Beruflich Dokumente

Kultur Dokumente

03 - Chemical Engineering

Hochgeladen von

Agung Prasetyo NugrohoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03 - Chemical Engineering

Hochgeladen von

Agung Prasetyo NugrohoCopyright:

Verfügbare Formate

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch

CHEMICAL ENGINEERING

[SPECILISATION CODE: 03]

PAPER- I (Choose Any ONE Subject) S.NO 2 3 4 5 6 7 8 9 SUBJECT NAME SUBJECTCODE APPLIED NUMERICAL METHODS R50302 ADVANCED PETROCHEMICAL ENGINEERING R50303 BIO-CHEMICAL ENGINEERING R50304 CHEMICAL REACTION ENGINEERING R50305 ENERGY ENGINEERING R50306 FUNDAMENTALS OF BIOCHEMISTRY AND R50307 MICROBIOLOGY MATHEMATICAL & STATISTICAL METHODS R50308 IN CHEMICAL ENGINEERING UPSTREAM AND DOWNSTREAM BIO R50309 PROCESSING

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch

CHEMICAL ENGINEERING

[SPECILISATION CODE: 03]

PAPER II (Choose Any ONE Subject) S.NO 1. 2. 3. 4. 5. 6. 7. 8. SUBJECT NAME ADVANCED BIOCHEMICAL ENGINEERING ADVANCED ENVIRONMENTAL ENGINEERING ADVANCED THERMODYNAMICS CHEMICAL ENGINEERING PLANT DESIGN ENERGY CONSERVATIONAL IN CHEMICAL PROCESS INDUSTRIES INDUSTRIAL MICROBIAL PRODUCTS MEMBRANE TECHNOLOGY SEPARATION PROCESSES SUBJECT CODE R50351

R50352 R50353 R50354 R50355 R50356 R50357 R50358

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50302

APPLIED NUMERICAL METHODS

1. 2. 3. 4. 5. 6. 7. 8. Linear Algebraic Equations introduction Gauss elimination LU decomposition Gauss jorden elimination. Gauss sieded methods. Nonlinear algebraic equations: introduction, single variable successive substitutions (Fixed point method) Multivariable Newton-Rapson technique. Eigen values and eigenvectors: Introduction power method. Function evaluation introduction least squares curve-fit (linear regression). InterpolationNewtons forward formulaic. Newtons backward formulae. Interpolation polynomial. Lagrangian interpolation (Unequal intervals). Pade approximations. Ordinary differential equations-initial value problems (ODE-JVPS) : introduction explicit Adams-Bash forth techniques. Predictor-corrector techniques. Runge-kutta methods. Ordinary differential equations Boundary value problems (ODE-BVPs). Introduction, Galerkin finite element (GFE) technique. Shooting Techniques. Partial Differential Equations (PDEs). Introduction the finite difference technique (method of lines), The Galerkin finite element (GFE) technique.

Text/ Reference 1. 2. 3. 4. Mathematical Methods in chemical Engg. S. Pushpavanam. Prentice Hall of India. Numerical methods in engineering, S.K. Gupta., Tata Mc Graw Hill. Numerical methods-P.konda swamy, K. Thilagravathyt, K.Gunavathy, S.Chand & Company Ltd. Introduction to the finite element methods, Erik G.Thompson. john wiley & Sons, 2004.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50303

ADVANCED PETROCHEMICAL ENGINEERING

Unit I 1. Past, present and future of petrochemicals 2. Refining of petroleum 3. Characterization of complex feed stocks 4. Simple methods to define conversion of complex feed stocks Unit II 1. Alternative sources and strategies to meet future needs of chemical process industries 2. Various processes and techniques involved in thermal cracking 3. Catalytic cracking 4. Fluidized catalytic cracking 5. Steam reforming and partial oxidation 6. Mechanism involved during thermal cracking reaction 7. Fundamentals of initiation, propagation, disproportionation and termination steps during free radical reactions and their applications to polymerization processes in the production of LDPE and HDPE. Unit-III 1. Recent trends in the production of LDPE and HDPE. 2. Details of thermal cracking to produce light olefins from various feed stocks. 3. Ethanol dehydration process to produce Ethylene. 4. Effect of various parameters i.e. temperature, residence time, HCCP and C/H ratio on yields of important products from various feed stocks during thermal cracking 5. R-K theory to predict product yields from various feed stocks during thermal cracking Unit IV 1. Coke formation during thermal cracking and catalytic cracking reactions from various petrochemical feed stocks 2. Simple models of coke formation during thermal cracking reactions to produce maximum light olefins 3. Various structures of deposited coke during Pyrolysis 4. Various ways to inhibit coke formation Unit V 1. Industrial process of hydro cracking and reforming 2. Global economic scenario of petrochemical industry 3. Newer materials of construction 4. Environmental aspects of petrochemical industry in general.

Texts/References: 1. 2. 3. 4. 5. 6. 7. Nelson, W.L.Petroleum Refinery Engineering, McGraw Hill, New York 1961. Hengstebeck R.J. Petroleum Refining, McGraw Hill, New York 1959. Steinier H, Introduction to petroleum Chemical Industry, Pergamon, London, 1961. V.Y.Sern, Gas Phase Oxidation, Pergamon, London, 1964. A.L.Waddams Chemicals from Petroleum. KNIEL, WINTER & STOCK Ethylene Derivatives, Marcell Dekker Publishers. Various Hydro Carbon Processing Journals.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS. 8. Various Publications in the relevant field.

W.e.f. 2005-2006 Batch

Subject Code: R50304

BIO-CHEMICAL ENGINEERING

1.

Bioresources, Biomolecules, Enzyme and Enzyme Kinetics, case study of commercial Enzyme process.

2.

General Micro biology, Metabolic Stoichiometry and energetic, molecular genetics, microbial kinetics and reactors.

3.

Case studies in microbial Processes.

Texts/ References: 1. 2. 3. Bailey , J.E. and Ollis, D.F., Biochemical Engineering fundamentals , 2 nd Ed. Mc. Graw- Hill, New York, 1986. Aiba, S., Humphrey , A. E, Biochemical Engineering , Academic Press, 1973. Precott, S.C., Dunn, C.G., Industrial Microbiology, Mc. Graw-Hill, New York, 1960 & 1983 edns.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50305

CHEMICAL REACTION ENGINEERING

Non-Ideal flow: Two-parameter models - Modeling real reactors with combination of ideal reactors, testing a model and determining its parameters. Mixing of fluids: Zero parameter models, Segregation model, and maximum mixedness. Fluid-Particle Reactions: Application to Design Various types of contacting in gas-solid operations; Development of performance equation for frequently met contacting pattern assuming uniform gas composition, application to a fluidized bed with entrainment of solid fines. Fluid-Fluid Reactions: Application to design - Towers for fast reaction; Towers for slow reaction, Mixer-settlers (Mixed flow of both phases), Semi-batch contacting patterns, Reactive distillation and extractive reactions. Catalysis and Catalytic Reactors: Design of reactors for Gas-Solid reactions Heterogeneous data analysis for reactor design, catalytic deactivation moving bed reactors, fluidized bed reactors. External diffusion effects on heterogeneous reactions - External resistance to mass transfer. Diffusion and Reaction in porous catalysts - Diffusion and Reaction in spherical catalyst pellets, Internal effectiveness factor, Falsified kinetics, Overall effectiveness factor, Estimation of diffusion and reaction limited regions, Mass transfer and reaction in a packed bed. Non-isothermal reactor design - energy balance, non-isothermal continuous flow reactors at steady state, equilibrium conversion; multiple steady states - heat removed term, heat of generation, ignition- extinction curve. Texts/ References 1. Fogler, H. S. Elements of Chemical Reaction Engineering, Prentice Hall, New Jersey, (1986) 2. Octave Levenspiel, Chemical Reaction Engineering, Wiley Eastern University, 2nd Edition New Delhi. (1972)

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50306

ENERGY ENGINEERING

Unit-I 1. Conventional energy sources 2. Past present and future states of conventional energy sources 3. Comparison between solid, liquid and gaseous feed stocks 4. Problems associated with coal as a source of energy 5. National scenario of coal reserves 5. Origin of coal, analysis classification, storage and utilization. Unit-II 1. Past, present and future status of petroleum as an energy source 2. Characterization of feed stocks 3. Compressed natural gas 4. Low sulfur Diesel as a ecofriendly fuel compared to conventional petrol-motor gasoline 5. Ecological aspects of petroleum feed stocks as energy source, their properties and uses 6. The total energy concept of petroleum industry Unit-III 1. Non-conventional energy sources 2. Solar energy, Wind energy, Tidal and Wave energy, Nuclear energy, Ocean, Thermal and Hydrogen energy Unit-IV 1. Principles of energy conservation 2. Economics of energy conservation measures 3. energy audit 4. Methanol and Ethanol fuels and comparison with gasoline and diesel Unit-V 1. Biomass as a source of energy 2. Pyrolysis, Gasification 3. compulsory and Combustion aspects of biomass and solid waste 4. Ecological and energy management of biomass and solid waste 5. Integrated Rural development to get clean energy and other needs of the country Texts/ References 1. 2. 3. 4. 5. S. Sirkar, Fuels and combustion, Orient Long man, II ed., G. D. Rai, Non-Conventional energy sources, Khanna publications. R.H. Taylor, Alternative energy sources, Adam Higler Ltd., Various Journals on Hydrocarbon Processing Various publications in the Brister.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R 50307

FUNDAMENTALS OF BIOCHEMISTRY AND MICROBIOLOGY

Unit-I: Biochemistry: Introduction; organization of a living cell, ultra structure of a cell, organelles: cell fractionation and cell makers. Function of organelles, classification, structure functions and chemistry f amino acids, proteins, carbohydrates and lipids. The nucleic acids, Nucleosides, Nucleotides. Watson and Crick model of DNA, central dogma, replication transcription, translation, enzymes a brief account of mechanism of action, cofactors, coenzymes. Bioenergetics: principles of bioenergetics energy rich compounds. Unit-II: Metabolism: carbohydrate metabolism glycolysis, TCA cycle, HMP shunt, lipid metabolism, cholesterol synthesis, B.oxidation; Urea cycle, synthesis of purines and pyrimidines biosynthesis. Bio chemistry of some important processes: photosynthesis, blood coagulation, vision, digestion, muscle contracts. Unit-III: Microbilogy Introduction, scope, history and development of microbiology, Spontaneous generation, germ theory of disease. Difference between prokaryotic and eucaryotic cells. Bacterial cell ultra structure. Outline classification of micro organism algae, fungi, protozoa, bacteria, archae, viruses, endospores. Nutritional groups among bacteria- autotrophs and heterotrophs; phototrophy, chemotrophy, methylotrophy, organotrophy, saprophytic, symbiotic and parasitic modes of nutrition. Brief account on isolation of bacteria. Unit-IV: Fundamentals of control, control by physical agents and chemical agents, antibiotic and other chemotherapeutic agents. Bacterial cell growth, synchronous, continuous cultures. Growth curve, chemostats and brief account of viruses morphology site, ultra structure and life cycle of some representative viruses. T.M.V., T4, phase. Texts/References: 1. Outlines of Biochemistry by Conn & Stump.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50308

MATHEMATICAL & STATISTICAL METHODS IN CHEMICAL ENGINEERING 1 .Matrices and Theory of Functions Matrices and Theory Properties, Matrix Polynomial and Matrix Functions, Transformation of Matrices and Canonical Forms, Applications of Matrices, Properties of Function Spaces, Eigen Value Problems, Orthogonal Polynomials, Linear Operators and their Properties, Partial Differential Equations-Classification of Differential Equations, Methods of Characteristics, Greens Functions. Similarity solutions of PDEs, Method of Separation of Variables, Laplace Transforms, Methods of Weighted, Residuals, Statistics Probability Distributions, Random Sampling, Significance Tests, Factorial Design of Experiments, Regression Analysis, Statistical Modeling.

2.

Texts/References: 1. 2. 3. Amundson, N.R., Mathematical Methods in Chemical Engineering; Matrices and their Applications, Prentice Hall, New Jersey, 1966. Kreyszig, E., Advanced Engineering Mathematics, 6th Edition, Wiley, New York 1978. Box, G.E.P., Hunter, W.G. and Hunter, J.S., Statistics for Experiments, Wiley, New York 1978.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50309

UP-STREAM AND DOWNSTREAM BIO PROCESSING.

1. 2. 3. 4. 5. 6. 7. 8. Substrate processing (Milling, grinding, extraction, etc) The chemistry of extraction, batch extraction, staged extractions. Differential extraction fractional extraction with a stationary phase, fractional extraction with two moving phases. Medium formulation-statiscal optimization techniques. Medium sterilization theory and mechanisms filter design. Physical separation processes-solid and liquid systems, Flocculation, coagulation centrifugation setting of solids, centrifuges, scale- up of centrifugation, centrifugation; centrifugal filtration. Equilibrium processes, distillation, liquid liquid extraction. Rate processes, chromatography (GPS,HPLC,A finite, Ion exchange). Elution chromatography; adsorbents, yields and purity discrete stage analysis, kinetic analysis, scaling-up chromatography. Emerging technologies for cell recovery, separation of intra cellular, extra cellular. Heat and photo sensitive materials. New down stream techniques, reverse osmosis, electrophoresis, electro dialysis, membrane technology.

Tests/references: 1. 2. T.L. Beller, E.L.Cushler, W.L.Hu,Bio separations down stream processing for bio technology, John Willey, New York, 1988. G.L. Solomon, Materials and methods in fermentation, academic press. New York, 1975.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50351

ADVANCED BIOCHEMICAL ENGINEERING

1. 2. 3. 4. 5. 6. 7. 8. Review of Enzyme and microbial kinetics, Metabolic Stoichiometry . Kinetics of substrate utilization, Product formation and biomass production in cell cultures Growth and product formation of filamentous organisms Thermal death kinetics for cell and spores Transport phenomena in bioprocess systems Mass transfer, heat transfer and power input calculations for different kinds of fermentors and for Newtonian and Non Newtonian fermentation broths Design and analysis of biological reactors; case studies in fermentation, enzymatic and waste treatment in bioprocess design Experiments to illustrate bioprocesses.

Texts/References: 1. 2. Baily J.E. and Ollis,D.F.,Biochemical engineering Fundamentals, 2nd Edn., McGraw Hill Intl Edn, New York, 1986. Flechter, ghose,T.K., Blakebrough,N Advances in Biochemical engineering series,Springers-Verlag, Berlin.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50352

ADVANCED ENVIRONMENTAL ENGINEERING

1. 2. 3. 4. 5. 6. 7. 8. Source of water, air and land pollutions: Legislation and standards: Analysis of pollutions: Design of waste water and industrial efficient treatment: Specification of clean technologies and recovery schemes of useful chemicals. Air pollution and its measurement: Design of pollution abatement systems for particulate matter and gaseous constituents: Hazardous waste disposed and treatment: Solid waste disposal and recovery of useful products through chemical and biological methods.

Texts/References: 1. 2. 3. 4. 5. Mahajan,S.P.Pollution Control in Process Industries, Tata-McGraw Hill, 1985. N.L.Nemerow, Liquid waste of industry-Theories, Practices and Treatment, addision Wesley, New York, 1971. W.J.Weber, Physico-Chemical Processes for Water quality Control, Wiley Interscience, New York, 1969. W,Strauss, Industrial gas cleaning, Pergamon, London, 1975. A.C.Stern, Air Pollution, Volumes I to VI, academic Press, New York, 1968.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R 50353

ADVANCED THERMODYNAMICS

1. 2. 3. 4. 5. 6. 7.. 8. Fundamental Concepts of Classical Thermodynamics and their review Fundamental concepts of Statistical Thermodynamics Intermolecular forces and Potential Energy functions Molecular theory of Corresponding States Thermodynamic Properties and Multicomponent Multiphase equilibria from equations of state Molecular theories of solutions and activity Coefficient models Biothermodynamics of dilute aqueous systems Thermodynamics of polymer solutions and Colloidal systems.

Texts/references:

1. 2. 3. Prausnitz,J.M , Linchtenthaler R.M and Azevedo, E.G Molecular Thermodynamics of Fluid phase Equilibria , 2nd edition, Prentice Hall Inc., Englewood Cliffs, New Jercy, 1986. Reid R. C., Prausnitz,J.M and Poling ,B.E The properties of Gases & Liquids, 4 th ed., McGraw Hill, New York, 1987. Edsall J.T. & Gutfreund H , Biothermodynamics, John Wiely & Sons Ltd., New York, 1983.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50354

CHEMICAL ENGINEERING PLANT DESIGN

Heat Exchanger Equipment Design (a) (b) (c) (d) Shell and Tube Exchanger and condenser Multiple effect evaporator Mixed Vapour condenser Vaporizers and reboilers.

General: (a) (b) (c) Packed towers Sieve towers Valve towers

Mechanical design of exchangers and towers, Criteria in pressure vessel design, Design of pressure vessel under external pressure. Agitator equipment for flow and mixing of slurries. Elements of scale up of process equipment.

Texts/ References:

1. Backhurst J.R. and Harker J.H.., Process Plant Design, Heinemann educational Books, London, 1973. 2. Kern, D.Q. Process Heat Transfer, McGraw Hill Book Co.,1950. 3. Joshi. M.V. Process Equipment Design, McMillan India Low cost edition, 1982 4. Ludwig, E.E., Applied Process Design for Chemical and Petroleum Plants, Vol 1 and 2., gulf publishing Co., Texas, 1971. 5. Coulson, J.M. and Richardson, J.F. Chemical Engineering, Volume 6, Pergamon Press, 1983.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50355

ENERGY CONSERVATION IN CHEMICAL PROCESS INDUSTRIES

1. Energy outlook: Introduction, scope of the problem. Thermodynamic Efficiencies. The fundamental strategy. The second law of thermodynamics revisited differences between laws definitions: Available Energy, Availability and energy available energy and fuel. Characterizing Energy use: Understanding Energy use Missing Data. An illustrate onsite Audit, An illustrative steam power balance. Optimum performance of Existing Facilities: Principle 1- Minimize waste combustion principles illustrative problems-Combustion efficiency steam trap principles. Principles 2manage energy Use Effectively Facilities improvement An overall site approach, utilizing the energy audit, overall site interactions, cogeneration, total site cogeneration potential illustrate problem; maximum potential fuel utilization. The linear programming introduction. Sign conventions. Detailed procedures, illustrative examples. Detailed Thermodynamic Analysis common unit operations: introduction heart exchange, expansion-pressure letdown- P. mixing distillation combination of simple process, combustion air, preheating use of thermodynamic analysis to improve energy efficiency: introduction overall strategy, reducing available energy (Work) losses. Accepting inevitable inefficiencies. Optimization through lost work analysis research guidance thermodynamics and economics: Capital cost relationships, Background information. The entire plant energy system is pertinent, investment optimization defining the limits of current technology, fundamental process improvements. Systematic Design Methods : Introduction, Process Synthesis, Applications to Congeneration System. Thermo economics, Systematic Optimisation Guidelines and Recommendations for improving process conditions : Introduction, Chemical Reactions, Separations, Heat Transfer, Process Machinery, System Interactions and Economics, A check list of Energy Conservation items, Shortcomings of Guidelines. Energy Conservation Measures : Introduction, Management Systems for Energy Conservation, Energy Audits and Energy Monitoring, Combined heat and power generation : Introduction, Technology of CHP Systems, Balancing Heat and Power Loads, Economic Incentives for Further CHP systems, Technical Potential for Further CHP systems, Good Housekeeping (Minor) Conservation Measures. Heat Recovery : Introduction, Heat Transfer Equipment, Heat Exchanger Networks, Heat Recovery from Waste Fuels. Heat Exchanger Fouling. Heat pumps, power recovery : Power recovery from pressure reduction of process fluids, Power recovery from low grade waste heat. Energy Conservation Measure : Thermodynamics of Separation Processes, Methods for reducing energy Conservation in drying, Energy Conservation in Approach to Energy Conservation in Mixing Energy Conservation in Comminution. Role of Equipment Manufactures. Process Design : Int5roduction, Product Substitution, Process Routes, Thermodynamic (Second Law) analysis of processes, Miscellaneous design methods, Effect of energy conservation , measures on reliability and control of processes. Batch processes, Mature Processes, Economic Assessment of Energy Conservation Measures, potential for Future Energy Saving : Potential saving through good house keeping (minor) measures, Potential savings through major measures and in the long term.

2.

3.

4.

5.

6.

7.

8.

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50356

INDUSTRIAL MICROBIAL PRODUCTS

1. Fundamentals involved in production of industrial microbial products details of fermentors, synthetic and natural medium, processors, Sterilization methods and inoculum preparation. A detailed study of ethanol production by fermentation, using black strap molasses, starchy substance and glucosic like waste sulphate liquid, purification methods of fermented broth and production of absolute ethyl alocohol. Materials for fermentative production of Vinegar, lactic acid, citric acid and Amino acids. The method involves selection of particular strain of the microorganism for industrial fermentation, process details and purification. Production of alcoholic beverages with beer, brandy , whisky and wine. Baked goods , cheeseand other dairy products. Production of antibiotics. Tetracyclines, alkaloids , bakers yeast and microbial enzymes and co-enzymes. Fermentative materials for producing vitamins.

2.

3.

4.

5.

Texts/References: 1. Industrail Microbiology by Samuel C.Presscot and Ceceil, G. Dunn; Publication. 2. Industrial Microbiology by L.E.casida.jr. Wiley Eastern Limited. 3. Microbial technology Vol I and II by H.J.Peppler and D. Pulman (Academic Press) AmcGrawhill

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code. R50357

MEMBRANE TECHNOLOGY

1.

2. Introduction to separation processes, salient features of membrane separation processes, history, definition of a membrane, various membrane separation processes and their separation. Material, Membrane Preparation and Characterization: Introduction to polymers, inorganic, ceramics, membranes. Preparation of synthetic membranes, phase inversion membranes, preparation technique for immersion precipitation, preparation technique for composite membranes, Influence of various parameters on membrane morphology. Characterization of porous membranes, characterization of ionic membranes, characterization of non porous membranes. Pressure driven processes: Reverse Osmosis, Ultra Filtration, Membrane Filtration, Nano Filtration, Gas Separation: Introduction, transport equations, process parameters and its effect on them and rejection. Concentration driven and Electrical driven processes: Dialysis, perevoparation and electro dialysis: introduction, variants, transport equations, process parameters. Polarization phenomenon and fouling: Introduction, concentration polarization, turbulence promoters, pressure drop, gel layer, model osmotic pressure model, boundary layer resistance model, concentration polarization in diffusive membrane separations and electro dialysis, temperature polarization, membrane fouling, methods to reduce fouling, compaction. Module: Introduction, plate and frame model, spiral wound module, tubular module, capillary module, hollow fiber-model, comparison of module configurations, system design, hollow fiber-module, hybrid dead end cross flow system, cascade operations. Design of Membrane System: Gas separation, Pressure Vessels. Reverse Osmosis, Ultra Filtration: complete mixing, cross flow, countercurrent flow, co current flow. Dialysis: Batch dialysis. Electro dialysis: design includes power requirement. Aspects and advances in Membrane Separation Process: Applications of Reverse Osmosis, Ultra Filtration, Gas separation, Pressure Vessels, Electro Dialysis in chemical and biotechnology and food separation. Instruments in membrane systems, hybrid separators and liquid membranes.

3. 4. 5.

6. 7. 8.

Texts/References:

1. 2. 3. 4. 5. 6. M.H.V.Mulder, Membrane Separations.Klawar Academic Publications, 1996 S.P. Nunes, and K.V. Peinemann, membrane Technology in the chemical industry, Wiley VCH. R.Rautanbach and R.Albrecht, Membrane Processes, John Wiley & Sons. R.Y.M.Huang, Perevoration Membrane Separation Process. Elsevier. J.G. Crespo, K.W. Boddekes, Membrane Process in Separation and Purification, Kluwer Academic Publications. Larry Ricci and the staff of chemical engineering separation techniques, Mc

Syllabi for Pre.PhD/Pre M.Phil/ Pre MS.

W.e.f. 2005-2006 Batch Subject Code: R50358

SEPARATION PROCESSES

Characteristics of separation processes, Inherent separation factors for equilibrium processes and rate governed processes. Equilibrium calculations, Analysis of simple equilibrium separation processes. Additional factors influencing product purities. Binary multistage separations: Distillation. Patterns of change and computational approaches Binary multistage separations, Multicomponent multistage separations, Computational approaches. Group methods; Empirical correlations for limiting flows and stage requirements. Capacity and efficiency of contacting devices. Energy requirements of separation processes. Selection of separation processes Factors influencing the choice of a separation process. Texts/References: 1. 2. Separation process by C.Judson King, McGraw Hill, 1982. Diffusional Separation Process by E.D. Oliver, John Wiley & Co, 1966.

Das könnte Ihnen auch gefallen

- Coldplay-Swallowed in The Sea Mp3Dokument1 SeiteColdplay-Swallowed in The Sea Mp3Agung Prasetyo NugrohoNoch keine Bewertungen

- Peddy Citra Nesa-Resume - ExtDokument16 SeitenPeddy Citra Nesa-Resume - ExtAgung Prasetyo NugrohoNoch keine Bewertungen

- Pump Calc 01Dokument47 SeitenPump Calc 01Agung Prasetyo NugrohoNoch keine Bewertungen

- Cash Flow Report: PemasukanDokument9 SeitenCash Flow Report: PemasukanAgung Prasetyo NugrohoNoch keine Bewertungen

- Fig1. Overall Water Flowsheet at A Factory, Showing The Most Probable Water Treatment ProcessesDokument3 SeitenFig1. Overall Water Flowsheet at A Factory, Showing The Most Probable Water Treatment ProcessesAgung Prasetyo NugrohoNoch keine Bewertungen

- HEATER (H-03) Fungsi: Menaikkan Temperatur Feed KD-01. Tipe GambarDokument7 SeitenHEATER (H-03) Fungsi: Menaikkan Temperatur Feed KD-01. Tipe GambarAgung Prasetyo NugrohoNoch keine Bewertungen

- Reaktor-01Dokument16 SeitenReaktor-01Agung Prasetyo NugrohoNoch keine Bewertungen

- Cooler 1 - 6Dokument31 SeitenCooler 1 - 6Agung Prasetyo NugrohoNoch keine Bewertungen

- COOLER (C-03) Fungsi: Menurunkan Temperatur Produk DIPE Sebelum Disimpan Di T-02. Tipe GambarDokument7 SeitenCOOLER (C-03) Fungsi: Menurunkan Temperatur Produk DIPE Sebelum Disimpan Di T-02. Tipe GambarAgung Prasetyo NugrohoNoch keine Bewertungen

- HEATER (H-01) Fungsi: Menaikkan Temperatur Air Sebelum Masuk Ke Reaktor R-01. Tipe GambarDokument7 SeitenHEATER (H-01) Fungsi: Menaikkan Temperatur Air Sebelum Masuk Ke Reaktor R-01. Tipe GambarAgung Prasetyo NugrohoNoch keine Bewertungen

- Untitled Scanned 31Dokument1 SeiteUntitled Scanned 31Agung Prasetyo NugrohoNoch keine Bewertungen

- Ucg CommercialisationDokument9 SeitenUcg CommercialisationAgung Prasetyo NugrohoNoch keine Bewertungen

- DK1998 ch6Dokument77 SeitenDK1998 ch6Agung Prasetyo NugrohoNoch keine Bewertungen

- Crude OilDokument23 SeitenCrude OilAgung Prasetyo NugrohoNoch keine Bewertungen

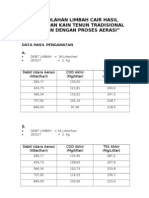

- Pengolahan Limbah Cair Hasil Pencelupan Kain Tenun Tradisional Jumputan Dengan Proses AerasiDokument3 SeitenPengolahan Limbah Cair Hasil Pencelupan Kain Tenun Tradisional Jumputan Dengan Proses AerasiAgung Prasetyo NugrohoNoch keine Bewertungen

- ChE414 HW1Dokument1 SeiteChE414 HW1Agung Prasetyo NugrohoNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Corrosion Prevention at Pipe SupportDokument6 SeitenCorrosion Prevention at Pipe SupportMohamed SamyNoch keine Bewertungen

- Hussain Sagar Lake PollutionDokument5 SeitenHussain Sagar Lake PollutionVenkateswarlu YadavalliNoch keine Bewertungen

- Skema Kertas 3Dokument13 SeitenSkema Kertas 3rhimalinyNoch keine Bewertungen

- Bio Craft CatalogDokument29 SeitenBio Craft CatalogHa LeNoch keine Bewertungen

- Fundamentals of Aircraft SystemsDokument353 SeitenFundamentals of Aircraft SystemsVishal Wagh100% (4)

- Use Pipet To Add Exactly The Same of The 0.1% Indicator Solution 0.50mL Is A Suitable VolumeDokument4 SeitenUse Pipet To Add Exactly The Same of The 0.1% Indicator Solution 0.50mL Is A Suitable Volume林鴻鈞Noch keine Bewertungen

- Machine Protection USA Web PDFDokument84 SeitenMachine Protection USA Web PDFEren GünerNoch keine Bewertungen

- JIG AND FIXTURE DESIGN MANUL Eric K HenriksenDokument160 SeitenJIG AND FIXTURE DESIGN MANUL Eric K HenriksenPrakashmech4028Noch keine Bewertungen

- Ex 4 Effect of PH On Enzyme ActivityDokument2 SeitenEx 4 Effect of PH On Enzyme ActivityRochel CaduyacNoch keine Bewertungen

- Ch.2 Deflection 1Dokument19 SeitenCh.2 Deflection 1Long TingNoch keine Bewertungen

- Infiltration CurveDokument20 SeitenInfiltration CurveParamveer RawatNoch keine Bewertungen

- Introduction To Pinch TechnologyDokument46 SeitenIntroduction To Pinch TechnologyM Scott GreenNoch keine Bewertungen

- Bromhead - A Simple Ring Shear ApparatusDokument3 SeitenBromhead - A Simple Ring Shear ApparatusDaniel Felipe Rodriguez RamirezNoch keine Bewertungen

- Trial MRSM SPM 2014 Physics K2 No SkemaDokument37 SeitenTrial MRSM SPM 2014 Physics K2 No SkemajeglilaNoch keine Bewertungen

- CERBERITE Hollow Glass Speciality Contact MaterialDokument5 SeitenCERBERITE Hollow Glass Speciality Contact MaterialPramendraSinghNoch keine Bewertungen

- LUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketDokument7 SeitenLUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketThobiasNoch keine Bewertungen

- CH 3 - AE Analysis and Design of Two-Way SlabsDokument111 SeitenCH 3 - AE Analysis and Design of Two-Way Slabsephrem100% (3)

- Key Concepts in Welding EngineeringDokument4 SeitenKey Concepts in Welding EngineeringXNoch keine Bewertungen

- SOM NotesDokument88 SeitenSOM NotesThiru Moorthy100% (1)

- 4Dokument13 Seiten4Aruna KumarasiriNoch keine Bewertungen

- Characterizing Metallic Microstructure Cu-Based AlloysDokument51 SeitenCharacterizing Metallic Microstructure Cu-Based AlloysjuegyiNoch keine Bewertungen

- CE225 SM 15 Stresses in SoilDokument46 SeitenCE225 SM 15 Stresses in SoilM Modood Abbasi AbbasiNoch keine Bewertungen

- 11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFDokument328 Seiten11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFTheresaNoch keine Bewertungen

- South Carolina Furniture IncDokument11 SeitenSouth Carolina Furniture Inchmz18113881Noch keine Bewertungen

- Manual CTI Technical Manual PDFDokument39 SeitenManual CTI Technical Manual PDFaricomen43% (7)

- NgspicemanualDokument517 SeitenNgspicemanualronakmehta31Noch keine Bewertungen

- KontloDokument3 SeitenKontloX'mix ĐreamerNoch keine Bewertungen

- XFLR5 GuidelinesDokument71 SeitenXFLR5 GuidelinesChangho NamNoch keine Bewertungen

- Eberhardt (2015) ISRM Suggested Method Por Failure Criteria - Hoek-BrownDokument13 SeitenEberhardt (2015) ISRM Suggested Method Por Failure Criteria - Hoek-BrownSebastian Jorquera HenriquezNoch keine Bewertungen

- A Detailed Lesson Plan in Science 10Dokument9 SeitenA Detailed Lesson Plan in Science 10Maricae NathanielNoch keine Bewertungen