Beruflich Dokumente

Kultur Dokumente

RE18136

Hochgeladen von

Ahmed Abd ElhakeemOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RE18136

Hochgeladen von

Ahmed Abd ElhakeemCopyright:

Verfügbare Formate

RE 18136-02/05.

00

RE 18 136-02/05.00

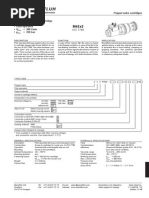

2/2-way directional poppet valves with solenoid actuation Type YSE1

Nominal size 1 Maximum operating pressure 350 bar Maximum flow 20 L/min

H/AID 6540/00

Type YSE1.A/C

Overview of contents

Contents Features Ordering details Function, section, symbols Technical data, switching times Characteristic curves, performance limits Unit dimensions, cavity Page 1 1, 2 2 3 3 4

Features

Direct operated directional poppet valve with solenoid actuation, leak-free on both sides Closed port is leak-free Switching is ensured even with longer duty times Wet pin DC solenoids Rotatable solenoid coil With protected hand override

Ordering details Y

Cartridge Poppet valve Electrical Standard 350 bar Nominal size

Pressure 350 bar Symbols

N9

No code = FKM seals K4 = Without plug-in connector 2) C4 = Coil junior timer (on request) N9 = Protected hand override G24 = 24 V DC Wet pin DC solenoid, C= with removable coil

=Y =S =E = No code =1

No. of connections 2

2 a b 1

2 a b 1

Cavity

1)

A=

1)

Series

qV = L/min

=N

2)

See page 4 Plug-in connectors must be ordered separately (see page 2) Type YSE1PA/CG24N9K4 YSE1NA/CG24N9K4

T-13A

20

=P

Preferred types Material No. 00993076 00993075

YSE1

1/4

RE 18 136-02/05.00

Ordering details: plug-in connectors to DIN 43 650 A and ISO 4400 for component plug "K4"

Further plug-in connectors see RE 08 006

Material No.

With indicator light 12 240 V 00057292 With indicator light and Z-diode protective circuit 24 V 00310995

Colour Grey Black

Without circuitry 00074683

Function, section, symbols

General: The cartridge solenoid valve is a direct operated pressure balanced 2/2-way directional poppet valve. It controls the start, stop and direction of a flow. It basically comprises of a cartridge (6), a solenoid (7), a valve seat (3) as well as the closing element (5). Basic principle: The valves initial position (normally open P or normally closed N) is determined by the closing element version (5) and by the arrangement of the spring (8). The 2/2-way directional poppet valves are, due to their design, always pressure balanced with regard to the adjustment forces. Ports 1 and 2 can be applied with an operating pressure of 350 bar and the flow can pass in both directions (see symbols). With symbol P the closing element (5) is pushed onto its seat by solenoid (7), with symbol N the closing element (5) is pushed onto its seat via spring (8). The flow is closed leak-free. The hand override (4) makes it possible to switch the valve without energising the solenoid.

2 a b 1

Symbol "N":

2 1

Symbol "P":

b 1

2 1

3

Rexroth Hydraulics

8

2/4

7

YSE1

RE 18 136-02/05.00

Technical data (for applications outside these parameters, please consult us!)

General

Installation Ambient temperature range Weight C kg Optional 30 to + 50 0.5

Hydraulic

Maximum operating pressure Maximum flow Pressure fluid FKM seals Pressure fluid temperature range Viscostiy range Degree of contamination C mm2/s bar L/min 350 20 Mineral oil (HL, HLP) to DIN 51 524; Fast bio-degradable pressure fluids to VDMA 24 568 (see also RE 90 221); HETG (rape seed oil); HEPG (polyglycol); HEES (synthetic ester); Other pressure fluids on request 20 to + 80 (with FKM seals) 2.8 to 500 Maximum permissible degree of contamination of the pressure fluid is to NAS 1638 class 9. We, therefore, recommend a filter with a minimum retention rate of 10 75.

Electrical

Voltage type Available voltage

1)

DC V % W 24 10 19 Continuous See table below cycles/h

2)

Voltage tolerance (nominal voltage) Power consumption Duty Switching time to ISO 6403 Switching frequency Protection to DIN 40 050 Maximum coil temperature

1) 2)

15000 IP 65 150 When connecting the electrics, the protective conductor (PE ) must be connected according to the relevant regulations.

Further voltages on request. Due to the occuring surface temperature of the solenoid coils, please observe the European standards EN563 and EN982!

Switching time t in ms (installation: solenoid horizontal) Characteristic curves

Symbols N P DC solenoid Switching time (measured at = 41 mm2/s and = 50 C)

ton

50 50

toff

Pressure differential in bar

10 10

p-qV-characteristic curves

16

12

Performance limits

(measured at = 41 mm2/s and = 50 C) Max. operating pressure Max. flow

pmax = 350 bar qV = 20 L/min

YSE1P YSE1N

Attention! The performance limit was determined with the solenoids at operating temperture and a 10% under voltage.

12

16

20

Flow in L/min YSE1 3/4 Rexroth Hydraulics

RE 18 136-02/05.00

Unit dimensions

(Dimensions in mm)

1 2 3 4 5 6 7 8

Actuator connection 1 Actuator connection 2 Plug-in connector to DIN 43 650 must be ordered separately, see page 2 Space required to remove the plug-in connector Protected hand override 24 A/F; tightening torque, MA = 45 to 50 Nm Dim. for plug-in connector without circuitry Dim. ( ) for plug-in connector with circuitry 6

4 3 8 7 5

82,7 (88,7) 037

2

010

1

05

LS stop

68 86,6

2,8

34,7

Symbol P Symbol N

Cavity T-13A; 2 actuator connections; thread M20 x 1.5 ** a

30 0,000 LS 3,96 21,11** 21,21

(Dimensions in mm)

0,8 Recommended distance from Free area for solenoid valve

the surface (with spot face)

1,6 Recommended distance from 32,0 32,1 A 20,62 20,67

39 mm

a

4 5

the surface (without spot face)

LS stop (dim. ref. edge) 17,5

min. spacing (central axis to the central axis of an identical cavity)

0,000

12,7 Min. distance for area

with full threads

27,4 35,05 35,18 41,28 Min. depth

18,54** 18,64 17,45** R0,5 17,50

45

General dimensional tolerances 0.05 A ** Concentrictiy 0.2 mm One pos. (X,X) 0.1 mm Two pos. (X,XX) 18,26 1/2 Angular tolerance 1,6 Surface finish 0,5 Corner radius

1 13,5

Support for the valve bush

Min. depth of 13.5 = 40.4 (valve working range)

max. 0,25 x 45

Mannesmann Rexroth AG Rexroth Hydraulics D-97813 Lohr am Main Jahnstrae 3-5 D-97816 Lohr am Main Telefon 0 93 52 / 18-0 Telefax 0 93 52 / 18-23 58 Telex 6 89 418-0 E-Mail product.support@rexroth.de Internet www.rexroth.com

Mannesmann Rexroth Limited Cromwell Road, St Neots, Cambs, PE19 2ES Tel: 0 14 80/22 32 56 Fax: 0 14 80/21 90 52 E-mail: info@rexroth.co.uk

The specified data is for product description purposes only and may not be deemed to be guaranteed unless expressly confirmed in the contract.

All rights reserved Subject to revision

4/4

15

YSE1

Das könnte Ihnen auch gefallen

- Re 22049Dokument16 SeitenRe 22049ShortcutterNoch keine Bewertungen

- Re 23178Dokument20 SeitenRe 23178borigueNoch keine Bewertungen

- Duplo MaticDokument8 SeitenDuplo MaticHENRYGALLEGOSNoch keine Bewertungen

- Rexroth 4WE6D6X-G24 Directional ValveDokument12 SeitenRexroth 4WE6D6X-G24 Directional ValveCosma Petru-RaulNoch keine Bewertungen

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Dokument4 SeitenSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9Noch keine Bewertungen

- Rexroth电磁阀手册Dokument12 SeitenRexroth电磁阀手册davidwang85120% (1)

- Pizzato Elettrica Position Switches FR Series - Catalog 2011-2012Dokument12 SeitenPizzato Elettrica Position Switches FR Series - Catalog 2011-2012IBJSC.comNoch keine Bewertungen

- FR 502-1W3XGM2K70 position switchDokument12 SeitenFR 502-1W3XGM2K70 position switchMehmetLeventÖzsinanNoch keine Bewertungen

- ElectrovalvulasDokument8 SeitenElectrovalvulasRaul Guevara TorresNoch keine Bewertungen

- E5907 ws08z01-1Dokument2 SeitenE5907 ws08z01-1raul20132013Noch keine Bewertungen

- Rexroth 4we10 Data SheetDokument10 SeitenRexroth 4we10 Data SheetOrlando Arias100% (1)

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDokument10 SeitenHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111Noch keine Bewertungen

- 3-En2200-B - 4VP01Dokument15 Seiten3-En2200-B - 4VP01najafali1Noch keine Bewertungen

- Piston Positioning Wire System for Olaer AccumulatorsDokument6 SeitenPiston Positioning Wire System for Olaer AccumulatorsankvepeNoch keine Bewertungen

- Breaker Control SwitchDokument4 SeitenBreaker Control Switchpankaj_electricalNoch keine Bewertungen

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDokument8 Seiten4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNoch keine Bewertungen

- Atos Industrial ValvesDokument22 SeitenAtos Industrial ValvesM S GokulNoch keine Bewertungen

- Proportionala Bosch REPDokument16 SeitenProportionala Bosch REPMihaiNoch keine Bewertungen

- Ra 23351Dokument10 SeitenRa 23351GuilhermeGFCNoch keine Bewertungen

- Ev DG05Dokument14 SeitenEv DG05mtbecerrapNoch keine Bewertungen

- 3730-1 Positioner for Pneumatic Control ValvesDokument6 Seiten3730-1 Positioner for Pneumatic Control ValvesJuan MuñozNoch keine Bewertungen

- 4wre 6-10 Sew1xDokument12 Seiten4wre 6-10 Sew1x2267airportNoch keine Bewertungen

- Limit Switch eDokument16 SeitenLimit Switch esalmo83:18Noch keine Bewertungen

- DS PV2201 GB 10873Dokument6 SeitenDS PV2201 GB 10873eeghbaliNoch keine Bewertungen

- Moog D633Dokument16 SeitenMoog D633Balu M100% (1)

- DKRCC - pd.Vd1.d5.02 Ets6 SWDokument16 SeitenDKRCC - pd.Vd1.d5.02 Ets6 SWJaroslav BiresNoch keine Bewertungen

- Proportional Control Valves ISO 4401 Size 05Dokument8 SeitenProportional Control Valves ISO 4401 Size 05Devendra BangarNoch keine Bewertungen

- Elettrovalvole Denison HydraulicsDokument62 SeitenElettrovalvole Denison HydraulicsZMCONTROLNoch keine Bewertungen

- Control 80 l/min directional valve with low pressure dropDokument9 SeitenControl 80 l/min directional valve with low pressure dropjuanNoch keine Bewertungen

- Technical Data Sheet SY4-24-MF-TDokument10 SeitenTechnical Data Sheet SY4-24-MF-TMarcelo Magalhães QuaiottiNoch keine Bewertungen

- D631 Series Servo Control Valves ISO 4401 Size 05Dokument12 SeitenD631 Series Servo Control Valves ISO 4401 Size 05José OlaveNoch keine Bewertungen

- CT Relays (Act) : Features Typical ApplicationsDokument5 SeitenCT Relays (Act) : Features Typical ApplicationsandersonovalheNoch keine Bewertungen

- D 633 Series Valves eDokument16 SeitenD 633 Series Valves ehaggNoch keine Bewertungen

- Re29061 4WREEDokument18 SeitenRe29061 4WREEManuel VizcarraNoch keine Bewertungen

- Re29564 2007-011Dokument12 SeitenRe29564 2007-011engineer86Noch keine Bewertungen

- MH 182 Multi-Purpose Hall Effect Latch Technical SpecificationDokument11 SeitenMH 182 Multi-Purpose Hall Effect Latch Technical SpecificationharshalvikasNoch keine Bewertungen

- J Series ValveDokument16 SeitenJ Series ValvejpmanikandanNoch keine Bewertungen

- 62 Series Servovalves Technical OverviewDokument8 Seiten62 Series Servovalves Technical OverviewDevendra BangarNoch keine Bewertungen

- Electro Válvula Del CompresorDokument4 SeitenElectro Válvula Del CompresorneumaticoNoch keine Bewertungen

- Catalago PDFDokument12 SeitenCatalago PDFGregory StewartNoch keine Bewertungen

- Solinoid Popet ValveDokument3 SeitenSolinoid Popet ValvesaqureshNoch keine Bewertungen

- S4 5Dokument12 SeitenS4 5Fabian CaizaNoch keine Bewertungen

- Hall-Effect Latches: FeaturesDokument8 SeitenHall-Effect Latches: Featuresjdaudpoto100% (1)

- ALISON HIDRAULIC - Catalogue PDFDokument250 SeitenALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- Re92711 2012-01Dokument48 SeitenRe92711 2012-01Edson Huarachi FloresNoch keine Bewertungen

- Directional Valve Spec SheetDokument4 SeitenDirectional Valve Spec SheetRFIGUEROACNoch keine Bewertungen

- Electronic Pressure Switch EDS 300: Description: Technical SpecificationsDokument3 SeitenElectronic Pressure Switch EDS 300: Description: Technical Specificationsmohsinullah420Noch keine Bewertungen

- PT420A Series: FeaturesDokument3 SeitenPT420A Series: FeaturesA.K.A. HajiNoch keine Bewertungen

- 4RP01Dokument12 Seiten4RP01Margaret DaughertyNoch keine Bewertungen

- Gessmann Master SwitchDokument6 SeitenGessmann Master Switchjaviertecsa100% (3)

- DSV 100 34TRDokument2 SeitenDSV 100 34TRsgfdrfNoch keine Bewertungen

- DatasheetDokument10 SeitenDatasheetax_13Noch keine Bewertungen

- Proportional Reducing ValveDokument8 SeitenProportional Reducing ValvediabalziabNoch keine Bewertungen

- 3/2-Way Solenoid Valve, Direct-Acting, NcornoDokument7 Seiten3/2-Way Solenoid Valve, Direct-Acting, NcornoAmarnath YadavNoch keine Bewertungen

- AEGContactors10Pages 000Dokument10 SeitenAEGContactors10Pages 000Hameed Alam KhanNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesVon EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesBewertung: 4.5 von 5 Sternen4.5/5 (7)

- Mechanical engineering termsDokument8 SeitenMechanical engineering termsAhmed Abd ElhakeemNoch keine Bewertungen

- Funda05c PDFDokument11 SeitenFunda05c PDFAhmed Abd ElhakeemNoch keine Bewertungen

- En Automotive Auto Electric Basic Technology Part2 PDFDokument56 SeitenEn Automotive Auto Electric Basic Technology Part2 PDFAhmed Abd ElhakeemNoch keine Bewertungen

- WeldingDokument38 SeitenWeldingAhmed Abd ElhakeemNoch keine Bewertungen

- Re 29929Dokument4 SeitenRe 29929Ahmed Abd ElhakeemNoch keine Bewertungen

- Test Proportional & Servo ValvesDokument12 SeitenTest Proportional & Servo ValvesAhmed Abd ElhakeemNoch keine Bewertungen

- Steering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minDokument10 SeitenSteering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minAhmed Abd ElhakeemNoch keine Bewertungen

- Re 10223Dokument26 SeitenRe 10223Ahmed Abd ElhakeemNoch keine Bewertungen

- Check Valve Type Z2SRK 10 Technical SpecificationsDokument4 SeitenCheck Valve Type Z2SRK 10 Technical SpecificationsAhmed Abd ElhakeemNoch keine Bewertungen

- Piston PDFDokument1 SeitePiston PDFAhmed Abd ElhakeemNoch keine Bewertungen

- Vane Pumps, Internal Gear Pumps, Radial Piston Motors, Internal Gear MotorsDokument2 SeitenVane Pumps, Internal Gear Pumps, Radial Piston Motors, Internal Gear MotorsAhmed Abd ElhakeemNoch keine Bewertungen

- OpenDokument1 SeiteOpenAhmed Abd ElhakeemNoch keine Bewertungen

- RE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMDokument8 SeitenRE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMAhmed Abd ElhakeemNoch keine Bewertungen

- Re 10460Dokument20 SeitenRe 10460Ahmed Abd ElhakeemNoch keine Bewertungen

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDokument4 SeitenCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemNoch keine Bewertungen

- Re 29933Dokument4 SeitenRe 29933Ahmed Abd ElhakeemNoch keine Bewertungen

- Re 92012Dokument12 SeitenRe 92012Ahmed Abd Elhakeem100% (1)

- Re 57020Dokument8 SeitenRe 57020Ahmed Abd ElhakeemNoch keine Bewertungen

- Re 20375Dokument2 SeitenRe 20375Ahmed Abd ElhakeemNoch keine Bewertungen

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDokument4 SeitenCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemNoch keine Bewertungen

- Test Point Card for Monitoring SignalsDokument2 SeitenTest Point Card for Monitoring SignalsAhmed Abd ElhakeemNoch keine Bewertungen

- Piston PumpDokument4 SeitenPiston PumpAhmed Abd ElhakeemNoch keine Bewertungen

- Solenoid-actuated directional poppet valves overviewDokument4 SeitenSolenoid-actuated directional poppet valves overviewAhmed Abd ElhakeemNoch keine Bewertungen

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDokument4 SeitenCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemNoch keine Bewertungen

- Re 20375Dokument2 SeitenRe 20375Ahmed Abd ElhakeemNoch keine Bewertungen

- صمامات مؤازرةDokument10 Seitenصمامات مؤازرةAhmed Abd ElhakeemNoch keine Bewertungen

- Re 15190Dokument24 SeitenRe 15190Ahmed Abd ElhakeemNoch keine Bewertungen

- Re 20375Dokument2 SeitenRe 20375Ahmed Abd ElhakeemNoch keine Bewertungen

- Re 20375Dokument2 SeitenRe 20375Ahmed Abd ElhakeemNoch keine Bewertungen

- Re 21536Dokument4 SeitenRe 21536Ahmed Abd ElhakeemNoch keine Bewertungen