Beruflich Dokumente

Kultur Dokumente

M & G Code Sample File

Hochgeladen von

andhab1Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

M & G Code Sample File

Hochgeladen von

andhab1Copyright:

Verfügbare Formate

M & G Code Sample Files

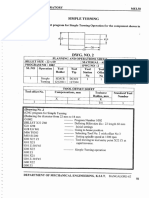

Sample File 1

The following is a 5" square. Rapid level .5 inches above material, feed down 60 IPM, cut feed 200 IPM, rapid down to .1 above material, depth .25 inches. This is for a single head system with manual tool change (The manual tool change is highlighted in Gray below and is optional.)

Machine Code

M90 G90 G75 G97 S18000 G00 T1 G00 CE-MILL .2500 2FL.

Description of Machine Code

Program Start Absolute Coordinate Mode Follow the XY coordinate Arc Mode (Standard) Spindle Speed Set to 18,000 RPM Tool 1 call. Following moves will use tool one. "E-MILL .2500 2FL." will displayed on the keypad. The user will now be able to load the tool manually and Z reference the tool. This line can be sent multiple times in the same file to support manual tool changes. Position the Z axis .5 inches above Z=0 or above the Material. Position X=0.0 and Y=0.0 The M12 command should be called before the Z axis is lows the tool into the Material or at the start of a new contour. - The Auxiliary output for the selected tool is turned on. (This output can be wired to operate a tool misting or cooling unit.) - The Motion will change from Slew mode (high speed rapid) to Machine mode (Cutting Mode) - If this is the first M12 called in the program the spindle output will come on for the current selected tool. Position the Z axis 0.1 inches above Z=0.0 or above the Material. Position the Z axis 0.25 inches below Z=0.0 or into the Material at the feed rate of 1 inch/second (60 inches/minute). Position the X=5.0 inches at the feed rate of 3.333 inch/second (200 inches/minute). Position the Y=5.0 inches (feed rate will continue at last set speed) Position the X=0.0 inches Position the Y=0.0 inches Position the Z axis 0.5 inches above Z=0.0 or above the Material. The M22 command should be called after the Z axis lifts the tool out of the Material. Completing the current contour. - The Auxiliary output for the selected tool is turned off.. - The Motion will change from Machine mode (Cutting Mode) to Slew mode (high speed rapid) Position X=0.0 and Y=0.0 End of Program Spindle is turned off.

// This file is for a non atc system A line that begins with // is a comment line.

G00 Z-0.5 G00 X0. Y0. M12

G00 Z-0.1 G01 Z0.25 F1. G01 X5. F3.333 G01 Y5. G01 X0. G01 Y0. G00 Z-0.5 M22

G00 X0. Y0. M02

More Sample Files

Sample File 2 (ATC or Single Tool) This is the same file for an ATC system with the ATC tool change command. Notice That there is no "G00 C" command. M90 G90 G75 G97 S18000 G00 T1 G00 Z-0.5 G00 X0. Y0. M12 G00 Z-0.1 G01 Z0.25 F1. G01 X5. F3.333 G01 Y5. G01 X0. G01 Y0. G00 Z-0.5 M22 G00 X0. Y0. M02 Sample File 3 (ATC Tool 3) The following is a 5" circle clockwise, center at 2.5,2.5, .5 rapid level, feed down 60 IPM, cut feed 120 IPM, rapid down to .1, depth of .4". ATC system using tool #3. M90 G90 G75 G97 S18000 G00 T3 G00 Z-0.5 G00 X2.5 Y5. M12 G00 Z-0.1 G01 Z0.4 F1. G02 I2.5 J2.5 F2. G00 Z-0.5 M22 G00 X0. Y0. M02 M90 G90 G75 G97 S18000 G00 T1 G00 Z-0.5 G00 X0. Y0. M12 G00 Z-0.1 G01 Z0.25 F1. G01 X5. F3.333 G01 Y5. G01 X0. G01 Y0. G00 Z-0.5 M22 G97 S18000 G00 T3 G00 Z-0.5 G00 X2.5 Y5. M12 G00 Z-0.1 G01 Z0.4 F1. G02 I2.5 J2.5 F2. G00 Z-0.5 M22 G00 X0. Y0. M02 Sample File 4 (Samples 2 and 3 together)

Sample Boring File Comments in Red

M90 G90 G75

G00 X6.0394 Y6.0394 M38 Lowers the drill bank into place and turns on the drill motor G00 X6.0394 Y6.0394 Z-0.5 Moves X and Y so that boring drill one is centered at X = 6.0394 Y = 6.0394 and Z is 0.5 inches above the materials surface. G98 P300 D496 Engages drills 5, 6, 7, 8, and 9. G00 Z-0.1 Slew Move in Z to .1 inches above the material G01 Z0.4 F1.333 Plunge the Z axis .4 inches into the material at 80 IPM G00 Z-0.5 Slew Move in Z to .5 inches above the material G00 X6.0394 Y8.5591 Move X and Y and continue to drill more holes with the same engaged drills G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y11.0787 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y12.3386 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y13.5984 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y14.8583 Z-0.5 G98 P300 D480 Engages drills 6, 7, 8, and 9. G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y16.1181 Z-0.5 G98 P300 D448 Engages drills 7, 8, and 9. G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y17.378 Z-0.5 G98 P300 D384 Engages drills 8 and 9. G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X6.0394 Y18.6378 Z-0.5 G98 P300 D256 Engages drill 9. G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X12.3386 Y12.3386 Z-0.5 G98 P300 D31 Engages drills 1, 2, 3, 4, and 5. G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X12.3386 Y6.0394 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X13.5984 Y6.0394 G00 Z-0.1 G01 Z0.4 F1.333

G00 Z-0.5 G00 X14.8583 Y6.0394 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X16.1181 Y6.0394 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X17.378 Y6.0394 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 G00 X18.6378 Y6.0394 G00 Z-0.1 G01 Z0.4 F1.333 G00 Z-0.5 M48 Retract all boring drills, Retract Drill Bank, turn off drill bank G97 S24000 G00 T3 G00 X18. Y12.875 Z-0.5 M12 G00 Z-0.1 G01 Z0.5 F1.667 G02 I18. J12. F3.333 G00 Z-0.5 M22 G00 X22. Y8.375 Z-0.5 M12 G00 Z-0.1 G01 Z0.5 F1.667 G02 I22. J7. F3.333 G00 Z-0.5 M22 G97 S18000 G00 T1 G00 X0. Y-0.25 Z-0.5 M12 G00 Z-0.1 G01 Z0.77 F1.667 G01 X25. F13.333 G03 X25.25 Y0. I25. J0. G01 Y15. G03 X25. Y15.25 I25. J15. G01 X0. G03 X-0.25 Y15. I0. J15. G01 Y0. G03 X0. Y-0.25 I0. J0. G00 Z-0.5 M22 G00 X35.0 Y0.0 M02

Cutter Comp G40\G41\G42 examples

Note that before all Cutter Compensation, G41\G42, will work the cut MUST start with a lead in and end with a lead out. The type of compensation that is applied depends on the direction you have selected. If the cut is going clockwise in the inside of a pocket, then the machine should be compensated to the RIGHT (G42), if it is going clockwise on the outside of a contour, then it should be set to LEFT (G41), and so on. N10 M90 N20 G90 N40 G75 N50 G97 S24000 N60 G00 T1 N70 G00 Z-0.5 N80 G00 X-0.25 Y-0.25 N90 M12 N100 G00 Z-0.1 N110 G01 Z0.5 F1. N120 G42 N130 G02 X-0.125 Y-0.125 I-0.125 J-0.25 F3.333 N140 G01 X10.125 N150 G01 Y10.125 N160 G01 X-0.125 N170 G01 Y-0.125 N180 G02 X-0.25 Y-0.25 I-0.25 J-0.125 N190 G40 N200 G00 Z-0.5 N210 M22 N220 G00 X0. Y0. N230 M02 Program Start Absolute coordinate system Use absolute mode (G90 from above) for arcs Set spindle speed to 24000 RPM Select Tool #1 Rapid move to safe rapid level Rapid move Device on code rapid move feed move to final depth, feedrate 1 inch per second set cutter comp right ON lead in arc feed move feed move feed move feed move lead out arc set cutter comp OFF retract to safe rapid level device off code move to home position end of job code

N10 M90 N20 G90 N30 G75 N40 G97 S18000 N50 G00 T2 N60 G00 Z-0.5 N70 G00 X5.125 Y10.25 N80 M12 N90 G00 Z-0.1 N100 G01 Z0.5 F1.

Program Start Absolute coordinate system Use absolute mode (G90 from above) for arcs Set spindle speed to 18000 RPM Select Tool #2 Rapid move to safe Z level rapid move device on rapid move feed move to final depth, feedrate 1

inch per second N110 G42 N120 G02 X5. Y10. I5. J10.25 F3.333 N130 G03 I5. J5. N140 G02 X4.75 Y10.25 I5. J10.25 N150 G40 N160 G00 Z-0.5 N170 M22 N180 G00 X0. Y0. N190 M02 set cutter comp right ON lead in arc feed move circle lead out arc set cutter comp OFF retract to safe rapid level device off code move to home position end of job code

N10 M90 N20 G90 N30 G75 N40 G97 S24000 N50 G00 T2 N60 G00 Z-0.5 N70 G00 X5.125 Y7.75 N80 M12 N90 G00 Z-0.1 N100 G01 Z0.5 F1. N110 G41 N130 G03 I5. J5. N140 G03 X4.875 Y7.75 I5. J7.75 N150 G40 N160 G00 Z-0.5 N170 M22 N180 G97 S18000 N190 G00 T1 N200 G00 Z-0.5 N210 G00 X-0.375 Y-0.125 N220 M12 N230 G00 Z-0.1 N240 G01 Z0.5 F1. N250 G42 N260 G01 X0. F3.333

Program Start Absolute coordinate system Use absolute mode (G90 from above) for arcs Set spindle speed to 24000 RPM Select Tool #2 Rapid move to safe Z level rapid move device on rapid move feed move to final depth, feedrate 1 inch per second set cutter comp left ON feed move lead out arc set cutter comp OFF retract to safe rapid level device off code Set spindle speed to 18000 RPM select tool #1 Rapid move to safe Z level rapid move device on rapid move feed move to final depth, feedrate 1 inch per second set cutter comp right ON lead in line feedrate 200 inched per

N120 G03 X5. Y7.875 I5. J7.75 F6.667 lead in arc

minute N270 G01 X10. N280 G03 X10.125 Y0. I10. J0. N290 G01 Y10. N300 G03 X10. Y10.125 I10. J10. N310 G01 X0. N320 G03 X-0.125 Y10. I0. J10. N330 G01 Y0. N340 G03 X0. Y-0.125 I0. J0. N350 G02 X0.125 Y-0.25 I0. J-0.25 N360 G40 N370 G00 Z-0.5 N380 M22 N390 G00 X0. Y0. N400 M02 feed move line feed move arc feed move line feed move arc feed move line feed move arc feed move line feed move arc lead out arc set cutter comp OFF Rapid move to safe Z level device off code move to home position end of job code

Sample GCode File

Drilling, Peck drilling, cutter comp, no cutter comp N10 M90 N20 G90 N30 G75 N40 G97 S10000 N50 G00 T1 N60 G00 Z-0.5 N70 G00 X1. Y1. N80 M12 N90 G83 R0.1 Z0.75 D0.2 F1.667 N100 G00 Z-0.5 N110 M22 N120 G00 X2. Y1. N130 M12 N150 G00 Z-0.5 N160 M22 N170 G00 X3. Y1. N180 M12 N200 G00 Z-0.5 program start absolute coordinate system use absolute coordinates for arc set spindle speed to 10000 RPM select tool # 1 rapid Z move (note Z negative is UP) rapid XY move device on peck drill rapid Z move device off rapid XY move device on rapid Z move device off rapid XY move device on rapid Z move

N140 G83 R0.1 Z0.75 D0.2 F1.667 peck drill

N190 G83 R0.1 Z0.75 D0.2 F1.667 peck drill

N210 M22 N220 G00 X4. Y1. N230 M12 N250 G00 Z-0.5 N260 M22 N270 G00 X5. Y1. N280 M12 N300 G00 Z-0.5 N310 M22 N320 G97 S12000 N330 G00 T11 N340 G00 Z-0.5 N350 G00 X1. Y4. N360 M11 N370 M21 N380 G00 X2. Y4. N390 M11 N400 M21 N410 G00 X3. Y4. N420 M11 N430 M21 N440 G00 X4. Y4. N450 M11 N460 M21 N470 G00 X5. Y4. N480 M11 N490 M21 N500 G97 S18000 N510 G00 T2 N520 G00 Z-0.5 N530 G00 X-0.5 Y3. N540 M12 N550 G00 Z-0.1 N560 G01 Z0.375 F1. N570 G01 X0. F6.667 N580 G01 X12. N590 G01 X12.5 N600 G00 Z-0.5

device off rapid XY move device on rapid Z move device off rapid XY move device on rapid Z move device off set spindle speed to 12000 RPM select tool # 11 (a pneumatic drill) rapid Z move rapid XY move fire drill retract drill rapid XY move fire drill retract drill rapid XY move fire drill retract drill rapid XY move fire drill retract drill rapid XY move fire drill retract drill set spindle speed to 18000 RPM select tool # 2 rapid Z move rapid XY move device on rapid Z move feed Z move linear feed XY move linear feed XY move linear feed XY move rapid Z move

N240 G83 R0.1 Z0.75 D0.2 F1.667 peck drill

N290 G83 R0.1 Z0.75 D0.2 F1.667 peck drill

N610 M22 N620 G97 S24000 N630 G00 T5 N640 G00 Z-0.5 N650 G00 X-0.563 Y-0.187 N660 M12 N670 G00 Z-0.1 N680 G01 Z0.75 F1. N690 G42 N700 G01 X0. Y-0.188 F8.333 N710 G01 X12. N720 G03 X12.188 Y0. I12. J0. N730 G01 Y6. N740 G03 X12. Y6.188 I12. J6. N750 G01 X0. N760 G03 X-0.188 Y6. I0. J6. N770 G01 Y0. N780 G03 X0. Y-0.188 I0. J0. N790 G02 X0.188 Y-0.375 I0. J0.375 N800 G40 N810 G00 Z-0.5 N820 M22 N830 G00 X0. Y0. N840 M02

device off set spindle speed to 24000 RPM select tool # 5 rapid Z move rapid XY move device on rapid Z move feed down Z move turn on cutter comp right linear feed XY move linear feed XY move arc feed XY move linear feed XY move arc feed XY move linear feed XY move arc feed XY move linear feed XY move arc feed XY move lead out arc cutter comp off rapid Z move device off rapid XY move End of Job

Das könnte Ihnen auch gefallen

- VMC 4020Dokument11 SeitenVMC 4020Arul SakthiNoch keine Bewertungen

- IndexingDokument6 SeitenIndexingMuhammad Junaid Chohan100% (1)

- Evaporative Air Cooler Service Manual: CautionDokument20 SeitenEvaporative Air Cooler Service Manual: CautionRafael SaresNoch keine Bewertungen

- BCS630 Kta38 G1 PDFDokument9 SeitenBCS630 Kta38 G1 PDFAlbertoNoch keine Bewertungen

- NC ProgrammingDokument54 SeitenNC ProgrammingVed Vrat NuclearNoch keine Bewertungen

- Haas G72 Type I Rough and G70 Finish Facing Program ExampleDokument3 SeitenHaas G72 Type I Rough and G70 Finish Facing Program ExampleCnc Page100% (1)

- Module 2 Part 1Dokument147 SeitenModule 2 Part 1FRANCIS THOMASNoch keine Bewertungen

- Cncmillingprograms 160318071113 PDFDokument33 SeitenCncmillingprograms 160318071113 PDFAsad ZahidNoch keine Bewertungen

- Milling ProgramDokument20 SeitenMilling ProgramSudeep Kumar SinghNoch keine Bewertungen

- CNC Programs ExamplesDokument5 SeitenCNC Programs ExamplesNemikumar GandhiNoch keine Bewertungen

- Live Tool Drill TapDokument25 SeitenLive Tool Drill TapRA Javier100% (1)

- Turning Exercies - Ip710 - Dr.V.RameshDokument8 SeitenTurning Exercies - Ip710 - Dr.V.Rameshvajram1100% (2)

- CNC TRAINDokument124 SeitenCNC TRAINakshat naiduNoch keine Bewertungen

- Lathe ProgramDokument6 SeitenLathe ProgramAwoke TesfaNoch keine Bewertungen

- Turning Moment Diagram & FlywheelDokument88 SeitenTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- ALL CNC Printouts PROGRAMS PRINTOUTDokument26 SeitenALL CNC Printouts PROGRAMS PRINTOUTGajananNoch keine Bewertungen

- Hass AnswersDokument7 SeitenHass AnswersRelu ChiruNoch keine Bewertungen

- CNC Turning (Bridgeport)Dokument63 SeitenCNC Turning (Bridgeport)Siti Idah TawhidNoch keine Bewertungen

- Machinist'S Reference GuideDokument52 SeitenMachinist'S Reference Guidedelta toNoch keine Bewertungen

- Basic Machine Codes PDFDokument31 SeitenBasic Machine Codes PDFsabiha12Noch keine Bewertungen

- G-Code For CNC MachineDokument13 SeitenG-Code For CNC MachinezokiplusNoch keine Bewertungen

- G CodeDokument9 SeitenG CodeArga Rio MugafiNoch keine Bewertungen

- Swan SoftDokument90 SeitenSwan Softandreeaoana45Noch keine Bewertungen

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Dokument11 SeitenIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNoch keine Bewertungen

- A Letter Engraving Custom MacroDokument15 SeitenA Letter Engraving Custom Macrofirepower117Noch keine Bewertungen

- CNC For CADCAM and Technology StudentsDokument95 SeitenCNC For CADCAM and Technology Studentscaptain_jack_zzz609Noch keine Bewertungen

- Kinematics of Machinery ManualDokument29 SeitenKinematics of Machinery ManualShubham NaikNoch keine Bewertungen

- NC ProgrammingDokument23 SeitenNC ProgrammingAkash Byju100% (1)

- Programming MillDokument81 SeitenProgramming MillEddy ZalieNoch keine Bewertungen

- Codigos CNCDokument4 SeitenCodigos CNCLuis Enrique Pichardo100% (1)

- Involute Spur Gear ProblemsDokument6 SeitenInvolute Spur Gear ProblemsChiragJansari100% (1)

- CNC Programming Examples Lathe MachiningDokument2 SeitenCNC Programming Examples Lathe MachiningchandruNoch keine Bewertungen

- Custom MacroDokument31 SeitenCustom Macroshiva d100% (1)

- Chapter Two 2. Manual NC Part ProgrammingDokument33 SeitenChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeNoch keine Bewertungen

- Ch-11 NC CNC DNC FMS Automation and RoboticsDokument191 SeitenCh-11 NC CNC DNC FMS Automation and RoboticsPrateek BayalNoch keine Bewertungen

- Camworks Manual Based On Vtu SyllabusDokument25 SeitenCamworks Manual Based On Vtu Syllabusviper7887Noch keine Bewertungen

- CNC Programing ConceptDokument11 SeitenCNC Programing ConceptGatot PrasetyoNoch keine Bewertungen

- DDCS Expert User's Manual V1 (Part1)Dokument82 SeitenDDCS Expert User's Manual V1 (Part1)เปี๊ยก คนเดิมNoch keine Bewertungen

- CNC Turning Programming Exellent ExplainationDokument29 SeitenCNC Turning Programming Exellent ExplainationschrienerNoch keine Bewertungen

- Machine Tool Gearbox Design.Dokument9 SeitenMachine Tool Gearbox Design.Mohamed Osama67% (3)

- CNC ProgrammingDokument60 SeitenCNC ProgrammingRohan Dutta100% (2)

- G Codes CommandsDokument45 SeitenG Codes CommandsordamNoch keine Bewertungen

- SeeNC Mill ProgramsDokument4 SeitenSeeNC Mill ProgramsBharat VinjamuriNoch keine Bewertungen

- Fanuc Lathe ProgramDokument93 SeitenFanuc Lathe Programnguyenanhso100% (1)

- English - Lathe NGC - Operator's Manual - 2018Dokument456 SeitenEnglish - Lathe NGC - Operator's Manual - 2018Francisco Salas GalvánNoch keine Bewertungen

- CNC Programming Tutorials Examples G and M Codes Programming Tutorial Example Code For Beginner To Advance Level CNC Machinist PDFDokument302 SeitenCNC Programming Tutorials Examples G and M Codes Programming Tutorial Example Code For Beginner To Advance Level CNC Machinist PDFSanjai RohanNoch keine Bewertungen

- G Code FanukDokument5 SeitenG Code FanukCucoș Marius MarianNoch keine Bewertungen

- Gear Train ProblemsDokument3 SeitenGear Train ProblemsM PervaizNoch keine Bewertungen

- Super Sel e - G (Iai 038C - V7) eDokument266 SeitenSuper Sel e - G (Iai 038C - V7) eEudel TeyNoch keine Bewertungen

- CNC Edge Programming - 3 Axis ProgrammingDokument9 SeitenCNC Edge Programming - 3 Axis ProgrammingVishvanth SubramaniNoch keine Bewertungen

- Main Spindle Motor Selection: 9/30/2018 Aruna Kumar.p 1Dokument19 SeitenMain Spindle Motor Selection: 9/30/2018 Aruna Kumar.p 1srinivas murthyNoch keine Bewertungen

- CNC Turning Programming Fundementalsls, Step by StepDokument14 SeitenCNC Turning Programming Fundementalsls, Step by Stepschriener50% (2)

- Dmu 60 / 80 / 100 Monoblock Classic Series: CNC Universal Milling MachinesDokument24 SeitenDmu 60 / 80 / 100 Monoblock Classic Series: CNC Universal Milling MachinesButch BorjaNoch keine Bewertungen

- The Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Dokument10 SeitenThe Use of Variables, Macros and Subroutines and Compatibility With FANUC Parametric Programming ......................... 3Jérôme GRANGENoch keine Bewertungen

- Unsolved Problems On Brakes and ClutchesDokument8 SeitenUnsolved Problems On Brakes and ClutchesAuthorized EarthlingNoch keine Bewertungen

- CNC Turn-Mill G and M CodesDokument51 SeitenCNC Turn-Mill G and M CodespptmnltNoch keine Bewertungen

- Manual Guide Milling and Turning Manual PDFDokument978 SeitenManual Guide Milling and Turning Manual PDFkalede2100% (1)

- VMC Manual Programming Handbook - Chinmaya BeheraDokument19 SeitenVMC Manual Programming Handbook - Chinmaya BeherapradeepNoch keine Bewertungen

- 11 Cad Cam CNC Programming MVVDokument37 Seiten11 Cad Cam CNC Programming MVVbassem smatiNoch keine Bewertungen

- Fanuc 0m-ADokument3 SeitenFanuc 0m-ASanchai ProgaeewNoch keine Bewertungen

- Heidenhain M Codes & G CODESDokument18 SeitenHeidenhain M Codes & G CODESMohamed Ben Salem100% (1)

- Advanced CNC Programming & Code PDFDokument38 SeitenAdvanced CNC Programming & Code PDFAswath SridharNoch keine Bewertungen

- CNC ProgrammingDokument62 SeitenCNC ProgrammingSanjog Maiti100% (1)

- Metal WorkDokument60 SeitenMetal Workandhab1Noch keine Bewertungen

- Toc Pmt1700-Eng Ess2017Dokument15 SeitenToc Pmt1700-Eng Ess2017andhab1Noch keine Bewertungen

- Exercise - FANUCDokument175 SeitenExercise - FANUCsubbu.v1987100% (1)

- The 10 Best Tips For Resisting TemptationDokument2 SeitenThe 10 Best Tips For Resisting Temptationandhab1Noch keine Bewertungen

- G and M Programming For CNC LathesDokument106 SeitenG and M Programming For CNC LathesAlexandru Precup100% (3)

- NTN Bearing en AllDokument411 SeitenNTN Bearing en Allbhupinder85Noch keine Bewertungen

- Capstan & Turret LathesDokument22 SeitenCapstan & Turret LathesAhmed Kamal100% (1)

- Use of Dividing HeadDokument20 SeitenUse of Dividing Headajs_pto3117Noch keine Bewertungen

- Gear MakingDokument145 SeitenGear Makingandhab1Noch keine Bewertungen

- Harman Kardon HK 3380 - Mk2 Service ManualDokument54 SeitenHarman Kardon HK 3380 - Mk2 Service ManualDimceStereophileski100% (2)

- ICMICA 2023 Information Brochure 06.09.2023Dokument1 SeiteICMICA 2023 Information Brochure 06.09.2023ramsss4uNoch keine Bewertungen

- Sipmos Small-Signal Transistor BSS 88: V I R VDokument6 SeitenSipmos Small-Signal Transistor BSS 88: V I R Vessen999Noch keine Bewertungen

- Signals and Systems Module 1Dokument35 SeitenSignals and Systems Module 1ASUTOSH PATNAIKNoch keine Bewertungen

- CB20 SpecsDokument4 SeitenCB20 SpecsmarceloNoch keine Bewertungen

- Ipad Lecture 1-3 On Ring TheoryDokument47 SeitenIpad Lecture 1-3 On Ring TheoryVivek SinghNoch keine Bewertungen

- HeightadjustabledesksDokument238 SeitenHeightadjustabledesksPepitofanNoch keine Bewertungen

- Unmatched Style. Unrivaled Comforts.: Welcome Door Lamp Wireless Charger (2 Row)Dokument2 SeitenUnmatched Style. Unrivaled Comforts.: Welcome Door Lamp Wireless Charger (2 Row)laddu100Noch keine Bewertungen

- Inf311 01 42016022Dokument12 SeitenInf311 01 42016022Hazem QaedNoch keine Bewertungen

- LQG 15 HSR 10 J 02Dokument3 SeitenLQG 15 HSR 10 J 02David AlexNoch keine Bewertungen

- Elster-Eca G4 KörüklüDokument2 SeitenElster-Eca G4 KörüklüAli ŞengülNoch keine Bewertungen

- Briefing-Note-9---Soft-LandingsDokument6 SeitenBriefing-Note-9---Soft-LandingsIDEAL DRAGONSNoch keine Bewertungen

- GSM Gateway Function Overview: AP-GSM1002 (2-Port) AP-GSM1004 (4-Port)Dokument16 SeitenGSM Gateway Function Overview: AP-GSM1002 (2-Port) AP-GSM1004 (4-Port)M.g. Mostofa OheeNoch keine Bewertungen

- Scheme of ExaminationDokument42 SeitenScheme of ExaminationpkdhabraNoch keine Bewertungen

- Project Proposal: For Bidding AppDokument13 SeitenProject Proposal: For Bidding AppMaria AsifNoch keine Bewertungen

- DCC Micro-ProjectDokument20 SeitenDCC Micro-ProjectRaviraj Tekale0% (1)

- Energy Saving Plan Vs Actual 20-21 MarchDokument19 SeitenEnergy Saving Plan Vs Actual 20-21 Marchdhir.ankurNoch keine Bewertungen

- Up6 15c PartesDokument108 SeitenUp6 15c PartesFernando Guaman Remache100% (1)

- Valves PresentationDokument45 SeitenValves PresentationChiheb KaanicheNoch keine Bewertungen

- EC Council University CatalogDokument105 SeitenEC Council University CatalogBhargav SriramNoch keine Bewertungen

- Oogway AscendsDokument1 SeiteOogway AscendsHaythem ChakrounNoch keine Bewertungen

- SPYWAREDokument1 SeiteSPYWARECayllex BinondoNoch keine Bewertungen

- Registration User GuideDokument20 SeitenRegistration User GuideMelody ShekharNoch keine Bewertungen

- CH12 Instruction Sets Characteristics and FunctionsDokument36 SeitenCH12 Instruction Sets Characteristics and FunctionsNguyen Phuc Nam Giang (K18 HL)Noch keine Bewertungen

- 022543-074e 5700 DS 0808 LR PDFDokument2 Seiten022543-074e 5700 DS 0808 LR PDFcecil5alfonso5ariza5Noch keine Bewertungen

- Depth (M) Soil Description Depth (M) Soil Description: Subsurface Exploration (SPT) Geoforma Engenharia LtdaDokument9 SeitenDepth (M) Soil Description Depth (M) Soil Description: Subsurface Exploration (SPT) Geoforma Engenharia LtdaJAVIER ADRIANNoch keine Bewertungen

- LSA Exam TempleteDokument2 SeitenLSA Exam TempleteMuhammad ArshedNoch keine Bewertungen

- Water Storage Tanks (M) - Rev 02-09-2017Dokument4 SeitenWater Storage Tanks (M) - Rev 02-09-2017arjun 11Noch keine Bewertungen