Beruflich Dokumente

Kultur Dokumente

nAN400 08 QFN Soldering Reflow Guidelines Rev1 1 PDF

Hochgeladen von

Luis OliveiraOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

nAN400 08 QFN Soldering Reflow Guidelines Rev1 1 PDF

Hochgeladen von

Luis OliveiraCopyright:

Verfügbare Formate

QFN Soldering Reflow Guidelines nAN400-08 Application Note

All rights reserved. Reproduction in whole or in part is prohibited without the prior written permission of the copyright holder. December 2006

Application Note Liability disclaimer

Nordic Semiconductor ASA reserves the right to make changes without further notice to the product to improve reliability, function or design. Nordic Semiconductor ASA does not assume any liability arising out of the application or use of any product or circuits described herein.

Life support applications

These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be expected to result in personal injury. Nordic Semiconductor ASA customers using or selling these products for use in such applications do so at their own risk and agree to fully indemnify Nordic Semiconductor ASA for any damages resulting from such improper use or sale.

Contact details

For your nearest dealer, please see http://www.nordicsemi.no Receive available updates automatically by subscribing to eNews from our homepage or check our website regularly for any available updates.

Main office: Otto Nielsens vei 12 7004 Trondheim Phone: +47 72 89 89 00 Fax: +47 72 89 89 89 www.nordicsemi.no

Revision History

Date January 2004 December 2006 Version 1.0 1.1 Description Added note on wetting of package side wall.

Application Note order code: 260104-nAN400-08

Revision 1.1

Page 2 of 6

QFN Soldering Reflow Guidelines Contents

1 2 2.1 2.2 Introduction ................................................................................................. 4 Solder reflow process basics ...................................................................... 5 Tin/Lead Solder reflow profile .............................................................. 5 Green (lead free) soldering reflow profile ............................................. 6

Revision 1.1

Page 3 of 6

Application Note 1 Introduction

The electronic manufacturing industry is moving towards environmentally safe lead-free, or Green, assembly processes. Factors that should be considered when switching to lead-free soldering materials are: Circuit board thickness Surface finish Fabrication complexity Assembly process compatibility

This application note focuses on solder reflow recommendations for QFN packages with Tin/Lead and Matte Tin (Green) finishes. Note: The wetting of the package side wall is not guaranteed. This is because the QFN package is by design a contact down package. The sidewalls of the leads are not plated since they are exposed by the singulation step, which takes place after the plating. Depending on the surface state of the bare copper the sidewalls of the leads may not wet during soldering. Please see Figure 1. The QFN package is by design a contact down package.

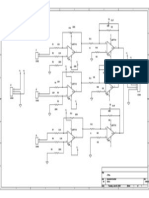

Figure 1. The QFN package is by design a contact down package

Revision 1.1

Page 4 of 6

QFN Soldering Reflow Guidelines 2 Solder reflow process basics

Lead-free soldering processes have been available for some years. However, they do not always meet the same physical criteria for attachments as soldering alloys containing lead. In the past, the most common soldering alloy for joining electronic components was the mixture of 63% tin and 37% lead. This composition of Tin and Lead provided excellent bonding strength as well as enough elasticity to withstand the thermal stresses in the products operating environment. As electronic companies began to reduce or even eliminate the lead alloy component in their products, these attributes were often adversely affected. We recommend using the solder profiles shown in Figure 2. Recommended reflow profile for 63/37 solder paste for QFN with tin/lead plating and Figure 3. Recommended solder reflow profile for lead-free (Green) solder paste for Green QFN packages for soldering QFN packages. However, factors such as circuit board thickness, size, other semiconductor packages, passive components and reflow equipment may affect the total profile time.

2.1

Tin/Lead Solder reflow profile

The tin/lead solder reflow process typically undergoes four transitions as shown in Figure 2. Recommended reflow profile for 63/37 solder paste for QFN with tin/lead plating. Heating up from 25 to 140 C at a rate of 1~3 C/sec. Preheat at 140-150 C for 120 ~ 150 seconds Solder reflow. Ramp up temperature at 2-3 C/sec to a peak temperature of 220-225 C. Temperature over 183 C for 45 ~ 75 sec. Cooling down to room temperature at 2-4 C/sec to avoid undesired intermetallic compound layer.

250

200

Temperature (C)

150

100

50

0 0 30 60 90 120 150 180 210 Time (s) 240 270 300 330 360 390 420

Figure 2. Recommended reflow profile for 63/37 solder paste for QFN with tin/lead plating

Revision 1.1

Page 5 of 6

Application Note 2.2 Green (lead free) soldering reflow profile

Figure 3. Recommended solder reflow profile for lead-free (Green) solder paste for Green QFN packages shows the reflow recommendations for our Green QFN packages. All green QFN packages have matte Tin plating. The SnAgCu solder paste with a melting temperature of 217 C is recommended for the Green (lead-free) reflow soldering process. The tin/lead solder reflow process typically undergoes four transitions as shown in Figure 3. Recommended solder reflow profile for lead-free (Green) solder paste for Green QFN packages. Heating up from 25 to 160 C at a rate of 1~3 C/sec. Preheat at 155-165 C for 120 ~ 150 seconds Solder reflow. Ramp up temperature at 2-3 C/sec to a peak temperature of 240-245 C. Temperature over 217 C for 40 ~ 60 sec. Cooling down to room temperature at 2-4 C/sec to avoid undesired intermetallic compound layer.

250

200

Temperature (C)

150

100

50

0 0 30 60 90 120 150 180 210 Time (s) 240 270 300 330 360 390 420

Figure 3. Recommended solder reflow profile for lead-free (Green) solder paste for Green QFN packages

Revision 1.1

Page 6 of 6

Das könnte Ihnen auch gefallen

- 1114 430423 Afr DODokument1 Seite1114 430423 Afr DOLuis OliveiraNoch keine Bewertungen

- CA 3 GD Panel Socket Product InfoDokument2 SeitenCA 3 GD Panel Socket Product InfoLuis OliveiraNoch keine Bewertungen

- Coach House Paper Model-01 PDFDokument1 SeiteCoach House Paper Model-01 PDFLuis OliveiraNoch keine Bewertungen

- A Day Dark As Night (Exalted 1) PDFDokument290 SeitenA Day Dark As Night (Exalted 1) PDFalocer_xul100% (2)

- Coach House Paper Model-05 PDFDokument1 SeiteCoach House Paper Model-05 PDFLuis OliveiraNoch keine Bewertungen

- Applique Armor On M4 Series Medium TanksDokument13 SeitenApplique Armor On M4 Series Medium TanksFordM4A3100% (8)

- Coach House Paper Model-03 PDFDokument1 SeiteCoach House Paper Model-03 PDFLuis OliveiraNoch keine Bewertungen

- CM 02 E 14S-2 P Surface Mounted ConnectorDokument2 SeitenCM 02 E 14S-2 P Surface Mounted ConnectorLuis OliveiraNoch keine Bewertungen

- Coach House Paper Model-04 PDFDokument1 SeiteCoach House Paper Model-04 PDFLuis OliveiraNoch keine Bewertungen

- Paper ModelDokument1 SeitePaper ModellittleGI4NT50% (2)

- Cognac Bidoit Shops PDFDokument1 SeiteCognac Bidoit Shops PDFLuis OliveiraNoch keine Bewertungen

- Single Layered PDFDokument5 SeitenSingle Layered PDFLuis Oliveira100% (1)

- Transform Any Meter into a Smart MeterDokument2 SeitenTransform Any Meter into a Smart MeterLuis OliveiraNoch keine Bewertungen

- Cloud Building Clamp WCC PDFDokument2 SeitenCloud Building Clamp WCC PDFLuis OliveiraNoch keine Bewertungen

- Dual Op Amp Circuit SchematicDokument1 SeiteDual Op Amp Circuit SchematicLuis OliveiraNoch keine Bewertungen

- SSM3J02T Datasheet en 20071101 PDFDokument5 SeitenSSM3J02T Datasheet en 20071101 PDFLuis OliveiraNoch keine Bewertungen

- JSXXS XXX 5a PDFDokument2 SeitenJSXXS XXX 5a PDFLuis OliveiraNoch keine Bewertungen

- G S-2WDokument3 SeitenG S-2WLuis OliveiraNoch keine Bewertungen

- Fla Ts W Id TH A CR o SS: Female Socket M12x1 Angled, Frontmounting, Dip SolderDokument1 SeiteFla Ts W Id TH A CR o SS: Female Socket M12x1 Angled, Frontmounting, Dip SolderLuis OliveiraNoch keine Bewertungen

- Signs and Portents 34Dokument72 SeitenSigns and Portents 34Krypturian100% (1)

- Best Practice in Circuit Board Design: Tim Jarvis KTL-HullDokument6 SeitenBest Practice in Circuit Board Design: Tim Jarvis KTL-HullLuis OliveiraNoch keine Bewertungen

- White Scout Car PDFDokument2 SeitenWhite Scout Car PDFLuis OliveiraNoch keine Bewertungen

- Office of The Chief of Ordnance - Terminal Ballistic Data - Volume 3 - Bombs, Artillery, Mortar Fire and Rockets (August 1944)Dokument214 SeitenOffice of The Chief of Ordnance - Terminal Ballistic Data - Volume 3 - Bombs, Artillery, Mortar Fire and Rockets (August 1944)MarcMichael77100% (1)

- JSCXX XXXX 1a PDFDokument2 SeitenJSCXX XXXX 1a PDFLuis OliveiraNoch keine Bewertungen

- CT VT Basics SonnenbergDokument71 SeitenCT VT Basics SonnenbergAnonymous OCDJg17Z67% (3)

- 6571 UsingRogowski VS 20120913Dokument10 Seiten6571 UsingRogowski VS 20120913Luis OliveiraNoch keine Bewertungen

- Fundamentals of Grounding, From Circuit To SystemDokument81 SeitenFundamentals of Grounding, From Circuit To SystemLuis OliveiraNoch keine Bewertungen

- Terminal Ballistic Data II PDFDokument186 SeitenTerminal Ballistic Data II PDFLuis Oliveira100% (1)

- Datasheet: Typical USB 2.0/3.0 Application Block DiagramDokument2 SeitenDatasheet: Typical USB 2.0/3.0 Application Block DiagramLuis OliveiraNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Slurry Shield AdditivesDokument8 SeitenSlurry Shield AdditivesfabiodbdbNoch keine Bewertungen

- Slon Magnetic Separators Applied in TheDokument8 SeitenSlon Magnetic Separators Applied in TheMulti DELLNoch keine Bewertungen

- PCC Technova Series CPL Cylindrical ValvesDokument5 SeitenPCC Technova Series CPL Cylindrical ValvesAnju VijayanNoch keine Bewertungen

- Aci 318-14 RC-BM-001Dokument7 SeitenAci 318-14 RC-BM-001Bunkun15Noch keine Bewertungen

- About Welding Process 47Dokument1 SeiteAbout Welding Process 47XerexNoch keine Bewertungen

- Hans OerstedDokument17 SeitenHans OerstedseialuwisNoch keine Bewertungen

- PMR v39 I3 117 126Dokument10 SeitenPMR v39 I3 117 126rezaeibehrouzNoch keine Bewertungen

- Road Project Steps and Interview QuestionsDokument54 SeitenRoad Project Steps and Interview QuestionsaamirNoch keine Bewertungen

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDokument4 SeitenSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNoch keine Bewertungen

- BaugsDokument10 SeitenBaugsmarcoliveriniqzNoch keine Bewertungen

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDokument4 SeitenWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainNoch keine Bewertungen

- TranslateDokument9 SeitenTranslateWira AdjieNoch keine Bewertungen

- ZOLLERN-Broschuere ZGF Legierungen ENGDokument16 SeitenZOLLERN-Broschuere ZGF Legierungen ENGPablo PadillaNoch keine Bewertungen

- Propylene - Carbonate Data SheetDokument2 SeitenPropylene - Carbonate Data SheetcNoch keine Bewertungen

- Alina Dawood - QS - Long AssignmentDokument11 SeitenAlina Dawood - QS - Long AssignmentK AndreNoch keine Bewertungen

- Organic Synthesis Capabilities and Core TechnologiesDokument8 SeitenOrganic Synthesis Capabilities and Core TechnologiesNguyễn Huy CườngNoch keine Bewertungen

- Filter Paper TestDokument14 SeitenFilter Paper TestSallam MohammedNoch keine Bewertungen

- Brosur Globond Alumunium Composite PanelDokument8 SeitenBrosur Globond Alumunium Composite PanelDede SubhanNoch keine Bewertungen

- Compact C Pump Flyer v2Dokument2 SeitenCompact C Pump Flyer v2GonzalezElizaNoch keine Bewertungen

- Disposable: VWR GlovesDokument25 SeitenDisposable: VWR GlovesSANJAY KHATRINoch keine Bewertungen

- HHD-S Cavity anchor installation guideDokument2 SeitenHHD-S Cavity anchor installation guideIngeniero Miguel VillarroelNoch keine Bewertungen

- Zimbabwe School Examinations Council Chemistry 6031/3Dokument12 SeitenZimbabwe School Examinations Council Chemistry 6031/3takundavs100% (2)

- Ds Oil and Grease TypesDokument2 SeitenDs Oil and Grease TypesIsaias BarbaNoch keine Bewertungen

- Lesker FeedthroughsDokument39 SeitenLesker FeedthroughspericoNoch keine Bewertungen

- Mechanical Engineering-Steam Boilers, Engines, Nozzles and Turbines Important MCQ PDFDokument28 SeitenMechanical Engineering-Steam Boilers, Engines, Nozzles and Turbines Important MCQ PDFRobert Michael CorpusNoch keine Bewertungen

- Revised PT Program April-May 2021 30% Discount Metal TestingDokument2 SeitenRevised PT Program April-May 2021 30% Discount Metal TestingSaravanan PNoch keine Bewertungen

- Module 7 (Maintenance Practices) Sub Module 7.11 (Bearings) PDFDokument15 SeitenModule 7 (Maintenance Practices) Sub Module 7.11 (Bearings) PDFshareyhou0% (1)

- Sika Lightcrete I-500: Admixture For Lightweight ConcreteDokument3 SeitenSika Lightcrete I-500: Admixture For Lightweight ConcreteAmmar A. AliNoch keine Bewertungen

- Fruit Juice ClarificationDokument26 SeitenFruit Juice ClarificationRoshan JainNoch keine Bewertungen

- DBR Cvs AuditoriumDokument9 SeitenDBR Cvs AuditoriumJohn JacksonNoch keine Bewertungen