Beruflich Dokumente

Kultur Dokumente

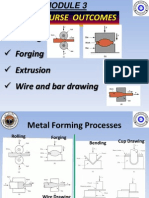

Forging and Sheet Metal Forming

Hochgeladen von

nvemanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Forging and Sheet Metal Forming

Hochgeladen von

nvemanCopyright:

Verfügbare Formate

Forging and Forging and

Sheet Metal Forming Sheet Metal Forming

Dr. Tapany Udomphol

Automotive Production Engineer

by

T

.

U

d

o

m

p

h

o

l

Suranaree University of Technology September 2007

Dr. Tapany Udomphol

School of Metallurgical Engineering

Suranaree University of Technology

T

.

U

d

o

m

p

h

o

l

Forging and Forging and

Sheet Metal Forming Sheet Metal Forming

T

.

U

d

o

m

p

h

o

l

Introduction to metal forming

Hot and cold working

Deformation geometry

Classification of forging processes

Die design and die materials

Metal flow in forging

Force in metal forging

Forging defects

Outline Part I: Forging of Metals ( )

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Introduction to metal forming

Hot and cold working

Deformation geometry

Classification of forging processes

Die design and die materials

Metal flow in forging

Force in metal forging

Forging defects

Forging and Forging and

Sheet Metal Forming Sheet Metal Forming

T

.

U

d

o

m

p

h

o

l

Outline Part II: Sheet metal forming ( )

Introduction to sheet metal forming

Sheet metal parts

Classification of sheet metal forming

Forming limit criteria

Defects in formed parts

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Introduction to sheet metal forming

Sheet metal parts

Classification of sheet metal forming

Forming limit criteria

Defects in formed parts

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

There are a wide range of different metal parts involved in an

automobile production.

www.designchain.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

encarta.msn.com

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

Casting

Gravity die casting

Pressure die casting

Centrifugal casting

Injection moulding

Rotational moulding

i.e.

Electrochemical machining

Electrical discharge machining

Single/multiple point cutting

Grinding

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Metal

processing

Cutting

Forming

Joining

Electrochemical machining

Electrical discharge machining

Single/multiple point cutting

Grinding

i.e.

Sheet metal forming

Forging

Rolling

Extrusion

Wire drawing

i.e.

i.e.

Fusion welding (arc, laser,

electron beam)

Solid state welding (friction)

Mechanical joining

T

.

U

d

o

m

p

h

o

l

Metal forming

Compressive

forming

Combined tensile

and compressive

forming

Tensile

forming

Forming by

bending

Forming by

shearing

Classification of metal forming

by subgroups

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Compressive

forming

Combined tensile

and compressive

forming

Tensile

forming

Forming by

bending

Forming by

shearing

Rolling

Open die forming

Closed die forming

Indenting

Pushing through a die

Pulling through a die

Deep drawing

Flange forming

Spinning

Upset bulging

Stretching

Expanding

Recessing

Bending with

linear tool

motion

Bending with

rotary tool

motion

Joggling

Twisting

Blanking

Coining

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

Forgings

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Forged wheels

Hot forming

product

Forged aluminium

pistons and

connecting rods

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

Net shape and metal powder forming products

Powder metal

forming parts

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Net shape

metal power

parts

Sintered

metal parts

Metal injection

moulding parts

Powder metal

forming parts

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

Metal Sheet forming products

www.numerica-srl.it

Electromagnetic

forming of

automotive parts

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Stamped plates

www.mse.eng.ohio-state.edu

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

www.ducommunaero.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Forging machine

www.macri.it

Hot and cold working Hot and cold working

T

.

U

d

o

m

p

h

o

l

The methods used to mechanically shape metals

into other product forms.

Working

processes

Hot working (0.6-0.8T

m

)

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Hot working (0.6-0.8T

m

)

Cold working (< 0.3T

m

)

Primary process

Recrystallisation

Secondary process

No recrystallisation

T

.

U

d

o

m

p

h

o

l

Annealing mechanisms Annealing mechanisms

in cold worked metals in cold worked metals

Mechanical properties change due

to temperature after cold working

T

.

U

d

o

m

p

h

o

l

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Annealing mechanisms Annealing mechanisms

in cold worked metals in cold worked metals

Ductility

Hardness

Strength

P

r

o

p

e

r

t

i

e

s

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Annealing mechanisms in cold worked metals

Recovery Recrystallisation Grain growth

Temperature

P

r

o

p

e

r

t

i

e

s

Cold worked and

recovered

New grains

~0.3T

m

~0.5T

m

T

.

U

d

o

m

p

h

o

l

Effects of grain size and strain Effects of grain size and strain

on recrystallisation temperature on recrystallisation temperature

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Schematic of recrystallisation diagram

Smaller grains Better strength/properties

T

.

U

d

o

m

p

h

o

l

Effects of grain size and strain Effects of grain size and strain

on recrystallisation temperature on recrystallisation temperature

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Flow stress of aluminium as a function of

strain at different temperature

Flow curves of Cu Zn28

Flow stress

Flow stress Temp

Strain rate

Advantages and disadvantages Advantages and disadvantages

of hot and cold working of hot and cold working

T

.

U

d

o

m

p

h

o

l

Hot working Cold working

Advantages Advantages

Stronger

Good surface finish

Good dimensional control

Easy handling

Low flow stress + high ductility

Pore sealed up

Smaller grains

Softer metals

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Disadvantages Disadvantages

Stronger

Good surface finish

Good dimensional control

Easy handling

High deformation

Reduced ductility

Expensive equipment

Low flow stress + high ductility

Pore sealed up

Smaller grains

Softer metals

Surface oxidation

Poor dimensional control

Hot shortness

Difficult handling

T

.

U

d

o

m

p

h

o

l

Deformation geometry Deformation geometry

Biaxial-plane stress condition

Triaxial-plane strain condition

Two principal stresses,

1

and

2

.

Three principal stresses,

1

,

2

and

3

, where

1

>

2

>

3

.

EX: Sheet metal forming

Effect of principal stresses

in metal working

T

.

U

d

o

m

p

h

o

l

Three principal stresses,

1

,

2

and

3

, where

1

>

2

>

3

.

Biaxial Triaxial

EX: Forging, rolling extrusion

Suranaree University of Technology September 2007

Part I: Part I: Forging of metals Forging of metals

T

.

U

d

o

m

p

h

o

l

Forging is the working of metal into a useful

shape by hammering or pressing.

Primitive blacksmith

Parts ranging in size of a bolt to a turbine

rotor.

Most carried out hot, although certain metals

may be cold-forged.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Forging is the working of metal into a useful

shape by hammering or pressing.

Primitive blacksmith

Parts ranging in size of a bolt to a turbine

rotor.

Most carried out hot, although certain metals

may be cold-forged.

www.eindiabusiness.com

www.prime-metals.com

T

.

U

d

o

m

p

h

o

l

Classification of forging Classification of forging

processes processes

By equipment

1) Forging hammer or drop hammer

2) Press forging

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

1) Forging hammer or drop hammer

2) Press forging

By process

1) Open - die forging

2) Closed - die forging

T

.

U

d

o

m

p

h

o

l

Forging machines Forging machines

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

T

.

U

d

o

m

p

h

o

l

Drop hammer

Forging machines Forging machines

Potential energy = mgh

The energy supplied by the blow

is equal to the potential energy

due to the weight of the ram and

the height of the fall.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Potential energy = mgh

Mass production (60-150 blow / min)

Dies are subject to impact loading

Forging machines Forging machines

T

.

U

d

o

m

p

h

o

l

Hydraulic Press forging

Continuous forming at slower rate

Deeper penetration

Expensive equipment

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Heat loss from workpiece

(long contact)

Die life

T

.

U

d

o

m

p

h

o

l

Closed and open die forging Closed and open die forging

Open-die forging

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Closed-die forging

Impression-die

forging

T

.

U

d

o

m

p

h

o

l

Open Open--die forging die forging

Flat dies

Simple shape

Large objects.

Pre-forming

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l Flat dies

Simple shape

Large objects.

Pre-forming

T

.

U

d

o

m

p

h

o

l

Close Close--die forging (Impression forging) die forging (Impression forging)

Workpiece is formed under high

pressure in a closed cavity.

Small components

Precision forging

Expensive die

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Workpiece is formed under high

pressure in a closed cavity.

Small components

Precision forging

Expensive die

T

.

U

d

o

m

p

h

o

l

F

o

r

g

i

n

g

l

o

a

d

F

o

r

g

i

n

g

c

o

m

p

l

e

t

e

Die cavity

completely

filled

Flash begins

to form

Forging load Forging load

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

F

o

r

g

i

n

g

l

o

a

d

F

o

r

g

i

n

g

c

o

m

p

l

e

t

e

Forging stroke

Flash begins

to form

Dies contact

workpiece

Typical curve of forging load vs. stroke for

closed-die forging.

Flash is the excess metal, which

squirts out of the cavity as a thick

ribbon of metal.

T

.

U

d

o

m

p

h

o

l

The flash serves two purposes:

Acts as a safety value for excess metal.

Builds up high pressure to ensure that

the metal fills all recesses of the die cavity.

Functions of flash Functions of flash

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

The flash serves two purposes:

Acts as a safety value for excess metal.

Builds up high pressure to ensure that

the metal fills all recesses of the die cavity.

Remark: It is necessary to achieve complete filling of the forging cavity

without generating excessive pressures against the die that may

cause it to fracture.

T

.

U

d

o

m

p

h

o

l

Closed Closed--die design die design

Considerations

workpiece volume and weight

number of preforming steps and their configuration

flash dimensions in preforming and finishing dies

the load and energy requirement for each forging operation, for

example; the flow stress of the materials, the fictional condition,

the flow of the material in order to develop the optimum geometry for

the dies.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Considerations

workpiece volume and weight

number of preforming steps and their configuration

flash dimensions in preforming and finishing dies

the load and energy requirement for each forging operation, for

example; the flow stress of the materials, the fictional condition,

the flow of the material in order to develop the optimum geometry for

the dies.

Shape classification Shape classification

T

.

U

d

o

m

p

h

o

l

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Shape classification Shape classification

T

.

U

d

o

m

p

h

o

l

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

T

.

U

d

o

m

p

h

o

l

Die set and forging steps for Die set and forging steps for

automobile engine connecting rod automobile engine connecting rod

Preforming of a round piece in an open die arrangement.

Rough shape is formed using a block die.

Finishing die gives final tolerances and surface finish.

Removal of flash (excess metal).

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Steering knuckle

Flange

Rail

http://www.hirschvogel.de/en/produkti

onsverfahren/warmumformung.php

See simulation

T

.

U

d

o

m

p

h

o

l

General considerations General considerations

for preform design for preform design

Metal used = Metal preform + Flash.

Concave radii of the preform > radii on the final forging part.

Cross section of the preform should be higher and narrower than the

final cross section.

draft angle

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Shapes with thin and long sections or

projections (ribs and webs) are more

difficult to process due to

higher surface area per unit volume

increasing friction

temperature effects.

draft angle

web

rib

Some typical nomenclature

T

.

U

d

o

m

p

h

o

l

Smooth metal flow symmetry dies

Avoid shape change

Minimum flash to do the job.

Tapered or drafted to facilitate removal of the finished piece.

Draft allowance is approximately 3-5

o

outside and 7-10

o

inside.

Counterlock to prevent side thrust.

General considerations

for preform design

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Smooth metal flow symmetry dies

Avoid shape change

Minimum flash to do the job.

Tapered or drafted to facilitate removal of the finished piece.

Draft allowance is approximately 3-5

o

outside and 7-10

o

inside.

Counterlock to prevent side thrust.

Counterlock

Side thrust

draft angle

web

rib

T

.

U

d

o

m

p

h

o

l

Die materials

Thermal shock resistance

Thermal fatigue resistance

High temperature strength

High wear resistance

High toughness and ductility

High hardenability

High dimensional stability

during hardening

High machinability

Required properties

Die materials: alloyed steels (with Cr,

Mo, W, V), tool steels, cast steels or cast

iron. (Heat treatments such as nitriding or

chromium plating)

Forging die

www.nitrex.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Thermal shock resistance

Thermal fatigue resistance

High temperature strength

High wear resistance

High toughness and ductility

High hardenability

High dimensional stability

during hardening

High machinability

Die materials: alloyed steels (with Cr,

Mo, W, V), tool steels, cast steels or cast

iron. (Heat treatments such as nitriding or

chromium plating)

1) Carbon steels with 0.7-0.85% C are

appropriate for small tools and flat

impressions.

2) Medium-alloyed tool steels for

hammer dies.

3) Highly alloyed steels for high

temperature resistant dies used in

presses and horizontal forging

machines.

T

.

U

d

o

m

p

h

o

l

Forging

materials

Steels Copper and copper alloys Light alloys

DIN AISI DIN AISI DIN AISI

Forging dies C70 W2 -

C85 W2 -

60MnSi4 - X30WCrV53 H21 X30WCrV53 -

Die materials

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

40CrMnMo7 - X38CrMoV51 H11 X38CrMoV51 H11

X32CrMoV33 H10

Die inserts 55NiCrMoV6 6F2 55NiCrMoV6

56NiCrMoV7 6F3 56NiCrMoV7 6F2

57NiCrMoV77 - 57NiCrMoV77 - 57NiCrMoV77 6F3

35NiCrMo16 -

X38CrMoV51 H11 X30WCrV93 H21 X38CrMoV51 H11

X32CrMoV33 H10 X32CrMoV33 H10 X32CrMoV33 H10

X30WCrV53 - X30WCrV52 - X30WCrV53 -

X37CrMoW51 H12

T

.

U

d

o

m

p

h

o

l

To increase die life

1) Improving die materials such

as using composite die or

2) Using surface coating or self-

lubricating coatings

Current forging Future forging

Die life improvement

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Ultra hard surface coatings

Improve die life.

Reduce energy input.

Reduce die-related uptime

and downtime.

Reduce particulate emission

from lubricants.

http://www.eere.energy.gov/industry/supporting_industries

/pdfs/innovative_die_materials.pdf

Die failures Die failures

T

.

U

d

o

m

p

h

o

l

Wear (abrasion)

Thermal fatigue

Mechanical fatigue

Permanent deformation

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Wear (abrasion)

Thermal fatigue

Mechanical fatigue

Permanent deformation

Different parts of dies are liable to permanent deformation and wear

resulting from mechanical and thermal fatigue

Metal flow in forging Metal flow in forging

T

.

U

d

o

m

p

h

o

l

I

n

c

r

e

a

s

i

n

g

r

e

d

u

c

t

i

o

n

Deformation

bands

associated

with plastic

instability.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Finite element analysis of upsetting an aluminium cylinder

I

n

c

r

e

a

s

i

n

g

r

e

d

u

c

t

i

o

n

Schematic representation of shear band

formation in compression of a cylinder.

Deformation

bands

associated

with plastic

instability.

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Fibre structure in forged steels

Grain structure resulting from

(a) forging, (b) machining and

(c) casting.

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Metal flow in forging

Identify the neutral surface

Metal flows away from the

neutral surface in a direction

perpendicular to the die motion.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Identify the neutral surface

Metal flows away from the

neutral surface in a direction

perpendicular to the die motion.

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Cold forging

Forging of nut and bolt

Step I Step II Step III Step IV

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

www.qform3d.com

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Cold forging

Forging of nut and bolt

Step I Step II Step III

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

www.qform3d.com

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

http://www.qform3d.com/en/59.html

Hot forging

Titanium alloy being forged at 930

o

C to

produce preliminary turbine blade pre-form.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Suck in flaw

www.qform3d.com

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Hot forging

AISI 1040 being forged from a square

bar at 1200

o

C to produce a shaft.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Extensive metal flow into flash

Incomplete fill up at the upper part

www.qform3d.com

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Hot forging

DIN/C43 being forged from a round

bar at 1250

o

C to produce a shaft fork.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Possible die filling with minimum

flash used.

www.qform3d.com

T

.

U

d

o

m

p

h

o

l

Metal flow in forging Metal flow in forging

Forging from compact bar

Powder compact bar of 0.78

density being forged.

The density increases first

in the intermediate area then

spread throughout the cross

section.

www.qform3d.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Powder compact bar of 0.78

density being forged.

The density increases first

in the intermediate area then

spread throughout the cross

section.

Forces in metal forging Forces in metal forging

T

.

U

d

o

m

p

h

o

l

Eq.1

p pA

A

P

F

i

r

r i

= = =

Friction between two surfaces

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Where

= frictional coefficient

= the shearing stress at the interface

P = the load normal to the interface

F = the shearing force

A

r

= summation of asperity areas in contact

p = the stress normal to the interface

p pA

A

P

F

i

r

r i

= = =

Forces in metal forging Forces in metal forging

T

.

U

d

o

m

p

h

o

l

1. No friction

2. Small friction

3. Sticky friction

The calculation of forging load can be

considered in three cases

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

1. No friction

2. Small friction

3. Sticky friction

No friction No friction

T

.

U

d

o

m

p

h

o

l

A P

o

= .Eq. 2

D

o

h

o

D

h h D h D

o o

2 2

=

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

A P

o

=

Where P is the compressive force

o

is the yield stress of the metal

A is the cross sectional area of the metal.

o o

o

o o

h D

Ah

h D

Ph

D

P

p

2 2 2

4 4 4

= =

.Eq. 3

T

.

U

d

o

m

p

h

o

l

p

=

Assumption:

- no barrelling

- small thickness,

Then

- frictional conditions on the top

and bottom faces of the disk

are a constant coefficient of

Coulomb friction;

Small friction (homogeneous forging)

Small friction Small friction

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

p

=

Where

= frictional coefficient

= the shearing stress at the interface

p = the stress normal to the interface

Eq.4

Assumption:

- no barrelling

- small thickness,

Then

- frictional conditions on the top

and bottom faces of the disk

are a constant coefficient of

Coulomb friction;

T

.

U

d

o

m

p

h

o

l

X=0 X=a

P

P

max

Friction hill

o

Small friction Small friction

Small friction

(non-homogeneous forging)

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

h

P

P

X

a -a

o

Functions of a metal working lubricant

- Reduces deformation load

- Increases limit of deformation before fracture

- Controls surface finish

- Minimises metal pickup on tools

- Minimises tool wear

- Thermally insulates the workpiece and the tools

- Cools the workpiece and/or tools

Small friction Small friction

T

.

U

d

o

m

p

h

o

l

, )

(

= x a

h

o y

2

exp

'

.Eq. 5

o

y

|

.

|

\

|

h

a

o

2

exp

'

, )

(

x a

h

o

2

exp

'

Friction hill

Forging stress

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

.Eq. 5

x = a x = 0 x = -a

X

a -a

o

|

.

|

\

|

+ =

h

a

p

o

1

'

_

.Eq. 6

Average forging pressure

a/h

Forging pressure

High friction (Sticky friction) High friction (Sticky friction)

T

.

U

d

o

m

p

h

o

l

.Eq. 7

o

y

|

.

|

\

|

+1

'

h

a

o

|

.

|

\

|

+

1

'

h

x a

o

Friction hill

Forging stress

|

.

|

\

|

+

= 1

'

h

x a

o y

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

x = a x = 0 x = -a

X

a -a

o

.Eq. 8

Average forging pressure

a/h

Forging pressure

|

.

|

\

|

+ = 1

2 3

2

_

h

a

p

o

T

.

U

d

o

m

p

h

o

l

Example:

A block of lead 25x25x150 mm

3

is pressed between flat dies to a size

6.25x100x150 mm

3

. If the uniaxial flow stress

o

= 6.9 MPa and = 0.25,

determine the pressure distribution over the 100 mm dimension (at x = 0, 25

and 50 mm) and the total forging load in the sticky friction condition.

, )

(

= x a

h

o y

2

exp

3

2

o o

3

2

'

=

Dieter, page 574-575

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

, )

(

= x a

h

o y

2

exp

3

2

At the centreline of the slab (x = 0)

, ) MPa 435 0 50

25 . 6

) 25 . 0 ( 2

exp

3

) 9 . 6 ( 2

max

=

(

=

Likewise, at 25 and 50 mm, the stress distribution will be 58.9 and 8.0 MPa

respectively.

o o

3

2

'

=

where

T

.

U

d

o

m

p

h

o

l

Example: Dieter, page 574-575

The mean forging load (in the sticky friction condition) is

|

.

|

\

|

+ = 1

2

3

2

_

h

a

p

o

MPa p 8 . 39 1

5 . 12

50

3

) 9 . 6 ( 2

_

=

|

.

|

\

|

+ =

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

MPa p 8 . 39 1

5 . 12

50

3

) 9 . 6 ( 2

_

=

|

.

|

\

|

+ =

We calculate the forging load on the assumption that the stress distribution

is based on 100 percent sticky friction. Then

The forging load is P = stress x area

= (39.8x10

6

)(100x10

-3

)(150x10

-3

)

= 597 kN

= 61 tonnes.

Defects in forging Defects in forging

T

.

U

d

o

m

p

h

o

l

Fluorescence penetrant

reveals Forging laps

files.bnpmedia.com

Incomplete die filling.

Die misalignment.

Forging laps.

Incomplete forging penetration- should

forge on the press.

Microstructural differences resulting in

pronounced property variation.

Hot shortness, due to high sulphur

concentration in steel and nickel.

Residual stresses

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

See simulation

www.komatsusanki.co.jp

Incomplete die filling.

Die misalignment.

Forging laps.

Incomplete forging penetration- should

forge on the press.

Microstructural differences resulting in

pronounced property variation.

Hot shortness, due to high sulphur

concentration in steel and nickel.

Residual stresses

Forging of automobile parts Forging of automobile parts

T

.

U

d

o

m

p

h

o

l

www.jocmachinery.com

www.jocmachinery.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Metals to be forged

Shape and size

Forging temperature

Strain rate

Forging load

Lubrication

Die design

Die materials

Die life

Part II: Part II: Sheet metal forming Sheet metal forming

T

.

U

d

o

m

p

h

o

l

Permanent deformation by

cold forming (RT).

Complex 3D shapes.

The process is carried out in the

plane of sheet by tensile forces

with high ratio of surface area

to thickness.

Sheet metal forming

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Permanent deformation by

cold forming (RT).

Complex 3D shapes.

The process is carried out in the

plane of sheet by tensile forces

with high ratio of surface area

to thickness.

Friction conditions at the

tool-metal interface.

High rate of production

and formability

T

.

U

d

o

m

p

h

o

l

Classification

(Base on operation)

Classification of sheet Classification of sheet--metal metal

forming forming

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Stretching

Deep drawing Blanking

Punching

Stretching

T

.

U

d

o

m

p

h

o

l

Classification

(Base on operation)

Classification of sheet Classification of sheet--metal metal

forming forming

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Stamping

Ironing Coining

Classification of sheet Classification of sheet--metal metal

forming forming

T

.

U

d

o

m

p

h

o

l

Classification

(Base on operation)

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Wiping down a flange Roll forming of sheet Folding Bending

Tooling Tooling

T

.

U

d

o

m

p

h

o

l

Punch A convex tool for making

holes by shearing, making surface or

displacing metal with a hammer.

Die A concave die (female part).

Basic tools

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Punch A convex tool for making

holes by shearing, making surface or

displacing metal with a hammer.

Die A concave die (female part).

Punches and dies

Punch and die in stamping

Die materials:

High alloyed steels heat

treated for the punches and

dies.

Compound and transfer dies Compound and transfer dies

T

.

U

d

o

m

p

h

o

l

Compound dies

Several operations in one stroke.

Combined processes and create a

complex product in one shot.

Stamping processes of thin sheets.

www.lyons.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Several operations in one stroke.

Combined processes and create a

complex product in one shot.

Stamping processes of thin sheets.

Transfer dies

Also called compound dies.

The part is moved from station to

station within the press for each

operation.

www.deltatooling.co.jp/

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

Die set consists of

1) Punch holder

2) Die block

3) Pilot

4) Striper plate

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

1) Punch holder

2) Die block

3) Pilot

4) Striper plate

pilot

Schematic diagram of a die set

Forming methods Forming methods

T

.

U

d

o

m

p

h

o

l

There are a great variety of sheet metal forming methods,

mainly using shear and tensile forces in the operation.

Progressive forming

Hydroforming

Stretch forming

Explosive forming

Stamping

Shearing and blanking

Bending and contouring

Spinning process

Deep drawing

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Progressive forming

Hydroforming

Stretch forming

Explosive forming

Stamping

Shearing and blanking

Bending and contouring

Spinning process

Deep drawing

Progressive forming Progressive forming

T

.

U

d

o

m

p

h

o

l

Die

Stripper

plate

Punch

www.hillengr.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

washers

washer

Die

Strip

Progressive die

Optimise the material usage.

Determining factors are

1) volume of production

2) the complexity of the shape

Hydroforming Hydroforming

T

.

U

d

o

m

p

h

o

l

Using Rubber or polyurethane pad as dies.

Single - action hydraulic press.

Pressure medium- water or oil.

Transmits a nearly uniform hydrostatic pressure

against the sheet.

Pressure ~ 10 MPa or higher

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Using Rubber or polyurethane pad as dies.

Single - action hydraulic press.

Pressure medium- water or oil.

Transmits a nearly uniform hydrostatic pressure

against the sheet.

Pressure ~ 10 MPa or higher

www.thefabricator.com

Hydroforming

Stretch forming Stretch forming

T

.

U

d

o

m

p

h

o

l

Using tensile forces, normally for uniform cross section).

required materials with appreciable ductility.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

www.ducommunaero.com

Ram Ram

Explosive forming Explosive forming

T

.

U

d

o

m

p

h

o

l

Explosive charge is detonated in medium (water) at an appropriate

standoff distance from the sheet blank at a very high velocity.

The shockwave propagating from the explosion serves as a

friction-less punch

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Stamping Stamping

T

.

U

d

o

m

p

h

o

l

www.fpi.co.th

Key factors: data collections on die sets, die

failure and material handling damage and machine

failure to identify weak areas in the stamping

process.

Materials require good ductility, work

hardening and strength

www.ugs.com/

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Automotive stamped parts

img.alibaba.com

Automobile panel die

Panel, fender, bumper

Materials require good ductility, work

hardening and strength

Stamping Stamping

T

.

U

d

o

m

p

h

o

l

Multi-cone design giving structural

integrity and rigidity equivalent to

a steel beam panel at half the weight,

and without cutouts,

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Aluminium inner hood panel

www.psc.edu

Shearing and blanking Shearing and blanking

T

.

U

d

o

m

p

h

o

l

(normally 2-10% thickness)

Proper clean fracture surface.

Insufficientragged fracture surface.

Excessive greater distortion, greater energy

required to separate metal.

(a) Proper clearance

Ragged

surface

Clearance

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

(normally 2-10% thickness)

Proper clean fracture surface.

Insufficientragged fracture surface.

Excessive greater distortion, greater energy

required to separate metal.

Thickness clearance

(b) Insufficient clearance

(c) Excessive clearance

blurr

Ragged

surface

Bending and contouring Bending and contouring

T

.

U

d

o

m

p

h

o

l

Wiper rolls

www.macri.it

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Form block

Clamp

Tension

Clamp

www.lathes.co.uk

Bending and contouring Bending and contouring

T

.

U

d

o

m

p

h

o

l

Outer surface strained.

Inner surface contracted.

b/h biaxiality

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

R

thickness on

bending

b/h biaxiality

Strain, ductility

Cracks occur near the

centre of the sheet

Springback

Spinning process Spinning process

T

.

U

d

o

m

p

h

o

l

Deep parts of circular symmetry

such as tank heads, television cones.

Materials: aluminium and alloys, high

strength - low alloy steels, copper,

brass and alloys, stainless steel,

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

(a) Manual spinning (b) Shear spinning

Materials: aluminium and alloys, high

strength - low alloy steels, copper,

brass and alloys, stainless steel,

T

.

U

d

o

m

p

h

o

l

Deep drawing Deep drawing

A cup is subjected to

three different types of

deformation.

Shaping flat sheets into cup-shaped articles.

Examples: bathtubs, shell cases, automobile panels.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Lamp cover

Stresses and deformation in a section from a drawn cup

T

.

U

d

o

m

p

h

o

l

Deep drawing Deep drawing

Thickness profile of drawn cup

Clearance > 10-20%

thickness.

Die radius 10 x sheet thickness.

Punch radius Clearance between punch

and die ~10-20% > sheet thickness.

Hold-down pressure ~ 2% of

o

and

u

.

Lubrication of die side.

Material properties - low yield stress, high

work hardening rates.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Thickness profile of drawn cup

Clearance > 10-20%

thickness.

Die radius 10 x sheet thickness.

Punch radius Clearance between punch

and die ~10-20% > sheet thickness.

Hold-down pressure ~ 2% of

o

and

u

.

Lubrication of die side.

Material properties - low yield stress, high

work hardening rates.

Forming limit criteria Forming limit criteria

T

.

U

d

o

m

p

h

o

l

Major strain

1

(%)

Failure

100

120

Stretching of circles into ellipses

after punching

Percentage changes in these

strains are compared in the diagram.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Grid analysis (a) before (b) after deformation of

sheet.

AK steel

0 20 40 60 80 100

1

2

1

2

A B

Failure

Safe

Minor strain

2

(%)

-40 -20

20

40

60

80

Forming limit diagram

Stretching of circles into ellipses

after punching

Percentage changes in these

strains are compared in the diagram.

Defects in formed parts Defects in formed parts

T

.

U

d

o

m

p

h

o

l

Springback problem

www.bgprecision.com

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Springback problem

Edge condition

Crack near punch & shoulder

Localised necking in a strip in tension

n

u

2 =

~ 55

o

for an isotropic

material in pure tension

Introduction to metal forming Introduction to metal forming

T

.

U

d

o

m

p

h

o

l

aluminium.matter.org.uk

Earing in drawn can

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Stretcher strain in low-carbon steel.

Radial crack

Surface blemish (orange peel)

Wrinkling

Mechanical fibering

T

.

U

d

o

m

p

h

o

l

Processing route

Tool geometry

-Die

-Punch

-Blankholder

-Drawbeads

-Spacers

Material characteristics

-Stress-strain curve

-Directionality

-Forming criteria

-Youngs modulus

-Friction

Process parameters

-Process steps

-Blank outline

-Blankholder pressure

-Blankholder stiffness

-Stress relief cuts

-Sheet gauge

-Drawbeads

-Friction

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

www.thefabricator.com

Process parameters

-Process steps

-Blank outline

-Blankholder pressure

-Blankholder stiffness

-Stress relief cuts

-Sheet gauge

-Drawbeads

-Friction

Forming simulation

Forming

Result

References References

T

.

U

d

o

m

p

h

o

l

Dieter, G.E., Mechanical metallurgy, SI metric Edition, 1988, McGraw-Hill,

ISBN 0-07-100406-8

Edwards, L. and Endean, M., Manufacturing with material, 1998,

Butterworth Heinemann, ISBN 0 7506 2754 9.

Beddoes, J. and Bibbly M.J., Principles of metal manufacturing process,

1999, Arnold, ISBN 0-470-35241-8.

Lange, K., Handbook of metal forming, 1985, R.R Donnelly & Sons

Company, ISBN 0-07-036285-8.

Lecture notes, Sheffield University, 2003.

Lecture notes, Birmingham University, 2003.

Lecture notes, Metal forming processes, Prof Manus Satirajinda.

Suranaree University of Technology September 2007

T

.

U

d

o

m

p

h

o

l

Dieter, G.E., Mechanical metallurgy, SI metric Edition, 1988, McGraw-Hill,

ISBN 0-07-100406-8

Edwards, L. and Endean, M., Manufacturing with material, 1998,

Butterworth Heinemann, ISBN 0 7506 2754 9.

Beddoes, J. and Bibbly M.J., Principles of metal manufacturing process,

1999, Arnold, ISBN 0-470-35241-8.

Lange, K., Handbook of metal forming, 1985, R.R Donnelly & Sons

Company, ISBN 0-07-036285-8.

Lecture notes, Sheffield University, 2003.

Lecture notes, Birmingham University, 2003.

Lecture notes, Metal forming processes, Prof Manus Satirajinda.

Das könnte Ihnen auch gefallen

- Applied Science in the Casting of MetalsVon EverandApplied Science in the Casting of MetalsK. StraussNoch keine Bewertungen

- Forging CalculationsDokument49 SeitenForging CalculationsMinhaj Akbar78% (40)

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsVon EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsBewertung: 5 von 5 Sternen5/5 (1)

- Force Power in Metal CuttingDokument7 SeitenForce Power in Metal CuttingRavinder AntilNoch keine Bewertungen

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingVon EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingBewertung: 1 von 5 Sternen1/5 (1)

- Module 3: Cutting Tool Materials and FluidsDokument88 SeitenModule 3: Cutting Tool Materials and FluidssushilNoch keine Bewertungen

- Experiment p1 Metal Cutting ProcessDokument13 SeitenExperiment p1 Metal Cutting Processvipin_shrivastava25Noch keine Bewertungen

- The Iron Puddler My life in the rolling mills and what came of itVon EverandThe Iron Puddler My life in the rolling mills and what came of itNoch keine Bewertungen

- Engg Metallurgy Lecture 5Dokument54 SeitenEngg Metallurgy Lecture 5Patil Sudheer GowdNoch keine Bewertungen

- Advances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967Von EverandAdvances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967S. A. TobiasBewertung: 4 von 5 Sternen4/5 (1)

- Production Process.II (CBCGS) Module.1 Metal CuttingDokument24 SeitenProduction Process.II (CBCGS) Module.1 Metal CuttingOmkar BedadeNoch keine Bewertungen

- Heat TreatmentDokument30 SeitenHeat Treatmentjhamlal100% (2)

- Cold FormingDokument7 SeitenCold FormingglaxionNoch keine Bewertungen

- Unit-I Theory of Metal CuttingDokument73 SeitenUnit-I Theory of Metal CuttingSarvesh Kumarasamy100% (1)

- Hot Working & Cold WorkingDokument34 SeitenHot Working & Cold Workingavutu_kunduruNoch keine Bewertungen

- E2 Deep DrawingDokument43 SeitenE2 Deep DrawingAllen MarshNoch keine Bewertungen

- Metal Cutting Forces and Chip FormationDokument38 SeitenMetal Cutting Forces and Chip FormationcrazynupNoch keine Bewertungen

- ForgingDokument58 SeitenForgingSamir Bose100% (4)

- Metal Cutting Processes and MechanismsDokument86 SeitenMetal Cutting Processes and MechanismsscorpionarnoldNoch keine Bewertungen

- Sheet Metal WorkingDokument66 SeitenSheet Metal Workingsamurai7_77Noch keine Bewertungen

- Forging FundamentalsDokument23 SeitenForging FundamentalsJoNoch keine Bewertungen

- Tool GeometryDokument3 SeitenTool GeometrynikhilasoknNoch keine Bewertungen

- Course Material TwoDay Workshop Sheetemetal DHIO GTTCDokument132 SeitenCourse Material TwoDay Workshop Sheetemetal DHIO GTTChsvjvv100% (1)

- Benefits of induction heating for metal forging applicationsDokument4 SeitenBenefits of induction heating for metal forging applicationsdhruvNoch keine Bewertungen

- Heat Treatment Definition and ObjectivesDokument56 SeitenHeat Treatment Definition and ObjectivesAakarsh RastogiNoch keine Bewertungen

- Unit I - Theory of Metal CuttingDokument111 SeitenUnit I - Theory of Metal CuttingSaravana KumarNoch keine Bewertungen

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDokument17 Seiten15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- Theory of Metal CuttingDokument162 SeitenTheory of Metal CuttingShrikrushna MaliNoch keine Bewertungen

- 1 s2.0 S0143974X21002212 MainDokument14 Seiten1 s2.0 S0143974X21002212 MainRavi PadmanabhanNoch keine Bewertungen

- Forging ApplicationsDokument24 SeitenForging ApplicationsdstifterNoch keine Bewertungen

- ForgingDokument52 SeitenForgingRavichandran G100% (1)

- Extrusion ProcessDokument24 SeitenExtrusion Processchris mushunjeNoch keine Bewertungen

- Design and Fabrication of a Wind Mill Hub Using SG IronDokument5 SeitenDesign and Fabrication of a Wind Mill Hub Using SG IronKannan Seenu100% (1)

- Metal Forming Technology GuideDokument1 SeiteMetal Forming Technology GuidearunsunderNoch keine Bewertungen

- Press ToolsDokument31 SeitenPress ToolsSunil MandoreNoch keine Bewertungen

- Ch#20 SHEET METAL WORKINGDokument119 SeitenCh#20 SHEET METAL WORKINGMustaqeem Sajid Khan100% (1)

- Chip Formation and Tool LifeDokument37 SeitenChip Formation and Tool LifeSquakx BescilNoch keine Bewertungen

- MTDM Machine Tools and Digital ManufacturingDokument90 SeitenMTDM Machine Tools and Digital ManufacturingLibin AbrahamNoch keine Bewertungen

- Orbital ForgingDokument4 SeitenOrbital ForgingMrLanternNoch keine Bewertungen

- Selection of Material and Hardware Used in Press ToolDokument22 SeitenSelection of Material and Hardware Used in Press ToolVipul MetaNoch keine Bewertungen

- Theory of Metal Cutting 2Dokument39 SeitenTheory of Metal Cutting 2Anonymous p0mg44x100% (1)

- Sheet Metal Forming WorkshopDokument7 SeitenSheet Metal Forming WorkshopIbrahim Khaled0% (1)

- Extrusión-Rolling and Forming ProcessDokument50 SeitenExtrusión-Rolling and Forming Processquiron2010Noch keine Bewertungen

- CH 2 Metal Cutting ToolsDokument19 SeitenCH 2 Metal Cutting ToolsAlex AdmasNoch keine Bewertungen

- Unit-III - Theory On The Metal Cutting OperationDokument217 SeitenUnit-III - Theory On The Metal Cutting OperationKansath KamalNoch keine Bewertungen

- Chapter 4 Die DesignDokument102 SeitenChapter 4 Die DesignTamirat Nemomsa100% (3)

- Sheetmetal IntroductionDokument9 SeitenSheetmetal IntroductionVinay BalineniNoch keine Bewertungen

- Product Design For Sand CastingDokument10 SeitenProduct Design For Sand CastingChinmay Das100% (7)

- 4 Die DesignDokument40 Seiten4 Die DesignNarendrareddy RamireddyNoch keine Bewertungen

- Cutting Tool Materials: Properties and ApplicationsDokument23 SeitenCutting Tool Materials: Properties and ApplicationsRavichandran G100% (3)

- Unit IV 180208091907Dokument153 SeitenUnit IV 180208091907tamilselvan nNoch keine Bewertungen

- Introduction To Forging ProcessDokument8 SeitenIntroduction To Forging ProcessSirat kalsiiNoch keine Bewertungen

- Types of Forging ProcessesDokument9 SeitenTypes of Forging ProcessesAryan Singh100% (1)

- Hot Forge UpsetDokument13 SeitenHot Forge UpsetAnonymous QiMB2lBCJLNoch keine Bewertungen

- Sheet Forming Processes: Shearing & BendingDokument50 SeitenSheet Forming Processes: Shearing & Bendingsudharsans88Noch keine Bewertungen

- Metal Cutting (F) SDokument62 SeitenMetal Cutting (F) SBrijesh VermaNoch keine Bewertungen

- Sheet MetalDokument11 SeitenSheet Metalshah_faizan123Noch keine Bewertungen

- MFG Tooling - 09 Progressive Dies PDFDokument16 SeitenMFG Tooling - 09 Progressive Dies PDFNhan LeNoch keine Bewertungen

- Scripting Languages1 PDFDokument1 SeiteScripting Languages1 PDFnvemanNoch keine Bewertungen

- Technology of Pharmaceuticals and Fine ChemicalsDokument1 SeiteTechnology of Pharmaceuticals and Fine ChemicalsnvemanNoch keine Bewertungen

- Digital Design Through Verilog HDLDokument1 SeiteDigital Design Through Verilog HDLnvemanNoch keine Bewertungen

- Power Plant Instrumentation PDFDokument1 SeitePower Plant Instrumentation PDFnvemanNoch keine Bewertungen

- Vehicle Transport ManagementDokument1 SeiteVehicle Transport ManagementnvemanNoch keine Bewertungen

- Seemandhra - Co.in - Management Science 1Dokument2 SeitenSeemandhra - Co.in - Management Science 1nvemanNoch keine Bewertungen

- Seemandhra - Co.in - MANAGEMENT - SCIENCE - 1 PDFDokument2 SeitenSeemandhra - Co.in - MANAGEMENT - SCIENCE - 1 PDFnvemanNoch keine Bewertungen

- Reliability Engineering For Me AmeDokument1 SeiteReliability Engineering For Me AmenvemanNoch keine Bewertungen

- Scripting Languages1Dokument1 SeiteScripting Languages1nvemanNoch keine Bewertungen

- Seemandhra - Co.in - Production Planning and Control 0Dokument2 SeitenSeemandhra - Co.in - Production Planning and Control 0nvemanNoch keine Bewertungen

- Seemandhra - Co.in - Artificial Neural Networks 0Dokument1 SeiteSeemandhra - Co.in - Artificial Neural Networks 0nvemanNoch keine Bewertungen

- Web ServicesDokument1 SeiteWeb ServicesnvemanNoch keine Bewertungen

- Seemandhra - Co.in - GAS DYNAMICS 0Dokument2 SeitenSeemandhra - Co.in - GAS DYNAMICS 0nvemanNoch keine Bewertungen

- Seemandhra - Co.in - Maintenance and Safety Engineering 0Dokument1 SeiteSeemandhra - Co.in - Maintenance and Safety Engineering 0nvemanNoch keine Bewertungen

- Seemandhra - Co.in - Rehabilitation and Retrofitting of StructuresDokument1 SeiteSeemandhra - Co.in - Rehabilitation and Retrofitting of StructuresnvemanNoch keine Bewertungen

- Storage Area NetworksDokument1 SeiteStorage Area NetworksnvemanNoch keine Bewertungen

- Design and Drawing of Irrigation StructuresDokument2 SeitenDesign and Drawing of Irrigation StructuresnvemanNoch keine Bewertungen

- Super AlloysDokument1 SeiteSuper AlloysnvemanNoch keine Bewertungen

- Ground Improvement TechniquesDokument1 SeiteGround Improvement TechniquesnvemanNoch keine Bewertungen

- Automation in Manufacturing For MectDokument2 SeitenAutomation in Manufacturing For MectnvemanNoch keine Bewertungen

- Wireless Communications NetworksDokument1 SeiteWireless Communications NetworksnvemanNoch keine Bewertungen

- Wind Engineering and Industrial AerodynamicsDokument1 SeiteWind Engineering and Industrial AerodynamicsnvemanNoch keine Bewertungen

- Design Patterns1Dokument1 SeiteDesign Patterns1nvemanNoch keine Bewertungen

- Automation in Manufacturing For AmeDokument1 SeiteAutomation in Manufacturing For AmenvemanNoch keine Bewertungen

- Alternate Fuels For AutomobilesDokument1 SeiteAlternate Fuels For AutomobilesnvemanNoch keine Bewertungen

- Animal Cell Science and Technology PDFDokument1 SeiteAnimal Cell Science and Technology PDFnvemanNoch keine Bewertungen

- Aero ElasticityDokument1 SeiteAero ElasticitynvemanNoch keine Bewertungen

- RPD Fab Alm Cem Cores GTB Sta GelcastingDokument6 SeitenRPD Fab Alm Cem Cores GTB Sta GelcastingnvemanNoch keine Bewertungen

- Adaptive Control SystemsDokument1 SeiteAdaptive Control SystemsnvemanNoch keine Bewertungen

- MechatronicsDokument1 SeiteMechatronicsnvemanNoch keine Bewertungen

- MT305 Nonferrous Extractive MetallurgyDokument2 SeitenMT305 Nonferrous Extractive MetallurgyMerrin John VarkeyNoch keine Bewertungen

- Production Techniques I (ME F243) : BITS PilaniDokument15 SeitenProduction Techniques I (ME F243) : BITS PilaniDave BatistaNoch keine Bewertungen

- Metal Processes: V L C K ND of Proc H T Ca Ar HDokument2 SeitenMetal Processes: V L C K ND of Proc H T Ca Ar HTere Romero50% (2)

- Hardox 450 Abrasion Resistant Steel Data SheetDokument2 SeitenHardox 450 Abrasion Resistant Steel Data SheetpedroNoch keine Bewertungen

- H.R.Steel Industries: Job Card For M 20X2.5X 155 MM Hex Bolt (HSFG)Dokument1 SeiteH.R.Steel Industries: Job Card For M 20X2.5X 155 MM Hex Bolt (HSFG)mahesh agarwalNoch keine Bewertungen

- RMK Engineering College Question Bank on Unconventional Machining ProcessesDokument7 SeitenRMK Engineering College Question Bank on Unconventional Machining ProcessesUdamanNoch keine Bewertungen

- Manufacturing Technology AnswersDokument32 SeitenManufacturing Technology AnswersDaRkSouLNoch keine Bewertungen

- FGCZ9 Bolt DimsDokument3 SeitenFGCZ9 Bolt DimsColin DNoch keine Bewertungen

- Dos and Donts of SolderingDokument4 SeitenDos and Donts of SolderingJose C. Lita Jr100% (1)

- A 484 - A 484m - 03Dokument16 SeitenA 484 - A 484m - 03etwcNoch keine Bewertungen

- PROJECT1Dokument6 SeitenPROJECT1Ramiro Acosta CepedaNoch keine Bewertungen

- Heat Treatment ProcessesDokument7 SeitenHeat Treatment Processessonu100% (1)

- Taiwan Company ListDokument37 SeitenTaiwan Company ListAh EunNoch keine Bewertungen

- Design of Components With Casting ConsiderationsDokument49 SeitenDesign of Components With Casting ConsiderationsOrville SutariNoch keine Bewertungen

- Limit and Fit - ISO Hole Chart - ToleranceDokument2 SeitenLimit and Fit - ISO Hole Chart - Toleranceagniva datta100% (2)

- The ISASMELT ProcessDokument3 SeitenThe ISASMELT ProcesssatyaNoch keine Bewertungen

- Aluminum and Its AlloyDokument36 SeitenAluminum and Its AlloyRic Rupert Guino-oNoch keine Bewertungen

- MARTEMPERINGDokument9 SeitenMARTEMPERINGviswa dNoch keine Bewertungen

- 10TH - PPT - TECHNICAL TERMS USED IN RESEARCH - ROMBODokument24 Seiten10TH - PPT - TECHNICAL TERMS USED IN RESEARCH - ROMBOAstrea Selene SanfordNoch keine Bewertungen

- Manufacturing TechnologyDokument37 SeitenManufacturing TechnologyHoàng MinhNoch keine Bewertungen

- ZINKLAD 750 2page 231017Dokument2 SeitenZINKLAD 750 2page 231017Jerry ChenNoch keine Bewertungen

- Adu & VduDokument19 SeitenAdu & Vduvijetakumari.201ch059Noch keine Bewertungen

- Norm - EN 197 1 2000 PDFDokument1 SeiteNorm - EN 197 1 2000 PDFrobin rezkNoch keine Bewertungen

- Fastening of Machine Elements - Permanent JointsDokument29 SeitenFastening of Machine Elements - Permanent JointsAhmed IbrahimNoch keine Bewertungen

- 52crmov4 PDFDokument3 Seiten52crmov4 PDFMartin HristovNoch keine Bewertungen

- Pengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDokument7 SeitenPengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDwi BintangNoch keine Bewertungen

- Homemade Bandsaw Plans YouTube PDFDokument3 SeitenHomemade Bandsaw Plans YouTube PDFsanosyNoch keine Bewertungen

- BZ090Dokument3 SeitenBZ090ImronNoch keine Bewertungen

- SWMS Fabrication Works On Pipe With Cutting, Grinding, Welding, Fitting-UpDokument2 SeitenSWMS Fabrication Works On Pipe With Cutting, Grinding, Welding, Fitting-UpCao Anh HuyenNoch keine Bewertungen

- Hot Dip Galvanizing Design ConsiderationsDokument22 SeitenHot Dip Galvanizing Design Considerationsabhi_akNoch keine Bewertungen

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)