Beruflich Dokumente

Kultur Dokumente

Understanding Sound For HVAC Eqm

Hochgeladen von

majortay0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

110 Ansichten8 SeitenCarrier looks for ways to minimize sound with every new product we develop. Sound plays a major role in people's lives everyday. Understanding Sound ratings for HVAC Equipment is important.

Originalbeschreibung:

Originaltitel

Understanding Sound for HVAC Eqm

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCarrier looks for ways to minimize sound with every new product we develop. Sound plays a major role in people's lives everyday. Understanding Sound ratings for HVAC Equipment is important.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

110 Ansichten8 SeitenUnderstanding Sound For HVAC Eqm

Hochgeladen von

majortayCarrier looks for ways to minimize sound with every new product we develop. Sound plays a major role in people's lives everyday. Understanding Sound ratings for HVAC Equipment is important.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

Understanding Sound for HVAC Equipment

Enhancing Customer Satisfaction

TURN TO THE EXPERTS FOR SOUND ADVICE.

When consumers Turn to the Experts at Carrier, they expect the very best in HVAC innovation, technology, quality and customer service. And, more and more, when people think of high quality products, they look at sound as a key differentiating factor in the decisions they make. To maintain our competitive edge, we continuously look for ways to minimize sound with every new product we develop and with every product line upgrade we make. We feel that by taking sound out of the product, we are giving our distributors and dealers an advantage they can use when selling Carrier products. To make the most of Carrier's sound advantage, it is important that every distributor and dealer understands the basics of how sounds are generated, measured and compared. With this understanding, you'll be able to better communicate the differences in sound ratings and how homeowners can expect Carrier products to make a difference.

The Indianapolis engineering facility includes a reverberant sound room with rotating vane to test sound ratings of HVAC equipment.

THE ROLE OF SOUND IN CUSTOMER SATISFACTION

Sound plays a major role in people's lives everyday. From waking to the electronic beep of a bedside alarm clock to sliding back into a quiet resting place at the end of a long day, people are inundated with sounds at home, work and play that are both pleasing to the ear and annoying. In an effort to take noise out of their lives, homeowners today are placing more and more emphasis on minimizing unwanted sounds in their home environments. And, for the typical homeowner, HVAC equipment falls into the category of products that are better appreciated when they are quiet.

Understanding Sound for HVAC Equipment

WHY ARE STANDARDIZED SOUND RATINGS SO IMPORTANT?

The complex qualities of sounds and how they are perceived by the human ear make some louder, some quieter, some more annoying and others more soothing. These variances can make accurately measuring and comparing sounds fairly difficult. When trying to compare the sound levels of products that you can't, in all practicality, line up side-by-side and listen to, it's extremely important to have a standardized, consistent rating system. And, that's why understanding sound ratings for HVAC systems and knowing how to interpret them for your customers can be such a critical component to selling systems and retaining satisfied customers.

ARI SOUND RATINGS AND MILES PER GALLON

The ARI Sound Ratings provided by Carrier and many other HVAC manufacturers is a voluntary, standardized rating system that allows customers to accurately compare sound levels between products. It's kind of like comparing miles per gallon (mpg) ratings on a new car. Most consumers are familiar enough with mpg ratings to know that their driving habits, terrain, city or highway driving, type of gas used, and other variables will affect their actual mileage. At the same time, they accept the miles per gallon concept as a good way to compare the type of mileage they can expect from different makes and models of cars. Homeowners shopping for HVAC equipment should understand that the ARI sound ratings provided by Carrier offer an excellent comparison to competitors who also list ARI sound ratings for their products. At the same time, they should also be aware that environmental conditions, installation location and other variables will affect the amount of noise their system will make.

WHAT IS SOUND AND WHY DO WE MEASURE IT?

Any pressure variance detected by the human ear can be defined as sound. Some are pleasing to the ear, some are irritating, and all ears will hear sounds and interpret them a little differently. Measuring sounds allows us to accurately describe differing sounds and provides a basis for the following: Consumer comparison between models and brands Troubleshooting HVAC equipment Scientific analysis of annoying sounds Benchmarking for product quality improvements

Understanding Sound for HVAC Equipment

UNITS OF SOUND MEASUREMENT

Hertz (Hz) - Hertz is the unit used to measure sound frequency (number of pressure vibrations per second). The frequency of a sound is directly related to its distinctive tone - for example, the low rumble of thunder is a low frequency sound, while the shrill sound of a siren is a high frequency sound. Decibel (dB) - Decibels measure the amplitude of a sound's pressure fluctuations. Decibels are typically associated with the loudness of sound. Also, it's important to know that decibel measurements can be fine-tuned for greater accuracy using weighting networks that process the sounds much like a human ear, and filtering out specific sound frequencies for consistency. All HVAC manufacturers who conform to ARI standards (ARI Standard 270-95) list their sound measurements in A weighted decibels, or dBA. The above statement is important to remember because there is no simple way to compare dB sound measurements to dBA sound measurements. For a fair comparison for homeowners, the sound ratings MUST be listed in the same unit of measurement.

EFFECTS OF SOUND ON THE HUMAN EAR

The typical, healthy human ear can sense sounds between the frequencies of 20Hz to 20kHz, or in a measurement more familiar to most, from 0 decibel (dB) to the threshold of pain, about 130 dB or more. The smallest change in sound the ear can sense is about 3dB. Because of the way sound is interpreted by the ear, an increase of 6dB, or twice the amount the ear can detect, would need to increase to about 10dB to sound twice as loud. To make this subject even more complicated, the way the sound is perceived by the ear can be affected by several factors: Not all ears are sensitive to all frequencies Sounds at lower frequencies will need to be made at higher decibels to have the same relative loudness Impulse sounds, or sounds that are made in short spurts (such as a hammer striking a nail), may not sound as loud as sounds made at slightly lower dB but occur for a longer duration.

IUnderstanding Sound for HVAC Equipment

HOW SOUNDS ARE MEASURED

To ensure the greatest accuracy and consistency for comparison, HVAC manufacturers measure sound using equipment that responds to sounds in approximately the same way as a human ear. The sound data is collected in a highly controlled environment -- typically in a certified, reverberant sound room with a rotating vane, equipment that averages sound according to ARI standards, and a handheld sound meter. Because the environment is so controlled, any field measurements you might take in dBA units will almost certainly not match the listed equipment ratings. Variables that will affect any field measurements you take might include: Temperature Wind Humidity Any other exterior noise

Sound lab reverberant sound room.

SOUND FROM MULTIPLE UNITS

In situations where you are gauging the sound of more than one piece of equipment, you cannot simply add the dBA ratings of each to get a combined sound rating for both. Because decibel units are based on a logarithmic relationship, adding two ratings involves several calculations. This is important to know, as some of our marketing literature exploits the relative loudness of some competing products by showing how many Carrier units operating simultaneously it would take to equal the sound of one competitive product model.

Understanding Sound for HVAC Equipment

HOW DOES ALL THIS RELATE TO RESIDENTIAL HVAC SYSTEMS?

Because manufacturers voluntarily provide sound information on their products, it's not always easy to guarantee your customers will be able to make a fair and accurate comparison of which product is quietest. However, because Carrier does conform to ARI Standards, you can be confident that your comparisons are accurate if: The competing brand also conforms to ARI standards Competitor ratings are listed as dBA If competitor ratings are not listed as dBA, try to obtain a dBA rating by contacting a distributor or dealer of that product If competitor ratings are not listed with pure tone penalty, try to obtain a rating with pure tone penalty by contacting a distributor or dealer of that product Then, when they choose Carrier, go the extra mile by: Helping them select the quietest product that fits their application needs and budget If practical, work with them to determine the best installation location to minimize the effects of equipment noise during operation Follow up with a maintenance plan to keep the system operating trouble free and as quietly as possible By maintaining an open line of communication with the homeowner, and using the information in this document to provide honest, well-informed answers to questions they may have regarding sound, you'll improve your chances of making and retaining happy, satisfied customers.

Understanding Sound for HVAC Equipment

Understanding Sound for HVAC Equipment

www.carrier.com

A member of the United Technologies Corporation family. Stock Symbol UTX.

Carrier Corporation 2005

01-811-20090-25

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice or without incurring obligations.

Das könnte Ihnen auch gefallen

- Emerging Sustainable Design Technologies For Green BldgsDokument42 SeitenEmerging Sustainable Design Technologies For Green BldgsmajortayNoch keine Bewertungen

- Restaurant Fire Protection System - PYROCHEM KK IIDokument78 SeitenRestaurant Fire Protection System - PYROCHEM KK IImajortayNoch keine Bewertungen

- Multistage Multioutlet PumpDokument11 SeitenMultistage Multioutlet Pumpmajortay100% (1)

- Variable FlowDokument31 SeitenVariable FlowmajortayNoch keine Bewertungen

- ACMV - 21 - Code of PracticeDokument26 SeitenACMV - 21 - Code of PracticemajortayNoch keine Bewertungen

- Air Flow DesignDokument65 SeitenAir Flow DesignmajortayNoch keine Bewertungen

- Air Distribution Basics and Duct DesignDokument46 SeitenAir Distribution Basics and Duct DesignVali GheorghisorNoch keine Bewertungen

- FW Twin Wheel System Sales BrochureDokument7 SeitenFW Twin Wheel System Sales BrochuremajortayNoch keine Bewertungen

- FW Education BrochureDokument6 SeitenFW Education BrochuremajortayNoch keine Bewertungen

- FWG TwinWheel System BrochureDokument7 SeitenFWG TwinWheel System BrochuremajortayNoch keine Bewertungen

- FW Combi Cooler System BrochureDokument7 SeitenFW Combi Cooler System BrochuremajortayNoch keine Bewertungen

- FWG Food Application BrochureDokument12 SeitenFWG Food Application BrochuremajortayNoch keine Bewertungen

- Management Vs Leadership - Linked 2 LeadershipDokument119 SeitenManagement Vs Leadership - Linked 2 LeadershipTom Schulte100% (20)

- FW Twist Wing Sales BrochureDokument8 SeitenFW Twist Wing Sales BrochuremajortayNoch keine Bewertungen

- Ventilation Solutions Brochure 2012 ENGDokument7 SeitenVentilation Solutions Brochure 2012 ENGCarlos PintoNoch keine Bewertungen

- FW SuperLite Standard Range Catalogue 2012-13Dokument212 SeitenFW SuperLite Standard Range Catalogue 2012-13majortayNoch keine Bewertungen

- FW Tunnel & Metro Sales BrochureDokument8 SeitenFW Tunnel & Metro Sales BrochuremajortayNoch keine Bewertungen

- FW Energy Performance of Buildings BrochureDokument8 SeitenFW Energy Performance of Buildings BrochuremajortayNoch keine Bewertungen

- FW Eq Sales BrochureDokument12 SeitenFW Eq Sales BrochuremajortayNoch keine Bewertungen

- FW Natural Ventilation FreeFlowDokument8 SeitenFW Natural Ventilation FreeFlowmajortayNoch keine Bewertungen

- FW Service Uk Tss 2012Dokument5 SeitenFW Service Uk Tss 2012majortayNoch keine Bewertungen

- FW Eq Prime Sales BrochureDokument12 SeitenFW Eq Prime Sales BrochuremajortayNoch keine Bewertungen

- FW Optivent System BrochureDokument5 SeitenFW Optivent System BrochuremajortayNoch keine Bewertungen

- FW E3co Crown Technical Catalogue UKDokument13 SeitenFW E3co Crown Technical Catalogue UKmajortayNoch keine Bewertungen

- FW Iq Star Stella MSCB BrochureDokument7 SeitenFW Iq Star Stella MSCB BrochuremajortayNoch keine Bewertungen

- FW JM HT Large BrochureDokument11 SeitenFW JM HT Large BrochuremajortayNoch keine Bewertungen

- FW E3co Star Technical CatalogueDokument16 SeitenFW E3co Star Technical CataloguemajortayNoch keine Bewertungen

- FW Jetfoil Fan BrochureDokument9 SeitenFW Jetfoil Fan BrochuremajortayNoch keine Bewertungen

- FW E3co Star Sales BrochureDokument5 SeitenFW E3co Star Sales BrochuremajortayNoch keine Bewertungen

- FW Indoor Climate System BrochureDokument5 SeitenFW Indoor Climate System BrochuremajortayNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Liebherr PR 712 Litronic Final DrivesDokument8 SeitenLiebherr PR 712 Litronic Final DrivesLiebherr75% (4)

- Brochure Delegation Training For LeadersDokument6 SeitenBrochure Delegation Training For LeadersSupport ALProgramsNoch keine Bewertungen

- Kalbelia Dance Rajasthan - Kalbelia Rajasthani Folk Dance KalbeliaDokument6 SeitenKalbelia Dance Rajasthan - Kalbelia Rajasthani Folk Dance KalbeliarahulgabdaNoch keine Bewertungen

- Hal Foster Vision and Visuality Discussions in Contemporary Culture PDFDokument75 SeitenHal Foster Vision and Visuality Discussions in Contemporary Culture PDFEd GomesNoch keine Bewertungen

- ESUR Guidelines 10.0 Final VersionDokument46 SeitenESUR Guidelines 10.0 Final Versionkon shireNoch keine Bewertungen

- Otis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFDokument201 SeitenOtis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFbodyfull100% (2)

- AH Business-Management All 2011Dokument11 SeitenAH Business-Management All 2011Sanam PuriNoch keine Bewertungen

- Competency #14 Ay 2022-2023 Social StudiesDokument22 SeitenCompetency #14 Ay 2022-2023 Social StudiesCharis RebanalNoch keine Bewertungen

- Optimizing Patient Flow: Innovation Series 2003Dokument16 SeitenOptimizing Patient Flow: Innovation Series 2003Jeff SavageNoch keine Bewertungen

- 1.4 BG00381946 - ADokument1 Seite1.4 BG00381946 - AAnand KesarkarNoch keine Bewertungen

- Under The SHODH Program For ResearchDokument3 SeitenUnder The SHODH Program For ResearchSurya ShuklaNoch keine Bewertungen

- ISO StandardsDokument7 SeitenISO StandardsHusnain BaigNoch keine Bewertungen

- D D D D D D D: SN54HC574, SN74HC574 Octal Edge-Triggered D-Type Flip-Flops With 3-State OutputsDokument16 SeitenD D D D D D D: SN54HC574, SN74HC574 Octal Edge-Triggered D-Type Flip-Flops With 3-State OutputsJADERSONNoch keine Bewertungen

- PLLTutorial ISSCC2004Dokument131 SeitenPLLTutorial ISSCC2004Siddharth MathurNoch keine Bewertungen

- LP Addition of PolynomialsDokument5 SeitenLP Addition of PolynomialsJolina Bagwisa LptNoch keine Bewertungen

- Register A Custom Table in Apps SchemaDokument5 SeitenRegister A Custom Table in Apps SchemaIapps ErpSolutionsNoch keine Bewertungen

- Pset 2Dokument13 SeitenPset 2rishiko aquinoNoch keine Bewertungen

- TSM 101 Course Outline (2022)Dokument2 SeitenTSM 101 Course Outline (2022)ChryseanjNoch keine Bewertungen

- "Design, Modeling and Analysis of Steam Turbine Blade": Dayananda Sagar College of EngineeringDokument66 Seiten"Design, Modeling and Analysis of Steam Turbine Blade": Dayananda Sagar College of EngineeringSHREENIVAS MNoch keine Bewertungen

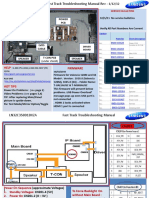

- Samsung LN55C610N1FXZA Fast Track Guide (SM)Dokument4 SeitenSamsung LN55C610N1FXZA Fast Track Guide (SM)Carlos OdilonNoch keine Bewertungen

- Rapid History Taking: 1. Patient ProfileDokument3 SeitenRapid History Taking: 1. Patient ProfileTunio UsamaNoch keine Bewertungen

- Net June 2013Dokument22 SeitenNet June 2013Sunil PandeyNoch keine Bewertungen

- FPI - Study Permit Application GuideDokument9 SeitenFPI - Study Permit Application GuideKian Mark DarioNoch keine Bewertungen

- Arch Plan-Agner Boco (For Blue Print) - p1Dokument1 SeiteArch Plan-Agner Boco (For Blue Print) - p1Jay CeeNoch keine Bewertungen

- Central Venous PressureDokument3 SeitenCentral Venous PressureHuy NguyễnNoch keine Bewertungen

- Performace Task 2 Electric Field LinesDokument31 SeitenPerformace Task 2 Electric Field LinesStephanie Nichole Ian CasemNoch keine Bewertungen

- User Instructions: Installation Operation Maintenance NAF Duball DL Pocket ValveDokument12 SeitenUser Instructions: Installation Operation Maintenance NAF Duball DL Pocket ValveMauricio Contreras R.Noch keine Bewertungen

- GundamDokument25 SeitenGundamBattlecruiser ScharnhorstNoch keine Bewertungen

- Content and Context Analysis of Selected Primary SourccesDokument3 SeitenContent and Context Analysis of Selected Primary SourccesToshi CodmNoch keine Bewertungen

- Shaira Narrative Report (Final)Dokument7 SeitenShaira Narrative Report (Final)Sheryll TamangNoch keine Bewertungen