Beruflich Dokumente

Kultur Dokumente

Medical Gas & Vacuum System

Hochgeladen von

zampacaanasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Medical Gas & Vacuum System

Hochgeladen von

zampacaanasCopyright:

Verfügbare Formate

P

S

D

1

3

1

Medical Gas

and Vacuum

Systems

Continuing Education from Plumbing Systems & Design

Kenneth G.Wentink, PE, CPD, and Robert D. Jackson

JANUARY/FEBRUARY 2006

PSDMAGAZINE.ORG

GENErAl

Health care is in a constant state of change, which forces the

plumbing engineer to keep up with new technology to provide

innovative approaches to the design of medical-gas systems. In

designingmedical-gasandvacuumsystems,thegoalistoprovide

asafeandsufcientfowatrequiredpressurestothemedical-gas

outletorinletterminalsserved.Systemdesignandlayoutshould

allowconvenientaccessbythemedicalstaftooutlet/inlettermi-

nals,valves,andequipmentduringpatientcareoremergencies.

Tis section focuses on design parameters and current stan-

dards required for the design of nonfammable medical-gas and

vacuum systems used in therapeutic and anesthetic care. Te

plumbing engineer must determine the needs of the health-care

staf.Trytoworkcloselywiththemedicalstaftoseekanswersto

thefollowingfundamentaldesignquestionsatthestartofaproj-

ect:

1. Howmanyoutlet/inletsarerequestedbystaf?

2. Howmanyoutlet/inletsarerequired?

3. Basedoncurrentconditions,howoftenistheoutlet/inlet

used?

4. Basedoncurrentconditions,whatistheaveragedurationof

useforeachoutlet/inlet?

5. Whatistheproperusage(diversity)factortobeused?

MEDICAl-GASSySTEMDESIGNChECklIST

As any hospital facility must be specially designed to meet the

applicablelocalcoderequirementsandthehealth-careneedsof

thecommunityitserves,themedical-gasandvacuumpipingsys-

temsmustalsobedesignedtomeetthespecifcrequirementsof

eachhospital.

Following are the essential steps to a well-designed and func-

tionalmedical-gaspipedsystem,whicharerecommendedtothe

plumbingengineer:

1. Analyzeeachspecifcareaofthehealth-carefacilitytodeter-

minethefollowingitems:

A. Whichpipedmedical-gassystemsarerequired?

B. Howmanyofeachdiferenttypeofmedical-gasoutlet/inlet

terminalarerequired?

C. Whereshouldtheoutlet/inletterminalsbelocatedfor

maximumefciencyandconvenience?

D. Whichtypeandstyleofoutlet/inletterminalbestmeetthe

needsofthemedicalstaf?

2. Anticipateanybuildingexpansionandplaninwhichdirec-

tiontheexpansionwilltakeplace(verticallyorhorizontally).

Determinehowthemedical-gassystemshouldbesizedand

valvedinordertoaccommodatethefutureexpansion.

3. Determinelocationsforthevariousmedical-gassupply

sources.

A. Bulkoxygen(O

2

).

B. High-pressurecylindermanifolds(O

2

,N

2

OorN

2

).

C. Vacuumpumps(VAC).

D. Medical-aircompressors(MA).

4. Preparetheschematicpipinglayoutlocatingthefollowing:

A. Zonevalves.

B. Isolationvalves.

C. Masteralarms.

D. Areaalarms.

5. Calculatetheanticipatedpeakdemandsforeachmedical-gas

system.Appropriatelysizeeachparticularsectionso asto

avoidexceedingthemaximumpressuredropsallowed.

6. Sizeandselectthevariousmedical-gasandvacuumsupply

equipmentthatwillhandlethepeakdemandsforeach

system,includingfutureexpansions.Ifthisprojectisanaddi-

tiontoanexistingfacility,determinethefollowing:

A. Whatmedicalgasesarecurrentlyprovidedandwhatare

thelocationsandnumberofthestations?

B. Canthecurrentgassupplier(orthehospitalspurchasing

department)furnishtheconsumptionrecords?

C. Arethecapacitiesoftheexistingmedical-gassupplysys-

temsadequatetohandletheadditionaldemand?

D. Areanyexistingsystemsvalvedthatcouldbeusedforan

extension?Aretheexistingpipesizesadequatetohandle

theanticipatedadditionalloads?

E. Whattypeofequipmentisinuseandwhoisthemanufac-

turer?Isthisequipmentstate-of-the-art?

F. Isitfeasibletomanifoldthenewandexistingequipment?

G. Whatisthephysicalconditionoftheexistingequipment?

H. Isthereadequatespaceavailableforthenewmedical-gas

supplysystemsandrelatedequipmentattheexistingloca-

tion?

I. Isexistingequipmentscheduledtobereplaced?(Amain-

tenancehistoryoftheexistingequipmentmayhelpinthis

determination.)

NuMBEroFSTATIoNS

Tefrststepistolocateandcounttheoutlet/inlets,oftencalled

stations,foreachrespectivemedical-gassystem.Tisisusually

donebyconsultingaprogrampreparedbythefacilityplanneror

architect. Tis program is a list of all the rooms and areas in the

facilityandtheservicesthatarerequiredineach.Ifaprogramhas

not been prepared, the foor plans for the proposed facility shall

beused.

Tere is no code that specifcally mandates the exact number

ofstationsthatmustbeprovidedinvariousareasorroomsforall

health-carefacilities.Infact,thereisnoclearconsensusofopinion

amongmedicalauthoritiesordesignprofessionalsastohowmany

stations are actually required in the facility areas. Guidelines are

C0N7INUINC DUCA7I0N

Medical Gas and

Vacuum Systems

Reprinted from American Society of Plumbing Engineers Data Book Volume 3: Special Plumbing Systems, Chapter 2: Medical Gas and Vacuum

Systems. 2000, American Society of Plumbing Engineers.

44 PlumbingSystems&Design JANUARY/FEBRUARY 2006 PSDMAGAZINE.ORG

published by the American Institute of Architects

(AIA),NationalFireProtectionAssociation(NFPA),

and ASPE that recommend the minimum number

ofstationsforvariousservicesinspecifcareas.

Te most often-used recommendations in deter-

miningthenumberofstationsforhospitalsarethose

necessarytobeaccreditedbytheJointCommission

for the Accreditation of Hospitals Organization

(JCAHO).AccreditationisrequiredforMedicareand

Medicaid compensation. Te JCAHO publishes a

manualthatreferstotheAIAguidelinesforthemini-

mum number of stations for oxygen, medical air,

andvacuumthatmustbeinstalledinordertoobtain

accreditation. If this is a factor for the facility, these

requirements are mandatory. Other jurisdictions,

such as state or local authorities, may require plans

to be approved by local health or building ofcials.

Tese approvals may require adhering to the state

orlocalrequirementsand/orNFPA99,Health-Care

Facilities.

If accreditation or the approval of authorities is

not a factor, the number and area locations of sta-

tions are not mandated. Te actual count then will

depend upon requirements determined by each

individualfacilityoranothermemberofthedesign

team using both past experience and anticipated

future use, often using the guideline recommenda-

tionsasastartingpoint.

MEDICAl-GASFlowrATES

Eachstationmustprovideaminimumfowrateforthe

proper functioning of connected equipment under

designandemergencyconditions.Tefowratesand

diversity factors vary for individual stations in each

systemdependingonthetotalnumberofoutletsand

thetypeofcareprovided.

Tefowratefromthetotalnumberofoutlets,with-

out regard for any diversity, is called the total con-

nectedload.Ifthetotalconnectedloadwereusedfor

sizingpurposes,theresultwouldbeavastlyoversized

system, since not all of the stations in the facility will

be used at the same time. A diversity, or simultane-

ous-usefactor,isusedtoallowforthefactthatnotall

ofthestationswillbeusedatonce.Itisusedtoreduce

thesystemfowrateinconjunctionwiththetotalcon-

nectedloadforsizingmainsandbranchpipingtoall

parts of the distribution system. Tis factor varies for

diferentareasthroughoutanyfacility.

Teestimatedfowrateanddiversityfactorsforvarioussystems,

areastations,andpiecesofequipmentarefoundinTable1.

Total demand for medical-gas systems varies as a function of

time of day, month, patient-care requirements, and facility type.

Te number of stations needed for patient care is subjective and

cannot be qualifed based on physical measurements. Knowing

thetypesofpatientcareand/orauthorityrequirementswillallow

placementofstationsinusagegroups.Tesegroupscanestablish

demand and simultaneous-use factors (diversities), which are

usedinthecalculationforsizingaparticularsystem.Allmedical-

gas piping systems must be clearly identifed using an approved

color-codingsystemsimilartothatshowninTable2.

MEDICAl-GASSySTEMDISPENSINGEquIPMENT

Medical-gas outlet/inlet terminals Most manufacturers of

medical-gas system equipment ofer various types of medical-

gasoutlets.Tesemedical-gasoutletsareavailableinvariousgas

orders(e.g.,O

2

-N

2

O-Air),center-linespacing,andforexposedand

concealedmountings.Outlettypesandconfgurationsmustmeet

the requirements of the local jurisdictional authority and NFPA

99. All outlets must be properly identifed and confrmed. Care

shouldalsobetakentoaccuratelycoordinatethevariouspiecesof

medical-gasdispensingequipmentwiththearchitectandmedical

stafinvolvedinthegivenproject.Iftheprojectisarenovation,the

outlettypesshouldmatchexistingequipment.Withprefabricated

patient headwall units, the medical-gas outlets are generally fur-

nished by the equipment manufacturer, and it is very important

thatcoordinationbemaintainedbytheengineersothatunneces-

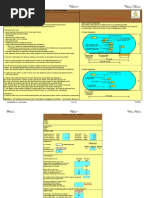

table 1 Outlet Rating Chart for Medical-Vacuum Piping Systems

Free-Air Allowance, cfm

(L/min) at 1 atmosphere

Zone Allowances Corridors,

Risers, Main Supply Line,

Valves

Location of Medical-Surgical Vacuum

Outlets Per Room Per Outlet

Simultaneous

Usage Factor

(%)

Air to Be

Transported,

cfm (L/min)

a

Operating rooms:

Major A(Radical, open heart; organ

transplant; radical thoracic) 3.5 (100) 100 3.5 (100)

Major B(All other major ORs) 2.0 (60) 100 2.0 (60)

Minor 1.0 (30) 100 1.0 (30)

Delivery rooms 1.0 (30) 100 1.0 (30)

Recovery room (post anesthesia) and

intensive-care units (a minimum of 2

outlets per bed in each such department):

1st outlet at each bed 3 (85) 50 1.5 (40)

2nd outlet at each bed 1.0 (30) 50 0.5 (15)

3rd outlet at each bed 1.0 (30) 10 0.1 (3)

All others at each bed 1.0 (30) 10 0.1 (3)

Emergency rooms 1.0 (30) 100 1.0 (30)

Patient rooms:

Surgical 1.0 (30) 50 0.5 (15)

Medical 1.0 (30) 10 0.1 (3)

Nurseries 1.0 (30) 10 0.1 (3)

Treatment & examining rooms 0.5 (15) 10 0.05 (1)

Autopsy 2.0 (60) 20 0.04 (1)

Inhalation therapy, central supply &

instructional areas 1.0 (30) 10 0.1 (3)

a

Free air at 1 atmosphere.

table 2 Color Coding for Piped Medical Gases

Gas Intended for Medical Use United States Color Canada Color

Oxygen Green Green on white

a

Carbon dioxide Gray Black on gray

Nitrous oxide Blue Silver on blue

Cyclopropane Orange Silver on orange

Helium Brown Silver on brown

Nitrogen Black Silver on black

Air Yellow* White and black on black and white

Vacuum White Silver on yellow

a

Gas mixtures (other than

mixtures of oxygen and nitrogen)

Color marking of mixtures shall be a combination of color

corresponding to each component gas.

Gas mixtures of oxygen and

nitrogen

19.5 to 23.5% oxygen

All other oxygen concentrations

Yellow

a

Black and green

Black and white

Pink

Source: Compressed Gas Association, Inc.

a

Historically, white has been used in the United States and yellow has been used in Canada to identify vacuum systems.

Therefore, it is recommended that white not be used in the United States and yellow not be used in Canada as a marking

to identify containers for use with any medical gas. Other countries may have difering specifc requirements.

JANUARY/FEBRUARY 2006 PlumbingSystems&Design 45

C0N7INUINC DUCA7I0N: MedicaI Cas and Vacuum Systems

saryduplicationofworkisavoided.Also,withregardtotheover-

the-bed medical-gas service consoles, these consoles are often

specifed in the electrical or equipment section of the specifca-

tionandmedical-gasserviceoutletsarespecifed,furnished,and

installedunderthemechanicalcontract.

Gas-outlet sequence, center-line spacing, and multiple-gang-

service outlets are some of the considerations to be taken into

accountwhenrequestinginformationfromthevariousequipment

manufacturers.Itismorepractical,intermsofboththecostofthe

equipmentandtheinstallation,tospecifyandselectthemanufac-

turersstandardoutlet(s).Detailsandspecifcationsregardingthe

individualstandardoutletsareusuallyavailablefromallmanufac-

turersuponrequest.

Teexistingoutletsarecompatiblewiththeadaptersfoundon

the hospitals anesthesia machines, fow meters, vacuum regula-

tors,etc.Careshouldbetakentomakesureallfutureexpansions

inthesamefacilityhavecompatibleequipment.

Patient head-wall systems A recent and growing trend in

hospital construction is the requirement for patient head-wall

systems, which incorporate many services for the patients care.

Teseunitsmayincludethefollowing:

1. Medical-gasoutlets.

2. Electrical-serviceoutlets(includingemergencypower).

3. Directandindirectlighting.

4. Nurse-callsystem.

5. Isolationtransformers.

6. Groundingoutlets.

7. Patient-monitoringreceptacles.

8. VacuumslideandIVbrackets.

9. Nightlights.

10.Electricalswitches.

Bed locator units are also available, which serve to provide

powerforthemoreadvancedpatientbeds,telephone,nightlights,

and standard power. Tese units

also function to protect the walls

from damage as beds are moved

andadjusted.

Head walls currently vary in

shape, size, type, and cost from a

simple over-the-patient-bed stan-

dard confguration to elaborate

total-wall units. Most manufactur-

ersofmedical-gasequipmentofer

medical-gas outlets for all types

of patient consoles available in

todays market. When specifying

head-walls outlets, the plumbing

engineer should consider the fol-

lowing:

1. Istheserviceoutletselected

compatiblewiththeexisting

outletcomponent?

2. Doesthepatienthead-wall

manufacturerincludethetype

ofmedical-gasoutletsrequired

aspartoftheproduct?

Special types of ceiling-

mounted, medical-gas out-

lets In critical-care areas, which are generally considered by

mostindividualstobethoselocationsofthehospitalprovidinga

specialtreatmentorserviceforthepatient(suchassurgery,recov-

ery,coronary,orintensive-careunits),thedesignersselectionand

placement of the medical-gas service equipment must be done

verycarefullyinordertoprovideefcientworkcentersaroundthe

patientforthemedicalstaf.

Manufacturers of medical-gas service equipment usually pro-

vide a wide range of equipment that is available for use in these

areas. Depending upon the customers preference and the avail-

able budget, the equipment is selected to provide the necessary

individualgasservicesandaccessories.

Table3providesaquickreferenceguidefortheengineertouse

asabasisforselectingthecommonlyusedtypesofoutletdispens-

ingequipment.

Example 1

Te following illustrative example presents some of the most

importantcritical-careareaequipmentandoptionsfortheselec-

tionoftheequipment.

Surgerymedical-gasservicestobepipedinclude:

1. Oxygen.

2. Nitrousoxide.

3. Nitrogen.

4. Medicalcompressedair.

5. Vacuum.

6. Wasteanesthetic-gasdisposal.

Providingmedical-gasserviceoutletsinthesurgeryroommay

beaccomplishedinseveralways,suchasthefollowing:

1. Ceiling outlets Individualmedical-gasoutletsmountedinthe

ceilingwithhoseassembliesprovidingthemedicalstafwith

connectionsfromtheoutletstotheadministeringapparatus.

Tismethodisconsideredbymosttobethemosteconomi-

calmeansofprovidinganadequategasservicetothesurgery

table 3 Types of Dispensing Equipment for Specifc Areas

Hospital Areas

Medical Gas Outlet Dispensing Equipment

Wall-

Mounted

Outlets

Patient

Care Head

Wall

Ceiling-

Mounted

Outlets with

Hose Stops

Rigid

Ceiling

Columns

Retractable

Ceiling

Columns

Ceiling

with Gas

Stacks

Nitrogen

Control

Cabinets

Autopsy rooms

Delivery rooms

Emergency examination and treatment

rooms

Emergency operating rooms

Induction rooms

Labor rooms

Major surgery rooms

Minor surgery, cystoscopy

Neonatal intensive care units

Normal nursery rooms

Nursery workrooms

O.B. recovery rooms

Patient rooms

Pediatric and youth intensive care unit

Post-operative recovery rooms

Premature and pediatric nursery rooms

Pre-op holding rooms

Radiology rooms

Respiratory care unit

Specialized surgeries (cardiac and neuro)

46 PlumbingSystems&Design JANUARY/FEBRUARY 2006 PSDMAGAZINE.ORG

areas.Teceilinggas-serviceoutletsaregenerallylocatedat

boththeheadandthefootoftheoperatingtableinorderto

providealternatepositioningoftheoperatingtable.

2. Surgical ceiling columns Surgicalceilingcolumnsareusu-

allyavailableintwodesigns:rigid(apredeterminedlength

fromtheceilingheightabovethefoor)andretractable.Both

surgicalceilingcolumnsprovidemedical-gasserviceswithin

anenclosurethatprojectsdownfromtheceiling.Teceiling

columnsareusuallylocatedatoppositeendsoftheoperating

tableinordertoprovideconvenientaccesstothemedical-gas

outletsbytheanesthesiologist.Inadditiontothemedical-gas

outlets,theseceilingcolumnscanbeequippedwithelectri-

caloutlets,groundingreceptacles,physiologicalmonitor

receptacles,andhooksforhangingintravenous-solution

bottles.

Mostmanufacturersoferingsurgicalceilingcolumnsallowfor

manyvariationsinroomarrangementsofmedical-gasservices

andrelatedaccessories,dependinguponthespecifccustomers

needsandtheengineersspecifcations.Whenspecifyingthis

typeofequipment,itisnecessarytospecifycarefullyallmedical-

gasservicerequirementsandtheirdesiredarrangement(s).Also,

theengineermustcoordinateallotherrequiredserviceswiththe

electricalengineerandmedicalstaf.

3. Surgical gas tracks Surgicalgastracksareformsofceiling

outletandhose-droparrangementsthatallowthemovement

ofthehosedropsfromoneendoftheoperatingtabletothe

otheronslidingtracksmountedontheceiling.Teseprod-

uctsarecurrentlyavailablefromvariousmanufacturersand

allprovidethesamebasicservices.Teproperselectionand

specifcationofspecifctypesarebasedonindividualcus-

tomerpreference.Manyvariationsinproductsandparticular

productapplicationsareavailableincritical(intensive)care

areas.Consultationwithappropriatemanufacturersforrec-

ommendationsisalwaysadvisable.

4. Articulating ceiling-service center Articulatedceiling-ser-

vicecentersaremovedbypneumaticdrivesystemsandare

designedfortheconvenientdispensingofmedical-gasand

electricalservicesinoperatingrooms.Temedical-gasand

electricalsystemsarecompleteforsingle-pointconnectionto

eachoutletatthemountingsupportplatform.

High-pressure nitrogen (N

2

) dispensing equipment Special

consideration must be given by the plumbing engineer to the

placementofthenitrogenoutlets.Teprimaryuseofnitrogengas

inhospitalsisfordrivingturbo-surgicalinstruments.Variationsof

these turbo-surgical instruments, in both their manufacture and

theirintendeduse,willrequirethatseveraldiferentnitrogen-gas

pressure levels be available. For this reason, it is necessary that

the engineer provide an adjustable pressure-regulating device

near the nitrogen gas outlet. A nitrogen control panel is usually

located on the wall (in the surgery room) opposite the operating

areasterilefeld.Teinstallationshouldallowfortheaccessand

adjustmentofpressuresettingsbyasurgicalnurse.

Pipingfromthenitrogencontrolpaneltoasurgicalceilingoutlet

willprovideaconvenientsourceofnitrogenforsurgicaltools.Tis

willpreventhosesfrombeinglocatedonthefoororbetweenthe

walloutletandtheoperatingtable.Excesshosecanbeobstructive

tothesurgicalteam.

MEDICAl-GASSTorAGE

Afterdecidingthemedical-gasservicestobeprovidedatthefacil-

ity, the engineer should determine the storage capacity and the

pipe sizing required and possible locations for the source. Local

codesandreferencesaswellastheadministrativeauthorityhaving

jurisdictionshouldbeconsultedforeachmedical-gassystem.

Because of the unique characteristics of each medical-gas

source, the gases are described separately in this section. Also,

an explanation of the techniques currently employed to exhaust

anestheticgasesisprovided.

Oxygen (O

2

) Severalfactorsmustbeknownwhenestimating

the monthly consumption of oxygen in new or existing health-

carefacilities:

1. Typeofmedicalcareprovided.

2. Numberofoxygenoutletsor

3. Numberofpatientbeds.

4. Futureexpansionoffacility.

5. Inexistingfacilities,approximateconsumption.

Two methods can be used by the plumbing engineer to esti-

matetheconsumptionofoxygen.Temoreaccuratemethodisto

obtainadetailedconsumptionrecordfromthehealth-carefacility

orobtainmonthlyoxygenshipmentinvoicesfromthesupplier.If

inventoryrecordsarenotavailablefromthehealth-carefacilityor

the supplier, use consumption records from a comparably sized

facility,withgoodjudgment.

Te second method is to apply the following rule of thumb to

estimate the monthly supply of oxygen. Tis estimating method

shouldbeusedwithgoodjudgment.Alwayscoordinateestimated

demandwiththeoxygensupplierduringthedesignprocess.

1. Innon-acute-careareas,allow500ft

3

(14m

3

)perbedper

monthforsupplyandreserveoxygenstorage.

2. Inacute-careareas,allow1000ft

3

(28m

3

)perbedpermonth

forsupplyandreserveoxygenstorage.

Oxygensupplysourcesaredividedintotwocategories:(1)bulk-

oxygen systems and (2)cylinder-manifold-supply systems. Bulk-

oxygen systems should be considered for health-care facilities

with an estimated monthly demand above 35,000 ft

3

(991 m

3

) or

equal to 70 oxygen outlets. Manifold systems are used in small

generalhospitalsorclinics.

Bulk-oxygen systems Whenselectingandplacingbulk-oxygen

systems,thereareseveralfactorstobeconsidered:Oxygentrans-

port truck size, truck access to bulk-storage tanks, and NFPA 50,

Standard for Bulk Oxygen Systems at Consumer Sites.Bulk-oxygen

equipment,construction,installation,andlocationmustcomply

with NFPA 50 recommendations. If liquid oxygen is spilled or

leaked,anextremefreorexplosivehazardcouldoccur.NFPAhas

designstandardstominimizefreexposuretoandfromsurround-

ingstructures.

Bulk-storagesystemsconsistofcryogenictanksthatstoreliquid

oxygen at low pressures (225 psi [1551.3 kPa] or less). Cryogenic

tanksareASMEunfred,double-walled,vacuum-insulated,pres-

sure vessels. Liquid oxygen has a boiling point (nbp) of 297.3F

(182.9C) and a liquid density of 71.27 lb/ft

3

(1141.8 kg/cm

3

).

Whenvaporizedintogas,itproduces900timesitsliquidvolume.

Furthermore,sincethetankischangedlessoften,processstabil-

ity is maximized and the introduction of atmospheric impurities

isreduced.Tanksystemsarefurnishedwithanintegralpressure-

relief valve vented to the atmosphere should the liquid oxygen

converttoagas.

JANUARY/FEBRUARY 2006 PlumbingSystems&Design 47

C0N7INUINC DUCA7I0N: MedicaI Cas and Vacuum Systems

Most bulk-oxygen storage systems are furnished with vapor-

izers. Vaporizers are banks of fnned-tube heat exchangers that

converttheliquidtoitsgaseousstate.Tevaporizerscomeinsev-

eral stylesincluding atmospheric, powered (forced-air, steam,

and electric), waste-heat, and hybridand sizes. Te selec-

tion of vaporizers should be based on demand, intermittent or

continuous usage, energy costs, and temperature zones. Poorly

ventilated sites or undersized heat exchangers can cause ice to

form on vaporizers during the conversion process. Excessive ice

formations can clog and damage the vaporizer. Also, ice could

allowextremelycoldgasorthecryogenicliquidtoenterthepiped

system; damage the valves, alarms, and medical components;

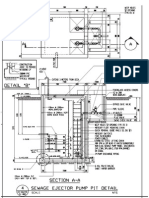

andeveninjurepatients.Figure1illustratesatypicalbulk-oxygen

systemschematic.

Automaticcontrolsfurnishedwiththetanksregulatethefowof

liquidthroughthevaporizers.Whenthereisademandforoxygen,

thesupplysystemdrawsliquidfromthebottomofthecryogenic

storagetankthroughthevaporizers.Tegasmovesthroughafnal

line regulator. Tus, a constant supply of oxygen at a regulated

pressureisprovided.

In case of mechanical difculty or the depletion of the liquid-

oxygensupply,thereservesupplywillbegintofeedintothedistri-

butionsystemautomatically.

An alarm signal should alert appropriate hospital personnel

when the liquid in the oxygen storage tank reaches a predeter-

mined level. Te alarm signals should indicate low liquid levels,

reserveinuse,andreservelow.

Cylinder-manifold supply systems Compressed-oxygen

systems are comprised of cylinder manifolds that allow a pri-

marysupplysourceofoxygencylinderstobeinuseandanequal

numberofoxygencylinderstobeconnectedasareservesupply.

Te controls of the cylinder manifold will automatically shift the

fow of the oxygen gas from the service side to the reserve side

whentheservicesideisdepleted.

Manifold systems can be located indoors or outdoors. When

manifolds are located indoors, the engineer should observe the

following:

Location Preferably,themanifoldshouldbeinadedicated

roomonanoutsidewallnearaloadingdockandhaveade-

quateventilationandserviceconvenience.

Adjacent areas Tereshouldbenodoors,vents,orother

directcommunicationsbetweentheanesthetizinglocationor

thestoragelocationandanycombustibleagents.Iflocating

nearoradjacenttoanelevatedtemperatureareaisunavoid-

able,theengineershouldspecifysufcientinsulationtopre-

ventcylinderoverheating;

Fire rating Tefre-resistanceratingoftheroomshouldbeat

least1h.

Ventilation Outsideventilationisrequired.

Security Teroom(orarea)mustbeprovidedwithadoorora

gatethatcanbelockedandlabeled.

Oxygen manifolds are sized taking into consideration the fol-

lowing:

1. Tesizeofthecylinders,244ft

3

(6909L)H-cylinder(seeTable

4forasizingchart).

2. Tehospitalsusageofoxygen,inft

3

(L)permonth.

Figure 1 Typical Bulk Supply System (Schematic)

48 PlumbingSystems&Design JANUARY/FEBRUARY 2006 PSDMAGAZINE.ORG

table 4 Selection Chart for Oxygen Manifolds

Hospital Usage Duplex Manifold Size

Cu. Ft. (10

3

L) per month Total Cylinders Cylinders per Side

5,856 (165.8) 6 3

9,760 (276.4) 10 5

13,664 (386.9) 14 7

17,568 (497.5) 18 9

21,472 (608.0) 22 11

25,376 (718.6) 26 13

29,280 (829.1) 30 15

33,154 (938.8) 34 17

Note: Based on use of 244 ft

3

(6909.35 L) H-cylinders.

Nitrous oxide(N

2

O) Tecommonsourceofnitrousoxideisa

cylinder-manifold system. High-pressure manifold systems con-

sist of two banks of cylinders, primary and reserve. (See discus-

sionunderOxygen,above.)

Systemdemandsfornitrousoxidecanbemoredifculttodeter-

minethantheyareforothermedicalgases.Tenumberofsurger-

ies scheduled, the types and lengths of surgery, and the admin-

istering techniques used by the anesthesiologists cause extreme

variations in the amount of nitrous oxide used. Because of this

variation, considerations must be given to the size and selection

ofthenitrous-oxidemanifoldsystem.

Avoid locating the nitrous-oxide manifold system outdoors in

areaswithextremelycoldclimates.Nitrousoxideissuppliedlique-

fed at its vapor pressure of 745 psi (5136.6 kPa) at 70F (21.1C).

At extremely cold temperatures, the cylinder pressure will drop

dramatically, reducing the cylinder pressure to a point where it is

impossibletomaintainanadequatelinepressure.Tisisduetoa

lackofheatforvaporization.

Fornitrous-oxidemanifoldslocatedindoors,thesameprecau-

tionspreviouslylistedforoxygensystemsmustbeobserved.

Te following should be considered when selecting and sizing

nitrous-oxidemanifoldsanddeterminingthenumberofcylinders

required:

1. Tesizeofthecylinders:489ft

3

(13847L)K-cylinders(see

Table5).

2. Tenumberofanesthetizinglocationsoroperatingrooms.

3. Provideof1cylinderperoperatingroomforin-serviceand

reservesupplies.

table 5 Sizing Chart for Nitrous Oxide Cylinder Manifolds

Number of

Operating

Rooms

Duplex Manifold Size

Indoor Outdoor

Total Cylinders

Cylinders per

Side Total Cylinders

Cylinders per

Side

4 4 2 4 2

8 8 4 10 5

10 10 5 12 5

12 12 6 14 7

16 16 8 20 10

Note: Based on use of 489 ft

3

(13.85 103 L) K-cylinders.

Medical compressed air Medical compressed air may be

supplied by two types of system: (1) a high-pressure cylinder-

manifoldsystem;and(2)amedicalair-compressorsystem.

Temanifoldsystemsforcompressedairaresimilarinconfgu-

rationtothoseforoxygenandnitrousoxide(seediscussionunder

Oxygen, above). Air supplied from cylinders or that has been

reconstitutedfromoxygenU.S.P.andnitrogenN.F.mustcomply,

asaminimum,withGradeDinANSIZE86.I,Commodity Specif-

cation for Air.

Medical compressed air can be produced on site from atmo-

spheric air using air compressors designed for medical applica-

tions.Terearethreemajortypesofaircompressorinthemarket-

place today: the centrifugal, reciprocating, and rotary screw. Te

reciprocating and rotary screw are positive-displacement type

units, while the centrifugal compressor is a dynamic type com-

pressor. Te medical air compressor shall be designed to prevent

theintroductionofcontaminantsorliquidintothepipelinebyone

oftwomethods:Type1aircompressorseliminateoilanywherein

thecompressor.Type2aircompressorsseparatetheoil-containing

sectionfromthecompressionchamber.Examplesofatype1com-

pressor are the liquid ring, rotary screw, and permanently sealed

bearingcompressor.Type2compressorshaveextendedheads.

Apositive-displacementcompressorisnormallyratedinactual

cubicfeetperminute(acfm).Tisistheamountofairtakenfrom

atmosphericconditionsthattheunitwilldeliveratitsdischarge.

Withinabroadrange,changesininletairtemperature,pressure,

andhumiditydonotchangetheacfmratingofeithertherecipro-

cating or the rotary screw compressor. Te centrifugal compres-

sors capacity, however, is afected slightly by the inlet air condi-

tionsduetothenatureofthecompressionprocess.Forexample,

as the air temperature decreases, the capacity of the dynamic

compressor will increase. Te capacity of a centrifugal compres-

sorisnormallydefnedininletcubicfeetperminute(icfm).Inan

eforttoobtainanapplestoapplescomparisonofvariouscom-

pressors,manymanufacturersspecifytheircapacityrequirements

instandardcubicfeetperminute(scfm).Tissometimescauses

much confusion because many people do not fully understand

how to convert from acfm or icfm to scfm. Te design engineer

specifying scfm must defne a typical inlet air condition at the

buildingsiteandtheirsetofstandardconditions(normally14.7

psia [101.4 kPa], 60F [15.6C], and 0% relative humidity). Typi-

cally, the warmest normal condition is specifed because as the

temperaturegoesupscfmwillgodown.

Toconvertfromacfmtoscfm,thefollowingequationisused.

Equation 1

scfm =acfm

P

i

(P

pi

%RH)

T

std

P

std

(P

p

std

%RH

std

) T

i

where

P

i

=Initialpressure

P

pi

=Partialinitialpressureofwatervaporin100%humidairat

thetemperatureinquestion

RH=Relativehumidity

P

std

=Pressureunderstandardconditions

P

pstd

=Partialstandardpressureofwatervaporin100%humid

airatthetemperatureinquestion

RH

std

=Relativehumidityatstandardconditions

T

std

=Temperatureatstandardconditions,F(C)

T

i

=Inlettemperature,F(C)

JANUARY/FEBRUARY 2006 PlumbingSystems&Design 49

C0N7INUINC DUCA7I0N: MedicaI Cas and Vacuum Systems

Equation 1a

TisequationisderivedfromthePerfectGaslaw,whichis:

P

1

V

1

=

P

2

V

2

T

1

T

2

or:

V

2

=V

1

P

1

T

2

P

2

T

1

where

P

1

=Initialpressure

V

1

=Initialvolume

T

1

=Initialtemperature

P

2

=Finalpressure

V

2

=Finalvolume

T

2

=Finaltemperature

Forareciprocatingorrotary-screwcompressor,theconversion

fromacfmtoscfmissimple.Teinletairconditionsandstandard

conditions are inserted into the above formula and multiplied

by the acfm capacity of the unit. It makes no diference what the

design conditions are for that compressor, as these do not fgure

intotheformula.Inthecaseofadynamiccompressor,theicfmair

fow at the given inlet conditions is inserted in place of the acfm

intheformula.Anotherdesignissuethattheengineershouldbe

aware of is how altitude afects the output of the compressor. At

altitudes above sea level, all medical-air systems have reduced

fow. In these cases, the required sizing will need to be adjusted

tocompensate.Todothis,multiplythescfmrequirementsbythe

correctionfactorinTable6.

table 6 Altitude Correction Factors for Medical-Air Systems

Altitude, ft (m)

Normal Barometric

Pressure, in. Hg (mm Hg)

Correction

Factor for SCFM

(L/min)

Sea level 29.92 (759.97) 1.0 (28.31)

1,000 (304.8) 28.86 (733.04) 1.01 (28.6)

2,000 (609.6) 27.82 (706.63) 1.03 (29.16)

3,000 (914.4) 26.82 (681.23) 1.05 (29.73)

4,000 (1219.2) 25.84 (656.33) 1.06 (30.01)

5,000 (1524) 24.90 (632.46) 1.08 (30.58)

6,000 (1828.8) 23.98 (609.09) 1.10 (31.14)

7,000 (2133.6) 23.09 (586.48) 1.12 (31.71)

8,000 (2438.4) 22.23 (564.64) 1.15 (32.56)

9,000 (2743.2) 21.39 (543.3) 1.17 (33.13)

10,000 (3048) 20.58 (522.7) 1.19 (33.69)

In other words, to correctly size the medical-air system, you

wouldapplythecorrectionfactorlistedinthechartabovetothe

peak-calculatedload(scfm)atsealevel.

Example 2

Afacilityislocatedat5000ft(1524m)abovesealevelandthesystem

demand is 29.4 SCFM. Take the 29.4 scfm and multiply it by 1.08

(correction factor from Table 5) to get the adjusted scfm require-

mentof31.8scfmat5000ftabovesealevel.Terefore,amedical-air

systemofgreatercapacityisneededathigheraltitudes.

Another handy formula for compressed-air systems is the fol-

lowing:toconvertscfmtoL/minmultiplyby28.31685.

Each compressor must be capable of maintaining 100% of the

medical-air peak demand regardless of the standby compressors

operating status. Te basic compressor package consists of flter

intakes, duplex compressors, after-coolers, receiving tanks, air

dryers, in-line flters, regulators, dew-point monitors, and valves.

Te compressor components are connected by piping that allows

equipment isolation, provides pressure relief, and removes con-

densate from receivers. Medical-air compressors must draw out-

sideairfromabovetherooflevel,remotefromanydoors,windows,

andexhaustorventopenings.Wheretheoutsideatmosphericairis

polluted,specialflterscanbeattachedtothecompressorsintake

to remove carbon monoxide and other contaminants. Refer to

NFPA99forproperlocationofmedical-airintakes.Medicalcom-

pressedairmustcomplywithNFPA99and/orCanadianStandards

Associations(CSAs)defnitionofair-qualitystandards.

Wheremorethantwounitsareprovidedforthefacility,anytwo

units must be capable of supplying the peak calculated demands.

Provide automatic alternators (duty-cycling controls) to ensure

evenwearinnormalusage.Alternatorcontrolsincorporateaposi-

tivemeansofautomaticallyactivatingtheadditionalunit(orunits)

shouldthein-servicepumpfailtomaintaintheminimumrequired

pressure.

Medical compressed air produced by compressors may be

defnedasoutsideatmospheretowhichnocontaminants(inthe

formofparticulatematter,odors,oilvapors,orothergases)have

been added by the compressor system. Not every compressor is

suitableforuseasasourceformedicalcompressedairinhealth-

care facilities. Only those compressor units specifcally designed

andmanufacturedformedicalpurposesshouldbeconsideredas

a reliable source of oil-free, moisture-free, and low-temperature

compressedair.Acceptablecompressortypesincludeoil-free,oil-

less, and liquid-ring compressors. Separation of the oil-contain-

ingsectionfromthecompressionchamberbyatleasttwosealsis

requiredbythecompressormanufacturers.

Aircompressedformedical-breathingpurposesaretobeused

for this purpose only and should not be used for other applica-

tionsorcross-connectedwithothercompressedairsystems.

table 7 Minimum Pipe Sizes for Medical Air-Compressor Intake Risers

Pipe size, in.

(mm)

Flow rate, cfm

(L/min)

2.5 (63.5) 50 (1416)

3 (76.2) 70 (1985)

4 (101.6) 210 (5950)

5 (127.0) 400 (11330)

Table7providestheminimumpipesizesformedicalair-com-

pressor intake risers. Consult with the compressor manufacturer

on intake recommendations and allowable friction loss for the

intakeriserbeforefnalizingthepipesizeequipmentselection.

50 PlumbingSystems&Design JANUARY/FEBRUARY 2006 PSDMAGAZINE.ORG

C0N7INUINC DUCA7I0N

1. When Iiquid oxygen is vaporized into a gas, it

produces ________ times its Iiquid voIume.

a. 0

b. 450

c. 900

d. 1,350

2. Nitrous oxide (N

2

0) is typicaIIy used by whom in the

surgery room!

a. the attending physician

b. the attending physicians assistant

c. the surgical nurse

d. the anesthesiologist

3. 7he medicaI-gas and vacuum piping systems must be

designed to ________.

a. meet the specifc requirements of each hospital

b. anticipate any building expansion

c. not cross connect to any existing system

d. all of the above

4. 7he primary use of nitrogen gas in hospitaIs is ______

__.

a. driving turbo-surgical instruments

b. pressurizing piping systems

c. in the laboratory Bunsen burners

d. none of the above

5. MedicaI-gas ow rates ________.

a. must include diversifcation

b. must provide for the total connected load

c. must provide the minimum required fow for the

proper functioning of connected equipment

d. must be estimated

6. Providing medicaI-gas service outIets in the surgery

room may be accompIished by Iocating them in

______.

a. the ceiling

b. the surgical ceiling columns

c. the surgical gas tracks

d. any of the above noted areas and others not listed

7. In acute-care areas, aIIow ________ cubic feet per bed

per month for suppIy and reserve oxygen storage.

a. 250

b. 500

c. 750

d. 1,000

8. 7he exact number of medicaI-gas outIets required in

the various areas or rooms is mandated by ________.

a. the various codes that apply to work at the project

site

b. the American Institute of Architects (AIA)

c. the National Fire Protection Association (NFPA)

d. none of the above

9. MedicaI-gas outIet types and congurations must

meet the requirements of the IocaI jurisdictionaI

authority and ________.

a. ANSI 1416

b. NFPA 99

c. NFPA 50

d. ANSI 1763

10. SeveraI factors must be known when estimating the

monthIy consumption of oxygen, such as ________.

a. the number of patient beds

b. the type of medical care provided

c. the future expansion plans of the facility

d. all of the above

11. What is the SCFM correction factor for a medicaI-air

system Iocated in a faciIity at an aItitude of 7,000 feet

above sea IeveI!

a. 1.05

b. 1.08

c. 1.12

d. 1.17

12. 7he goaI in designing medicaI-gas and vacuum

systems is ________.

a. to provide a safe system

b. to provide a sufcient fow of gas or vacuum

c. to provide the required pressure

d. all of the above

Doyoufnditdifculttoobtaincontinuingeducationunits(CEUs)?

Is it hard for you to attend technical seminars? Trough Plumbing

Systems & Design (PS&D), ASPE can help you accumulate the CEUs

required for maintaining your Certifed in Plumbing Design (CPD)

status.

ASPEfeaturesatechnicalarticleineveryissueofPS&D,excerpted

fromitsownpublications.Eacharticleisfollowedbyamultiple-choice

testandasimplereportingform.

Readingthearticleandcompletingtheformwillallowyoutoapply

to ASPE for CEU credit. For most people, this process will require

approximately 1 hour. A nominal processing fee is charged$25 for

ASPE members and $35 for nonmembers (until further notice, the

memberfeeiswaived).Ifyouearnagradeof90%orhigheronthetest,

youwillbenotifedthatyouhavelogged0.1CEU,whichcanbeapplied

towardtheCPDrenewalrequirementornumerousregulatory-agency

CE programs. (Please note that it is your responsibility to determine

theacceptancepolicyofaparticularagency.)CEUinformationwillbe

keptonfleattheASPEofcefor3years.

No certifcates will be issued in addition to the notifcation letter.

YoucanapplyforCEUcreditonanytechnicalarticlethathasappeared

inPS&Dwithinthepast12months.However,CEUcreditonlycanbe

obtainedonatotalofeightPS&Darticlesina12-monthperiod.

Note:IndeterminingyouranswerstotheCEquestions,useonlythe

material presented in the continuing education article. Using other

informationmayresultinawronganswer.

Continuing Education from Plumbing Systems & Design

Kenneth G.Wentink, PE, CPD

CE QuestionsMedical Gas and Vacuum Systems (PSD 131)

52 PlumbingSystems&Design JANUARY/FEBRUARY 2006 PSDMAGAZINE.ORG

Plumbing Systems & Design

Continuing ducation AppIication Form

1. Make a photocopy of this form. Leaving this page in PS&D allows others to use it to obtain continuing education units (CEUs).

2. PRINT your name and address. Be sure to place your membership number in the appropriate space. This form is valid up to

1 year from date of publication. The PS&D continuing education unit program is approved by ASPE for up to 1 contact hour

(0.1 CEU) of credit per article studied.

3. Answer the multiple-choice continuing education (CE) questions (found after each CE article) and the appraisal questions

on this page.

4. Submit this form and the answer sheet below, with the payment of the appropriate fee by check or money order made pay-

able to ASPE, or submit the credit card information to ASPE Education Credit, 8614 W. Catalpa Avenue, Suite 1007, Chicago,

IL 606561116.

5. Participants who earn a passing score (90%) on the CE questions will receive a letter of certifcation within 30 days of PS&Ds

receipt of the application (no special certifcates will be issued). (CEU information will be retained on the ASPE Database.)

Participants who wish to retake the test should submit their retest along with an additional fee$25 for an ASPE member

(currently waived) or $35 for a nonmember.

Please print or type; this information will be used to process your credits.

Name __________________________________________________________________________________________________

Title ______________________________________________ ASPE Membership No. ___________________________________

Organization ____________________________________________________________________________________________

Billing Address ___________________________________________________________________________________________

City _______________________________________ State/Province _______________________ Zip ____________________

Country ___________________________________________ E-mail ________________________________________________

Daytime telephone _________________________________ Fax __________________________________________________

PS&D Continuing ducation Answer Sheet

Medical Gas and Vacuum systems (PsD 131)

Questions appear on page 52. Circle the answer to each question.

1. A C D

2. A C D

3. A C D

4. A C D

5. A C D

6. A C D

7. A C D

8. A C D

9. A C D

10. A C D

11. A C D

12. A C D

AppraisaI uestions

Medical Gas and Vacuum systems (PsD 131)

1. Was the material new information for you? Yes No

2. Was the material presented clearly? Yes No

3. Was the material adequately covered? Yes No

4. Did the content help you achieve the stated objectives? Yes No

5. Did the CE questions help you identify specifc ways to use ideas presented in

the article? Yes No

6. How much time did you need to complete the CE ofering (i.e., to read the

article and answer the post-test questions)? __________________

I am applying for the following continuing education credits:

I certify that I have read the article indicated above.

Signature

Expiration date: Continuing education credit will be given

for this examination through 1anuary 31, 2007.

Applications received after that date will not be processed.

ASPE Member Nonmember

Each examination: $25 Each examination: $35

Limited Time: No Cost to ASPE Member

Payment: Personal Check (payable to ASPE) $ ___________

Business or government check $ ___________

DiscoverCard VISA MasterCard AMEX $ ___________

If rebilling of a credit card charge is necessary, a $25 processing fee will be charged.

ASPE is hereby authorized to charge my CE examination fee to my credit card.

Account Number Expiration date

Signature Cardholders name (Please print)

JANUARY/FEBRUARY 2006 PlumbingSystems&Design 53

Das könnte Ihnen auch gefallen

- Medical Gas SystemsDokument81 SeitenMedical Gas Systemszampacaanas100% (2)

- Medical Gas System PDFDokument7 SeitenMedical Gas System PDFk1l2d3Noch keine Bewertungen

- Medical Gas Piping SpecDokument22 SeitenMedical Gas Piping Specvvg100% (1)

- HTM 02-01 Part BDokument162 SeitenHTM 02-01 Part Bloirees100% (1)

- Medical Gas DesignDokument8 SeitenMedical Gas Designwetchkrub100% (1)

- 2-Medical Gases Systems. The Second Lecture.Dokument12 Seiten2-Medical Gases Systems. The Second Lecture.Fireproof Sistemas ElectromecánicosNoch keine Bewertungen

- Medical Gas Piping Design-Part1Dokument4 SeitenMedical Gas Piping Design-Part1Gage Floyd Bitayo100% (2)

- Medical GasDokument86 SeitenMedical Gasishoney100% (2)

- Medical Gas Vaccum Piping SystemDokument56 SeitenMedical Gas Vaccum Piping Systemssgjmlim67% (3)

- Central Medical Gas Systems 24506901708Dokument9 SeitenCentral Medical Gas Systems 24506901708PrestoneKNoch keine Bewertungen

- C11 SizingDokument36 SeitenC11 Sizingmirza057100% (1)

- Modern Hospital Lifeline: Medical Gas Distribution SystemDokument4 SeitenModern Hospital Lifeline: Medical Gas Distribution SystemDurjoy_Sarker_143450% (2)

- Medical Gas Pipeline SizingDokument6 SeitenMedical Gas Pipeline Sizingnini26100% (3)

- Design of Medical Gas System of Assiut I PDFDokument97 SeitenDesign of Medical Gas System of Assiut I PDFWalmick Santos100% (2)

- Medical Gas OutletsDokument48 SeitenMedical Gas OutletsIrvin Bradford Dee100% (1)

- Medical Gas Pipeline RequirementsDokument20 SeitenMedical Gas Pipeline RequirementsJoe_AverageNoch keine Bewertungen

- Designing Medical Gas Pipeline SystemsDokument152 SeitenDesigning Medical Gas Pipeline SystemsROMARU 2010Noch keine Bewertungen

- Medical Gas System - Installer Orientation NotesDokument8 SeitenMedical Gas System - Installer Orientation NoteszampacaanasNoch keine Bewertungen

- Medical Gas Pipe InstallationDokument2 SeitenMedical Gas Pipe InstallationSam ChoiNoch keine Bewertungen

- Low RH Design Guide For Pharmaceutical IndustryDokument93 SeitenLow RH Design Guide For Pharmaceutical IndustryMHNAD100% (1)

- Medical Gases. Piped and Cylinder Training. Aim Understand The Reasons For Medical Gas TrainingDokument36 SeitenMedical Gases. Piped and Cylinder Training. Aim Understand The Reasons For Medical Gas TrainingAhmed shawkyNoch keine Bewertungen

- Province of Kwazulu-Natal Department of Health: Standard Specification and DrawingsDokument55 SeitenProvince of Kwazulu-Natal Department of Health: Standard Specification and DrawingsjafarkhansfNoch keine Bewertungen

- Medical Gases CalculationsDokument25 SeitenMedical Gases CalculationsMANIKANDANoch keine Bewertungen

- ASHRAE Standard 62-2007Dokument26 SeitenASHRAE Standard 62-2007schiZ0prEni100% (1)

- Applying VRF?: Don't Overlook Standard 15Dokument7 SeitenApplying VRF?: Don't Overlook Standard 15Eric G. MagnayeNoch keine Bewertungen

- Heat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Dokument4 SeitenHeat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Michael LagundinoNoch keine Bewertungen

- PSD CEU 194dec12 PDFDokument22 SeitenPSD CEU 194dec12 PDFCesar Muñoz OssesNoch keine Bewertungen

- Medical Gases Design Seminar No. 2Dokument9 SeitenMedical Gases Design Seminar No. 2shi_zuka88Noch keine Bewertungen

- HTM 00Dokument73 SeitenHTM 00sbalu12674Noch keine Bewertungen

- AIGA 049 - 08 Guideline To Bulk Medical Oxygen Supply System For Healthcare FacilitiesDokument9 SeitenAIGA 049 - 08 Guideline To Bulk Medical Oxygen Supply System For Healthcare Facilitiesnachiappan_rameshNoch keine Bewertungen

- Lab ACH Rates Standards & Guidelines PDFDokument15 SeitenLab ACH Rates Standards & Guidelines PDFGopinath GopiNoch keine Bewertungen

- 200911ceu 162Dokument7 Seiten200911ceu 162Mohamed Mostafa AamerNoch keine Bewertungen

- Water 09 00098 v2Dokument40 SeitenWater 09 00098 v2enlightened171880% (5)

- Ashrae Pubcatalog 2019winter PDFDokument16 SeitenAshrae Pubcatalog 2019winter PDFkunkzNoch keine Bewertungen

- Medical Gas Design Guide Chapter 4 - Design: Continuing Education PublicationDokument16 SeitenMedical Gas Design Guide Chapter 4 - Design: Continuing Education PublicationWendy RosalNoch keine Bewertungen

- Balancing and flow control valves quick reference guideDokument47 SeitenBalancing and flow control valves quick reference guideNoushad P Hamsa100% (1)

- Medical GasDokument39 SeitenMedical GasFrancisco M. Ramos100% (1)

- Medical Gas CalculationDokument11 SeitenMedical Gas CalculationfaizNoch keine Bewertungen

- Previews ASHRAE D 98044 PreDokument31 SeitenPreviews ASHRAE D 98044 PreLee Chorney0% (1)

- 200905CEU-157 P& DDokument7 Seiten200905CEU-157 P& DMohamed Mostafa AamerNoch keine Bewertungen

- Redline Ashrae 41.1 2013-1986R2006Dokument64 SeitenRedline Ashrae 41.1 2013-1986R2006Huzaifah Bin YounusNoch keine Bewertungen

- Gas PipingDokument48 SeitenGas PipingAtef MohamedenNoch keine Bewertungen

- GMS System Draeger Medical GasDokument20 SeitenGMS System Draeger Medical GasFăşăn ĂmdăNoch keine Bewertungen

- Sizing Medical Gas PipingDokument6 SeitenSizing Medical Gas PipingYoke Shu100% (1)

- Medgas Pipe Sizing 2021Dokument11 SeitenMedgas Pipe Sizing 2021eimrehNoch keine Bewertungen

- Comfort and Critical Outdoor Design ConditionsDokument6 SeitenComfort and Critical Outdoor Design ConditionshueyliewNoch keine Bewertungen

- Hospital HVAC Design A Challenge For IAQ, Energy Recovery and System Reliability - Issue Jul-Sep 2002Dokument11 SeitenHospital HVAC Design A Challenge For IAQ, Energy Recovery and System Reliability - Issue Jul-Sep 2002Go Tze FongNoch keine Bewertungen

- NFPA 99-1999-2002 EditionsDokument20 SeitenNFPA 99-1999-2002 EditionsHenry Suarez100% (1)

- C6 VacuumDokument314 SeitenC6 VacuumAlroukn Mechanical100% (1)

- Medical Gas Design Guide Chapter 9 - Nitrogen Gas Sources: Continuing Education PublicationDokument8 SeitenMedical Gas Design Guide Chapter 9 - Nitrogen Gas Sources: Continuing Education PublicationAlroukn MechanicalNoch keine Bewertungen

- Chapter 4 Hangers and SupportsDokument20 SeitenChapter 4 Hangers and SupportsHari ManikandanNoch keine Bewertungen

- Medical Gas Systems InstallationDokument8 SeitenMedical Gas Systems InstallationHermi DavidNoch keine Bewertungen

- Medical GasesDokument6 SeitenMedical GasesAtal BhowmikNoch keine Bewertungen

- 2014 01847Dokument23 Seiten2014 01847PerezGutNoch keine Bewertungen

- ESSENTIAL SUPPLIES TO THE THEATRE DEPARTMENT (ROOM) - Power PointDokument40 SeitenESSENTIAL SUPPLIES TO THE THEATRE DEPARTMENT (ROOM) - Power PointMorgan SabinoNoch keine Bewertungen

- Specification and Acceptance Testing of Radiotherapy Treatment Planning SystemsDokument68 SeitenSpecification and Acceptance Testing of Radiotherapy Treatment Planning Systemsjiar001Noch keine Bewertungen

- USFDA On Stent UpdatesDokument10 SeitenUSFDA On Stent UpdatesKarishmaNoch keine Bewertungen

- Standards: Medical DevicesDokument3 SeitenStandards: Medical DevicesDr M GeethanjaliNoch keine Bewertungen

- Guidelines For Construction & Equipment of Hospital & Medical Facilities (1987)Dokument111 SeitenGuidelines For Construction & Equipment of Hospital & Medical Facilities (1987)J. CamachoNoch keine Bewertungen

- GabbDokument1 SeiteGabbzampacaanasNoch keine Bewertungen

- A036697001v03 PDFDokument1 SeiteA036697001v03 PDFzampacaanasNoch keine Bewertungen

- Bougainvillea GlabraDokument1 SeiteBougainvillea GlabrazampacaanasNoch keine Bewertungen

- Inspection Test Plan For ElectricalDokument38 SeitenInspection Test Plan For Electricalzampacaanas76% (29)

- AA-036911-001 Insulation Details For Hot Piping PDFDokument1 SeiteAA-036911-001 Insulation Details For Hot Piping PDFzampacaanas100% (2)

- Insulation Details For Cold Piping PDFDokument1 SeiteInsulation Details For Cold Piping PDFzampacaanasNoch keine Bewertungen

- Glowing GodzillaDokument1 SeiteGlowing GodzillazampacaanasNoch keine Bewertungen

- Fireproofing STD - ARAMCODokument1 SeiteFireproofing STD - ARAMCOzampacaanasNoch keine Bewertungen

- H359219001V00Dokument1 SeiteH359219001V00zampacaanasNoch keine Bewertungen

- Brochure Green FilterDokument2 SeitenBrochure Green FilterzampacaanasNoch keine Bewertungen

- Project Quality Plan RevDokument81 SeitenProject Quality Plan Revzampacaanas89% (9)

- Standard Water Height Level, Setting From Supplier (OASIS)Dokument2 SeitenStandard Water Height Level, Setting From Supplier (OASIS)zampacaanasNoch keine Bewertungen

- Manhole QuotationDokument6 SeitenManhole QuotationzampacaanasNoch keine Bewertungen

- S 00 Taa A 29 001 001Dokument1 SeiteS 00 Taa A 29 001 001zampacaanasNoch keine Bewertungen

- Xk-0092 - Gsoc SowDokument31 SeitenXk-0092 - Gsoc SowzampacaanasNoch keine Bewertungen

- H359217001V00Dokument1 SeiteH359217001V00zampacaanasNoch keine Bewertungen

- Alf - Ms For PaintingDokument3 SeitenAlf - Ms For PaintingzampacaanasNoch keine Bewertungen

- Quality Requirements For MFCDokument8 SeitenQuality Requirements For MFCzampacaanasNoch keine Bewertungen

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Dokument16 Seiten3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasNoch keine Bewertungen

- 3-Way Plug ValveDokument12 Seiten3-Way Plug ValvezampacaanasNoch keine Bewertungen

- 2-Square Ceiling DiffuserDokument21 Seiten2-Square Ceiling DiffuserzampacaanasNoch keine Bewertungen

- 3SE2094HDDokument1 Seite3SE2094HDzampacaanasNoch keine Bewertungen

- Submersible Pump Detail DrawingDokument1 SeiteSubmersible Pump Detail DrawingzampacaanasNoch keine Bewertungen

- Eco-Friendly Domestic Water Filtration Solution: Clean, Healthy and Tasty WaterDokument2 SeitenEco-Friendly Domestic Water Filtration Solution: Clean, Healthy and Tasty WaterzampacaanasNoch keine Bewertungen

- Vibration PadDokument2 SeitenVibration PadzampacaanasNoch keine Bewertungen

- C10!20!4Catalog Heating CalculationDokument64 SeitenC10!20!4Catalog Heating CalculationhoathinhdonNoch keine Bewertungen

- LSQ092H-3 Service ManualDokument75 SeitenLSQ092H-3 Service ManualzampacaanasNoch keine Bewertungen

- 28 SABG SchoolDokument4 Seiten28 SABG SchoolzampacaanasNoch keine Bewertungen

- PHE Method StatementDokument3 SeitenPHE Method Statementzampacaanas0% (1)

- 2017.08.28 - Gas - Liquid Contacting Equipments PDFDokument37 Seiten2017.08.28 - Gas - Liquid Contacting Equipments PDFdankshavali shaikNoch keine Bewertungen

- Horizontal Vessel Sizing ProgramDokument8 SeitenHorizontal Vessel Sizing ProgramsegunoyesNoch keine Bewertungen

- Size BOP Control SystemsDokument7 SeitenSize BOP Control SystemsQadriNoch keine Bewertungen

- Aspen Exchanger Design and Rating Shell & Tube V9: File: Printed: 24-08-2019 at 10:29:26 PM Overall SummaryDokument1 SeiteAspen Exchanger Design and Rating Shell & Tube V9: File: Printed: 24-08-2019 at 10:29:26 PM Overall Summarymohit kumarNoch keine Bewertungen

- Ooval Metal Catalogue (English) 120509Dokument16 SeitenOoval Metal Catalogue (English) 120509Stefce PetrovNoch keine Bewertungen

- Jackscrew Nut InstallationDokument12 SeitenJackscrew Nut InstallationinstsureshNoch keine Bewertungen

- 01 - Ashrae - AerodynamicsDokument52 Seiten01 - Ashrae - AerodynamicsAnonymous A8HV1JiN2TNoch keine Bewertungen

- HRSG Cogeneration Cycle EfficiencyDokument19 SeitenHRSG Cogeneration Cycle EfficiencyMuffin Everydays100% (1)

- Theory of Steam TurbineDokument29 SeitenTheory of Steam Turbinefahdiarzz100% (1)

- LNG Hazards and SafetyDokument60 SeitenLNG Hazards and SafetyAhmad Imran50% (2)

- Well Control Exercise 2: AnswersDokument6 SeitenWell Control Exercise 2: AnswersadeelsnNoch keine Bewertungen

- Experiment 5 Isolation of Caffeine From Tea LeavesDokument5 SeitenExperiment 5 Isolation of Caffeine From Tea LeavesJoevani DomingoNoch keine Bewertungen

- B2B Project On PraxairDokument25 SeitenB2B Project On Praxairindsumo100% (1)

- Discontinued: WarningDokument6 SeitenDiscontinued: WarningAnonymous zTUWsMNoch keine Bewertungen

- 125 en WE87j MOOHA 150330Dokument1 Seite125 en WE87j MOOHA 150330Senghy MaoNoch keine Bewertungen

- Drillers MethodDokument27 SeitenDrillers MethodAlif KrisnaNoch keine Bewertungen

- FM Question PaperDokument29 SeitenFM Question Papernitte5768Noch keine Bewertungen

- HPV32M - HPV Double Vane PumpDokument8 SeitenHPV32M - HPV Double Vane PumpNarasimha Rao JaggarapuNoch keine Bewertungen

- Refrigerant SafetyDokument4 SeitenRefrigerant SafetyPratikno SajaNoch keine Bewertungen

- Production Forecasting & Performance AnalysisDokument43 SeitenProduction Forecasting & Performance AnalysisAtul KhatriNoch keine Bewertungen

- Mini ProjectDokument4 SeitenMini ProjectAshrut AryalNoch keine Bewertungen

- Motion of Particles Through FluidsDokument9 SeitenMotion of Particles Through FluidsFarman AliNoch keine Bewertungen

- Homework 4 SolutionsDokument7 SeitenHomework 4 Solutionscalebgriffin31Noch keine Bewertungen

- CFM SPM 70-48-00Dokument8 SeitenCFM SPM 70-48-00ZakiHaunaNoch keine Bewertungen

- 08 - Heat and Gas - ExerciseDokument23 Seiten08 - Heat and Gas - Exercisekenchan0810.kcNoch keine Bewertungen

- Non Uniform FlowDokument60 SeitenNon Uniform Flowhelloyou101100% (1)

- Part 1 - Fundamentals of Airflow, Fans & DuctDokument49 SeitenPart 1 - Fundamentals of Airflow, Fans & Ductkhanh.vecNoch keine Bewertungen

- EMCO Orifice Plate With Single Pressure Tapping Series MEF For Insertion Between FlangesDokument4 SeitenEMCO Orifice Plate With Single Pressure Tapping Series MEF For Insertion Between FlangesJoan CandavaNoch keine Bewertungen

- Heating FormulasDokument2 SeitenHeating Formulasxenom4225Noch keine Bewertungen

- Service Kit Hcr1500-D20/D20 Ii/Ed Ii With Cat C9 EngineDokument3 SeitenService Kit Hcr1500-D20/D20 Ii/Ed Ii With Cat C9 EngineMustofa TofaNoch keine Bewertungen