Beruflich Dokumente

Kultur Dokumente

Quick Choice Of: Temperature Controls

Hochgeladen von

Lim Chee SiangOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quick Choice Of: Temperature Controls

Hochgeladen von

Lim Chee SiangCopyright:

Verfügbare Formate

9.0.

00-E GB

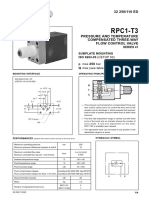

Quick Choice of

Temperature Controls

Sizing of Valves and Actuators

C o n t r o l s A/S

- ensures reliable control of heating, cooling and ventilation systems.

Quick Choice of Temperature Controls

Ever since 1902 we have produced reliable temperature controls for nearly all forms of water, oil and steam systems. The experience thereby gained has formed the basis of the present control and valve programme, which makes it possible to determine the optimal combination of valve and actuator. To avoid noise as well as wear and tear the sizing pressure drop pV across control valves for water should not exceed 1 bar in domestic premises. Otherwise the control should be distributed on more valves. pV must be at least 10% of the total pressure drop of the control circuit. Control circuits with 2-way valves should be sized so that the pressure drop across the valve pAB is 30-50% of the total pressure drop of the control circuit (pAB + pBA ), fig. 1. In diagram 1 the correct valve size is determined by the intersection between the lines for the water flow G and the pressure drop pV (e.g. 32 mm valve). The required proportional band (green field) and the max pressure pL, against which the controller is to close, is decisive for the choice of thermostat etc. which can be found from the table e.g. 32 mm single seated valve + V8.09 thermostat (pL = 6,8 bar) or 32 mm M3F valve + V4.10 thermostat (pL = 12 bar). When controlling cooling systems with V-thermostat and 2-way valve, reverse acting valves type L2SR, M2FR, G2FR or H2FR should always be used. See data sheet. Control Systems for Steam Only 2-way valves should be used for steam. Necessary sizing values: Control circuits with 3-way valves should be sized so that the following rules are observed: 1. The pressure drop across the valve port A and AB (pAAB) is more than 50% of the pressure drop across the section C-A (pCA), fig. 2 and 3. 2. The pressure drop across the section C-A (pCA) should be less than 25% of the pump pressure H, fig. 2 and 3. 3. The pressure drop across the section C-A (pCA) should be equal to the pressure drop across the section C-B (pCB), fig. 2 and 3. 1. Max. steam flow: G ton/h (e.g. G = 1,5 ton/h) 2. Inlet pressure (saturated steam) p1 bar absolute (e.g. p1 = 10 bar) 3. Steam temperature T at p1 bar (e.g. T = 179C) 4. Variation of load in the system (e.g. medium = green field) In diagram 2 the vertical line for the actual inlet pressure p1 should be followed to the intersection with the line for = 0,42 (or below if a smaller is specified). The intersection between the horizontal line from this point and the line for steam flow G lies in the field for the optimal valve size (e.g. 40 mm valve). The required proportional band (green field) and the max pressure pL, against which the controller is to close, is decisive for the choice of thermostat etc. which can be found from the table e.g. 40 mm single seated balanced M1FB valve + V8.09 thermostat (pL = 11 bar). Valve Material The necessary valve material is determined by diagram 3 at the intersection for the actual temperature and pressure lines. Control Systems for Other Media Oil systems with viscosity vk in: should If actual cSt < be sized as water systems. The flow G measured in m3/h. If measured in kg/h, G will have to be divided by the density of the oil (in kg/m3) before entering diagrams. When sizing other oil systems or systems for other media please contact our company.

Control types

Self-acting Temperature Controllers Work on the liquid expansion principle without any auxiliary energy P-controls Reliable under all conditions Secured against over-temperature Electronic Temperature Controllers Low energy consumption PI and PID performance Adjustable PID-values Many adjustment possibilities

Control Valves

All of our control valves fulfil the demands for seat leakage as per VDI/VDE 2174, i.e. the flow through the closed valve is less than the percentage of full flow (by same pV) indicated in this table: Type of valve Max. seat leakage

0,05% 0,05% 0,5% 0,5%

Single seated Single seated, balanced Double seated 3-way

Regarding the control characteristics and general characteristics of the valves, please refer to the corresponding data sheets. We can deliver the valves with certificates from the maritime classification companies.

Sizing of Controls

General points The diagrams have been worked out to obtain the optimal combination of valve and thermostat etc. In order to secure stability in the control circuit the following points should be observed: The valve is to be sized according to load and pressure over sizing (too big valve) corresponding to a large proportional band (PB) may cause unstable control. In case of thermostat control with large load variations a small proportional band should be avoided. The proportional band (PB) is calculated as the rated travel (mm) of the valve divided by the amplification of the thermostat (mm/C) = the two last figures of the type description of the V-thermostat. It is strongly recommended to calculate the PB. Example: 20 M1F valve (rated travel 6.5 mm) with V4.05 thermostat: PB= 6,5/0,5 = 13C Experience shows that a PB-value in the green field, 8-13C, is often to be preferred: Load variation

Small Medium Large

Control Systems for Water Necessary sizing values: 1. Max. water flow: G m3/h (e.g. G = 3,0 m3/h) 2. Pressure drop pV in bar across valve at G m3/h (e.g. pV = 0,1 bar). 3. Pressure drop pL in bar across closed valve (e.g. pL = 5,0 bar) 4. The working pressure of the system p bar (e.g. p = 5 bar) 5. The working temperature of the system T C (e.g. T = 90C) 6. Load variation of the system (e.g. medium = green field)

Proportional band (PB)

4-8 C 8-13 C Above 13 C

Colour

Red Green Yellow

Sizing for Water

Flow rate G l/h

40 50 60 80 100 200 300 400 500 600 800 1 20 30 8 10 2 3 Pressure drop pV in bar across the valve 10 6 4 5 6

Diagram 1

Flow rate G m3/h

800 1000 80 100 200 300 400 500 600 20 30 40 50 60

5:1

42 0, 25 0, 0, 02 0, 20 30

4

0 5 5 5 ,5 0,2 0,4 0,9 2,7 1 ,7 5 ,0 7 ,5 20 30 80 50 12 21 12 31

kVS-value:

0,

1 0,6 0,4

0,2

0,1 0,06 0,04

= p p V

0,

42

/4

/6

/9

/12

0,

Actual pV at 3 m3/h and 32 mm valve: 0,06 bar

0 5 0

0,

05

10

65

10

20

25

50

32

15

15

15

15

15

40

80

12

15

0,02

0,01 1 2 3 4 5 6 7 8 10 20 30 Inlet pressure p1 bar (absolute)

0,

Valve size in mm

01

0,

15

15/4

15/6 16 21

15/9 16 13

21

40

16 40

16 38

40

16 40

16 38

40

40

40

40

40

40

15/12 15 20 25 32 40 50 65 Max. pressure in bar (pL), against which the control can close 11 6,7 3,8 6 10 6,1 2,8 1,8 0,9 16 13 7,8 3,5 2,5 16 14 7,9 4,3 3,3 5,4 5,4 2,2 1,9 16 16 9,8 16 25 16 7,6 5 2,8 1,8 1,4 15 12 8,8 6,5 40 40 25 21 14 9,2 10 10 9,2 9,2 6,6 6,6 4,2 2,2 1,9 10 10 6,2 6,2 3,3 14 12 8 6,8 5,4 19 16 9,1 7,7 14 10 8 6,3 4 16 16 9,8 16 25 16 7,6 5 2,8 1,8 1,4 15 12 8,8 6,5 40 40 25 21 14 9,2 10 10 9,2 9,2 6,6 6,6 4,2 2,2 1,9 10 10 6,2 6,2 3,3 14 12 8 6,8 5,4 19 16 9,1 7,7 14 10 8 6,3 4 40 36 17 11 6,8 4,3 3,3 22 20 14 12 10 40 40 40 40 40 25 10 10 10 10 10 10 10 2,2 1,9 10 10 6,2 6,2 3,3 40 40 25 22 16 14 10 8 6,3 4 40 36 17 11 6,8 4,3 3,3 22 20 14 12 10 40 40 40 40 40 25 10 10 10 10 10 10 10 2,2 1,9 10 10 6,2 6,2 3,3 40 40 25 22 16 14 10 8 6,3 4 16 11,3 16 27 10 20 40 10 10 40 10 10 20 40 10 10 40 10 6,8 14 40 10 6,2 40 8 5,3 12 40 10 6,2 40 6,3

80 1)

100

125

150

7,3 3,7 2,9 3,7 2,9

5,7 2,9 2,1 2,9 2,1

3,8

2,7

7,3 3,7 2,9 3,7 3,9 5,2 20 10 2,9 10 2,9 5,2 20 10 2,9 10 2,9

5,7 2,9 2,1 2,9 2,1

3,8

2,7

17 10 2,1 10 2,1

11 5,9 3,2 6 3,3

9,3 5,9 3,2 4,3 2,1

17 10 2,1 10 2,1

11 5,9 3,2 6 3,3

9,3 5,9 3,2 4,3 2,1

Valve size in mm Type of valve 3) L1S / L1SB M1F, G1F, H1F L2S M2F, G2F, H2F 4) L3S 5) L3S L1S / L1SB M1F, G1F, H1F M/G/H1FB L2S, M/G/H2F 4) L3S, L3F 5) L3S, L3F 4) M3F 4) G3F, H3F 5) M3F, G3F, H3F L1S / L1SB M1F, G1F, H1F M/G/H1FB L2S, M/G/H2F 4) L3S, L3F 5) L3S, L3F 4) M3F 4) G3F, H3F 5) M3F, G3F, H3F L1S, M/G/H1F M/G/H1FB L2S, M/G/H2F 4) L3S, L3F 5) L3S, L3F 4) M3F, G3F, H3F 5) M3F, G3F, H3F L1S, M/G/H1F M/G/H1FB L2S, M/G/H2F 4) L3S, L3F 5) L3S, L3F 4) M3F, G3F, H3F 5) M3F, G3F, H3F L1UP, L1IP

Actuator single seated double seated 3-way single seated (200 N) 2) Type V2.05

Type V4.05, single seated,bal. TD-58, double seated TD-66-4 3-way (400 N) single seated Type V4.10, single seated,bal. TD-58, double seated TD-66-4 3-way (400 N) single seated Type single seated,bal. V8.09 double seated and type TD-66-8 3-way (800 N) single seated Type single seated,bal. V8.18 double seated and type TD-66-8 3-way

2)

2)

2)

single seated

(800 N) Valve motor type MT40/A (450 N)

16 18 22 40 40 10 10 10 2,2 1,9 10 40 14 16 16 16 16 16 16 40 40 40 40 40 27 18 22 40 40 10 10 10 2,2 1,9 10 40 14 1 bar = 100 kPa = 10,2 mVS = 0,99 Atm. = 1,02 kp/cm2 40

16 40

16 40

16 40

16 40

6,8 5,3 14 12 10 7/3,8 40 40 25 25/17 10 10 10 10 6,2 6,2 3,3 2,9 40 40 16 10 8 6,3 4 2,9 1 cSt = 0,01 St = 10-6 m2/sec.

L1S / L1SB M1F, G1F, H1F M/G/H1FB L2S, M/G/H2F 4) L3S, L3F 5) L3S, L3F 4) M3F, G3F, H3F 5) M3F, G3F, H3F L1S / L1SB M1F, G1F, H1F M/G/H1FB 25/14 19/7 16/5,3 L2S, M/G/H2F 10 10 10 4) L3S, L3F 2,1 3,2 3,2 5) L3S, L3F 10 10 9,4 4) M3F, G3F, H3F 2,1 3,3 2,1 5) M3F, G3F, H3F E into cSt: vk 7,6 x E (1-1/E3)

single seated Valve motor type VB, VBA single seated,bal. up to DN 50 double seated 3-way (1200 N) single seated Valve motor single seated,bal. type V, AV double seated 3-way (1200 N) 3)

Sizing for Steam

Flow rate G kg/h

100 200 300 400 500 600 800 0,8 10 20 30 40 50 60 80 1 2 3 4 5 6 8 1 2 3 4

Diagram 2

Flow rate G t/h

100 120 24 16 13 15,5 11 350 C 10 20 30 40 50 60 80 5 6 8

20

45

95

75

,5

5 21

kVS-value:

1, 7

7, 5

5, 0

20

12

Actual pV at 1,5 t/h and 40 mm valve: = x p1 = 0,15 x 10 = 1,5 bar

/1

15

32

40

50

10

12

20

30

40

15

15

20

25

65

80

15

15

15

Valve size in mm

/4

/6

/9

15/4

15/6 16 20 16 40

15/9 16 13 16 38

20

40

40

16 40

16 38

40

16 40

16 40

40

16 40

16 40

15/12 15 20 25 32 40 50 65 Max. pressure in bar (pL), against which the control can close 10 6 2,9 5 9,3 5,3 1,9 0,9 15 13 7,3 3,8 2,7 16 16 9 16 24 15 6,7 4,1 1,9 0,8 0,4 15 12 8,1 5,7 40 40 24 20 17 8,4 16 16 9 16 24 15 6,7 4,1 1,9 0,8 0,4 15 12 8,1 5,7 40 40 24 20 17 8,4 16 16 16 13 40 35 16 10 5,8 3,3 2,3 18 14 11 8,7 6,4 40 40 40 40 40 24 16 16 16 13 40 35 16 10 5,8 3,3 2,3 18 14 11 8,7 6,4 40 40 40 40 40 24 16 10,4 16 26 40 16 17 18 40 9,8 14 40 5,8 11 40 4,3 8,7 40

80 1)

100

125

150

6,5

4,9

2,9

1,8

6,5

4,9

2,9

1,8

4,3 19

16

10

8,4

4,3 19

16

10

8,4

Valve size in mm Type of valve 2) L1S / L1SB single seated M1F, G1F, H1F M2F, G2F, H2F double seated L1S / L1SB single seated M1F, G1F, H1F M/G/H1FB single seated, bal. M2F, G2F, H2F double seated L1S / L1SB single seated M1F, G1F, H1F M/G/H1FB single seated, bal. M2F, G2F, H2F double seated L1S / L1SB single seated M1F, G1F, H1F M/G/H1FB single seated, bal. M2F,G2F, H2F double seated L1S / L1SB single seated M1F, G1F, H1F M/G/H1FB single seated, bal. M2F,G2F, H2F double seated L1UP, L1IP

Actuator Type V2.05 (200 N) Type V4.05 (400 N) Type V4.10 (400 N) Type V8.09 (800 N) Type V8.18 (800 N)

40

16 40

16 40

16 40

16 40

6,4 25

5,1/2,8 25/16 25/13

19/6

L1S / L1SB M1F, G1F, H1F M/G/H1FB 15/4,4 M2F, G2F, H2F

Valve motor type single seated MT40/A (450 N) Valve motor 3) single seated type V, AV; single seated, bal. Type VB, VBA up to DN 50.(1200 N) double seated

1) As pL is normally decreasing by increasing inlet pressure p1, all pL values for water are calculated for p1 = pL - and for steam as max allowable inlet pressure (pos. pressure) on the basis of vacuum behind the valve. For 15/4 and 15/6 mm valves where pV is increasing by increasing inlet pressure (p1 is minimum by pV = 0), pL is, however, in both cases calculated as the max. allowable inlet pressure p1 by pV = 0. 2) Colour code (PB) is only valid for thermostats. The other type designations apply to pressure differential controls with the same tabular values. 3) Tabular values preceded by a slanted stroke (e.g. 4,9/0,5) apply for motors with spring return in cases where pL is reduced. 4) Tabular values valid for mixing valves by closing port A(2) and for diverting valves by opening port B(3). See also: 5). 5) For mixing valves by closing port B(3) and for diverting valves by opening port A(2) - pL is independent of actuator.

The sizing chart for steam is based on Superheat Increase flow by saturated steam. For superheated steam 10C 1% increase the required flow rate by the per50C 5% centage shown in this table before entering 100C 9% the chart: We reserve the right of changes without notice.

Bar 40 PN 40 Cast steel (H1, H3) PN 40 Cast steel (H2), 20-80 mm

Diagram 3

Pressure/Temperature according to DIN 2401

30 PN 25 Nodular cast iron (G1,G2,G3) 25 PN 25 Cast steel (H2), 100-150 mm 20 16 PN 16 Cast iron (M1, M2) (M3) (M3) 25-65 mm

(M1, M 2)

PN 16 Gun metal (L1, L2) 10 6 PN 10 Gun metal (L3), 15-200 mm Cast iron (M3), 80-200 mm PN 6 Gun metal (L3), 250-300 mm Cast iron (M3), 250-300 mm

0 0 Thermostat down: Thermostat up: 120 130 Without Cooling Unit Without Cooling Unit 170 200 225 250 300 Cooling Unit KS-5/KS-6 Must be avoided

Cooling Unit KS-4 Must be avoided

31

12

30

50

80

0,

0,

0,

2,

Complete control systems

Clorius Controls offers a complete range of tested and reliable equipment for control of heating, cooling and ventilation systems, all with the purpose of achieving the highest reliability and saving energy.

Controllers

Clorius Controls offers a wide range of electronic controllers for heating, cooling and ventilation systems. The controllers are available for systems in the maritime industry, general industry, institutions and residences. Clorius Controls offer controllers for simple stand-alone solutions or for larger BMS-plants.

Control valves

Clorius valves are simple and reliable for regulation of temperature and pressure differences in heating, cooling and ventilation systems for maritime industry, general industry, institutions and residences.

Motors

Clorius Controls offers a large program of conventional regulation motors and analogue motors. This includes special motors for maritime use, which are designed to withstand vibrations.

Balancing valves

With Ballorex balancing valves the amount of water in the individual heating circuits can be balanced and regulated.

Thermostats

Self-acting thermostats from Clorius Controls function directly and are available with sensors for air or liquids. They are also available as safety thermostats for the protection of secondary pipe installations.

Pressure differential controllers

The controllers from Clorius Controls lower large and variable pump pressure to stabilize the flow in the plant.

Service

Clorius Controls has an international network of service engineers who perform commissioning and trouble shooting in heating and ventilation plants. We are available 24 hours a day, 365 days a year. We offer service contracts including preventive maintenance for all brands of regulating equipment. We are also ready to help in case of urgent problems.

Vendor:

C o n t r o l s A/S

Clorius Controls A/S Tempovej 27 DK-2750 Ballerup Denmark Tel.: +45 77 32 31 30 Fax: +45 77 32 31 31 www.cloriuscontrols.com

Clorius Controls A/S - 9.0.00-E-GB

Das könnte Ihnen auch gefallen

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Dokument4 SeitenFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNoch keine Bewertungen

- Stad en MainDokument12 SeitenStad en Mainm_moreira1974Noch keine Bewertungen

- Control Valve SizingDokument5 SeitenControl Valve SizingOwen HennessyNoch keine Bewertungen

- Velocity of Water in PipeDokument4 SeitenVelocity of Water in Pipeabidch143100% (1)

- Capacity Regulator CpceDokument8 SeitenCapacity Regulator CpceNovan AndriantoNoch keine Bewertungen

- YOKOGAWA - Low Flow Transmitters With Integral Flow Orifice - TI01C20K00-01EDokument10 SeitenYOKOGAWA - Low Flow Transmitters With Integral Flow Orifice - TI01C20K00-01EChoochart ThongnarkNoch keine Bewertungen

- Control Valve Sizing-Engineering DataDokument21 SeitenControl Valve Sizing-Engineering DatapalindapcNoch keine Bewertungen

- ENGINEERING INFORMATION: Flow Data, Flow Factor and Orifice SizeDokument8 SeitenENGINEERING INFORMATION: Flow Data, Flow Factor and Orifice SizePrasit MeeboonNoch keine Bewertungen

- TraneDokument33 SeitenTranejake1000100% (1)

- EI Regulator Station Handbook TDC UK - DesbloqueadoDokument39 SeitenEI Regulator Station Handbook TDC UK - DesbloqueadoAlvaro Jhoel Quinteros RNoch keine Bewertungen

- 4wre 6-10 Sew1xDokument12 Seiten4wre 6-10 Sew1x2267airportNoch keine Bewertungen

- 2 Pdp10a202Dokument8 Seiten2 Pdp10a202Syed Noman AhmedNoch keine Bewertungen

- Municipal Water Supply Pump CatalogueDokument23 SeitenMunicipal Water Supply Pump CatalogueMandisa Sinenhlanhla NduliNoch keine Bewertungen

- Closed Expansion TankDokument4 SeitenClosed Expansion Tanka_salehiNoch keine Bewertungen

- PCV SizingDokument8 SeitenPCV SizingKhanh PhamNoch keine Bewertungen

- t-10 SensusDokument7 Seitent-10 SensusAlam Garcia RodriguezNoch keine Bewertungen

- Hydac SCADokument6 SeitenHydac SCADenis JimenezNoch keine Bewertungen

- Re92711 2012-01Dokument48 SeitenRe92711 2012-01Edson Huarachi FloresNoch keine Bewertungen

- Series RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDJoko Trend RedsNoch keine Bewertungen

- EI Regulator Station Handbook TDC UKDokument32 SeitenEI Regulator Station Handbook TDC UKupesddn2010Noch keine Bewertungen

- Yukenmodularvalves Yuken CatDokument140 SeitenYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Handbook No 1 Balancing of Control LoopsDokument56 SeitenHandbook No 1 Balancing of Control Loopstomislav_vucinic100% (1)

- Williams V Dual Seal Plunger 12-2012 PDFDokument12 SeitenWilliams V Dual Seal Plunger 12-2012 PDFDucVikingNoch keine Bewertungen

- Balancing and flow control valves quick reference guideDokument47 SeitenBalancing and flow control valves quick reference guideNoushad P Hamsa100% (1)

- Re29564 2007-011Dokument12 SeitenRe29564 2007-011engineer86Noch keine Bewertungen

- TN43183 - E 11-13C-St2-HighDokument3 SeitenTN43183 - E 11-13C-St2-HighYan RiveraNoch keine Bewertungen

- MassflowmetersandcontrollersDokument19 SeitenMassflowmetersandcontrollersMilectron Ion100% (1)

- Regulator RMG 201Dokument12 SeitenRegulator RMG 201Farraz Sarmento SalimNoch keine Bewertungen

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDokument8 Seiten4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNoch keine Bewertungen

- AMOT Datasheet C Thermostatic Valve 0512 Rev6Dokument12 SeitenAMOT Datasheet C Thermostatic Valve 0512 Rev6mlfaranoNoch keine Bewertungen

- Reznor HandbookDokument72 SeitenReznor Handbookethen223100% (1)

- Ta-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsDokument16 SeitenTa-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsCatalin DinuNoch keine Bewertungen

- Switch de PresiónDokument2 SeitenSwitch de PresiónCARLOS RAMOSNoch keine Bewertungen

- AG-101 Frac Design Proposal V2Dokument30 SeitenAG-101 Frac Design Proposal V2ayman morsyNoch keine Bewertungen

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDokument20 SeitenFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790Noch keine Bewertungen

- Digital Flow Meter For GasDokument2 SeitenDigital Flow Meter For GasMASSFLOWMEASUREMENTSNoch keine Bewertungen

- TA-FUSION-C EN LowDokument16 SeitenTA-FUSION-C EN LowTroi LauraNoch keine Bewertungen

- LAB REPORT-Gas AbsorptionDokument16 SeitenLAB REPORT-Gas Absorptionmizizasbonkure90100% (1)

- Double Regulating Valves (2601V)Dokument7 SeitenDouble Regulating Valves (2601V)Sujit RajanNoch keine Bewertungen

- GPSA Control Valve SizingDokument10 SeitenGPSA Control Valve SizingsudharshananNoch keine Bewertungen

- VDLSE502 - VRB2-3 - Danfoss VentiliDokument8 SeitenVDLSE502 - VRB2-3 - Danfoss VentilizigicsasaNoch keine Bewertungen

- HAZOP Footprint - UC Riverside, CHE175A, Chemical Process DesignDokument9 SeitenHAZOP Footprint - UC Riverside, CHE175A, Chemical Process DesignGabriel S. Gusmão (Freddie)Noch keine Bewertungen

- Dokumen - Tips Using The 1u5470 Engine Pressure GroupDokument11 SeitenDokumen - Tips Using The 1u5470 Engine Pressure Grouppedro sosaNoch keine Bewertungen

- Control Valve OcrDokument14 SeitenControl Valve OcrpathakshashankNoch keine Bewertungen

- Diseño Sistema Tuberia PVCDokument21 SeitenDiseño Sistema Tuberia PVCmavillaNoch keine Bewertungen

- 1-XI GBDokument20 Seiten1-XI GBdd6077Noch keine Bewertungen

- Flow TableDokument4 SeitenFlow Tableคุณชายธวัชชัย เจริญสุขNoch keine Bewertungen

- Choke SizingDokument19 SeitenChoke Sizingudokas50% (2)

- Pump selection and head calculation exampleDokument37 SeitenPump selection and head calculation exampleIhsan Wiratama100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SVon EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNoch keine Bewertungen

- Alarms and Fault Finding PDFDokument20 SeitenAlarms and Fault Finding PDFFlorian DraguNoch keine Bewertungen

- Seawage Treatment PDFDokument96 SeitenSeawage Treatment PDFaung koko100% (1)

- Condition Monitoring and Fault Diagnosis For Marine Diesel Engines Using Information Fusion TechniquesDokument4 SeitenCondition Monitoring and Fault Diagnosis For Marine Diesel Engines Using Information Fusion TechniquesFlorian DraguNoch keine Bewertungen

- Simulation of The Dynamics of A Marine Diesel EngineDokument16 SeitenSimulation of The Dynamics of A Marine Diesel EngineFlorian DraguNoch keine Bewertungen

- 2003 11020170 PDFDokument9 Seiten2003 11020170 PDFFlorian DraguNoch keine Bewertungen

- Condition Monitoring and Fault Diagnosis For Marine Diesel Engines Using Information Fusion TechniquesDokument4 SeitenCondition Monitoring and Fault Diagnosis For Marine Diesel Engines Using Information Fusion TechniquesFlorian DraguNoch keine Bewertungen