Beruflich Dokumente

Kultur Dokumente

Procurement 1 - 2 - Unit 1 - Sources of Supply

Hochgeladen von

hlyeohOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Procurement 1 - 2 - Unit 1 - Sources of Supply

Hochgeladen von

hlyeohCopyright:

Verfügbare Formate

PROCUREMENT 1_2_UNIT 1_SOURCES OF SUPPLY 1.2.1.

1 PURCHASING INFO RECORD Sources of Supply: Overview

In the SAP system, you can use different sources of supply. These include purchasing info record, outline agreement, and plant. The purchasing info record is the source of information for the procurement of a certain material from a certain vendor. In the purchase info record, data such as valid price for a material, invoice currency for vendor, and so on is maintained. The outline agreement is a long-term agreement between the organization and the vendor to cover the supply of material or service for a certain period. A plant in an organization can also be a source of supply to another plant within the same organization. If a material manufactured by one plant is the raw material for another plant, the material can be transferred from the first plant to the second one by creating a stock transfer order. Purchasing Info Record

The purchasing information record is a source of information for the buyer where data for a certain material and the vendor who supplies this material can be maintained. The information that is maintained and used from an info record includes the current prices and delivery costs for the responsible purchasing organization or plant; material number of vendor; delivery options; source data; the number of the last purchase order; the number of the quotation, if the info record has been generated automatically; price control indicator; tolerance limits for over- or under-deliveries; the vendor's planned delivery time for the material. The info record can be created manually as well as automatically by using the info update indicator in an RFQ, PO, and outline agreement. When you use the info update indicator in a PO, the system does not update the price condition, as conditions in a PO are time independent.

Purchasing Info Record: Structure

For Purchasing info record, you can enter data on different levels. General data is entered on client level. Control data, prices and conditions, statistics, and texts can be either entered on level of purchasing organizations, or on both plant and purchasing organization levels.

Default Price from Info Record

Once an info record is created, the system transfers the default valid price from the info record to the purchase order. It is possible to maintain different prices for different plants in an info record. Therefore, during a PO creation, if the valid price for the plant exists in the info record, it gets copied into the PO as the default price.

Info Record for Material Group

Info records can be maintained without a material master record. The material master record can be maintained with the material group. The system suggests info records as sources for material groups when a requisition item is manually created without a material master record. In the PO, however, you will have to assign the info record manually.

Negotiation Preparations Using the Buyer's Negotiation Sheet

A buyers negotiation sheet displays information pertaining to a vendor and the materials supplied by that vendor. It displays a summary of important vendor and material data from the purchasing info record that the buyer needs in order to prepare for price negotiations. It gives details about the current price and vendor conditions, internal consumption statistics for the material, vendor evaluations, and the total value of previous orders to the vendor.

Price Change in Info Record

Let us assume that for a particular vendor, the gross prices of EUR 100 and EUR 120 exist for two different materials. If there is a price increase of 5% (for example, due to market pressures); you can make collective changes to the prices in the info records.

1.2.1.2 CONTRACT Outline Purchase Agreements: Overview

In the SAP system, an outline agreement can be a contract or a scheduling agreement. After you create a contract, you have to create a new purchase order in the system each time you need goods or services. The contract can also be assigned automatically in the PR as a source of supply. On the other hand, for a scheduling agreement, you just have to create a schedule line for delivery of goods when required. It is also possible to generate schedule lines automatically from the planning run. Working with Contracts: Overview

When a contract is created, it can be done with or without a reference. You can create a contract with reference to a PR, RFQ, or outline agreement. You can use different item categories in a contract such as standard, consignment, and so on based on your organizational requirement. New item categories can also be added through Customizing. Contracts can be created with or without a material code. It is also possible to create a contract with the account assignment category U.

Contract Release Documentation

The release documentation is updated for each PO item that is made against a contract. The release documentation contains the details regarding the number of PO and the relevant item, order date, order quantity, and order value. The release documentation provides information on the releases to date for the item, target quantity/value planned for an item, and open quantity/value for the contract item. Contract Types

In the SAP system, you can create two type of contracts Value and Quantity Contracts. To create a value contract, contract type WK should be selected, and to create a quantity contract, contract type MK needs to be selected. Quantity contracts are used when the order needs to be fixed, i.e., when an organization wants that the total order quantity for a certain item should not exceed a predefined limit. Value contracts are used when an organization does not want to spend more than a predefined value on a particular item.

Selection Parameters

Selection parameter helps you define which purchasing documents need to be analyzed. The Scope of list identifies the data to be displayed for the documents you have selected.

Items of Centrally-Agreed and Plant Contracts

You can create a contract with or without a plant assignment. If you assign a plant in the contract, you can place a release order only for the plant assigned in the contract. If you create a contract without plant assignment, you can release an order for all plants in a purchase organization.

Plant Conditions in Centrally-Agreed Contract

It is possible to maintain plant-specific conditions for a centrally agreed contract. You can do this by going to Edit Plant Conditions on the Create Contract screen. In this screen, plant-specific conditions can be maintained. Item Categories M and W

For creating a contract without the material master data, item categories M and W are used. Item category M can be used when the material master record for the required material does not exist. Assume that you have set up a contract with your vendor covering various types of writing paper (lined, squared, blank, two-/four-hole prepunched). The different types of paper have the same weight, quality, and price. When entering this contract item of category M, you enter the short description, material group, target quantity, unit of measure, and price, but no material number. The short description must then be entered in the contract release order. Item category W is used when an order is placed for a group of materials and it is not clear which material will be required in what quantity but the price for all the materials happens to be the same. Assume that you have set up a contract with your vendor for various types of electrical equipment. The precise article is only determined upon ordering. Instead of creating one contract item for each article in the vendor's assortment, you can use item category W and the appropriate material group (for example, equipment). In the release order for this contract, you enter the exact information for the article (for example, a package of cable ties or an electrical socket). Note: The unit of measurement and material group for the material entered should be the same as entered in the contract.

1.2.1.3 SCHEDULING AGREEMENT

Working with Scheduling Agreements: Overview

Scheduling agreements can be created with or without a reference document. The scheduling agreement can be created with reference to an RFQ, PR, or contract. In the scheduling agreement, you can use item categories such as standard, consignment, subcontracting, third-party, and text. When you create a scheduling agreement without a material code, it is necessary to assign the scheduling agreement line item to the account assignment. Automatic Scheduling Agreement Schedule Lines

A scheduling agreement delivery schedule line can be generated automatically through MRP if the scheduling agreement is designated as a source of supply for MRP in the source list; the procurement indicator F (external procurement) is set in the MRP data of the material master record; or automatic scheduling agreement delivery schedules is permitted in the planning run.

Scheduling Agreements without Release Documentation

When scheduling agreements without release documentation, the schedule lines immediately have official character, that is, they are transmitted to the vendor the moment you save them. The document type for scheduling agreement without release documentation is LP.

Scheduling Agreements with Release Documentation

In case of scheduling agreements with release documentation, the schedule lines in the system have internal character. This means that you can change them in any way you wish. The schedule lines stored in the system are transmitted to the vendor only after you explicitly create either a forecast delivery schedule or a JIT delivery schedule. The release documentation allows you to display the releases transmitted to a vendor over a certain period in order to establish exactly when you transmitted which information to the vendor.

Scheduling Agreement with Forecast Delivery Schedule

A scheduling agreement with forecast delivery schedule can be used to give the vendor a medium-term overview of your material requirements. Once you have created a schedule agreement schedule line, you will have to generate a forecast schedule or just-in-time schedule. The release documentation enables you to find out when you sent which information to the vendor.

Scheduling Agreement with Forecast and JIT Delivery Schedules

Just-in-time delivery schedules can be used to inform the vendor of your short-term (near future) requirements. This type of schedule displays the requirements per day or even per hour.

Control Data for Scheduling Agreements

For using the different functionalities in a scheduling agreement, you will have to do some Customizing and create master records. If you want to create a scheduling agreement with release documentation, you will have to set the Release Documentation indicator in Customizing. This indicator is preset for the document type LPA. If you want to use the just-in-time schedule, it is necessary to set the JIT indicator in the material master for the material with which you are going to create the scheduling agreement. You can also use a Release Creation Profile to control the creation periodicity of scheduling agreement releases and the aggregation of scheduled quantities. The system can adopt the creation profile automatically from the vendor master data or you can maintain it manually.

Aggregation with the Release Creation Profile

The release creation profile is an instrument used to determine how frequently releases against a scheduling agreement are generated and sent to the vendor. The creation profile controls the creation periodicity of the scheduling agreement releases and the way in which quantities are aggregated, starting from the current date of release creation. The figure in the slide here explains how the release profile helps aggregate the schedule lines in case of forecast and JIT delivery schedules. In the case of a forecast delivery schedule, for a scheduling agreement where delivery schedule lines covering several months have been maintained, a release creation profile may facilitate releases to be transmitted weekly. While in the JIT schedule, for a scheduling agreement for which delivery schedule lines covering several months have been maintained, a release creation profile may facilitate the JIT schedules to be transmitted, generated daily and forecast schedules to be transmitted only in the event of changes in the delivery scheduling data that exceed predefined tolerances.

Tolerance Limits for Scheduling Agreement Items

The slide here shows how the system checks new quantities, and if they are beyond the permissible tolerance, then a new FRC/JIT schedule is created. For instance, instead of the original 100 pieces, 103 pieces are now needed. This represents a change of 3% in the quantity. Since the upper tolerance limit for forecast delivery schedule (2%) is thus exceeded, a new forecast delivery schedule is generated for issue to the vendor.

Firm and Trade-Off Zones

For an item of a scheduling agreement, you can define a firm zone and a trade-off zone: The firm zone defines the point in time at which the production go-ahead period ends. The production go-ahead period begins with the current date. The schedule lines falling within this zone or period are fixed and thus can be regarded as equivalent to firm orders. The trade-off zone defines the point in time at which the material go-ahead period ends. The material go-ahead period begins with the end of the production go-ahead period. Delivery schedule lines falling within this period can be less binding in nature than those in the firm zone.

Module Summary This module is now complete. You should now be able to create purchasing info records, create and change conditions in purchasing info records, use the buyer's negotiation sheet, create centrally agreed contracts and plant contracts, use item categories M and W in contracts, create contract release orders for different types of contract items, create scheduling agreements, maintain scheduling agreement schedule lines and generate scheduling agreement releases, use the functions of the release creation profile, and distinguish between forecast and JIT delivery schedules.

Das könnte Ihnen auch gefallen

- Procurement 1 - 2 - Unit 3 - Optimized Purchasing & Invoice PlanDokument30 SeitenProcurement 1 - 2 - Unit 3 - Optimized Purchasing & Invoice Planhlyeoh100% (1)

- TERP02 - Introduction To SAP NetWearverDokument11 SeitenTERP02 - Introduction To SAP NetWearverhlyeohNoch keine Bewertungen

- OM HR ProcessesDokument6 SeitenOM HR ProcesseshlyeohNoch keine Bewertungen

- Book 1 - PA Week Two HR Week 2 eDokument8 SeitenBook 1 - PA Week Two HR Week 2 ehlyeohNoch keine Bewertungen

- Exercise - Infotype AttributesDokument14 SeitenExercise - Infotype AttributeshlyeohNoch keine Bewertungen

- Exercise - Infotype Menus and Parameter AssignmentDokument17 SeitenExercise - Infotype Menus and Parameter AssignmenthlyeohNoch keine Bewertungen

- Exercise - Display Employee Groups and SubgroupsDokument14 SeitenExercise - Display Employee Groups and SubgroupshlyeohNoch keine Bewertungen

- WorksDokument6 SeitenWorkshlyeohNoch keine Bewertungen

- WorksDokument6 SeitenWorkshlyeohNoch keine Bewertungen

- Exercise - Display Employee Groups and SubgroupsDokument14 SeitenExercise - Display Employee Groups and SubgroupshlyeohNoch keine Bewertungen

- Exercise - Creating and Assigning Pay Scale Area and TypeDokument14 SeitenExercise - Creating and Assigning Pay Scale Area and TypehlyeohNoch keine Bewertungen

- WorksDokument6 SeitenWorkshlyeohNoch keine Bewertungen

- WorksDokument6 SeitenWorkshlyeohNoch keine Bewertungen

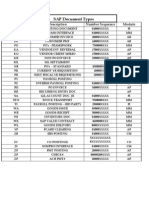

- Document Types in SAPDokument1 SeiteDocument Types in SAPhembeck119Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Conflict Management and Negotiation SkillsDokument22 SeitenConflict Management and Negotiation SkillsVikas Singh100% (1)

- Chapter 7 MasterDokument4 SeitenChapter 7 MasterSanjayDominiqueNoch keine Bewertungen

- Ir PresentationDokument25 SeitenIr Presentationhayat hanimNoch keine Bewertungen

- Genesys Cheat Sheet 0.9.5 PDFDokument5 SeitenGenesys Cheat Sheet 0.9.5 PDFArturo_U__1558Noch keine Bewertungen

- Keynote Speech IPITS Graduate School DR Vincentius Raki MahindaraDokument27 SeitenKeynote Speech IPITS Graduate School DR Vincentius Raki MahindaraAndi Muhammad Alfian ArafatNoch keine Bewertungen

- Procurement Raw Materials - DocxDokument12 SeitenProcurement Raw Materials - DocxAvnit kumarNoch keine Bewertungen

- Unit VDokument43 SeitenUnit VRUCHITA NAMBALLA VP21MGMT0100065Noch keine Bewertungen

- Consumer Electronics Servicing NC IIIDokument68 SeitenConsumer Electronics Servicing NC IIIMichael V. MagallanoNoch keine Bewertungen

- Stress and Conflict ManagementDokument6 SeitenStress and Conflict ManagementFERINALYN MontesNoch keine Bewertungen

- Selling & Negotiation Skills-PPT1Dokument52 SeitenSelling & Negotiation Skills-PPT1Debasree ChowdhuryNoch keine Bewertungen

- Slqs JournalDokument58 SeitenSlqs JournalMdms Payoe100% (1)

- Cooperative Negotiation Harvard PDFDokument76 SeitenCooperative Negotiation Harvard PDFdjamaludin djamaludinNoch keine Bewertungen

- Cross Cultural Issues in International BusinessDokument25 SeitenCross Cultural Issues in International BusinessSharron Michelle BharathNoch keine Bewertungen

- Business Communication For Managers - Payal Mehra - Business Communication For Managers (2016, Pearson India)Dokument433 SeitenBusiness Communication For Managers - Payal Mehra - Business Communication For Managers (2016, Pearson India)Tor 1Noch keine Bewertungen

- 3 1+readingc1-ManagersDokument2 Seiten3 1+readingc1-ManagersAlba etceteraNoch keine Bewertungen

- BSBLDR513 Learner Guide V2.0-1Dokument76 SeitenBSBLDR513 Learner Guide V2.0-1Balwinder KaurNoch keine Bewertungen

- Sales Process GuideDokument2 SeitenSales Process GuideHarsh Vijay Singh100% (1)

- Draft Pitch DeckDokument73 SeitenDraft Pitch DeckShebgatul MursalinNoch keine Bewertungen

- Lesson 6 Persuasion and Negotiating SkillsDokument3 SeitenLesson 6 Persuasion and Negotiating SkillsMelvinNoch keine Bewertungen

- Timor-Leste Vs Australia - SummaryDokument17 SeitenTimor-Leste Vs Australia - Summarybebs CachoNoch keine Bewertungen

- Negotiation TechniquesDokument14 SeitenNegotiation TechniquesND PROJECT IDNoch keine Bewertungen

- Pradipta Diwangkara - 29320469 - SMEMBA 5 - Planning For NegotiationsDokument3 SeitenPradipta Diwangkara - 29320469 - SMEMBA 5 - Planning For NegotiationsFau ZanNoch keine Bewertungen

- Iqra SP17-BBA-005: COMSATS University Islamabad, Wah Campus Terminal Exam SP2020Dokument18 SeitenIqra SP17-BBA-005: COMSATS University Islamabad, Wah Campus Terminal Exam SP2020Esha 1277-FBAS/BSBT/F19Noch keine Bewertungen

- 0454 Enterprise: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of TeachersDokument10 Seiten0454 Enterprise: MARK SCHEME For The May/June 2011 Question Paper For The Guidance of Teacherssaleha imranNoch keine Bewertungen

- (Alan M. Lesgold, James W. Pellegrino, Sipke) Cognitive Psychology & InstructionDokument197 Seiten(Alan M. Lesgold, James W. Pellegrino, Sipke) Cognitive Psychology & InstructionDũng LêNoch keine Bewertungen

- Section 37 Review - Final Report (January 2014)Dokument62 SeitenSection 37 Review - Final Report (January 2014)T.O. Nature & DevelopmentNoch keine Bewertungen

- CAO Director Global Real Estate in New York City Resume Robert CapuaDokument2 SeitenCAO Director Global Real Estate in New York City Resume Robert CapuaRobertCapuaNoch keine Bewertungen

- Case Study On Sales & Distribution ManagementDokument9 SeitenCase Study On Sales & Distribution ManagementMOHD.ARISH100% (1)

- Negotiation - Harvard Law SchoolDokument8 SeitenNegotiation - Harvard Law SchoolLukman Jahja100% (2)

- Orca Share Media1550407284187Dokument2 SeitenOrca Share Media1550407284187CH IrtazaNoch keine Bewertungen