Beruflich Dokumente

Kultur Dokumente

Rigid Pavement AASHTO 1993

Hochgeladen von

Gelbert SilotCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rigid Pavement AASHTO 1993

Hochgeladen von

Gelbert SilotCopyright:

Verfügbare Formate

Location Project No.

(REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

1.

GENERAL

1.1 OUTLINE OF STRUCTURE

Project Client Location Structure Name

1.2 DESIGN PHILOSOPHY

1.2.1 Unit of Measurment Unit of measurment in design is in metric/imperial system 1.2.2. Computer Software that is used in design analysis MS Excel

1.3 CODE AND STANDARD

1.3.1. General Codes and Standard AASHTO 1993 Guide for Design of Pavement Structures PCA Portland Cement Association SKBI 1.3.53 - 1987 Indonesian Loading Code for Building ACI 318 - 08 Building Code for Structural Concrete ASTM American Society for Testing and Material

1.3.2. Spesific Codes and Standard TPP-00-A0-ES-001-R Design Specification for Civil & Structural

1.4 USED MATERIAL AND ALLOWABLE STRESS

1.4.1 Concrete Compressive Strength of concrete at 28 days ( Cilinder Test ) shall be as follows , unless otherwise specified fc' fc' Concrete Specific Gravity 1.4.2 Reinforcing Steel Bar Material Grade Wiremesh Deformed Bar Plain Bar Steel Specific Gravity = 7850 > = = 100 kg/cm2 280 kg/cm2 2400 kg/m3 For Leveling Concrete For Road and Pavement

Yield Strength ( Min. ) fyw fyd fyp kg/m3 6000 = 3200 = 2400 = kg/cm2 kg/cm2 kg/cm2

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

2. ROAD & HEAVY DUTY PAVEMENT DESIGN

UR =

Pavement : Sub Base : Subgrade : CBR min

20

years (life time period)

rigid pavement none compacted soil 20%

2.1 HEAVY DUTY PAVEMENT AND ROAD - LAYER DESIGN

see 2.4 see 2.3

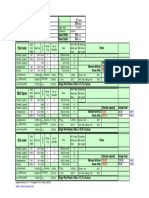

2.2 EQUIVALENT SINGLE AXLE LOAD - ESAL

Vehicles Type Light vehicle less than 5 t

Axle

Single Single Single Tandem Tandem Single Single

Truck Loading HS-20-44 36 t

Truck mounted crane HC-218-J 80 t

Tandem Tandem

Axle Load (ton) (kip) 2.5 5 2.5 5 4 8 16 32 16 32 10 20 10 20 30 60 30 60

Traffic 20 vehicles/day/week/2 lanes 20 vehicles/day/week/2 lanes 60 vehicles/day/week/2 lanes 60 vehicles/day/week/2 lanes 60 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes

Load Equivalent Factor

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

at first assumed D slab thickness is service ability designed in good condition

Vehicles Type Light vehicle less than 5 t

8 in = Pt = 3.0 Axle

Single Single Single Tandem Tandem Single Single

203.2 mm -0.301 = G then Lx 5 5 8 32 32 20 20 60 60 L2x 1 1 1 2 2 1 1 2 2 x 1.000 1.000 1.003 1.211 1.211 1.230 1.230 6.142 6.142 18 1.137 1.137 1.137 1.016 1.016 1.137 1.137 1.016 1.016 LEF 0.005 0.005 0.034 1.357 1.357 1.516 1.516 13.748 13.748

Truck Loading HS-20-44 36 t

Truck mounted crane HC-218-J 80 t

Tandem Tandem

Design ESAL life time period = growth factor g = 20 years 2%

Vehicles Type Light vehicle less than 5 t Truck Loading HS-20-44 36 t

Truck mounted crane HC-218-J 80 t

Traffic current 20 vehicles/day/week/2 lanes 20 vehicles/day/week/2 lanes 60 vehicles/day/week/2 lanes 60 vehicles/day/week/2 lanes 60 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes 1 vehicles/day/week/2 lanes

Annual 23325.5 23325.5 69976.4 69976.4 69976.4 1166.27 1166.27 1166.27 1166.27

LEF 0.005 0.005 0.034 1.357 1.357 1.516 1.516 13.748 13.748 W18

Design ESAL 123.368 123.368 2405.052 94928.328 94928.328 1768.043 1768.043 16033.723 16033.723 228111.975 0.228 million

Since total W18 ESAL is lower than 1.000.000 then road could be categorized as low-volume. To achieve economical criteria then jointed type is chosen rather than continuous type. For jointed concrete pavement, JRCP type used due to is advantaged of fewer joints than JPCP type. 2.3 MODULUS OF SUBGRADE REACTION from the soil investigation:

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

assumed backfiling material are clayel gravel or clayel sandy gravel type.

And designed CBR needed for Roadbed is 20%

and based on recommended value range of k value

then taken modulus of subgrade around 200 psi/in 2.4 SUBBASE based on AASHTO Design guide for design of pavement structure 1993, clause 1.6.2

since Total ESAL is

228,111.98 < 1,000,000.00

and the average CBR is higher than 20%

Since additional subbase doesn't needed refer to Code, then subbase layer will be provided with condition of CBR 20% below the Concrete pavement to achieve design strength requirement 2.5 LOAD TRANSFER COEFFICIENT

Load transfer for jointed reinforced concrete pavement JRCP with dowel bars as transfer joint and without tied concrete shoulder is J = 3.2 as per recommended by AASHTO at clause 2.4.2

Location Project No. (REK)

Doc No. TONASA CALCULATION SHEET FOR1 ROAD AND Rev. Date 2 10-1026 XPT 35 SEMEN MW TONASA CFPP TPP-00-A4-CS-010-R 2 Dec 2011 Load transfer for jointed reinforced concrete pavement JRCP with dowel bars as transfer joint and without tied concrete shoulder is J = 3.2 as per recommended by AASHTO at clause 2.4.2

2.6 DRAINAGE COEFFICIENT

Drainage coefficient taken Cd = 1.00 for design at Good quality of drainage, with assumed moisture levels approching saturation 25% for design purpose.

2.7 DESIGN SERVICE LOSS (PSI) service ability designed in good condition with original or initial service ability for rigid pavement based on AAHSTO clause 2.2.1 PSI = Po - Pt = 1.5 2.8 CONCRETE ELASTIC MODULUS based on ACI 318 clause 8.5.1 concrete strength

fc' = = 280 kg/cm2 For Road and Pavement

Pt = 3.0 Po = 4.5

4000 psi 3604996.533 psi

concrete elastic modulus Ec = 57000(fc psi)^0.5 2.9 CONCRETE MODULUS OF RUPTURE

based on ACI 318 clause 9.5.2.5 time dependent factor for sustained load ratio of flexural reinforcement due to creep and shrinkage factor = /(1+50) based on ACI 318 clause 9.5.2.3 modulus of rupture fr = 7.5 (fc psi)^0.5 2.10 STANDARD DEVIATION AND RELIABILITY based on AASHTO clause 2.1.3 standard deviation for rigid pavement is So = 0.35

= 2 for 5 years or more ' = "0.0018 x 420 = 0.0013 600 = 1.881

fr = 892.458 psi

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

2..11 RELIABILITY Based on AASHTO PART I Chapter 4 since the ESAL design is low expected the initial cost is low so pavement designed doesn't need maintenance. Reliability taken 99.9%

2.12 RIGID PAVEMENT THICKNESS thickness of pavement designed with AASHTO Designed chart as follows

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

minimum thickness rigid pavement slab Assumed D slab thickness is Thickness used

D min = D= D=

5.5 in

= 139.7 mm = 203.2 mm

200 mm

2.13 CONCRETE REINFORCEMENT

there are three variables to determine reinforcement of JRCP type of Rigid Pavement 2.13.1 Slab Length slab length designed, L 30 m = 2.13.2 Steel working stress allowable stell working stress for wire fabric based on material testing

98.43 ft

fy = 6072.9 kg/cm2 allowable steel working stress taken 0.75 fy based on AASHTO clause 2.5.1 fya = 4554.675 kg/cm2 2.13.3 Friction factor Based on AASHTO Table 2.8

64.781 ksi

Rigid pavement designed without subbase so friction factor taken from condition frictional resistance between bottom of slab and natural subgrade

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

friction factor for natural subgrade is 0.9

2.13.4 Reinforcement area based on figure 3.8 AASHTO

percent steel reinforcement Ps = minimum area of steel reinforcement permeter length thickness of slab D= length L= minimum area A min = Design used double layer wiremesh M6-150 with area =

0.07 % 200 mm 1000 mm 140 mm2 376.991 mm2 higher than A minimum OK

2.14 JOINT CONNECTION DETAIL

2.14.1 Transverse Joint Joint opening coefficient based on AASHTO clause 2.5.2

S=

25 %

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

c = 6.5E-06 tensile strength = 4(fc^0.5) = L= 1000 mm DTd = 104 F C= 0.65 L = To satisfy joint opening between two panels, the width of joint is about 2x L use joint opening Dowels based on AASHTO clause 2.4.2 minimum diameter of Dowel is D/8 with dowel spacing maximum 12in and length minimum 18in 0.100 in

252.4263 = -77

Z= 39.37 in F =

0.0008 27 F

2.536 mm 5.07 mm 10 mm

= =

Db spacing length

= = =

25 mm 304.8 mm 457.2 mm

Dowel used Db 25@300 with length 460mm 2.14.2 Longitudinal Joint Tie bars required is specify :

unit weight of concrete

As used

Db = 13 mm

yc D L' fa fs As min As used n permeter spacing length

= = = = = = = = = =

2400 200 3500 0.9 266.7 55.606 132.7323 1 1000 800

kg/m3 mm mm Mpa mm2/m mm2 mm mm

2.354E-05 N/mm3

Tiebar used Db 13@1000 with length 800mm

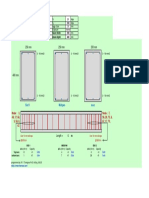

2.15 ILLUSTRATION DRAWING

L = 30m

TRANSVERSE JOINT

Db 25@300, length 460mm

W = 3.5m

Location Project No. (REK)

TONASA 2 10-1026 XPT 35 SEMEN MW TONASA CFPP

LONGITUDINAL JOINT

Db 13@1000, length 800mm

Doc No. CALCULATION SHEET FOR1 ROAD AND Rev. Date TPP-00-A4-CS-010-R 2 Dec 2011

W = 3.5m

Design used double layer wiremesh M6-150 with area =376.991mm2

2.16 REFERENCE

D, Norbert. 2008. Concrete Pavement Design, Construction, and Performance. London, Taylor & Francis Pavement Design Manual. Alberta Transportaion & Utilies. 1997

Das könnte Ihnen auch gefallen

- Sizing of Cable Tray Rev. D PDFDokument13 SeitenSizing of Cable Tray Rev. D PDFAlvin SmithNoch keine Bewertungen

- Pavement Design Excel SheetDokument23 SeitenPavement Design Excel Sheetharishreddy198571% (17)

- Design of C.C.Pavement: I) Modulus of Reaction of Sub Base (K)Dokument2 SeitenDesign of C.C.Pavement: I) Modulus of Reaction of Sub Base (K)D.V.Srinivasa Rao100% (1)

- Raft Slab DesignDokument5 SeitenRaft Slab DesignLekins Sefiu Yekini100% (2)

- Determine critical storm duration and peak flowDokument31 SeitenDetermine critical storm duration and peak flowRenukadevi Rpt100% (1)

- Soil Pile CapacityDokument26 SeitenSoil Pile CapacityOmar Najm100% (2)

- Kda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesDokument4 SeitenKda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesRoda Cadiz100% (4)

- Pile DesignDokument3 SeitenPile Designalinawaz91100% (9)

- Bs 5400 - Concrete DesignDokument1 SeiteBs 5400 - Concrete Designcaner_kurtoglu-1Noch keine Bewertungen

- Settlement of FoundationDokument11 SeitenSettlement of FoundationShane BondNoch keine Bewertungen

- Calculation Sheet Bored PileDokument9 SeitenCalculation Sheet Bored PileDavid Sinambela100% (5)

- Foundation Bearing Capacity (SPT BasedDokument8 SeitenFoundation Bearing Capacity (SPT BasedAziz ul HakeemNoch keine Bewertungen

- Disappearance of Madeleine McCannDokument36 SeitenDisappearance of Madeleine McCannCopernicNoch keine Bewertungen

- TCC62 Retaining WallDokument9 SeitenTCC62 Retaining Wallshafiq_05Noch keine Bewertungen

- DRAFT - Masonry Wall DesignDokument2 SeitenDRAFT - Masonry Wall DesignChetan SohalNoch keine Bewertungen

- Pile Design CalculationDokument6 SeitenPile Design Calculationjologscresencia100% (5)

- Pavement DesignDokument45 SeitenPavement Designjologscresencia100% (4)

- Civil Calculation Sheet for KO Drum Foundation Pile DesignDokument13 SeitenCivil Calculation Sheet for KO Drum Foundation Pile DesignDwiadi Cahyabudi100% (1)

- Micro PileDokument8 SeitenMicro PileJennifer Pearson100% (3)

- Bored Pile Design - Deep FoundationDokument6 SeitenBored Pile Design - Deep Foundationbuffyto5377Noch keine Bewertungen

- Rigid Pavement Design by Aashto MethodDokument1 SeiteRigid Pavement Design by Aashto MethodmdalgamouniNoch keine Bewertungen

- Rigid Pavement DesignDokument33 SeitenRigid Pavement DesignDebasis PalNoch keine Bewertungen

- JRCP - Parking Yard Calc R1Dokument8 SeitenJRCP - Parking Yard Calc R1Pieter HarryNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables) GGGDokument3 SeitenRCC94 Two-Way Slabs (Tables) GGGThomas OluwafemiNoch keine Bewertungen

- Submitted Rigid Pavement Design Guidelines - September - 2018Dokument62 SeitenSubmitted Rigid Pavement Design Guidelines - September - 2018Padma Shahi100% (2)

- Portal Frame Rafter DesignDokument132 SeitenPortal Frame Rafter DesignBobor Emmanuel OfovweNoch keine Bewertungen

- Pile Set CriteriaDokument3 SeitenPile Set CriteriaAnonymous O404LiV4CNoch keine Bewertungen

- Pile Conditions: Input Quantities Value Units CommentDokument18 SeitenPile Conditions: Input Quantities Value Units CommentFidel Rodriguez HerrerosNoch keine Bewertungen

- Earthing System Design Basis Report For Arar DTD 28th AugDokument17 SeitenEarthing System Design Basis Report For Arar DTD 28th Augsrigirisetty208100% (1)

- Rigid Pavement DesignDokument10 SeitenRigid Pavement DesignBilal A BarbhuiyaNoch keine Bewertungen

- Rigid PavementDokument17 SeitenRigid Pavementsunilgera50% (2)

- Ground Anchor DesignDokument4 SeitenGround Anchor DesignVardhanNoch keine Bewertungen

- Pavement Design of Rigid PavementDokument15 SeitenPavement Design of Rigid PavementJove Revocal100% (1)

- 13 - Structural Design Retaining Walls-3Dokument23 Seiten13 - Structural Design Retaining Walls-3faridhassaniNoch keine Bewertungen

- Pile Group:: Piling Works For Bukit Batok N4C18 To C21 468A Pile Ecentricity Calculation G22Dokument2 SeitenPile Group:: Piling Works For Bukit Batok N4C18 To C21 468A Pile Ecentricity Calculation G22lattmdy100% (3)

- Steel Pile API (LRFD) - Primary DesignDokument2 SeitenSteel Pile API (LRFD) - Primary Designbhavdip_shahNoch keine Bewertungen

- Concrete Pavement DesignDokument3 SeitenConcrete Pavement Designsyxomphous100% (1)

- Calculation Sheet For Road and Paving - Rev 2 For Construction - 7 Agustus 2012Dokument43 SeitenCalculation Sheet For Road and Paving - Rev 2 For Construction - 7 Agustus 2012Rochmi TisnaviantiNoch keine Bewertungen

- Earthing Design Calculation for 230kV SwitchyardDokument10 SeitenEarthing Design Calculation for 230kV SwitchyardS Manohar100% (1)

- Jetty DesignDokument366 SeitenJetty Designvasanthk8125% (4)

- Graphic Organizers for Organizing IdeasDokument11 SeitenGraphic Organizers for Organizing IdeasMargie Tirado JavierNoch keine Bewertungen

- Chapter 3 - Example Flexible Pavement Thickness DesignDokument3 SeitenChapter 3 - Example Flexible Pavement Thickness DesignelleyashahariNoch keine Bewertungen

- DOH AO 2019-0047 National Standard On The Design, Construction, Operation and Maintenance of A Septic Tank SystemDokument16 SeitenDOH AO 2019-0047 National Standard On The Design, Construction, Operation and Maintenance of A Septic Tank SystemMaria Theresa Limos83% (6)

- Compressor RoomDokument15 SeitenCompressor RoomRajesh KyasanipalleyNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument4 SeitenRCC94 Two-Way Slabs (Tables)Zayyan RomjonNoch keine Bewertungen

- Design of Bored Pile at Abut A & BDokument10 SeitenDesign of Bored Pile at Abut A & BLenielle AmatosaNoch keine Bewertungen

- Road Crossing DesignDokument18 SeitenRoad Crossing DesignSyuraizat SabarudinNoch keine Bewertungen

- C++ NotesDokument129 SeitenC++ NotesNikhil Kant Saxena100% (4)

- Deviated Pile Cap DesignDokument10 SeitenDeviated Pile Cap Designirmreza68Noch keine Bewertungen

- Design of Micropile Structural CapacityDokument4 SeitenDesign of Micropile Structural CapacitySohaib Anwar100% (1)

- DBR Lightning Protec ArarDokument9 SeitenDBR Lightning Protec Ararsrigirisetty208Noch keine Bewertungen

- 1-RC DesignDokument4 Seiten1-RC DesignOSCARTAWNNoch keine Bewertungen

- Rigid Pavement Thickness DesignDokument2 SeitenRigid Pavement Thickness DesignFaeez Zain100% (1)

- Pile Foundation Concrete Column DesignDokument27 SeitenPile Foundation Concrete Column DesignSaid FauzieNoch keine Bewertungen

- Organizing and Delivering A Memorized SpeechDokument9 SeitenOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- Pavement DesignDokument54 SeitenPavement DesignDhimas Surya NegaraNoch keine Bewertungen

- Naga-Toledo Road Project: Pavement Design Calculation SheetDokument3 SeitenNaga-Toledo Road Project: Pavement Design Calculation SheetElvin G. TactacNoch keine Bewertungen

- Beca Carter Hollings & Ferner LTD: Seismic Horizontal Forces Include Structure MassDokument1 SeiteBeca Carter Hollings & Ferner LTD: Seismic Horizontal Forces Include Structure MassSharyn PolleyNoch keine Bewertungen

- Replacement Bridge Design ProjectDokument64 SeitenReplacement Bridge Design ProjectTri Angga Dio SimamoraNoch keine Bewertungen

- S4 - SD - HOTS in Practice - EnglishDokument65 SeitenS4 - SD - HOTS in Practice - EnglishIries DanoNoch keine Bewertungen

- Details of CC Pavement DesignDokument10 SeitenDetails of CC Pavement DesignRajesh BabuNoch keine Bewertungen

- Sample Pavement Design ReportDokument13 SeitenSample Pavement Design ReportHugo Domingos100% (1)

- 2632 PL DS 001 Line PipeDokument3 Seiten2632 PL DS 001 Line PipeAdvisNoch keine Bewertungen

- Summary of Cost Estimate For Construction of 1000 LPM Oxygen Plant at Govt. Erode Medical College Hospital, Perundurai ErodeDokument12 SeitenSummary of Cost Estimate For Construction of 1000 LPM Oxygen Plant at Govt. Erode Medical College Hospital, Perundurai ErodeAshok KumarNoch keine Bewertungen

- Interim Payment For Concrete WorksDokument52 SeitenInterim Payment For Concrete Worksarchie_728Noch keine Bewertungen

- COMPARATIVE STATEMENT FOR GENERAL ABSTRACTDokument40 SeitenCOMPARATIVE STATEMENT FOR GENERAL ABSTRACTAnonymous EScBHSJRNoch keine Bewertungen

- SSS Seminar InvitationDokument2 SeitenSSS Seminar InvitationGelbert Silot100% (2)

- Tie Beams1Dokument1 SeiteTie Beams1Gelbert SilotNoch keine Bewertungen

- Reinforcing Steel Bars Price List: StructuralDokument1 SeiteReinforcing Steel Bars Price List: StructuralGelbert SilotNoch keine Bewertungen

- Android Smart TV BOX - (FREE Wireless Mini Keyboard) - Checkout DailyDokument14 SeitenAndroid Smart TV BOX - (FREE Wireless Mini Keyboard) - Checkout DailyGelbert SilotNoch keine Bewertungen

- Columnsteel 1Dokument1 SeiteColumnsteel 1Gelbert SilotNoch keine Bewertungen

- Jojo Layout1 PDFDokument1 SeiteJojo Layout1 PDFGelbert SilotNoch keine Bewertungen

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDokument26 Seiten2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsGelbert SilotNoch keine Bewertungen

- Beam Girder and Column Rebar Option Is Off, How To Activate This One?Dokument2 SeitenBeam Girder and Column Rebar Option Is Off, How To Activate This One?Gelbert SilotNoch keine Bewertungen

- Pile StirrupDokument1 SeitePile Stirrupbuffyto5377Noch keine Bewertungen

- (ANALYSIS) Why Filipinos Need To Stay at Home Until June (Or Even Longer) PDFDokument13 Seiten(ANALYSIS) Why Filipinos Need To Stay at Home Until June (Or Even Longer) PDFGelbert SilotNoch keine Bewertungen

- Latest FormDokument27 SeitenLatest FormGelbert SilotNoch keine Bewertungen

- C 1Dokument1 SeiteC 1Gelbert SilotNoch keine Bewertungen

- Structural Drawing PDFDokument1 SeiteStructural Drawing PDFGelbert SilotNoch keine Bewertungen

- STAAD ShortcutsDokument3 SeitenSTAAD ShortcutsGelbert SilotNoch keine Bewertungen

- SFB 1Dokument1 SeiteSFB 1Gelbert SilotNoch keine Bewertungen

- SFB 2Dokument1 SeiteSFB 2Gelbert SilotNoch keine Bewertungen

- SFB 2Dokument1 SeiteSFB 2Gelbert SilotNoch keine Bewertungen

- RC ColumnsDokument2 SeitenRC ColumnsGelbert SilotNoch keine Bewertungen

- B 1Dokument1 SeiteB 1Gelbert SilotNoch keine Bewertungen

- Tie Beams2Dokument1 SeiteTie Beams2Gelbert SilotNoch keine Bewertungen

- C 2Dokument1 SeiteC 2Gelbert SilotNoch keine Bewertungen

- SFB 1Dokument1 SeiteSFB 1Gelbert SilotNoch keine Bewertungen

- Two Way Slab Design DetailsDokument1 SeiteTwo Way Slab Design DetailsGelbert SilotNoch keine Bewertungen

- Summary of Bids - MadridDokument1 SeiteSummary of Bids - MadridGelbert SilotNoch keine Bewertungen

- 510Dokument1 Seite510Gelbert SilotNoch keine Bewertungen

- Det 11Dokument1 SeiteDet 11Gelbert SilotNoch keine Bewertungen

- Common Shape CodesDokument1 SeiteCommon Shape CodesIrfanNoch keine Bewertungen

- Cash Flow MadridDokument1 SeiteCash Flow MadridGelbert SilotNoch keine Bewertungen

- Axial ContourDokument1 SeiteAxial ContourGelbert SilotNoch keine Bewertungen

- Socio-cultural influences on educationDokument4 SeitenSocio-cultural influences on educationofelia acostaNoch keine Bewertungen

- Introduction MCC Oxo ProcessDokument5 SeitenIntroduction MCC Oxo ProcessDeep PatelNoch keine Bewertungen

- Bahasa InggrisDokument8 SeitenBahasa InggrisArintaChairaniBanurea33% (3)

- Videocon ProjectDokument54 SeitenVideocon ProjectDeepak AryaNoch keine Bewertungen

- 09 Chapter TeyyamDokument48 Seiten09 Chapter TeyyamABNoch keine Bewertungen

- Acc418 2020 2Dokument3 SeitenAcc418 2020 2faithNoch keine Bewertungen

- Strata KT Office OpportunityDokument41 SeitenStrata KT Office OpportunitySanskar SurekaNoch keine Bewertungen

- Filler SlabDokument4 SeitenFiller Slabthusiyanthanp100% (1)

- Magnets Catalog 2001Dokument20 SeitenMagnets Catalog 2001geckx100% (2)

- Rock Type Identification Flow Chart: Sedimentary SedimentaryDokument8 SeitenRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosNoch keine Bewertungen

- Ceeshsworkingstudents Abm Group2Dokument18 SeitenCeeshsworkingstudents Abm Group2kzz9c5hqrwNoch keine Bewertungen

- Salford Care Organisation Job Description & Person SpecificationDokument14 SeitenSalford Care Organisation Job Description & Person SpecificationAyesha EhsanNoch keine Bewertungen

- OsmanabadDokument5 SeitenOsmanabadKirankumar MutnaliNoch keine Bewertungen

- MMADDokument2 SeitenMMADHariharan SNoch keine Bewertungen

- Template - Time in ManufacturingDokument2 SeitenTemplate - Time in ManufacturingVero RoaNoch keine Bewertungen

- GEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1Dokument73 SeitenGEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1mrzdravko15Noch keine Bewertungen

- ANAPHYDokument23 SeitenANAPHYYu, Denise Kyla BernadetteNoch keine Bewertungen

- Writing A Formal Letter To The PresidentDokument1 SeiteWriting A Formal Letter To The PresidentPiaAnaisNoch keine Bewertungen

- Cat TSDDokument55 SeitenCat TSDvarsha sharmaNoch keine Bewertungen

- Kara&Suoglu ProjectreportDokument4 SeitenKara&Suoglu ProjectreportRicard Comas xacnóNoch keine Bewertungen

- Active Disturbance Rejection Control For Nonlinear SystemsDokument8 SeitenActive Disturbance Rejection Control For Nonlinear SystemsTrần Việt CườngNoch keine Bewertungen

- Health Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4Dokument7 SeitenHealth Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4John Wilfred PegranNoch keine Bewertungen

- Defining Public RelationsDokument4 SeitenDefining Public RelationsKARTAVYA SINGHNoch keine Bewertungen

- Gujarat Technological University: Emester ViDokument4 SeitenGujarat Technological University: Emester ViPradeep SutharNoch keine Bewertungen

- PPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractDokument5 SeitenPPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractJoy CeeNoch keine Bewertungen