Beruflich Dokumente

Kultur Dokumente

432 Project

Hochgeladen von

Sahil PalCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

432 Project

Hochgeladen von

Sahil PalCopyright:

Verfügbare Formate

CE 432 Wastewater Treatment Plant Design

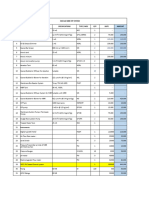

Sewer Design, edit bolded values: S, n, conduit fill ratio e.g. .75, Qavg (MGD) and the factors for Qpeak hour

Given:S = .005 ft/ft, n=.003, conduit 3/4 full BOD 5 250 S(ft/ft) = 0.005 SS 220 n= 0.013 Total P 9 NH3-N as N conduit fill ratio = 0.75 30 Q avg, MDG = 15 Q peak hourly, factor 2.5 Q min, factor 0.4 Find: D, Vmin, Vmax D, inches = 40.28 Use next larger commerically available size, subsequent d's and V's based on the calculate Vmax, fps = 8.15 davg, inches 28.56 Vavg, fps = 3.46 dmin, fps = 20.26 Vmin, fps = 2.08 Waste Flows Design Flow Q avg Q peak Q min

Factor 1 2.5 0.4

MGD 15.00 37.50 6.00

CFS 23.21 58.01 9.28

GPM 10417 26042 4167

Calculate the pipe diameter d/D= 0.75 -1 q = 2cos (1-(2d/D))= 240.00 q, radians 4.19 A=(D2/8)(q-sin(q)) R=(D/4)(1 - sin(q)/qr) AR2/3=(D8/3/ (8*4 2/3))(q-sin(q)(1 - sin(q)/qr)2/3 (q-sin(q)(1 - sin(q)/qr)2/3 = Qn(8*42/3)/ [ (1.486)*D8/3*S1/2 ] D based on peak flow = [ Qn(8*42/3)/ (1.486)S1/2(q-sin(q))(1 - sin(q)/qr)2/3 ] 3/8 D, feet = 3.36 D, inches = 40.28 Use next larger commercially available size Calculate the maximum velocity based on the peak hourly flow A=(D2/8)(q-sin(q)) d for max flow, ft 30.21 d/D= 0.75 q = 2cos-1(1-(2d/D))= 240.00 q, radians 4.19 A, ft2 = 7.12 Based on calculated D, not next larger commerically available size Vpeak, fps = 8.15 Calculate the average velocity based on the average flow d for avg flow, ft = 2.38 Based on calculated D, not next larger commerically available size

d for avg flow, inches = d/D= q = 2cos-1(1-(2d/D))= q, radians A, ft2 = Vavg, fps =

28.56 0.71 229.47 4.00 6.71 3.46

Calculate the minimum velocity based on the minimum flow d for min flow, ft = 1.69 Based on calculated D, not next larger commerically available size d for min flow, inches = 20.26 d/D= 0.50 q = 2cos-1(1-(2d/D))= 180.68 q, radians 3.15 2 A, ft = 4.46 Vmin, fps = 2.08

the factors for Qpeak hourly and Qmin.

s and V's based on the calculated value shown.

CE 432 Wastewater Treatment Plant Design

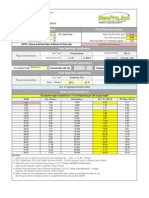

Bar Screens

Given: Provide 2 (1+1) mechanical screens, q=75, bars space = 1.0 inches, Vmax = 3.0 fps, Vavg = 2fps, Vmin =1.3 fps q, degrees = 0.005 Vmax, fps = 0.013 Vavg, fps = 0.75 Vmin, fps = Find: 1. Bar rack dimensions 2. Chamber dimensions d in the rack at peak flow headloss through the rack draw a dimensional plan and profile of the bar screen structure Waste Flows Design Flow Factor MGD CFS Q avg 1 15.0 23.21 Q peak 2.5 37.5 58.01 Q min 0.4 6.0 9.28

avg = 2fps, Vmin =1.3 fps

CE 432 Waste water treatment plant design Grit Chamber

Waste characteristics Design Flow MGD Ave Q 12 Peak Q 25 BOD 5 SS Total P

NH3-N as N

CFS 18.60 38.75

250 220 9 30

D. Primary

CE 432 Waste water treatment plant design

mg/l Waste characteristics Design Flow Ave Q Peak Q MGD 12 25 CFS 18.60 38.75 BOD 5 SS Total P

NH3-N as N

250 220 9 30

Plant Effluent Qualities BOD 5 SS VSS/SS ratio Module D-- Primary Treatment

(mg/l) 20 20 0.65

L/W ratio

BOD 5 Percent Removal Effluent (mg/l) 34 165

SS 63 81.4

Design Criteria No. of Tanks Detention Time SOR 2 1.5 800 hours min. gpd/sf

Calculations

Tank Dimensions Tank Area = Q/ SOR= Tank Vol = Q * DT Tank Depth = V/A = 15000 750000 sf total or gal total or 7500 sf each tank 375000 gal ea tank

6.68 ft

Use 7 ft plus 2 ft freeboard

A = Wx L = W x 4 W L = A/W=

W= 187.5

43.3 ft

use use

40 190

ft ft

Page 7

E. AS

Module E. Activated Sludge Treatment Tot BOD 5 Primary Effluent 165 SS 81.4 20 0.65 13 biodeg/SS biodg solid

Secondary Effluent Qualities (mg/l) 20 Peak Factor E1 BOD rate constant k Ratio of Lu to 5 day BOD = f = 2.1

0.1 per day 0.684 12.6 7.4

BOD due to biomass = 1.42 *biodg * BOD/Lu = Soluble BOD in effluent = Total BOD - BOD due to biomass=

Biological Treatment Efficienty based on soluble BOD = Biological Tramtment Efficiency based on total BOD=

95.5% 87.9%

E2

Aeration Volume

Use Metcalf and Eddy's Kinetic Model VX = Y Q C (S0-Se) / ( 1+ kd C) Design parameters X = MLVSS ( mg/l) Y = Cell yield co. ( per day) Q = Inflow ( MGD) C= Cell resident time (days) kd=endo. resp. rate ( per day) So = BOD in inflow (mg/l) Se = BOD in effl. (mg/l) 2800 0.6 12 MGD 10 days 0.06 165 7.4 MLSS = 3500 VSS/SS 0.80

Volume of tank ( MG) = V = Y Q C (S0-Se) / ( 1+ kd C) /X= Volume ( cf) = Hyd retention time = V/Q= 0.21 days or

2.53 338665 5.1 hrs

E3

Tank dimensions Tank depth ( ft) Total Tank area = V/d Area for each tank = Width of each tank = Length of each tank= 15 ft 22578 sf 5644 33.6 166 use 34 No. of Tanks L/W ratio 4 5

E4

Return Sludge Rate Calculate by balancing biomass around reactor ( not accurate/ ignores cell growth in reactor)

Page 8

E. AS

Q Xo + Qr Xr = ( Q+Qr) X Q Qr=Q X / ( Xr-X) 12 Xo 0 X 2800 Xr 10000 MG Qr 4.67 Qr/Q 0.39

E5

Waste Activated Sludge Rate Method A. Calculated from Cell Residence time C C = V X/(QwXr+QeXe) Qw =(VX/C-QeXe)/Xr= WAS--VSS (lbs/day)= WAS--SS (lbs/day) = 0.0553301 MG 4615 5768 Px = Yobs Q ( So-Se) 8.34 Y Yobs = Y / ( 1+kd C) Q Biomass SS WAS --SS (lbs/day) = Px - Q Xe 8.34 = 12 0.6 So 165 Kd 0.06 Se 7.4 C 10 Px 5916 7394 5393 Yobs 0.375 10 V 2.53 X 2800 Xr 10000 Xe 13

Method B. Calculate from BOD removal

Use the larger of two methods

WAS--SS =

5768 lbs/day

E-6

RAS and WAS Pumps

Tot Q MG

Q/pump gpm 4.67 0.055 1080 58

Qp/Pump gpm 2251 120

no. of RAS pumps no of WAS pumps (WAS pumps 8 hr/d)

3 2

E-7

Oxygen Requirements

O2 = C BODu - BODu in Px + N BODu Q So 12 165 Se 7.4 f 0.684 C BODu 23070

C BOD = Q ( So-Se) 8.34 / f

Px (SS lb/d))Biodg/SS BOD in WAS = 1.42 Px (biod) 5916 0.65

BOD in WAS 5460

O2 (lbs/d) =

17610 36688

For ave flow For peak flow

Page 9

E. AS

E-8

Compressor Requiement

Air requirement at STP ( 14.7 psi and 68 F) lbs/cf Air 0.0752 O2/Air Vol O2/Air Wt 0.21 0.23 transfer eff = air wt(lb/d) 76566 0.128 air (lb/sec) air (scfm) 0.886 6.923 14.42 Sized at Qp e 0.8 P2 (psia) 24.7 P1(psia) 13.7 R 53.3 Each compressor Av disch P 19.7 no of compressor HP max Check MIxing Ave Q (scfm/1000 cf aeration vol) At Qp cfm/scfm* cfm/1000cfm Ave flow At peak flow E-9 Calculate numuber of diffusers From M&E p. 562 T 10-7, typical values 3.3-10 cfm per diffuser Use diffuser with number of diffusers = number of diffuser per tank= 5 cfm/diffuser at Qp 2302 575 L Coarse bubble spiral Grid Diffuser spacing = L/n Spacing =sqrt( tank area/ no of diffusers) = 3 n Spacing(ft) spacing(in) Ceramic Disc Grids 0.87 14.2 29.5 (Ts/Ts) Vs 639 scfm 5524 6 V (1000 cf) scfm/1000cfm T tank 339 16.3 34.0 *Vt=(Pstp/Pt)x (Tt/Tstp) Vstp Range 20-30 560 106 P ave tank 17.9 T (R) 570 707 5524 11508

Air requirement= air /transfer efficiency Air requirement at Qp Compressor HP = [WRT/(550 n e) ][(P2/P1)**n-1] W (lb/sec) 14.42 Total n 0.283

E-10

F/M Ratio F (lb/d) = Sox Qx 8.34

So 165 MLVSS

Q 12 V 2.53

F (lbs/d) 16513 M 59155.7

M(lbs) = MLVSS V 8.34

2800

F/M ratio =

0.28

Typical range 0.2-0.4

Page 10

E. AS

E-11

Organic Loading ( #BOD/d per 1000 cf aetation volume)

F ( lbs/d) V ( 1000 cf) F/V

16513 339 48.8 Typical range 50-120

Alternate I. Trickling Filter Es = 100/(1+0.0085 sqrt(W/VF)) V = W/F [(100/Es-1)/0.0085]^(-2) V = Volume in Acre-Ft W = BOD applied lbs/d

Es= BOD removal Efficiency Es=100*(So-Se)/So

F = (1+R)/(1 + 0.1 R)**2 R = Recirculaiton ratio Es Calculate V # filters Filter Dimensions 6 88 R 2.0 Depth (ft) 6 SF each 36423 F 2.08 W 16513 Diam ( ft) 215 V (AC-Ft) V ( cf) 30.10 1,311,216

Alternate II. RBC

See Text Figure 10-39

Hydraulic loading depends in soluble BOD in influent and total BOD in effluent. Influent total BOD Influent soluble BOD Effluent total BOD Hydraulic loading rate Calculate A required Check Organic Loading Each shaft provides No of shafts required No of shafts per train No.of shafts per train 165 mg/l 115.5 20 1.6 gpd/sf 7500000 SF 2.20 lbs/d per 1000 SF Typical range 2- 3.5 27 ft From Fig 10-39 , P. 634 Assume 70% soluble

140 MSF( average value) for shaft length 54 4 13.4

Page 11

E. AS

Page 12

E. AS

Page 13

E. AS

Page 14

F. Final Clar

Module F. Final Clarifier Qp Design Criteria at Qp at Q ave (MGD) 25 12 16667 SF SOR (gpd/sf) 1500 SL (#/d per sf) 50

Area required for clarification = Q/SOR =

Note: See P.588. Q excludes Qr becasue return sludge is drawn off the bottom, therefore, does not contibute to overflow rate. Area required for thickening = Total SS lbs/d / SL Qr/Q Total solids (lb/d) 0.39 Qp 25 (Q+Qr) peak MLSS 34.72 20271 Total SS 3500 1013541.7 Use the higher area for design

Area required for thickening (SF) =

d Detention time = A d / (Q+Qr) No. of circular tanks= Tank dimensions Each Tank A 5068 4 Dia 80 10

DT (h) ave 2.2

DT (h) pk 1.05

Module G. Gravity Thickener # tanks Design Criteria 2 SLR lbs/d/sf 10 SOR gpd/sf 800 Thicken S % solids 8%

Sludge Quantity SS in WW WAS ( From E-5) Total Sludge

SS(mg/l) 220

Q 12

SS (lbs/d) VSS/SS 22018 5768 27786 0.7 0.80

VSS(lbs/d) 15412 4615 20027

Total A Circular Tank Dimensions 2779 SS (lb/d) Volume of Thickend Sludge 27786

Each A 1389.2881 SG 1.01

Diam (ft) 42 Solid % 8% V (cf/d) 5511 Depth (ft/d) 2.0

Blanket(ft) Rmvl(ft/d) SVI Sludge Volume Ratio = V of sludge blanket/ V sludge removal Typical range of SVI is 0.5-20. If SVI > 20, Bulking sludge. 8 2.0 4.0

Page 15

CE 432 Waste water treatment plant design Gravity Thickener

Waste characteristics Design Flow MGD Ave Q 12 Peak Q 25 BOD 5 SS Total P

NH3-N as N

CFS 18.60 38.75

250 220 9 30

H. Ana Dig

Module H. Anaerobic Digester Design Criteria # Tank T digester oF 3 95 50 40 40 T slud in T earth T air DT days 15 VSS load lb VSS/d/cf 0.2

SS (lbs/d) Primary sludge Biosludge Total sludge 22018 5768 27786

VSS/SS 0.7 0.8 0

VSS(lbs/d) V (cf/d) 15412 4615 20027 5511

1 Tank Dimensions Volume required for hyd loading = Volume required for VSS loading= Digester Dimensions #Tank Each Tank 3 V (cf) each Depth(ft) 33378 30 A each 1113 Daim 38 82664 cf 100134 cf Use the higher value

2 Energy Production Assumptions 15 cf gas per lb solids destroued 600 BTU per cf gas 50% of VSS applied are destroyed TSS app #/d 27786 Fix SS #/d 7759 VSS appl #/d 20027 VSS destr #/d 10013 Gas prod cf/d 150201 E prod MBTU/d 90121

Digested Sludge Characteristics VSS 10013 FS 7759 TSS 17772 ( lbs/d)

3 Energy Requirements for Digester Heating (BTU/d) Total Heat Req( Ht) = Heat req to raise temp of sludge ( Hs) + Heat req to compensate for loss ( Hl) Hs = P ( #/d sludge dry solids) x ( 100/ps) ( Td-Ts) x (1/24 )x Cp ps=% solids P Cal Hs 27786 Cp = sp heat of sludge Td= temp of digester Ts = temp of sludge ps 8% Td 95 Ts 50 Cp 1 Hs (BTU/hr) 651229

Page 17

H. Ana Dig

Hl= C ( Coef of heat flow) x A ( contact area) x ( T d- To) Cal Hl Dry earth Air ( Cover) Air ( walls) Wet earth Total heat loss C 0.08 0.3 0.3 0.26 Td 95 95 95 95 To 40 40 40 A 3338 3338 10642

To is temp of outside Hl 14686 55074 175591

245351

Total Heat requirements ( BTU/h) = Hs + Hl =

896580

Page 18

I. Sludge Dewater

Module I Sludge Dewatering

Disgested Sludge TSS (lbs/d)

17772

Solid Loading Rate for filter drum Filter Drum Area (sf) =

4 #/hr per sf 185

Chemical Requirements Dose Lime Ferric Chloride 8% 2% lbs/d 1422 355

Volume of Sludge Cake

Total Weight of sludge cake = Solid content of sludge cake = SG of dry solids is assumed to be Calculate SG of sludge

19550 18% 2 1.18

Volume of sludge cake (cf/d)

1475

Page 19

Das könnte Ihnen auch gefallen

- 432 ProjectDokument19 Seiten432 ProjectjnmanivannanNoch keine Bewertungen

- Physico-Chemical Wastewater Treatment IntroductionDokument27 SeitenPhysico-Chemical Wastewater Treatment IntroductionmsinsigneNoch keine Bewertungen

- Hydraulic Design of Sewage Treatment PlantDokument9 SeitenHydraulic Design of Sewage Treatment PlantSCR_010101Noch keine Bewertungen

- Calculation SheetDokument17 SeitenCalculation SheetMohamed ArafatNoch keine Bewertungen

- Final Bop TDDokument79 SeitenFinal Bop TDsuleman247Noch keine Bewertungen

- MBBR BOD Removal Nitrification - US UnitsDokument38 SeitenMBBR BOD Removal Nitrification - US UnitsruwaaquaNoch keine Bewertungen

- 03 Conventional Water TreatmentDokument80 Seiten03 Conventional Water Treatmentbksri1239561Noch keine Bewertungen

- Summary Report: RO System Flow DiagramDokument3 SeitenSummary Report: RO System Flow Diagramjugal ranaNoch keine Bewertungen

- Lime DosingDokument16 SeitenLime Dosingthiru84Noch keine Bewertungen

- Design FMR HighDensityDokument2 SeitenDesign FMR HighDensityPandiaraj MkNoch keine Bewertungen

- MBR Design SheetDokument9 SeitenMBR Design SheetVenkatesh SivaramanNoch keine Bewertungen

- Treatment Plant HydraulicsDokument11 SeitenTreatment Plant HydraulicsMadhavan DurairajNoch keine Bewertungen

- Al Ain Sludge Status - BwiDokument1 SeiteAl Ain Sludge Status - BwiHRK65Noch keine Bewertungen

- CIP Procedure of RO MembraneDokument2 SeitenCIP Procedure of RO MembraneTanzila SiddiquiNoch keine Bewertungen

- Trikling FiltersDokument16 SeitenTrikling Filtersmosaad khadrNoch keine Bewertungen

- Ecoprocesstm SBR Design NotesDokument3 SeitenEcoprocesstm SBR Design NotesTrilok ChandraNoch keine Bewertungen

- 40 KLD MBR QuoteDokument15 Seiten40 KLD MBR QuoteV Narasimha RajuNoch keine Bewertungen

- Lecture 7 + Biological-Activated Sludge PDFDokument13 SeitenLecture 7 + Biological-Activated Sludge PDFAli AlibrahimiNoch keine Bewertungen

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedDokument11 Seiten1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedsanjeevNoch keine Bewertungen

- 2015 CVL300 Tutorial 4 SolutionDokument7 Seiten2015 CVL300 Tutorial 4 SolutionAhmed Abuzour100% (2)

- Annex 29 Area Calculation For Extended AerationDokument1 SeiteAnnex 29 Area Calculation For Extended AerationPradeep DavuluriNoch keine Bewertungen

- De NitrificationDokument3 SeitenDe Nitrificationkiran raghukiranNoch keine Bewertungen

- FINAL Floc Design Waila Option3Dokument38 SeitenFINAL Floc Design Waila Option3dpkNoch keine Bewertungen

- Annexure 16 - Tool For Design of Tube SettlerDokument1 SeiteAnnexure 16 - Tool For Design of Tube SettlerWikaz FiansyahNoch keine Bewertungen

- 04 Manifold HydraulicsDokument29 Seiten04 Manifold HydraulicsVeena NageshNoch keine Bewertungen

- Lesson Plan: How Do We Clean Polluted Water?Dokument15 SeitenLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNoch keine Bewertungen

- WaterSoftner - Opened by M.gh.Dokument4 SeitenWaterSoftner - Opened by M.gh.Hamdy AdelNoch keine Bewertungen

- Design & Sizing WWTPDokument30 SeitenDesign & Sizing WWTPRavishankar ANoch keine Bewertungen

- 14-Lime Soda Ash Treatment PDFDokument43 Seiten14-Lime Soda Ash Treatment PDFRaj BisenNoch keine Bewertungen

- Pump Stationvvvvvvvvvvvv (Recovered)Dokument28 SeitenPump Stationvvvvvvvvvvvv (Recovered)TahirJabbarNoch keine Bewertungen

- Calculation 4Dokument12 SeitenCalculation 4Geevarghese Mammen Koyippally100% (1)

- Hydraulic Level Calculations For Revised Layout Dated March 8, 2013.Dokument10 SeitenHydraulic Level Calculations For Revised Layout Dated March 8, 2013.SEPC Anta100% (1)

- Sewer Pump Calculation ReportDokument4 SeitenSewer Pump Calculation Reportarguteconsultants0% (1)

- 1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage WaterDokument14 Seiten1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage Waterabdo magdyNoch keine Bewertungen

- Nitrogen RemovalDokument96 SeitenNitrogen RemovalnusageniNoch keine Bewertungen

- Design of Notch and WeirDokument24 SeitenDesign of Notch and WeirSparsh Shukal100% (1)

- All About WastewatertreatmentDokument383 SeitenAll About WastewatertreatmentLucian Apostu100% (2)

- Journal of Water Process Engineering: SciencedirectDokument8 SeitenJournal of Water Process Engineering: SciencedirectOmar GameelNoch keine Bewertungen

- Hyd - Cal. WTP BaggiDokument27 SeitenHyd - Cal. WTP BaggiChief Engineer PMUNoch keine Bewertungen

- Demand 10 MLD Input Prompts Colour CodeDokument2 SeitenDemand 10 MLD Input Prompts Colour CodeRyeanKRumano100% (1)

- 4b., 5. & 6. PDC, HDC & LCUDokument16 Seiten4b., 5. & 6. PDC, HDC & LCUepe civil1Noch keine Bewertungen

- Water Feature 1,2,3Dokument15 SeitenWater Feature 1,2,3Anonymous 6HjnToW6Noch keine Bewertungen

- Rapid Sand Filter and Tube SettlersDokument16 SeitenRapid Sand Filter and Tube Settlersnp27031990Noch keine Bewertungen

- UF Process DesignDokument58 SeitenUF Process DesignAsad RazaNoch keine Bewertungen

- Sps and Wetwell NTLDokument3 SeitenSps and Wetwell NTLProject ManagerStructuresNoch keine Bewertungen

- Workbook Contents: Find More Excel Spreadsheets For Engineering atDokument8 SeitenWorkbook Contents: Find More Excel Spreadsheets For Engineering atJuan Alberto Camarena MonroyNoch keine Bewertungen

- Techno Feasibility Report LAIL 1 PDFDokument28 SeitenTechno Feasibility Report LAIL 1 PDFGarad MadhukarNoch keine Bewertungen

- Water HammerDokument3 SeitenWater HammerSrinivas ReddyNoch keine Bewertungen

- Handling Dairy Milk House WastewaterDokument31 SeitenHandling Dairy Milk House WastewaterAndreea CalcanNoch keine Bewertungen

- Intake Design: DataDokument4 SeitenIntake Design: DataGokulNoch keine Bewertungen

- Chapter 1 Basic Design ConsiderationDokument38 SeitenChapter 1 Basic Design ConsiderationAce ThunderNoch keine Bewertungen

- Effluent Treatment Plant - Process Flow DiagramDokument45 SeitenEffluent Treatment Plant - Process Flow DiagramAmarnath PNoch keine Bewertungen

- Design CalculationsDokument26 SeitenDesign CalculationsBhavin SolankiNoch keine Bewertungen

- CAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignDokument4 SeitenCAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignNICOLAS SANCHEZ GOMEZNoch keine Bewertungen

- Ate Huber-1Dokument47 SeitenAte Huber-1Ravena RemaditaNoch keine Bewertungen

- WW ExcelDokument5 SeitenWW Excelpartha6789Noch keine Bewertungen

- Chlorine DosingDokument1 SeiteChlorine DosingkailashNoch keine Bewertungen

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultDokument87 SeitenAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalNoch keine Bewertungen

- Geo Pro Inc Head Loss TablesDokument1 SeiteGeo Pro Inc Head Loss TablesSahil PalNoch keine Bewertungen

- ASME Proceedings AllTitlesDokument48 SeitenASME Proceedings AllTitlesSahil Pal0% (1)

- Oasis Engg. (HRD) : Selection OrderDokument4 SeitenOasis Engg. (HRD) : Selection OrderSahil PalNoch keine Bewertungen

- Kaiser Water CalculatorDokument32 SeitenKaiser Water CalculatorSahil PalNoch keine Bewertungen

- Wings Media CRBT Codes (19!8!11)Dokument69 SeitenWings Media CRBT Codes (19!8!11)Sahil PalNoch keine Bewertungen

- List of NFPA Codes & StandardsDokument1 SeiteList of NFPA Codes & StandardsSahil PalNoch keine Bewertungen

- City of Jackson v. Gold Coast Complaint 06-09-2021 1Dokument24 SeitenCity of Jackson v. Gold Coast Complaint 06-09-2021 1the kingfishNoch keine Bewertungen

- Be Final ReportDokument59 SeitenBe Final ReportRohit SinghNoch keine Bewertungen

- Theory + ApplicationDokument4 SeitenTheory + ApplicationYazid NazriNoch keine Bewertungen

- Introduction To Environmental Engineering: Wastewater TreatmentDokument24 SeitenIntroduction To Environmental Engineering: Wastewater TreatmentlilibethbulisaNoch keine Bewertungen

- Pacific Northwest LNG Project DescriptionDokument58 SeitenPacific Northwest LNG Project DescriptionkkkelvinNoch keine Bewertungen

- Construction and Projects in Oman: OverviewDokument23 SeitenConstruction and Projects in Oman: Overviewpradeepmadhanan0% (1)

- Slide 3 Water and Waste Water System ÀaaddgkkgcjiygggghhhhDokument20 SeitenSlide 3 Water and Waste Water System ÀaaddgkkgcjiygggghhhhDwi Citra Oktara GuciNoch keine Bewertungen

- Hidden ConsequencesDokument80 SeitenHidden ConsequencesDanielle DacuanNoch keine Bewertungen

- C5305 - Water Supply & Waste Water Engineering (Kertas Soalan Politeknik-Politeknik Malaysia Kejuruteraan Awam)Dokument6 SeitenC5305 - Water Supply & Waste Water Engineering (Kertas Soalan Politeknik-Politeknik Malaysia Kejuruteraan Awam)Azil14100% (6)

- Pollution of The WaterDokument25 SeitenPollution of The WaterJeprox Martinez100% (1)

- DENR RequirementsDokument1 SeiteDENR RequirementsEmmarie Luz Posadas100% (1)

- Reduction of Cod From Secondary Effluent of Cetp by ChlorinationDokument63 SeitenReduction of Cod From Secondary Effluent of Cetp by ChlorinationMili ThakerNoch keine Bewertungen

- Fluidized-Bed Bioreactor Applications For Biological Wastewater Treatment - A Review of Research and DevelopmentsDokument13 SeitenFluidized-Bed Bioreactor Applications For Biological Wastewater Treatment - A Review of Research and DevelopmentsAgeng RizkyNoch keine Bewertungen

- Course Code: EEZG521: Physico-Chemical Treatment Principles & Design For Wastewater Systems Dr. Vivek RangarajanDokument47 SeitenCourse Code: EEZG521: Physico-Chemical Treatment Principles & Design For Wastewater Systems Dr. Vivek RangarajanBaskar ElNoch keine Bewertungen

- Saep 327 PDFDokument13 SeitenSaep 327 PDFRami Elloumi100% (1)

- Comprehesion 2011 To 2020Dokument76 SeitenComprehesion 2011 To 2020Sherlock HolmesNoch keine Bewertungen

- Erwat Annual 2012Dokument108 SeitenErwat Annual 2012LungisaniNoch keine Bewertungen

- Purposive Ni CyDokument3 SeitenPurposive Ni CyCj CantilloNoch keine Bewertungen

- SepticDokument4 SeitenSepticRoseanne CarsolaNoch keine Bewertungen

- Grundfosliterature 5439634Dokument156 SeitenGrundfosliterature 5439634Tondano TondanoNoch keine Bewertungen

- DAO35.Denr Administrative OrderDokument20 SeitenDAO35.Denr Administrative OrderJosefina Policarpio IINoch keine Bewertungen

- Presentation On Dairy Industry: Presented byDokument28 SeitenPresentation On Dairy Industry: Presented byHamXa CHNoch keine Bewertungen

- Water Quality Modeling - ThesisDokument89 SeitenWater Quality Modeling - ThesissubhaniNoch keine Bewertungen

- Group Project of Environmental Engineering (BFC32403)Dokument1 SeiteGroup Project of Environmental Engineering (BFC32403)Rome GentaNoch keine Bewertungen

- Grundfos Axial Flow Pumps BrochureDokument7 SeitenGrundfos Axial Flow Pumps Brochurefg_111307359Noch keine Bewertungen

- Water Management in Chemical IndustriesDokument40 SeitenWater Management in Chemical IndustriesBelgaumNoch keine Bewertungen

- Importance of ETP PlantsDokument4 SeitenImportance of ETP PlantsnidhinprkshNoch keine Bewertungen

- Biodegradabilidad Oxitop y AplicacionesDokument78 SeitenBiodegradabilidad Oxitop y AplicacionesAndres FalmacelNoch keine Bewertungen

- Novel Technologies Used in Wastewater Treatment in Fertilizer IndustryDokument5 SeitenNovel Technologies Used in Wastewater Treatment in Fertilizer IndustryManiel TipgosNoch keine Bewertungen

- ESIA WaadDokument463 SeitenESIA WaadRRHH100% (3)