Beruflich Dokumente

Kultur Dokumente

Plant Start Up Activities List - 02.04.2012

Hochgeladen von

Samsudin AhmadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Plant Start Up Activities List - 02.04.2012

Hochgeladen von

Samsudin AhmadCopyright:

Verfügbare Formate

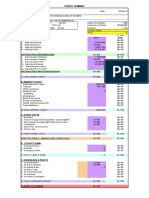

Description S.No. Execution of Plant Start Up Items:(Updated Additional Items Updated on 21.02.2012 Additional Items Updated on 02.04.2012 on 19.01.

2012) 1 GAS TURBINE

2 3 4 5 6 7 8 9 10 11 12 13 14 Mechanical

Local Services for air intake upgradation work Services for GT insulation work PCM Nr. 3-10-002450 Turning gear start from standstill issue( this job to be performed by Siemens during Plant Commissioning) New/Improved Air intake Filter House and accessories. GT Lube oil for top up (5 drum) GT Air Intake & Elbow Duct waterproofing 1 1 1 1 1 1

Priority

1

I&C

Redundancy in GT TXP compact unit /Procurement of TXP Compact Unit. Adjust pilot gas flow for load rejection to island mode. GT was last tripping out seconds after coming into island mode. (This commissioning issue to be resolved by Siemens) N95F failure investigation (This commissioning issue to be resolved by Siemens) Siemens training on control systems(TXP,SIMADYN,95F and PCS7) Replace MOD and reslove inability to log on to TXP Engineering Server E680(Resolution of this problem is essential until the redundancy of the compact unit is provided) TXP: Error Alarm persisting on OSM, connection b/w the engg. station and the redundant CPU failed just when on line logic transfer was attempted. Gas Turbine: one of the two GT compressor discharge thermocouples is not working. Needs to be ordered. Siemens expert for DCS,TXP and PCS7 to resolve items 49 to 51 and 53 to 57 by providing services at site. Siemens Fact Finder June 2010 -Connection of surge protection is located at the lower half of the compressor inlet. Recommended to change it to upper half with a continuous garde to the compressor(Siemens Commissioning Engineer to check and advise) System Field Programmer (PG): Original hard drive is faulty, however one image is available with which PG is operating well.This matter needs to resolved before start of commissioning activity. Purchase of GT Exhaust Thermocouples 1

1 1

15 16 17

18

19 20 21 22 23

1 1 1

Electrical

Ignition Cable and Ignition Transformer

Chemistry

24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62

Washing Detergent for GT

1 1 O-Ring replacement of ESV at HP Steam Line

STEAM TURBINE

Mechanical

I&C

Installed CPU of Steam Turbine got defective. Spare CPU is now installed. One spare CPU to be ordered for emergency. PCS7: Engineering Station WIN CC runtime and RAID not working. Purchase of Spare Fuse Boxes for Steam Turbine panel. 1 1 1

Electrical

--

GAS COMPRESSOR

Mechanical

Gas compressor # 1 & 2 servicing for ensuring 100% reliability of both gas compressor including spare part required for servicing. Gas Compressor 1& 2 Oil Replacement Level glass and isolating valves installation at Cylinder Water/Packing Water/Lube oil overhead tanks Gas pipe lines'/filter housings' internal cleaning ( to remove loose particals accumulated inside pipes due to external mechanical works for painting Non Sparking and other tools Gas Filter for Initial & Final separator 1 1 1

1 2 1 1 2 2 2

I&C

Installation of A/C unit for gas compressor PLC panel Diaphragm for inlet valve of fuel gas compressor Gas Compressor fire fighting system spares detectors are required and additional trolley type fire extinguishers to be addded. Power Supply for the PLC of Gas Compressor to be ordered.

Electrical

--

Chemistry

Coolant (glycol) 1 1 1 1 2 1 1 1 1 2 1 Change hydraulic oil in SWI hydraulic valves. 1

SEA WTER INTAKE CHANNEL

Mechanical

Steel Mesh for TBS(All) endless rubber seal for TBS (PR is on hold ) Checkers' plates re-inforcement/replacement at Pump basin and painting the supporting structure Services for Cleaning of sea water Intake channels, pump basin and pipes from silt. Maintenanace & Repair works in Sea Water IntakePenstocks etc. Shock chlorination in Intake and SW header. Repairing/rehabilitation of Chlorine dosing system Reisntallation of marking buoys for Intake at Off shore Chlorine unloading pumps (maintenance/replacement)

63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82

Replacement of all the lip Seals at Bar-Screens and Travelling Band Screens

I&C

--

Electrical

--

Chemistry

--

BOILERS

Mechanical

HRSG and Aux Boiler safety valve inspection, servicing and testing. Fabrication of guard cage around the HRSG stack at ground level for protection Oil analysis of all lube oil system Fixing of all leakages and other defects of the dosing system (Remineralized water System) Cut Samples of HRSG tubes and test/ analyse for condition Replacement of existing stubs on HRSG. Hydrostatic Testing of HRSG Renewal of certification of Main and Aux boiler Acid Cleaning for HRSG, if necessary. Gaskets for Deaerator/HP drum/LP drum and Flash Tank mon hole Replacement of HRSG tubes, if necessary. Replacement of Access Door's Collor at Transition Piece. Aluminium Cladding at some valves and pipes (where cladding is damaged) 1 1 1 1 1 1 1 1 2 1 1 1 2

83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 109 110 111 112

I&C

I/O cards for HRSG Panel( 2nos.) Replacement/repair of field instruments and servo motor for Aux. Boiler. Diaphragm for LP & HP drum control valve Purchase of Drum Instruments (pressure Tranimitters & level transmitters) Channel fabrication for mounting limit switches Purchase of Servo motor and modulating pressure transmitter Diaphragm for Attemperator Control Valve Pressure Transmitter for flue gas path Replacement of faulty thermocouples( 8 nos) Replacement of Air Filter Regulators(15 nos.) Manifolds for I&C (5 nos) 1 1 2 2 1 2 2 1 1 1 1

Electrical

--

Chemistry

--

FINE FILTRATION

Mechanical

Inspection/supervision of repairing work of MicroGiant's drive system and Bearings replacement by Passavent Engineer Nylon Mesh for Microgiant screen

1 1

113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139

Fixing of leaking penstocks Repair/touch up work on Coating applied at walls of the pump/MG basin's. Shock chlorination in FF Tank Fine Filtration DWT Pumps' internal inspection and servicing as per findings Rehabilitation of backwash system at MG FF Tank's roof repairing work

1 1 1 1 1 1 1 Level Transmitter Rehabilitation of Control Panel of Passavant 2 2

I&C

AUMA actuator for Fine Filtration(2nos.)

Electrical

--

Chemistry

--

MAIN GENERATOR

Mechanical --

I&C

--

Electrical

Tan Telta Test for Main Generator 2 1

GAS INSULATED SWITCH GEAR (GIS)

Mechanical --

I&C

--

Electrical

The differential protection for Defence and Creek feeders are not available due to problem in fibre optic cable on DHA and KESC end. To be attended by KESC. Further, KESC have to repair 132KV cable for Creek City feeder. Replace defective Rectifier for DC Power Supply System in GIS building. Exhaust Fans in Buildings(GIS, Chlorine Dosing) 1

140 141 142 143 144

1 2

DESALINATION PLANT

Mechanical

Repair of 200 micro filter basket for feed water Condensate Return high conductivity fixing and identification of leaks. Non Asbestos gasket sheet BA-50 for Desalination flange (1500 x 1500 x 2mm) Spare Bellows required to replace damaged ones steam Jet Ejectors complete servicing Distillate coolers' (PHE) cleaning internal inspection of Butterfly valves installed at Desalination units and servicing as per requirment Cyclone separators complete servicing Replacement of Root Valves at impulse line on process header (Different sizes) and all areas. Foreign purchase of Fapmo pump shaft & bearing housing 1 1 1 1 1 1 1 1 1

145 146 147 148 149 150 152

153 154 155 156

Plastic inserts for copper tube for End-Condenser and Preheaters Chemical unloading pumps (maintainance/replacement) Inspection and Commissioning supervision by OEM Engineer Modification of Filter housing as per Fichtner's recommendation Desalination Units Chemical Cleaning (PHE & Preheaters) as per OEM recommended procedure Feed Water Filters' (200 m) teflon bushes repairing/replacement

1 1 1 1

157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177

I&C

Arrange software back up (S7+WinCC Flexible) and attend following requirements from Operation : 1) Missing measurements for brine, conductivity,, pressure and temp. to CCR. 2)Make flow meter/converter functional for distillate. 1

Electrical

--

Chemistry

Anti-Scalant Chemical 1

POTABLE WATER AND REMINERALIZATION SYSTEM

Mechanical

Fixing of all leaking penstocks in PWST. Modification work at H2SO4 line as per M/s FICHTNER recommendations 1 1

I&C Electrical

--

Chemistry OTHERS

Mechanical

Risk Matrix spares, Mechanical ( Annex 3.1) Various wear Spare Parts for plant required before startup for MMS, IMS and EMS (NB: a number of purchase requisitions for spares required for corrective/preventive maintenace kept on hold since last one and a half year) 1

178 179 180 181 182 183 184

Maintenance services for product Water storage tank

Submersible pumps (maintainance/replacement) Procurement of Rupture Disk (2 Nos) Fixing of leaking penstocks in PWST Lube Oil analysis of various systems Fixing of all leakages and other defects of the dosing system (Remineralized water System) Refurbication of various Valves

2 1 1 1 1 1

185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203

I&C

Risk Matrix Spares, I & C ( Annex 3.3) Diaphragm for LP & HP by-pass valve Fire detectors with accessories to replace defective ones for BoP from MINIMAX. Motors for each type of Actuator(6 nos.) Electronic Assembly for each type of Actuator(6 nos.) Certification of Caliberation of critical Instrument Drain Points on positioners 1 2 1 2 2 2 1 1 2 2 2 1 Electrical Protection Relays Electrical Protection Relay Testing 1 1 1 1

Electrical

Risk Matrix Spares, Electrial( Annex 3.2) Plant UPS system battery discharge test Purchase of Electrical Motors(Used) Spare Cells for NiCd Battery Bank( 8 nos.) Purchase of Siemens Over Current Relays( 2 nos.)

Chemistry

Chemicals for Start Up. Purchase of Demineralized water for start up

Total:

Das könnte Ihnen auch gefallen

- P & ID Review Check List: Chemical Engineering SiteDokument8 SeitenP & ID Review Check List: Chemical Engineering SiteMAHESH CHANDNoch keine Bewertungen

- Master Deliverable Register: C Electrical C1Dokument2 SeitenMaster Deliverable Register: C Electrical C1LaelaeNoch keine Bewertungen

- 283 Lookahead Schedule 25 Oct 17Dokument2 Seiten283 Lookahead Schedule 25 Oct 17adnanNoch keine Bewertungen

- 71.0402 General Construction - Substructures - AssemblyDokument201 Seiten71.0402 General Construction - Substructures - Assemblythanhphucbr87Noch keine Bewertungen

- Specification Power Supply LGP42-11P EAY62170101 PDFDokument73 SeitenSpecification Power Supply LGP42-11P EAY62170101 PDFaplkduNoch keine Bewertungen

- Document Control Sheet: MahagencoDokument6 SeitenDocument Control Sheet: MahagenconileshwarkeNoch keine Bewertungen

- Instrument 1Dokument2 SeitenInstrument 1Elias EliasNoch keine Bewertungen

- UZGTL ITB Index20121120Dokument69 SeitenUZGTL ITB Index20121120Hyun Jin Yoo0% (1)

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDokument10 SeitenO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNoch keine Bewertungen

- BZ Est PD 002 Control Philosophy TestDokument55 SeitenBZ Est PD 002 Control Philosophy TestMertoiu GabrielNoch keine Bewertungen

- 0D107Line ListDokument1 Seite0D107Line Listgeverett2765Noch keine Bewertungen

- Weight Factors For Electrical Construction WorkDokument4 SeitenWeight Factors For Electrical Construction WorkS.m.sajjad Haider NaqviNoch keine Bewertungen

- PR Minent: Plan View Piping SchematicDokument1 SeitePR Minent: Plan View Piping SchematicrameshNoch keine Bewertungen

- Electrical Tray InstallationDokument4 SeitenElectrical Tray InstallationClinton OlivierNoch keine Bewertungen

- OPA Assessments: Advanced Technologies and Laboratories Int'l IncDokument23 SeitenOPA Assessments: Advanced Technologies and Laboratories Int'l IncAparna GanapathiNoch keine Bewertungen

- Man Hours HistogramDokument1 SeiteMan Hours HistogramMostafa Elkadi0% (1)

- Cable Sizing CalcDokument18 SeitenCable Sizing CalcJj SpNoch keine Bewertungen

- Pneumatic Instruments SpecDokument24 SeitenPneumatic Instruments Specraka rachmansyahNoch keine Bewertungen

- 2.35 Transmittal Log (Po-pgb-Desu-0001) (Imicci)Dokument27 Seiten2.35 Transmittal Log (Po-pgb-Desu-0001) (Imicci)zhangNoch keine Bewertungen

- SBG1 01 0H 3 MST 0028 C Chemical Dosing System OP Instruc - JCM - OMDokument46 SeitenSBG1 01 0H 3 MST 0028 C Chemical Dosing System OP Instruc - JCM - OMzainudin simonNoch keine Bewertungen

- 01 - Doc and Drawing Register - MOGS-Botling Plant Dtd. 04.1.12Dokument6 Seiten01 - Doc and Drawing Register - MOGS-Botling Plant Dtd. 04.1.12SaraswatapalitNoch keine Bewertungen

- Presentation Ron Water MeyerDokument22 SeitenPresentation Ron Water MeyerGordon RudmanNoch keine Bewertungen

- I Et 6000.67 0000 800 Pdy 001 eDokument178 SeitenI Et 6000.67 0000 800 Pdy 001 epitucha_hs100% (1)

- JM3-720-42-CAL-4-104-00 Rev. CDokument16 SeitenJM3-720-42-CAL-4-104-00 Rev. CAhmad Erfan0% (1)

- PT Borneo Mitra Sinergi: Project Close Out PlanDokument4 SeitenPT Borneo Mitra Sinergi: Project Close Out Planaswar100% (1)

- Oil and Gas Engineering - 2015 02Dokument32 SeitenOil and Gas Engineering - 2015 02jairo73scribdNoch keine Bewertungen

- TPC ProcDokument81 SeitenTPC Procanjangandak2932Noch keine Bewertungen

- 4 740078 G0 I 795 09 GE Water & Process TechnologiesDokument2 Seiten4 740078 G0 I 795 09 GE Water & Process TechnologiesniginpNoch keine Bewertungen

- Instrument List - DGN19 Oct, Rev ADokument12 SeitenInstrument List - DGN19 Oct, Rev ADheeraj YadavNoch keine Bewertungen

- Oil and Gas - P&ID SymbolsDokument22 SeitenOil and Gas - P&ID SymbolsParvez khanNoch keine Bewertungen

- Material Take-Off List: PFE-1: 10 Lbs. HAND TYPE FireDokument2 SeitenMaterial Take-Off List: PFE-1: 10 Lbs. HAND TYPE FireMohamed RizkNoch keine Bewertungen

- Cable Size Calculations SpreadsheetDokument4 SeitenCable Size Calculations SpreadsheetsdgafgafdhadNoch keine Bewertungen

- Costing Working 07.03.2018Dokument71 SeitenCosting Working 07.03.2018thirumal m0% (1)

- Phosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15Dokument6 SeitenPhosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15HassanSobohNoch keine Bewertungen

- Crc-p-600 Welding Machine Spec. Brochure 2Dokument4 SeitenCrc-p-600 Welding Machine Spec. Brochure 2gdgfd100% (1)

- Template (Electrical Works)Dokument10 SeitenTemplate (Electrical Works)Anonymous Qu7LeENoch keine Bewertungen

- Stock Preparation DIP Paper Machine BCTMP WH: NotesDokument2 SeitenStock Preparation DIP Paper Machine BCTMP WH: NotesFajar MaulanaNoch keine Bewertungen

- KG98 2 ONT OMF in 7861 DS 150 R3 Level Transmitter Code 1Dokument31 SeitenKG98 2 ONT OMF in 7861 DS 150 R3 Level Transmitter Code 1Madheswaran DharmapuriNoch keine Bewertungen

- Ptg-tmy-yad2-In-rfq-019 Rev 0 RFQ For Wave Protection For Esv-Sdv & Fo JBDokument15 SeitenPtg-tmy-yad2-In-rfq-019 Rev 0 RFQ For Wave Protection For Esv-Sdv & Fo JBAditya PranotoNoch keine Bewertungen

- Test Report (Revisi Fat)Dokument5 SeitenTest Report (Revisi Fat)Imamudin BuronanMertua TanpaSadar100% (1)

- Datasheet CCTVDokument6 SeitenDatasheet CCTVSeptian FirdausNoch keine Bewertungen

- 6 Fiber Multi Tube Fiber Optic Cable 2120006Dokument1 Seite6 Fiber Multi Tube Fiber Optic Cable 2120006Diego ValenteNoch keine Bewertungen

- Design BasisDokument34 SeitenDesign BasisRajesh BarkurNoch keine Bewertungen

- MWPS Daily Activity Report 28 August2011Dokument1 SeiteMWPS Daily Activity Report 28 August2011Francis RayeNoch keine Bewertungen

- Annexure of LPGDokument6 SeitenAnnexure of LPGKathir HaiNoch keine Bewertungen

- Document & Drawing RegistersDokument6 SeitenDocument & Drawing RegistersJulius BravoNoch keine Bewertungen

- Division Wise List of BM & BC Roads (DLP Expired Roads For Which Urgent Maintenance/Overlay Works Required)Dokument51 SeitenDivision Wise List of BM & BC Roads (DLP Expired Roads For Which Urgent Maintenance/Overlay Works Required)insafaNoch keine Bewertungen

- Ahu Hah 70701 AbDokument14 SeitenAhu Hah 70701 AbEzrizalSaidinNoch keine Bewertungen

- Inter Sugar 1969 v71 n850Dokument66 SeitenInter Sugar 1969 v71 n850mohammad ansaryNoch keine Bewertungen

- Boiler Input/Output List: REV Date Decription BY ApprvdDokument26 SeitenBoiler Input/Output List: REV Date Decription BY ApprvdJKKNoch keine Bewertungen

- PH Analyser Manual PH-13-SDokument22 SeitenPH Analyser Manual PH-13-SSunil Chouhan100% (1)

- 22146410-A02-DOC-LI-001-Master Document Register - V1.0 PDFDokument5 Seiten22146410-A02-DOC-LI-001-Master Document Register - V1.0 PDFBalasoobramaniam CarooppunnenNoch keine Bewertungen

- QIPP MPN013 M00 2203 - A - Status2Dokument5 SeitenQIPP MPN013 M00 2203 - A - Status2Ganesh R NairNoch keine Bewertungen

- Isolat orDokument2 SeitenIsolat orchin46Noch keine Bewertungen

- TDW SmartPlug BrochureDokument6 SeitenTDW SmartPlug BrochureRodolfo Cabrera100% (2)

- Instrument List For Condensate Polishing Plant PDFDokument8 SeitenInstrument List For Condensate Polishing Plant PDFKasthuri CoimbatoreNoch keine Bewertungen

- Project Final Vendor Dossier Summary - 15.10.2015Dokument39 SeitenProject Final Vendor Dossier Summary - 15.10.2015rajuNoch keine Bewertungen

- Spares ListDokument10 SeitenSpares ListEmmanuelNoch keine Bewertungen

- 2nd TA Modification Work List Rev1Dokument71 Seiten2nd TA Modification Work List Rev1Vy NguyenNoch keine Bewertungen

- Safety Health of OilDokument37 SeitenSafety Health of OilSamsudin AhmadNoch keine Bewertungen

- ASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsDokument31 SeitenASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsSamsudin AhmadNoch keine Bewertungen

- Transformer Oil PurificationDokument7 SeitenTransformer Oil PurificationAther AliNoch keine Bewertungen

- Transformer Sample ProcedureDokument1 SeiteTransformer Sample ProcedureSamsudin AhmadNoch keine Bewertungen

- IEEE C57 123 Transformer Loss MeasurementDokument45 SeitenIEEE C57 123 Transformer Loss MeasurementSamsudin Ahmad100% (1)

- Lubricant TestingDokument68 SeitenLubricant TestingSamsudin Ahmad100% (2)

- Clean Oil GuideDokument36 SeitenClean Oil GuidesppramNoch keine Bewertungen

- Electricity at Work Memorandum of GuidanceDokument52 SeitenElectricity at Work Memorandum of GuidanceSamsudin AhmadNoch keine Bewertungen

- Be Amex MC 6 FunctionalityDokument1 SeiteBe Amex MC 6 FunctionalitySamsudin AhmadNoch keine Bewertungen

- Beamex - The Production of The Beamex MC6, EnGDokument4 SeitenBeamex - The Production of The Beamex MC6, EnGSamsudin AhmadNoch keine Bewertungen

- Safety Management SystemsDokument29 SeitenSafety Management SystemsSamsudin AhmadNoch keine Bewertungen

- Garispanduan7 DOSH First AidDokument22 SeitenGarispanduan7 DOSH First Aiddrstein197450% (2)

- Power Transformer MaintenanceDokument19 SeitenPower Transformer Maintenanceadnan80% (5)

- Monthly Report Feb 2012 LaraibDokument9 SeitenMonthly Report Feb 2012 LaraibSamsudin AhmadNoch keine Bewertungen

- Testing of Power TransformersDokument6 SeitenTesting of Power TransformersSamsudin AhmadNoch keine Bewertungen

- Asset Masterlist - NBEHPPDokument248 SeitenAsset Masterlist - NBEHPPSamsudin Ahmad100% (1)

- Permit To Work - Mechanical ContractorDokument2 SeitenPermit To Work - Mechanical ContractorSamsudin AhmadNoch keine Bewertungen

- Confined Space Entry Permit Rev 1Dokument2 SeitenConfined Space Entry Permit Rev 1Samsudin AhmadNoch keine Bewertungen

- Home Technical Support ChartDokument1 SeiteHome Technical Support ChartSamsudin AhmadNoch keine Bewertungen

- Hot Work Permit Rev 1Dokument2 SeitenHot Work Permit Rev 1Samsudin AhmadNoch keine Bewertungen

- Permit To Work - Electrical ContractorDokument2 SeitenPermit To Work - Electrical ContractorSamsudin Ahmad100% (1)

- PTW Format Rev 1Dokument2 SeitenPTW Format Rev 1Samsudin AhmadNoch keine Bewertungen

- Sample MoMDokument1 SeiteSample MoMSamsudin AhmadNoch keine Bewertungen

- List of Vendors For The Main Plant EquipmentDokument15 SeitenList of Vendors For The Main Plant EquipmentSamsudin AhmadNoch keine Bewertungen

- Failure CodesDokument16 SeitenFailure CodesSamsudin Ahmad75% (4)

- CFT 01 - Tripping of Unit Due To Bearing or Governor Oil SystemDokument6 SeitenCFT 01 - Tripping of Unit Due To Bearing or Governor Oil SystemSamsudin AhmadNoch keine Bewertungen

- Company Profile - TNBDokument1 SeiteCompany Profile - TNBSamsudin AhmadNoch keine Bewertungen

- Annex - A PAX SOPHO Is3030 Site Test and Commissioning ProcedureDokument11 SeitenAnnex - A PAX SOPHO Is3030 Site Test and Commissioning ProcedureSamsudin AhmadNoch keine Bewertungen

- MAXIMO Support Service: # Part No. Description Qty 1 D0GybllDokument1 SeiteMAXIMO Support Service: # Part No. Description Qty 1 D0GybllSamsudin AhmadNoch keine Bewertungen

- Lecture 4 Maps Data Entry Part 1Dokument80 SeitenLecture 4 Maps Data Entry Part 1arifNoch keine Bewertungen

- V-Belt Sizing and Selection Guide: Standard V Belt Sizes FHP (Fractional Horsepower) V-Belts 3L, 4L, 5LDokument1 SeiteV-Belt Sizing and Selection Guide: Standard V Belt Sizes FHP (Fractional Horsepower) V-Belts 3L, 4L, 5LVijay ParmarNoch keine Bewertungen

- Muhammad Ajmal Farooqi: Chemical EngineerDokument4 SeitenMuhammad Ajmal Farooqi: Chemical EngineeromercomsatNoch keine Bewertungen

- FSU Electronics PrelabDokument7 SeitenFSU Electronics Prelabcamaguey5Noch keine Bewertungen

- Evolution of C-Si: PV Cell TechnologiesDokument52 SeitenEvolution of C-Si: PV Cell TechnologiesFábio VelôzoNoch keine Bewertungen

- AristotleDokument126 SeitenAristotlenda_naumNoch keine Bewertungen

- AQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of HydrologyDokument23 SeitenAQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of Hydrologyhoc_kinowNoch keine Bewertungen

- 2.lecture 1-Basics and PrecedenceDokument30 Seiten2.lecture 1-Basics and PrecedenceBhavesh ReddyNoch keine Bewertungen

- Phase Diagrams: By: Cherides P. MarianoDokument25 SeitenPhase Diagrams: By: Cherides P. MarianoWild RiftNoch keine Bewertungen

- Mariners' Polytechnic Colleges Foundation of Canaman, Camarines SurDokument4 SeitenMariners' Polytechnic Colleges Foundation of Canaman, Camarines SurKristian-Emman SarateNoch keine Bewertungen

- Asme Se-165 2004Dokument25 SeitenAsme Se-165 2004Kamalnath KpNoch keine Bewertungen

- DSC & Ftir 2Dokument13 SeitenDSC & Ftir 2Rashid HussainNoch keine Bewertungen

- Lecture 4 - IP Addressing-New PDFDokument51 SeitenLecture 4 - IP Addressing-New PDFKhông Có TênNoch keine Bewertungen

- Jj503 - Mechanical Workshop Practise 4Dokument2 SeitenJj503 - Mechanical Workshop Practise 4jayadarsini2113Noch keine Bewertungen

- Report Builder ENGDokument94 SeitenReport Builder ENGfran reyNoch keine Bewertungen

- Electronic Door LockDokument2 SeitenElectronic Door LocktaindiNoch keine Bewertungen

- RLC-circuits With Cobra4 Xpert-Link: (Item No.: P2440664)Dokument14 SeitenRLC-circuits With Cobra4 Xpert-Link: (Item No.: P2440664)fatjonmusli2016100% (1)

- What Is A Philosophical Problem - HackerDokument12 SeitenWhat Is A Philosophical Problem - Hackersnain1Noch keine Bewertungen

- Weld Map & NDE Extent of Pressure VesselDokument32 SeitenWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- MATHSDokument221 SeitenMATHSAbdulai FornahNoch keine Bewertungen

- Jimma Institute of Technology Faculty of Mechanical EngineeringDokument38 SeitenJimma Institute of Technology Faculty of Mechanical EngineeringIsmail Ibn BehailuNoch keine Bewertungen

- Airfield Pavement2Dokument12 SeitenAirfield Pavement2molgarNoch keine Bewertungen

- Univ of Michigan Flint Design Report 442Dokument74 SeitenUniv of Michigan Flint Design Report 442Extra TerrestrialNoch keine Bewertungen

- Registry TweaksDokument5 SeitenRegistry TweaksArlie TaylorNoch keine Bewertungen

- Correlational ResearchDokument10 SeitenCorrelational ResearchSari100% (1)

- Design of Adaptive Headlights For AutomobilesDokument5 SeitenDesign of Adaptive Headlights For AutomobilesEditor IJRITCCNoch keine Bewertungen

- Boxer EngineDokument84 SeitenBoxer EngineTOONGA100% (7)

- Ultra Structure of ChromosomeDokument9 SeitenUltra Structure of ChromosomeJigarS.MehtaNoch keine Bewertungen

- DA-100English ManualDokument10 SeitenDA-100English ManualGiang TrườngNoch keine Bewertungen

- SmartPRO 5000U Plus ManualDokument10 SeitenSmartPRO 5000U Plus ManualMugiranezaNoch keine Bewertungen