bolting Reinstatement of Sea Water Cooling Project Phase IijahaanNoch keine Bewertungen

- AKP Storage TanksDokument51 SeitenAKP Storage Tankscris_2010Noch keine Bewertungen

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDokument11 Seiten14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNoch keine Bewertungen

- Dual Fuel Installation, Commissioning & Operation Manual REV IIIDokument43 SeitenDual Fuel Installation, Commissioning & Operation Manual REV IIIJuan Manuel Llorente VaraNoch keine Bewertungen

- Weld RepireDokument91 SeitenWeld RepireKapil ManloiNoch keine Bewertungen

- PLIDCO Pipeline RepairDokument6 SeitenPLIDCO Pipeline RepairGhufran Ahmed BalaNoch keine Bewertungen

- Petrol & Gas Construction Co.: Elevator Shaft ErectionDokument9 SeitenPetrol & Gas Construction Co.: Elevator Shaft ErectionBoj MingiNoch keine Bewertungen

- MS-M-063 Rev. 1 - Air Fin Cooler InstallationDokument6 SeitenMS-M-063 Rev. 1 - Air Fin Cooler InstallationwalitedisonNoch keine Bewertungen

- Hot TapDokument1 SeiteHot Tapsharif339Noch keine Bewertungen

- JASMINE SchedaDokument1 SeiteJASMINE Schedasharif339Noch keine Bewertungen

- Hot TapDokument1 SeiteHot Tapsharif339Noch keine Bewertungen

- Hempel Price SheetapplicationinstructionsDokument4 SeitenHempel Price SheetapplicationinstructionsDurgaiah RathnamNoch keine Bewertungen

- Hot TapDokument1 SeiteHot Tapsharif339Noch keine Bewertungen

- Social Visit Pass PaperDokument0 SeitenSocial Visit Pass Papersharif339Noch keine Bewertungen

- AjayHanda (16 0)Dokument3 SeitenAjayHanda (16 0)sharif339Noch keine Bewertungen

- Owners Manual - JBL - SB150 EnglishDokument9 SeitenOwners Manual - JBL - SB150 EnglishBhavies BK100% (1)

- Work Over of RigDokument3 SeitenWork Over of Rigsharif339Noch keine Bewertungen

- Phulka 12Dokument1 SeitePhulka 12sharif339Noch keine Bewertungen

- Owners Manual - JBL - SB150 EnglishDokument9 SeitenOwners Manual - JBL - SB150 EnglishBhavies BK100% (1)

- Dear Sir /madam, Please Find My C.V For Project Engineer Position For Further Queries Please Feel Free To With Regards SharifDokument1 SeiteDear Sir /madam, Please Find My C.V For Project Engineer Position For Further Queries Please Feel Free To With Regards Sharifsharif339Noch keine Bewertungen

- Completion of DrillingDokument1 SeiteCompletion of Drillingsharif339Noch keine Bewertungen

- EP SPass Form8Dokument12 SeitenEP SPass Form8Min ZawNoch keine Bewertungen

- Choa Chu Kang: Bus & Train Ser Vices Guide Bus & Train Ser Vices GuideDokument9 SeitenChoa Chu Kang: Bus & Train Ser Vices Guide Bus & Train Ser Vices Guidesharif339Noch keine Bewertungen

- AmitPMilmile (11 0)Dokument4 SeitenAmitPMilmile (11 0)sharif339Noch keine Bewertungen

- Bganesh (11 0)Dokument3 SeitenBganesh (11 0)sharif339Noch keine Bewertungen

- Dipakajadhav (8 0) PDFDokument3 SeitenDipakajadhav (8 0) PDFsharif339Noch keine Bewertungen

- Amanvasir@live - Co.uk: 6 Years + 10 Months of ExperienceDokument4 SeitenAmanvasir@live - Co.uk: 6 Years + 10 Months of Experiencesharif339Noch keine Bewertungen

- AnilKumarNaharia (23 0)Dokument7 SeitenAnilKumarNaharia (23 0)sharif339Noch keine Bewertungen

- AakashSureshchandraParikh (7 0)Dokument5 SeitenAakashSureshchandraParikh (7 0)sharif339Noch keine Bewertungen

- EmptyDokument1 SeiteEmptysharif339Noch keine Bewertungen

- BP Oil Grangemouth Refinery LTD, Stirlingshire, ScotlandDokument1 SeiteBP Oil Grangemouth Refinery LTD, Stirlingshire, Scotlandsharif339Noch keine Bewertungen

- AakashSureshchandraParikh (7 0)Dokument5 SeitenAakashSureshchandraParikh (7 0)sharif339Noch keine Bewertungen

- Offshore HVACDokument45 SeitenOffshore HVACRajakumar Bajji Subburaman100% (1)

- Production Rel Decision MakingDokument97 SeitenProduction Rel Decision Makingsharif339Noch keine Bewertungen

- Guide To Purchasing Equipment: Finance Division Purchasing OfficeDokument16 SeitenGuide To Purchasing Equipment: Finance Division Purchasing Officesharif339Noch keine Bewertungen

- Experience Details Project Engineer (Mechanical and Drilling (Feb 2007-May 2008) in Neptune Marine Oil and Gas Private Limited, SingaporeDokument4 SeitenExperience Details Project Engineer (Mechanical and Drilling (Feb 2007-May 2008) in Neptune Marine Oil and Gas Private Limited, Singaporesharif339Noch keine Bewertungen

- Stone Arch Bridge Maintenance ManualDokument45 SeitenStone Arch Bridge Maintenance ManualGlaukopis1Noch keine Bewertungen

- Taking-Off Sheet, BQ Sheet and Concrete Mix Design FormDokument7 SeitenTaking-Off Sheet, BQ Sheet and Concrete Mix Design FormiskandarNoch keine Bewertungen

- Detailed Material StatusDokument47 SeitenDetailed Material StatusMohamed AlaaNoch keine Bewertungen

- Cruciform Construction ManualDokument37 SeitenCruciform Construction ManualDipak BorsaikiaNoch keine Bewertungen

- Chapter-3 SpecificationDokument30 SeitenChapter-3 SpecificationAbdanur JihadNoch keine Bewertungen

- AndualemDokument8 SeitenAndualemAsegidNoch keine Bewertungen

- Willian Aung Resume - Site EngineerDokument1 SeiteWillian Aung Resume - Site EngineerPYAE SOAMNoch keine Bewertungen

- Ferrocemnt Channel Roof PDFDokument2 SeitenFerrocemnt Channel Roof PDFRafael CuaNoch keine Bewertungen

- A Leading Crane and Alfaris Heavy Equirpement Rental Co. in UaeDokument1 SeiteA Leading Crane and Alfaris Heavy Equirpement Rental Co. in UaeGovinda DhageNoch keine Bewertungen

- 2021 Price ListDokument114 Seiten2021 Price ListHelices CostaNoch keine Bewertungen

- Analysis of Rates: Mat. Id Descreption Quantity Unit Rate TotalDokument20 SeitenAnalysis of Rates: Mat. Id Descreption Quantity Unit Rate TotalSHAILENDRANoch keine Bewertungen

- Preparation of Layout of A Plan of A Building and It's Marking On GroundDokument13 SeitenPreparation of Layout of A Plan of A Building and It's Marking On GroundUtkarsh GautamNoch keine Bewertungen

- Monthly Work ProgrammeDokument15 SeitenMonthly Work ProgrammeSRK QSNoch keine Bewertungen

- CaseDokument6 SeitenCaseGeorge LeeNoch keine Bewertungen

- PARISDokument53 SeitenPARISDHANA LAKSHMINoch keine Bewertungen

- 1 - Method Statement For Sika WaterproofingDokument6 Seiten1 - Method Statement For Sika WaterproofingAyda JohariNoch keine Bewertungen

- Vv216a-109-A-807 - 12 - 0001 - Laminator's Training ProcedureDokument27 SeitenVv216a-109-A-807 - 12 - 0001 - Laminator's Training Proceduretonful143Noch keine Bewertungen

- Block Work Method of StatementDokument5 SeitenBlock Work Method of StatementyasNoch keine Bewertungen

- Concrete Masonry - Site Practice and Workmanship GuideDokument28 SeitenConcrete Masonry - Site Practice and Workmanship GuideRey Eduard Q. UmelNoch keine Bewertungen

- Quantity Surveyor Interview Questions Part-2Dokument7 SeitenQuantity Surveyor Interview Questions Part-2Ravi KumarNoch keine Bewertungen

- Ez Rocks Co., Inc - Company ProfileDokument81 SeitenEz Rocks Co., Inc - Company ProfileJesusa EstradaNoch keine Bewertungen

- Philippine Construction Productivity Rates Archives - PHILCON PRICESDokument11 SeitenPhilippine Construction Productivity Rates Archives - PHILCON PRICESJoaquin BernabeNoch keine Bewertungen

- Industrial BuildingDokument2 SeitenIndustrial BuildingYASTISHA GUSMARINoch keine Bewertungen

- Waterproofing and DampproofingDokument3 SeitenWaterproofing and DampproofingQuinn HarloweNoch keine Bewertungen

- 02 Task Performance 1 - ARG - DATUDokument2 Seiten02 Task Performance 1 - ARG - DATUCarl Louis DatuNoch keine Bewertungen

- ACI India Chapter Webinar On Mass Concrete 2020-10-16Dokument25 SeitenACI India Chapter Webinar On Mass Concrete 2020-10-16darshan100% (1)

- Produce Water Tank S.PCMDokument3 SeitenProduce Water Tank S.PCMsudeesh kumarNoch keine Bewertungen

- Construction of A Large Commercial MallDokument17 SeitenConstruction of A Large Commercial MallAditya MalpaniNoch keine Bewertungen

- World Famous Parabolic ArchesDokument4 SeitenWorld Famous Parabolic ArchesKlare Montefalco100% (2)