Beruflich Dokumente

Kultur Dokumente

Marking and Meaning of ATEX Regulations (Quoted PEPPERL+FUCHS)

Hochgeladen von

Hoang CongOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Marking and Meaning of ATEX Regulations (Quoted PEPPERL+FUCHS)

Hochgeladen von

Hoang CongCopyright:

Verfügbare Formate

PROTECTING YOUR PROCESS MARKING AND MEANING OF ATEX REGULATIONS

CLASSIFICATION OF EXPLOSION HAZARDOUS ENVIRONMENTS

IEC/EN 60079-10

A place in which an explosive atmosphere consisting of a mixture with air of ammable substances in the form of gas, vapor or mist is

IEC/EN 61241-10

A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is

ZONE 0

if present continuously or for long periods or frequently.

ZONE 1 if likely to occur in normal

operation occasionally.

ZONE 2 if not likely to occur in normal

operation but, if it does occur, will persist for a short period only.

ZONE 20 if present continuously, or for

long periods or frequently for short periods.

ZONE 21 if likely to occur occasionally in

normal operation.

ZONE 22 if not likely to occur in normal

operation but, if it does occur, will persist for a short period only.

The employer or person responsible for safety shall classify places where explosive atmospheres may occur into zones in accordance with Annex I [...] and [...] shall ensure that the minimum requirements laid down in Annex II are applied [...] to these zones.

Source: directive 1999/92/EC, article 7

INSTALLATION AND SELECTION OF APPARATUS

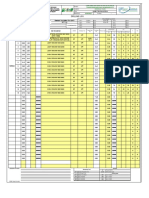

SELECTION OF ELECTRICAL APPARATUS, PROTECTION FROM DANGEROUS SPARKING, WIRING SYSTEMS AND FURTHER REQUIREMENTS ACCORDING TO IEC/EN 60079-14 (GAS) AND IEC/EN 61241-14 (DUST) Device groups

Group I comprises equipment which is approved for operation in redamp endangered mines. Group II applies to the areas above-ground, such as chemical/ petrochemical plants, reneries and mills (dust). For the ignition protection classes Intrinsic safety and Flameproof enclosure, a further classication is made into the groups IIA to IIC due to the different ignition energies of the different gases.

Temperature classes

Electrical equipment of group II is divided into temperature classes according to its maximum surface temperature. In the same manner, the gases are classied on the basis of the different ignition temperatures. Highest surface temperature at the apparatus:

Meaning of optional brackets

[E Ex ib]

Corresponding electrical equipment is located in the safe area. Signal lines lead to the explosion hazardous area.

CENELEC Typical marking gas

ADDITIONAL MARKING ACCORDING TO DIRECTIVE 94/9/EC (ATEX 95)

Certied according to the European CENELEC standard EN 50.../ EN 60079-...

Ignition engergy J 280 > 180 60...180

T1 T2 T3 T4 T5 T6

450 C 300 C 200 C 135 C 100 C 85 C

Explosion proof

I II A II B II C

Methane Propane Ethylene

Hydrogen < 60

II 2 G

Design tested according to Directive 94/9/EC Device Group I = Mining Equipment II = Surface Industries Application area

Equipment that is certied according to the ATEX 95 directive is provided with an additional marking that describes the usage site (or, in the case of corresponding electric equipment, explains to where the signal lines may lead). First the device groups appear, then the category and nally the information concerning the atmosphere (gas and/or dust). The following category division applies to device group II:

E Ex ib IIC T4

MARKING ACCORDING TO IEC/EN 60079 MARKING ACCORDING TO EN 50014 Types of Protection

Marking code EEx d EEx e EEx p EEx m EEx o EEx q EEx i EEx n nA Non-sparking equipment (rotating machines, fuses, luminaries, measuring instruments and low power equipment) nC Sparking equipment with hot surfaces (closed switchgear and non-igitable components, hermetically sealed equipment, tightly sealed equipment) nR Equipment protected by a restricted breathing enclosure nL Energy-limited equipment and electric circuits (to be integrated into EEx ic-Standard)

Subject to reasonable modifications due to technical advances Copyright PEPPERL+FUCHS Printed in Germany Part. No. 204806 09/07 00

Type of Protection Protection principle

General requirements

Flameproof enclosure Transmission of an explosion to the outside is excluded

Increased safety Prevention of sparks and temperatures

Pressurized apparatus Ex atmosphere is isolated from the source of ignition

Encapsulation

Oil immersion Ex atmosphere is isolated from the source of ignition

Powder lling Transmission of an explosion to the outside is excluded

Intrinsic safety Energy restriction of sparks and temperatures

Type of protection n Different protection principles for Zone 2

Ex atmosphere is isolated from the source of ignition

Category 1 Very high safety measure Sufcient safety by means of 2 protective measures / 2 faults

Category 2 High safety measure Sufcient safety in the case of frequently occuring equipment faults / 1 fault For use in Zone 1 21 Atmosphere G D

Category 3 Normal safety measure Sufcient safety during normal operation

Application in zone CENELEC* standard IEC/EN standard Use EN 50014 IEC 60079-0

1 or 2 EN 50018 IEC 60079-1

1 or 2 EN 50019 IEC 60079-7

1 or 2 EN 50016 IEC 60079-2***

1 or 2 EN 50028 IEC 60079-18

1 or 2 EN 50015 IEC 60079-6

1 or 2 EN 50017 IEC 60079-5

0,1 or 2**** EN 50020

2 EN 50021

IEC 60079-11** IEC 60079-15

All applications

For use in Zone 0 20 Atmosphere G D

For use in Zone 2 22 Atmosphere G D

Control units, controllers, engines, command & monitoring units, power electronics

Branching and connecting boxes, housings, engines, luminaires, terminals

Control cabinets, engines, measurement and analytical equipment, computers

Relay and engine coils, electronics, solenoid valves, connecting systems

Transformers, relays, start-up controls, switching devices

Transformers, relays, condensors

Measurement, All applications control and for zone 2 regulation technology, instrumentation

G=Gas, D=Dust For details on dust explosion protection please refer to the Pepperl+Fuchs Explosion Protection Manual.

* Cenelec Standards in process of being transferred to IEC/EN Norms. ** Equipment, *** Systems, **** ia used in Zone 0,1 and 2, **** ib used in Zone 1 and 2, **** ic used in Zone 2 For non-electric explosion protection please refer to the Pepperl+Fuchs Explosion Protection Manual.

INSPECTION AND MAINTENANCE

DIRECTIVE 1999/92/EC (MINIMUM REQUIREMENTS FOR IMPROVING THE SAFETY AND HEALTH PROTECTION OF WORKERS POTENTIALLY AT RISK FROM EXPLOSIVE ATMOSPHERES), ANNEX II:

All necessary measures must be taken to ensure that the workplace, work equipment and any associated connecting device [] are maintained and operated in such a way as to minimize the risks of an explosion []. The IEC/EN 60079-17 and IEC/EN 61241-17 respectively assists on complying with this legal requirement by describing various items such as the basics of inspection and maintenance with regard to documentation, qualication of personnel, extent and manner of inspections and schedules. Important: the valid national and regional standards and regulations must be observed. Are you interested in more detailled information on explosion protection? Please dont hesitate to contact your local Pepperl+Fuchs representative and ask for the comprehensive Explosion Protection Manual and Video-DVD. The manual is also available as free download on www.pepperl-fuchs.com.

PEPPERL+FUCHS AND THE PROCESS AUTOMATION MARKET

Pepperl+Fuchs delivers electronic instrumentation for the automation market. With over 3,400 employees in more than 30 countries to design, produce and distribute products, we are located where our customers need us. The Process Automation Division is the market leader for intrinsic safety interfaces and hazardous location equipment. Our FieldConnex Fieldbus Installation System provides highest exibility to modern process automation applications while the BEBCO EPS Purge & Pressurization System offers protection for any type of instrumentation. This comprehensive range of explosion protection systems is complemented by further leading-edge technologies such as EXTEC Visualization+Operation Systems, Separator Alarm Systems, Level and Corrosion Monitoring devices and, of course, our world-wide support services. Pepperl+Fuchs is the recognized expert in our technologies and we have earned this reputation by supplying the worlds largest process industry companies with the broadest line of proven components for a diverse range of applications.

www.pepperl-fuchs.com

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- StruCalc 60 TutorialDokument21 SeitenStruCalc 60 TutorialHoang CongNoch keine Bewertungen

- Punchlist Items For Tay Ninh Cement Plant 050309 Quoted 13-16Dokument1 SeitePunchlist Items For Tay Ninh Cement Plant 050309 Quoted 13-16Hoang CongNoch keine Bewertungen

- Japanese H SectionsDokument4 SeitenJapanese H SectionsHoang CongNoch keine Bewertungen

- American HPDokument2 SeitenAmerican HPTuan Nguyen MinhNoch keine Bewertungen

- Classifications of PumpsDokument3 SeitenClassifications of PumpsHoang CongNoch keine Bewertungen

- Condensate PumpingDokument2 SeitenCondensate PumpingHoang CongNoch keine Bewertungen

- Assembly Instructions For Bondstrand Fiberglass FlangesDokument8 SeitenAssembly Instructions For Bondstrand Fiberglass FlangesHoang CongNoch keine Bewertungen

- 5G-RANGE Brazil Attachment - 0Dokument73 Seiten5G-RANGE Brazil Attachment - 0ALEXANDRE JOSE FIGUEIREDO LOUREIRONoch keine Bewertungen

- Unity P Replication Config PDFDokument94 SeitenUnity P Replication Config PDFgupteshbheriNoch keine Bewertungen

- Datasheet IC 3771 PDFDokument20 SeitenDatasheet IC 3771 PDFekodianirawanto100% (1)

- 7.SAP2000 Report With StiffenerDokument36 Seiten7.SAP2000 Report With StiffenerAlaa Al-habashNoch keine Bewertungen

- Security Issues in EcommerceDokument12 SeitenSecurity Issues in EcommerceDBS MANFESTNoch keine Bewertungen

- Syllabus ptsv2Dokument7 SeitenSyllabus ptsv2adam593Noch keine Bewertungen

- Job Details - Join Indian NavyDokument6 SeitenJob Details - Join Indian NavySaurabh KatkarNoch keine Bewertungen

- Panasonic Ptae700 Service ManualDokument215 SeitenPanasonic Ptae700 Service ManualTarra Ramakrishna RaoNoch keine Bewertungen

- DRF450 Workshop Manual VDRF03 - 02GB PDFDokument128 SeitenDRF450 Workshop Manual VDRF03 - 02GB PDFANH LÊ100% (1)

- 12drilling Log Spt04 160622Dokument2 Seiten12drilling Log Spt04 160622Angelica E. Rabago LopezNoch keine Bewertungen

- Budgeting and Financing Substation: SubstationsDokument2 SeitenBudgeting and Financing Substation: SubstationsManuel Henríquez SantanaNoch keine Bewertungen

- Mini Agri Operation and Maintenance ManualDokument234 SeitenMini Agri Operation and Maintenance ManualYahya KhadhraNoch keine Bewertungen

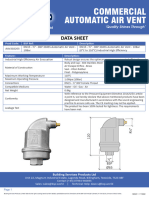

- BSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022Dokument1 SeiteBSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022j.iqubalNoch keine Bewertungen

- Siebel 8.1 Integration With Avaya IC 7.2Dokument3 SeitenSiebel 8.1 Integration With Avaya IC 7.2Shipra JainNoch keine Bewertungen

- Gda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Dokument17 SeitenGda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Vũ Khánh Trang BùiNoch keine Bewertungen

- Sunrise Systems: Presentation Pipenet SoftwareDokument35 SeitenSunrise Systems: Presentation Pipenet SoftwareKathirNoch keine Bewertungen

- A Driving Simulator As A Virtual Reality ToolDokument6 SeitenA Driving Simulator As A Virtual Reality ToolmiaNoch keine Bewertungen

- TLE Grade 10Dokument13 SeitenTLE Grade 10Althea Bonggal100% (1)

- Time: 20 Minutes Date: 16-7-2022 FN Max Marks:10 Name: H.T. No: Sign. of An InvigilatorDokument4 SeitenTime: 20 Minutes Date: 16-7-2022 FN Max Marks:10 Name: H.T. No: Sign. of An InvigilatorHOD CIVILNoch keine Bewertungen

- Epson Workforce Enterprise WF-C20600 - 20750 - 21000 (April2021)Dokument12 SeitenEpson Workforce Enterprise WF-C20600 - 20750 - 21000 (April2021)John Christopher Z. RectoNoch keine Bewertungen

- Urn - Isbn - 978 952 61 4462 7Dokument278 SeitenUrn - Isbn - 978 952 61 4462 7Sami BEN AISSIANoch keine Bewertungen

- ICT 34 Data Structures and Analysis of AlgorithmDokument9 SeitenICT 34 Data Structures and Analysis of AlgorithmKimondo KingNoch keine Bewertungen

- Elec Grs Pumps 203seriesDokument5 SeitenElec Grs Pumps 203serieschand_yelNoch keine Bewertungen

- Mutoh PhotoPrintDX10 SpectoVue ProfilingDokument12 SeitenMutoh PhotoPrintDX10 SpectoVue ProfilingДенис ЛобачевскийNoch keine Bewertungen

- SURVEYING WITH A TOTAL STATIONDokument65 SeitenSURVEYING WITH A TOTAL STATIONBindeshwar YadavNoch keine Bewertungen

- Resume Amit BhagwatDokument5 SeitenResume Amit Bhagwatabh93071046100% (3)

- Apollo Saturn V Facility Description Vol. 3Dokument124 SeitenApollo Saturn V Facility Description Vol. 3Bob Andrepont86% (7)

- Résumé For Arjun JayaramanDokument1 SeiteRésumé For Arjun JayaramanArjun JayaramanNoch keine Bewertungen

- Apc7900 PDFDokument186 SeitenApc7900 PDFhalasz_evaNoch keine Bewertungen

- Ciena DTM-100G2 - DS PDFDokument2 SeitenCiena DTM-100G2 - DS PDFrobert adamsNoch keine Bewertungen