Beruflich Dokumente

Kultur Dokumente

3092834-Varco Bulletin On TDS

Hochgeladen von

Sushil GuptaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3092834-Varco Bulletin On TDS

Hochgeladen von

Sushil GuptaCopyright:

Verfügbare Formate

Release

Product Bulletin No.: TDS-04-14 Top Drive Drilling System

Date: October 8, 2004

Subject: Product: Affected Assemblies: Objective: Problem:

Fractured Mainshaft on TDS-6S Top Drive with Retract Dolly System All Varco Top Drives with Retract Dolly Systems

Motor Housing Assembly and Retract Dolly Controls Advise Operators of Potential Damage to Mainshaft A rig crew was recently drilling with a TDS-6S Top Drive Drilling System when they noticed drilling fluid leaking from the mainshaft of the Top Drive. As was later confirmed, leakage of drilling fluid indicated a fracture through to the bore of the mainshaft in the area of the landing collar. Drilling operations ceased with no injuries being reported as a result of this incident. Investigation of this incident included disassembly and inspection of the mainshaft, landing collar, and Rotating Head Assembly with the following findings: MPI inspection of the mainshaft confirmed the there was a fracture around 360 of the mainshaft, located at the root of the upper-most landing collar groove. This fracture penetrated to the bore of the shaft on one side, allowing the drilling fluid leak when under tension. The condition of the mainshaft outer surface in the landing collar area was heavily corroded. The internal surfaces of the landing collar showed corrosion pitting similar to that found on the landing collar grooves of the mainshaft. In addition, the outside diameter of the mainshaft where it passes through the Rotating Head Assembly was severely galled. Inspection of the Rotating Head Assembly swivel flange showed that the bottom portion of the bore was heavily worn on the side closest to well center.

2004 Varco LP All Rights Reserved

TDS-04-14 Page 1 of 2

Solution:

Inspection of the disassembled hardware and review of the incident report and drilling data indicate that the TDS-6S Top Drive was drilling with the retract system not fully extended over well center. This caused severe bending loads to be imparted to the mainshaft. The estimated bending loads in combination with the recorded drill string weight resulted in deflections and stresses consistent with the damage to the mainshaft and rotating head. Varco warns that all operators of Varco Top Drives with Retract Dolly Systems should continually verify that the Top Drive is fully extended to well center during all drilling and hoisting operations. Most Retract Dolly Systems have proximity sensors which provide a visual indication to the driller when the Top Drive is at its fully extended and retracted positions. Proper operation of these indicators and controls should be verified For those Retract Dolly Systems without any indicator lights, the driller must ensure that the dolly extend and retract control switch is always left in the desired state, and not turned to the off position. Visual verification will be required. Regarding inspection of the mainshaft and other primary load carrying components, Varco reminds operators of periodic Magnetic Particle Inspection (MPI) requirements that are outlined in Product Bulletin TDS-03-25, issued in October 2003.

Please contact your local Varco Service Center if you have any questions regarding this safety alert.

2004 Varco LP All Rights Reserved

TDS-04-14 Page 2 of 2

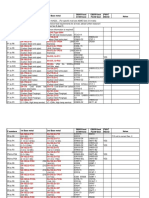

NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49

SAFETY REV TITLE ALERT Counterbalance System Adjustment A B A A F A A GE Motor Lubrication EMD Motor Lubrication Field Welding of Service Loop Bracket Gearbox Lubrication Schedule Blower Impeller Loosening Gearbox Sight Gauge Installation Saver Sub Thread Recut Make-Up Torques Safety Valve Actuator Cylinder Locking Safety Valve Actuator Assembly Waterproofing Driller's Controls Pipehandler Cylinder Clevis Loosening IBOP Actuator - Pipehandler Kits Torque Wrench Operation Adjustment Dual IBOP Valve Kit Field Welding, Bail Pin Lock Tabs Rotating Pipehandler, Inst. /Oper. Oil Pump Shaft Retention GE Motor/Main Shaft Housing Rework Blower Motor Lubrication Solid Body Elevator Ear IBOP Actuator Sleeve Link Tilt Improvement Kit Pipehandler/Torque Arrestor Pins Pipehandler Speed-Up Kit Bearing Shield Installation IBOP Actuator Arm Replacement I.S. Cable Slack Hydraulic Pressure Filter Installation Solid Body Elevator Plate Short and Long Term Storage IBOP Valve Corrosion Upper Safety Valve Lubrication Safety Valve Actuator Installation Load Carrying Component Replacement Dolly Link Adjustment Load Carring Component Care Drilling Motor & Cooling System Maint. Closed Loop Cooling System Air Req. STUMP Wiring Changes Guide Rail Installation Tolerances Closed Loop Cooling System Water Supply Shunt Motor Field Coil Maintenance 500 Ton System Upgrade Motor Alignment Cylinder Torque Wrench Body Chamfer Exhaust Cleaning, Overtemp Protection Active vs Passive Shunt Field Supply

DATE REL. 1/3/84 2/2/84 1/5/84 1/5/84 6/5/84 2/9/84 2/29/84 2/24/84 2/24/84 2/29/84 2/29/84 3/29/84 4/6/84 8/2/84 4/6/84 8/29/84 9/24/84 11/2/84 12/21/84 1/29/85 1/30/86 10/31/85 11/19/85 12/13/85 12/2/85 1/31/86 1/29/86 2/6/86 2/5/86 2/13/86 3/11/86 3/11/86 5/2/86 9/3/86 9/8/86 3/14/94 11/17/86 8/29/94 11/17/86 11/17/86 12/1/86 10/9/87 9/11/87 9/11/87 7/9/90 10/23/90 11/6/87 12/2/87 1/18/88

EFFECTIVITY Serial Numbers 1 Thru 31 Incorporated, See Sec. 8 of original Service Manual Incorporated, See Sec. 8 of original Service Manual Incorporated, See Sec. 2 of original Service Manual Incorporated, See Sec. 8 of original Service Manual Obsolete, See Sec. 3 of original Service Manual Obsolete, See Sec. 7 (Mtr/Housing Assy) of original Service Manual Obsolete, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Obsolete, See Sec. 4 of original Service Manual Serial Numbers 1 Thru 14 Serial Numbers 1 Thru 12 Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 2 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Obsolete, See Sec. 3 & 7 of original Service Manual Serial Number 1 only Incorporated, See Sec. 8 of original Service Manual Serial Numbers 1 Thru 60 Serial Numbers 1 Thru 64 Serial Numbers 1 Thru 70 Serial Numbers 1 Thru 70 Serial Numbers 1 Thru 70 Serial Numbers 1 Thru 74 Serial Numbers 1 Thru 31 Serial Numbers 1 Thru 75 w/Expo Purge Serial Numbers 1 Thru 80 Serial Numbers 1 Thru 83 Serial Numbers 1 Thru 35 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 93(w/o 500 Ton Conversion) Serial Numbers 1 thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90(w/Closed Loop Cooling) All Units to Date Equipped w/ STUMP All Units All Units w/Closed Loop Cooling All Units W/ Shunt Drilling Motor Serial Numbers 1 Thru 93 Serial Numbers 1 thru 93 Torque Wrench S/N 1 Thru 110 Serial Numbers 1 Thru 92 All Units Equipped w/ Shunt Drilling Motor

NO. 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 92 92.1 92.2 92.3 92.4 92.5 92.6 93-1 93.2

SAFETY REV TITLE ALERT Revised Operation Section Yes A A B A A Yes Yes A Yes Yes A B Yes Yes A Yes Yes Yes Yes A A Clevises on Link Tilt Assy.P/N 74967 IBOP Control Circuit Kit P/N 87235 Purge Air Oil Removal Filter P/N 86608 Torque Wrench Hinge Pin P/N 76532 Motor Frame Fatigue Cracking Solid Body Elevator Plate Interference Link Tilt Intermediate Stop Spring Fatigue Purge System Cycle Times High Torque Drilling Heavy Duty Guide Roller Lube Problems Motor Lubrication Changes Motor Bearing Lubrication TDS Torque Wrench Body Pins TDS IBOP Valve Assy Control Circuit, IBOP Actuator Shell EMD Bearing/Seal Replacement Operation Safety Notice Safety Notice/Pipe Handler Safety Notice/RBS Pipehandler Connections Varco/Best IBOP Seal Kit Elevator Floor Stand Bushing Replacement DOE Notice Safety Notice/Perforating Tools PH 60/85 Torque Readout Gauges Drill Collar Dolly P/M Trans. Oil Heat Exchanger Transmission Oil Selection Trans. Lube Pump Adjust. Swing Bolt Modification Not Released Safety Notice/IBOP Actuator Shell S/B Numbering System Change Varco BJ Internal Release Pipehandler Hinge Pins Inspect. of 500T Split Land. Collars&Equip Varco/Best Blow Out Preventers AR3000 Maintenance Safety RBS Position Indicator Post Jarring Inspection of Top Drives S/B Numbering System Change Compound Brg Thrust Ring Letter Bonnet Seals Letter VOID VOID Yes Transmission Oil Pumping & Cooling Sys Wireline Adapter

DATE REL. 1/19/88 9/30/88 9/30/88 9/30/88 10/19/88 6/9/89 6/13/89 1/17/91 8/21/89 10/23/90 8/21/89 6/11/91 10/19/89 10/24/89 12/13/89 7/5/90 7/5/90 6/1/90 9/19/90 11/20/90 1/17/91 10/23/90 1/17/91 1/17/91 3/5/91 3/5/91 3/5/91 4/18/91 4/4/91 4/4/91 4/4/91 6/11/91 7/8/92 4/14/92 7/8/92 5/30/92 8/21/92 10/8/92 5/14/03 2/22/93 1/25/93 1/19/93

EFFECTIVITY Serial Numbers 1 Thru 97 Serial Numbers 109, 127-129 & 133-149 Serial Numbers 1 Thru 153 Serial Numbers 1 Thru 113 w/ Closed Loop Cooling Serial Numbers 1 Thru 117 & 119 Serial Numbers 1 Thru 174 per list Serial Numbers 1 Thru 172 Serial Numbers 1 Thru 172 Units w/ Expo Purge Sys. All Units Units w/ 80230 Rollers Units w/ G. E. Motors All TDS Units All TDS Before 10/89 Selected MFGs.10/88-89 TDS-3 Up Through Serial Number 25 All M89 VTS Mfg. up to 8/89 All Units All Units All TDS w/ RBS All TDS Units All Varco/Best Style Valves All Units All U.K. Customers All Units All Unit w/ PH 60-85 All Units w/ Drill Collar Dolly All TDS 4 & 4H Units All TDS Units All TDS Units All TDS Units All TDS Units using PH60 Service Bulletin No. 92 (Admin. only) PH-60 Pipehandler All 500T IDS or IDS Pipehandlers Mfg. w/ provisions for installation of a mud saver All AR3000 units All Raised Backup Systems All TDS Models Administrative Only TDS-4H/4S Owners All S-Model Top Drive Owners

TDS-93-1 TDS-93-2 TDS-93-3 TDS-93-4

2/25/93 2/24/93

All TDS-3S, -4H & -4S Top Drives All Model Top Drives

NO. TDS-93-5 TDS-93-6 TDS-93-7 TDS-93-8 TDS-93-9 TDS-93-10 TDS-93-11 TDS-93-12 TDS-93-13 TDS-93-14 TDS-93-15 TDS-93-16 TDS-93-17 TDS-93-18 TDS-93-19 TDS-93-20 TDS-93-21 TDS-93-22 TDS-93-23 TDS-93-24 TDS-93-25 TDS-93-26 TDS-94-01 TDS-94-02 TDS-94-03 TDS-94-04 TDS-94-05 TDS-94-06 TDS-95-01 TDS-95-02 TDS-95-03 TDS-95-04 TDS-95-05 TDS-95-06 TDS-95-07 TDS-95-08 TDS-95-09 TDS-96-01 TDS-96-2 TDS-97-01 TDS-97-02 TDS-98-01 TDS-98-02 TDS-98-03 TDS-98-04

SAFETY REV TITLE ALERT A Upper IBOP Valve A A A A A Yes Yes Yes Yes Yes Yes B A Yes Yes Yes Yes Yes Yes A A B Yes Yes B B B A B B Air Brake Quick Exhaust Valve Elimination Servicing of Air filters/regulators/lubricators Lower IBOP Valves Maint. & Improve. on Pipe Handlers, PH-60&PH-80 TDS Torque Arrestors Varco BJ 350Ton BNC Elevator TDS-5 Gear Box Oil Capacities Link Tilt Adjustment Locking Device Hydraulic Quick Disconnect Pre-Charging the C'balance System TDS Pipehandler PH-60 Pinion Gear and Drive Train Life Varco/Best Upper IBOP Valves Top Drive Rotating Head Locking Handle Upper IBOP Valve Crank Actuator Inspection TDS-4 Gearshift Maintenance Electrical Service Loop Handling TDS Pipehandler Booster Kit Air Operated Elev. used w/TDS or IDS TDS Split Landing Collar TDS DC Motor Exhaust Duct Covers TDS Mainshaft Wear Allowances 500T Landing Collar Up Grade Installation of Elevator Links on TDS Link Adapter C'Bal Cylinders Accumulator Nitrogen Precharge Model Upper Bonnet Seal Lubrication Top Drive Pipehandler Make-up Torque TDS Lube Oil Filter TDS Work Platform Latch Elevator Link Retainers TDS Link Tilt Stop Adjustment Pipe Handler Torque Tube Access Holes TDS Parking Brake Lock Tabs on TDS Pressure & Temp. Switches Retractable Guide Dollies Well Control Stripping Operations TDS-9S Carriage Roller Contacting Guide Beam Hinge Pin TDS Inline Orifice Bearing Filter Kit TDS Retract Dolly Stops TDS-3S, -4S, -6S & -7S Upper Bearing Seal Retrofit Kit TDS-9S Guide Beam, Slide Type (Non-roller) TDS-9S Hydraulic Manifold Hose Retrofit Falling Crank from PH-85 Upper 7-5/8 IBOP TDS-9S Connector Label & Lockwire Kit

DATE REL. 12/9/94 3/10/93 3/10/93 3/10/93 3/10/93 3/10/93 3/3/93 3/10/93 3/26/93 4/5/93 4/5/93 4/5/93 4/13/93 4/7/93 4/5/93 4/7/93 4/8/93 6/8/93 9/8/93 9/9/93 6/21/93 8/25/93 3/14/94 5/10/94 5/17/94 12/9/94 11/15/94 12/6/94 3/2/95 5/18/95 4/6/95 7/7/03 6/15/95 7/19/95 7/21/95 9/1/95 11/13/95 2/9/96 3/15/96 4/28/97 2/15/00 7/8/98 5/29/98 6/12/98 6/9/98

EFFECTIVITY Varco/Best IBOPs mfg. w/provisions for Mud Saver All Top Drives w/Air Brakes Immediately, on all Top Drives IBOP Valves w/lip seals on spring loaded seat All TDS Models, PH-60 & PH-85 All TDS Users All TDS Units All TDS-5 Units All Top Drives w/PH-60 or PH-85 Pipehandlers TDS Pipehandlers PH-60 & PH-85 All TDS Units All PH-60 Pipehandlers All TDS Units All Varco/Best Type Upper IBOP Valves TDS w/PH-60 & Ph-85 & IDS w/PH-60 Pipehandlers All TDS Units All TDS-4 Units All TDS Units All Booster Kits All Air Operated Elev. used w/TDS or IDS TDS w/Landing Collar Load Pickup Device TDS w/Local or Remote Cooling Sys All TDS-3, 4, 5 & 6 Units All 500T TDS w/Landing Collars All TDS All TDS All TDS-3S, 4S, 6S, 7S Units All PH-60 and PH-85 Pipehandlers All TDS TDS-3, -4, -5, -3H & -4H, 5H All TDS All TDS w/link tilt stops TDS/IDS w/PH-60 & PH-80 Pipe Handlers All Top Drives Baseefa/European TDS 7 IDS All TDS All TDS All TDS-9S Units with Guide Beam All TDS-3S & 4S models TDS Retract Dolly W/Rubber Stops All TDS-3S, -4S, -6S & -7S with 3 and 4 Bore Wash Pipe TDS-9S w/Slide Type Carriages TDS-9S Units All PH-85 Upper 7-5/8 IBOP All TDS-9S Units

NO. TDS-98-05 TDS-98-06 TDS-98-07 TDS-98-08 TDS-99-01 TDS-99-02 TDS-99-03 TDS-99-04

SAFETY REV TITLE ALERT TDS-9S Upper Seal Kit (P/N 119227) Yes Yes Yes Yes B A API Torque Specifications in relation to the use of Large Bore Saver Subs to Smaller ID Drill Pipe TDS-10S Sight Gages on Oil Reservoir TDS-9S Guide Beam Hoisting Hook Failure Improved Terminal Blocks Available For TDS-9S, TDS-10S and TDS-11S Motors Availability of Retrofit Kit for Lubricating Vents for TDS Counterbalance Chain Connecting Link P/N 80392 Falling Object Incident of a TDS Pressure Filter (P/N 82747)

DATE REL. 6/9/98 10/22/99 9/29/98 10/13/98 3/16/99 8/16/00 5/6/99 7/1/99

EFFECTIVITY TDS-9S w/ S/N TDS9SXXXX39 & under All Varco Customers with Large Bore Top Drive All TDS-10S Units w/Serial Number TDS10SXXXX39 & Under All TDS-9S, -11S Portable Top Drives All AC Motors P/N 108235 built before January 1999 All TDS-4, TDS-6, TDS-8 Units All Top Drive Models TDS-3, -3H, -3S, TDS-4, -4H, -4S, TDS-5, -5H, TDS-7S & TDS-8SA All Top Drives

TDS-99-05 TDS-99-06 TDS-99-07

Yes Yes Yes

PH-100 Pipehandler IBOP Actuator Inspection Guidelines for Retract Dollies Removal of U-Cup Seal (P/N 65260490 or P/N 109209) in Large Bore Lower IBOP Valve Repair Kits and Rebuilt Valves Falling TDS-10S Wear Pads Wear Pad Kit (P/N 128406) HPU Breather Obstruction Implementation of Helical Gears in Varco Top Drives Blower Motor Inspection / Lock wire of Impeller PH-60 Single Crank, Upper 6-5/8 IBOP Falling Crank Top Drive Hydraulic Link Tilt Bolt Failure

5/18/99 5/26/99 6/4/99

All PH-100 Pipehandlers All TDS and Block Retract Dollies All Rebuilt Large Bore Lower IBOP Valves using Repair Kits (P/N 95385-1 to 3) issued before August 1998 All TDS-10S Top Drives All Hydraulic Power Units (HPUs) All Top Drives All Portable AC Top Drives (TDS-9S, -10S & -11S All Single Crank, Upper 6-5/8 IBOPs, P/Ns 94099, 94100 & 94769 (Model #s 500, -501 & -502 All PH-85 Pipehandlers with Hydraulic Link Tilt Systems (Pipehandler Installation Kits #118992 on configurations) All Portable AC Top Drives (TDS-9S, -10S & -11S) All Top Drives with a PH-85 Pipehandler Early TDS-3S, -4H, -4S Top Drives, All Top Drives with P/N 91264 & 94767 Oil Cooler Assemblies (AKA Batwing Coolers) Used on Remote Air Cooled Drilling Systems PH-50 Pipehandlers Shipped before November 14, 1997. Used on TDS-9S Top Drives with Serial Nos. TDS9SM30D52 and Earlier All TDS-8SA Top Drives TDS-9S Top Drives With Two Double Rod Hydraulic Link Tilt Cylinders And Guide Beam With Recessed Lifting Pockets All PH-100 Pipehandlers, Tool Joint Clamp Assemblies All TDS-3, -3H and IDS Top Drives with Landing Collar and 500 Ton PH-85 Pipehandler and Elevator Support Split Plate Assembly P/N 97256 All PH-85 Pipehandlers All TDS-3, -3H -3S, -4, -4H, -4S, -5 and 5H with UL Electric Controls All TDS-4H and -4S Top Drive Drilling Systems All Top Drives with Dolly Retract Control Systems Equipped with Accumulators

TDS-99-08 TDS-99-09 TDS-99-10 TDS-99-11 TDS-99-12 TDS-99-13

Yes Yes Yes Yes

A B A

6/9/99 6/9/99 6/14/99 9/21/99 11/8/01 6/15/01

TDS-99-14 TDS-99-15 TDS-99-16

A -

Potting Inspection of AC Top Drive Connectors New PH-85 Upper IBOP Break Out Tool (P/N 127700-500) Oil Cooler Motor Shield Kit, P/N 126997

9/21/99 3/26/02 11/15/99

TDS-99-17

Yes

Falling Link Tilt Pin from PH-50 Pipehandler

3/15/01

TDS-99-18 TDS-00-01

Yes

TDS-8SA Motor Alignment Cylinder Link Tilt Cylinder Interference PH-100 Pipehandler Possible Interference Between Solid Body Elevator Support Guide Shoes and Upper IBOP Dropped PH-85 Pipehandler Die U. L. Instrument J-Box Cover Proper Method of Changing Transmission Speeds on TDS-4 Top Drives Top Drive Dolly Retract Systems Guard and Guide Beam

12/7/99 2/24/00

TDS-00-02 TDS-00-03

Yes

A A

12/3/01 6/17/04

TDS-00-04 TDS-00-05 TDS-00-06 TDS-00-07

Yes Yes Yes -

6/28/00 9/5/00 11/8/00 12/21/00

NO. TDS-01-01 TDS-01-02 TDS-01-03 TDS-01-04 TDS-01-05 TDS-01-06 TDS-01-07 TDS-01-08 TDS-01-09 TDS-01-10 TDS-01-11 TDS-01-12 TDS-01-13 TDS-01-14 TDS-01-15 TDS-01-16 TDS-01-17 TDS-01-18 TDS-01-19 TDS-01-20 TDS-02-01 TDS-02-02 TDS-02-03 TDS-02-04 TDS-02-05 TDS-02-06 TDS-02-07 TDS-02-08 TDS-02-09 TDS-02-10 TDS-02-11 TDS-02-12 TDS-02-13

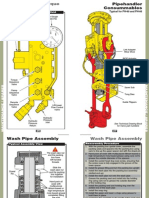

SAFETY REV TITLE ALERT Yes Falling Shim Report from Top Drive Dolly Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes YES Yes Yes Yes Yes B A D A A A A A A A Large Bore Washpipe Assemblies Falling Pin from PH-50 Pipehandler Link Tilt Adjustment Stop Mechanism Falling Outer Collar from PH-60 Pipehandler Dropped Jaw Pin on PH-85 Pipehandler TDS Rotating Head Assembly Locking Handle Link Tilt Assembly Pivot Pins Rotating Hook Adapter Bypass Check Valve Kit Link Tilt Clamp Base Failure and Chain Upgrade Falling Pin from Drill Pipe Elevator Link Clamp Clevis TDS-9S and 11S Guide Beams Cam Follower on 500 Ton Rotating Head Assy TDS-4 Maintenance Guides Rotating Hook Adapter Structural Modification Kit TDS IBOP Actuator Shell and Torque Arrestor Interference Operation of Link Tilt Assemblies Revised Make-Up Torque Values for AC Top Drive Drill String Load Carrying Components Falling Objects From PH-50 Pipehandler TDS Retract Dolly Stop Plates Screws Falling from PH-85 Pipehandler End Cap Falling from a Cam Follower Report of Sheared Gearcase to Main Body Fasteners on TDS-3S Damage to Hydraulic Link Tilt Operation of Hydraulic Link Tilt Systems Advise Users of Inspection Requirements Faulty Caliper Brake Pads Report of Falling Fasteners from PH-85 Pipehandler PH-100 Pipehandler Stabbing Guide Report of Falling Fastener from PH-50 Pipehandler Control Loop Attachment Links Temperature Alarm and Trip for TDS-8S with RTD Feedback Reliability of PH-100 Powered Rotating Link Adapter Assemblies

DATE REL. 2/12/01 2/27/01 10/15/02 4/2/01 4/25/01 5/2/01 5/11/01 9/26/01 7/12/01 12/04/01 5/29/03 10/3/01 11/8/01 11/15/01 11/16/01 6/16/04 11/20/01 12/5/01 12/6/01 7/1/04 3/13/02 5/27/03 4/26/02 5/17/02 10/25/02 5/31/02 6/20/02 7/7/03 7/3/02 8/2/02 9/3/02 10/3/02 10/10/02

EFFECTIVITY All Top Drives / Traveling Blocks with Retract Systems All Varco 4 Washpipe Assembly Users All Top Drive Drilling Systems with PH-50 Pipehandlers All Units with PH-60 or PH-85 Pipehandlers All Top Drive Drilling Systems with PH-60 Pipehandlers All Top Drive Drilling Systems with PH-85 Pipehandlers All Top Drive Drilling Systems w/PH-60, PH-85 & PH-100 Pipe Handlers All Pneumatic Link Tilt Users Powered Rotating Hook Adapter (PRHA) All Top Drive Units with Standard (52) and Extended Reach (76) Link Tilt Assemblies All Top Drive Drilling Systems with PH-60 or PH85 Pipehandlers All TDS-9S & -11S Top Drive Drilling Systems All Varco PH 60 & 85 Rotating Head Assemblies All TDS-4, -4H, and -4S Top Drive Drilling Systems All Powered Rotating Hook Adapter (PRHA) Assemblies All 650-Ton Top Drive Drilling Systems w/Landing Collar All Units with PH-60 or PH-85 Pipehandlers All AC Top Drive Drilling Systems with PH-50 and PH-100 Pipehandlers All Top Drive Drilling Systems with PH-50 Pipehandlers All Top Drives with Retract Dollies All Top Drive Drilling Systems with PH-85 Pipehandlers All TDS-9S and TDS-11S Top Drives with Cam Follower Type Carriages All Top Drive Drilling Systems PH-50, Ph-75 and PH-100 Pipehandler Hydraulic Link Tilt Systems All Top Drive Drilling Systems w/ PH-50/55/75/100 Pipehandlers PH-50 and PH-75 Pipehandlers Hydraulic Link Tilt Systems TDS-9S, -10S and -11S Top Drives All Top Drive Drilling Systems w/ PH-85 Pipehandlers All PH-100 Pipehandlers All PH-50, -55, -60, -75, -85 and -100 Pipehandlers TDS with Auxiliary Electrical Service Loop Kit, Varco P/N 30157644 TDS-8S with GE Multilin RTD Monitor AC Top Drive Drilling Systems with PH-100 Pipehandlers (Refer to Table on Page 4)

NO. TDS-02-14 TDS-02-15 TDS-02-16

SAFETY REV TITLE ALERT Yes Report of Falling Dust Plug/Cap from TDS-11SA During Drilling Operations Yes Reported Interference between PH-85 Pipehandler Link Tilt Assembly and Monkeyboard Yes Report of Falling Stop Tube from PH-85 Pipehandler Yes PH-50 and PH-75 Pipehandler Unclamp Speed Improvements Report of Roller Assembly Falling from PH-60 Pipehandler IBOP Actuator Shell Proper Setup for Siemens DB Choppers

DATE REL. 10/25/05 11/4/02 11/14/02

EFFECTIVITY All TDS-9SA, -10SA and -11SA Top Drive Drilling Systems All PH-60 and PH-85 Pipehandlers with Link Tilt Assemblies All Top Drive Drilling Systems w/ PH-60 and PH-85 Pipehandlers All TDS-9SA, -11SAA and -11HP Top Drive Drilling Systems All Top Drive Drilling Systems w/ PH-60 Pipehandlers (Single Crank IBOP Design only All TDS-8SA, -9SA, -10SA & -11SA Top Drives with Varco Control Systems utilizing Siemens 70 series VFDs All Varco Becket Assemblies All Varco TDS-9SA, -10SA and -11SA Top Drive Drilling Systems w/ Type GG Drill Pipe Elevator Assemblies All TDS-4S Powered Rotating Head Assemblies All Varco IDS, TDS-9SA, -10SA and -11SA Top Drive Drilling Systems All Top Drive Drilling Systems with PH-50, -55, -60, -75, -85 and PH-100 Pipehandlers TDS-11HP Top Drive Drilling Systems All PH-60 Pipehandlers PH-50, PH-75 and PH-100 Pipehandlers All TDS-11SA Top Drive Drilling Systems PH-85 Pipe Handlers Using Upper IBOP Quick Change Systems (P/N 127700) PH-50 and -75 Pipe Handlers Used with TDS-9SA and -11SA Top Drive Systems TDS-9SA and 11SA Top Drive Systems PH-60/PH-85 Pipe Handlers TDS-3H, -3S, -4H, -4S, -5 and -6S Top Drive Drilling Systems Electrical Package, TDS-9SA, TDS-11SA and TDS11HP TDS-11SA and 11HP Top Drives with PH-50/75 Pipehandlers TDS-3, TDS-3H, TDS-4H and TDS-5H Top Drives All PH-50, -60, -75, -85 and PH-100 Pipehandlers All TDS-9SA, TDS-10SA, and TDS-11S Top Drive Drilling Systems w/PH-50 Pipehandlers TDS-4S Units with the Remote Counterbalance (P/N 122549-100) TDS-9SA and TDS-11SA Top Drive Drilling Systems Digital Encoder Assembly TDS-3, 4, 5, 7, 8SA, 9SA, 11SA, 11HP, IDS-1, IDS-3 and Top Drive Drilling Systems PH-50, 55, 60, 75, 85 and 100 Pipe Handlers All Varco Top Drive Primary Load Carrying Components All Varco Top Drive Drilling Systems TDS-4S and TDS-8SA Oil Circulating Kits

TDS-02-17 TDS-02-18 TDS-03-01

12/13/02 12/13/02 1/16/03

TDS-03-02 TDS-03-03

Yes Yes

Report of Falling End Plate on Becket Assembly Report of Damaged Elevator Drill Pipe Assembly Possible Dowel Pin and Bolt Failures on Powered Rotating Head Assemblies Report of Sheared Hinge Joint Pin on TDS-11SA Guide Beam Assembly Potential Dropped Object from Link Tilt Intermediate Stop Release Cable Bumped/Broken Directional Control Valve Handle Sheared Hinge Pin on PH-60 Pipehandler Report of Stabbing Guide Falling from PH-50 Pipehandlers Report of Broken Fasteners on TDS-11SA Motor Housing Guard All Operators of PH-85 Upper IBOP Quick Change Systems All Top Drive Operators with PH-50 and PH-75 Pipe Handlers All Operators of TDS-9SA and TDS-11SA Top Drive Drilling Systems All PH-60 and PH-85 Pipe Handler Operators To Advise DC Top Drive Users of Motor Inspection Following Jarring To Advise Users of Revised Lube Pressure Switch Settings To Advise Users of Proper Setup and Capabilities of Link Tilt Installation of Incorrect Parts in Swivel/Bail Pin/Swivel Link Assemblies Torque Values for TDS Drill String Load Carrying Components Damaged Lower Guide Beam Tieback Link During Saver Sub Break Out Counterbalance Mounting Bolts Falling from a Top Drive Damage to Attachment Bolts on TDS-11SA Carriage Assembly Operation of AC Top Drives in Encoder Bypass Mode Secondary Retention of Pins & Fasteners on Top Drive Drilling Systems Magnetic Particle Inspection (MPI) Requirements Maintenance of Hydraulic Piston Accumulators Upgrade of TDS-4S and TDS-8SA Oil Circulating Systems

1/17/03 1/20/03

TDS-03-04 TDS-03-05 TDS-03-06 TDS-03-07 TDS-03-08 TDS-03-09 TDS-03-10 TDS-03-11 TDS-03-12 TDS-03-13 TDS-03-14 TDS-03-15 TDS-03-16 TDS-03-17 TDS-03-18 TDS-03-19 TDS-03-20 TDS-03-21 TDS-03-22 TDS-03-23 TDS-03-24

Yes Yes Yes Yes Yes Yes Yes Yes Yes -

A A A A A A

1/20/03 2/27/04 2/5/03 2/7/03 2/18/03 2/19/03 3/3/03 3/21/03 3/27/03 4/12/04 3/28/03 4/3/03 4/10/03 4/15/03 5/12/03 5/16/03 6/3/03 6/19/03 12/16/03 6/22/03 11/18/03

TDS-03-25 TDS-03-26 TDS-03-27

10/17/03 10/20/03 10/27/03

TDS-03-28 TDS-03-29 TDS-04-01 TDS-04-02

Yes Yes Yes

A -

Periodic Lubrication of TDS-9SA and -11SA AC Drilling Motors Falling Extension Spring from PH-85 Pipe Handler Stabbing Guide Assembly Sheared Retaining Pin on Torque Arrestor Roller Assembly Failure Resulting in a Dropped Cam Follower from the IBOP External Crank Assembly Inductive Voltage Buildup on AC Top Drive Service Loops Falling Stabilizer Liner on PH-75 Pipehandler Performance Update on Washpipe Assemblies Damaged Motor Guard on Top Drive Alignment Cylinder Retrofit for TDS-8SA and -1000 Top Drives Lubrication of AC Top Drive Drilling Motors Maintenance of Hydraulic Oil Reservoirs Sheared Fasteners on TDS-10SA Carriage Assembly Adjustment of PH-85 Torque Wrench Assembly Sheared Crank Stop Pivot Screw on PH-100 Pipehandler Link Tilt Stop Broken Mounting Lug Welds on TDS-8SA/1000 Top Drive Power Junction Box Fractured Mainshaft on TDS-6S Top Drive with Retract Dolly System

11/21/03 12/2/03 2/20/04 2/20/04

TDS-9SA and -11SA Motor Housing Assemblies All Top Drive Drilling Systems with PH-85 Pipe Handlers TDS Torque Arrestor Assemblies (P/N 90471, 90471-1 and 90471-2) External Crank Assembly (P/N 98898)

TDS-04-03 TDS-04-04 TDS-04-05 TDS-04-06 TDS-04-07 TDS-04-08 TDS-04-09 TDS-04-10 TDS-04-11 TDS-04-12 TDS-04-13

Yes Yrs Yes Yes Yes

2/23/04 3/29/04 4/8/04 4/15/04 4/28/04 4/28/04 4/30/04 6/1/04 6/22/04 7/12/04 10/7/04

Power Service Loop Assemblies Clamp Cylinder Assembly, PH-75 (P/N 30157287) Varco Washpipe Assemblies TDS Motor Guard Alignment Cylinder Assembly (P/N 30172237) and TDS-8S General Electric AC Drilling Motors Hydraulic Oil Reservoir Assembly TDS-10SA Motor/Main Body and Carriage Assembly (P/N 119800) PH-85 Pipe Handler Assembly Rotating Adapter Assemblies (P/N 124900 for TDS8SA & P/N 30170265 for TDS-1000) Motor Power Junction Box (P/N 30156329-L or -R & 30174019-L or -R) Motor Housing Assembly and Retract Dolly Controls 140891 &

TDS-04-14

Yes

10/8/04

Das könnte Ihnen auch gefallen

- 3119049Dokument10 Seiten3119049Sug E QalanderNoch keine Bewertungen

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDokument8 SeitenProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85Noch keine Bewertungen

- Washpipe Packing AssembliesDokument10 SeitenWashpipe Packing AssembliesJohn Holding100% (1)

- Epl 1711Dokument161 SeitenEpl 1711Alessandra Floresfar0% (1)

- Operation Manual (Auto Generated From .Docx File) - S01G1288-OPM-800 - Rev 0 - SSGD DrawworksDokument77 SeitenOperation Manual (Auto Generated From .Docx File) - S01G1288-OPM-800 - Rev 0 - SSGD Drawworkshumberto NascimentoNoch keine Bewertungen

- Electric House Manual: Top Drive Drilling EquipmentDokument22 SeitenElectric House Manual: Top Drive Drilling EquipmentAlejandro HernadezNoch keine Bewertungen

- SEC6 (1) PartsDokument401 SeitenSEC6 (1) PartsCarlos Alberto Perdomo100% (2)

- Torque TDS4 Pocket Guide-2 PDFDokument5 SeitenTorque TDS4 Pocket Guide-2 PDFHaridev67% (3)

- SEC6 Partes y PlanosDokument380 SeitenSEC6 Partes y PlanosJohn Suarez100% (1)

- 355 TDS-11S Parts Manual CC Rev1 GDSDokument170 Seiten355 TDS-11S Parts Manual CC Rev1 GDSrig602.mechanicNoch keine Bewertungen

- Rotary Checklist Rev4Dokument6 SeitenRotary Checklist Rev4Shag ShaggyNoch keine Bewertungen

- TDS-3S Maint and Troubleshooting GuideDokument68 SeitenTDS-3S Maint and Troubleshooting GuideSaid100% (1)

- Difference Between TDS 9S & TDS 9SADokument7 SeitenDifference Between TDS 9S & TDS 9SAAbdelghani ZitouniNoch keine Bewertungen

- 第6.0章电气故障排除指南tds 9satds 11sa 64 页Dokument64 Seiten第6.0章电气故障排除指南tds 9satds 11sa 64 页HayLenLeeNoch keine Bewertungen

- 1000012667-PIB Shot PinDokument3 Seiten1000012667-PIB Shot PinAdrian CantaragiuNoch keine Bewertungen

- Sec6 PDFDokument424 SeitenSec6 PDFAlex Ramirez100% (1)

- NOV TDS PIB Brake CoverDokument4 SeitenNOV TDS PIB Brake CoverAdrian CantaragiuNoch keine Bewertungen

- TM 0000 Rig Up Manual en Rev00Dokument132 SeitenTM 0000 Rig Up Manual en Rev00Noureddine AdjNoch keine Bewertungen

- 11 Sa DrawingDokument160 Seiten11 Sa DrawingLakshmi KishoreNoch keine Bewertungen

- Top DriveDokument314 SeitenTop Drivesebastian zorroNoch keine Bewertungen

- Top Drive HPS 03 1000Dokument649 SeitenTop Drive HPS 03 1000Rhdh kldmk100% (1)

- Canrig TD 4 Inch Actuator ManualDokument42 SeitenCanrig TD 4 Inch Actuator ManualAshrafNoch keine Bewertungen

- Tde 100 Electrical SystemDokument110 SeitenTde 100 Electrical SystemChaouki BoukhamlaNoch keine Bewertungen

- TDM 100 Mechanical Systems Manual Revision March 2010Dokument63 SeitenTDM 100 Mechanical Systems Manual Revision March 2010Chaouki BoukhamlaNoch keine Bewertungen

- Varco SystemsDokument34 SeitenVarco SystemsJesus Oliveros100% (1)

- T3035 Complete User Manual Rev.1Dokument557 SeitenT3035 Complete User Manual Rev.1Suat Yaman100% (1)

- SSGD Draworks Operation Manual - S0100827-OPM-800Dokument68 SeitenSSGD Draworks Operation Manual - S0100827-OPM-800Ashish JhaNoch keine Bewertungen

- West TucanaDokument3 SeitenWest TucanaSarfaraz PatelNoch keine Bewertungen

- 6923 PDFDokument5 Seiten6923 PDFMEHDINoch keine Bewertungen

- Quantity Item BSC Part Number Description: TDS-11SA With PH-75 Pipe Handler and NOV Drive House A 3OM00252 ADokument1 SeiteQuantity Item BSC Part Number Description: TDS-11SA With PH-75 Pipe Handler and NOV Drive House A 3OM00252 AAli AliNoch keine Bewertungen

- Can Rig LWCV Actuator ManualDokument58 SeitenCan Rig LWCV Actuator ManualAhmed Magd100% (2)

- Top DrveDokument2 SeitenTop DrveJohn Jairo SimancaNoch keine Bewertungen

- Section 5: Optional Equipment: Top Drive Drilling SystemDokument12 SeitenSection 5: Optional Equipment: Top Drive Drilling SystemAnibal Jose Cruz LarezNoch keine Bewertungen

- Iron RoughneckDokument200 SeitenIron RoughneckChris K100% (1)

- 250T EMI 400HP 50Hz - Install PDFDokument106 Seiten250T EMI 400HP 50Hz - Install PDFdaniel nunezNoch keine Bewertungen

- Drawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Dokument5 SeitenDrawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Noureddine AdjNoch keine Bewertungen

- Top DriveDokument6 SeitenTop DriveRenny Gracezifa BandasoNoch keine Bewertungen

- 2010 Specs 1035ac - CanrigDokument4 Seiten2010 Specs 1035ac - Canrigaldino020203100% (1)

- TDS1000AInstallationManual 03May28AbridgedDokument20 SeitenTDS1000AInstallationManual 03May28Abridgedbwd104Noch keine Bewertungen

- Equipment RecordDokument12 SeitenEquipment Recordjesus alfonso fragozo calderonNoch keine Bewertungen

- V5365 Z Ma 007 - 79445813Dokument26 SeitenV5365 Z Ma 007 - 79445813peeps1980100% (1)

- HH-Rotary Table ZP175 - ZP205 PDFDokument3 SeitenHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNoch keine Bewertungen

- Vol.10 SCR MCCDokument1.083 SeitenVol.10 SCR MCCSaleh TaalabNoch keine Bewertungen

- IDS 350PE Top DriveDokument2 SeitenIDS 350PE Top Drivealan camposNoch keine Bewertungen

- Top Drive pb175 - Alert - Block Guide Pin Inspection PDFDokument4 SeitenTop Drive pb175 - Alert - Block Guide Pin Inspection PDFFranco SotoNoch keine Bewertungen

- Ideal Top Drive Riggingup ProcedureDokument14 SeitenIdeal Top Drive Riggingup ProcedureBabi Lakhdari100% (1)

- Product Information: Model 1050E-500 Top DriveDokument6 SeitenProduct Information: Model 1050E-500 Top Drivezanella88100% (1)

- EMSCO Drwks. ELECTROHOIST V C&O PDFDokument186 SeitenEMSCO Drwks. ELECTROHOIST V C&O PDFalex albinoNoch keine Bewertungen

- Traveling Equipment Anti-Collision System Tac-Ii ManualDokument66 SeitenTraveling Equipment Anti-Collision System Tac-Ii ManualAlex RamirezNoch keine Bewertungen

- DW Operating and Maintenance ManualDokument31 SeitenDW Operating and Maintenance Manualehuamanib100% (1)

- DP TD-500-HT DR523 0051 EN Rev00 PDFDokument99 SeitenDP TD-500-HT DR523 0051 EN Rev00 PDFAbderrahmane Abdo100% (1)

- HTD 250 En-ItDokument60 SeitenHTD 250 En-ItbrasgNoch keine Bewertungen

- G1280-Z-MA-001 Complete PDF - G1280-Z-MA-001 - Rev 0 - Bulk SystemDokument763 SeitenG1280-Z-MA-001 Complete PDF - G1280-Z-MA-001 - Rev 0 - Bulk Systemhumberto NascimentoNoch keine Bewertungen

- Lewco Direct Drive BrochureDokument4 SeitenLewco Direct Drive Brochurenepotu25100% (3)

- Electrical MotorDokument35 SeitenElectrical MotorTshering Peljor100% (4)

- Keystone Atuador de Dupla Ação Pneumático PDFDokument8 SeitenKeystone Atuador de Dupla Ação Pneumático PDFdiforaNoch keine Bewertungen

- Undercowl Pocket Guide RRDokument32 SeitenUndercowl Pocket Guide RRbnmmauricio100% (3)

- 160.75-RP1 (210) - Yk (G)Dokument92 Seiten160.75-RP1 (210) - Yk (G)JayashtonNoch keine Bewertungen

- Derbi Atlantis 50 - 100 4T (En)Dokument91 SeitenDerbi Atlantis 50 - 100 4T (En)Manualles0% (1)

- GM 6t70 UpdatesDokument45 SeitenGM 6t70 UpdatesThePokeOne100% (9)

- Stcwcir2 2012 annexIIIDokument2 SeitenStcwcir2 2012 annexIIISushil GuptaNoch keine Bewertungen

- Millimeters To Inches TabelleDokument2 SeitenMillimeters To Inches Tabellecris180550% (2)

- Vendor Evaluation FormDokument1 SeiteVendor Evaluation FormSushil GuptaNoch keine Bewertungen

- Anchor Handling Manual MSFDokument45 SeitenAnchor Handling Manual MSFfeghuolhakim100% (4)

- Cruising Log BookDokument100 SeitenCruising Log BookSushil GuptaNoch keine Bewertungen

- Coc ChecklistDokument1 SeiteCoc ChecklistSushil GuptaNoch keine Bewertungen

- Cat D398 Lubrication and Maintenance Chart2Dokument6 SeitenCat D398 Lubrication and Maintenance Chart2Sushil Gupta75% (4)

- Water Ballast GuideDokument84 SeitenWater Ballast GuideKenneth TanNoch keine Bewertungen

- Gas CarriersDokument14 SeitenGas CarriersdressfeetNoch keine Bewertungen

- 6896859660Dokument36 Seiten6896859660Sushil GuptaNoch keine Bewertungen

- Ship Construction Young)Dokument72 SeitenShip Construction Young)Sushil Gupta100% (4)

- Cement 12Dokument24 SeitenCement 12prashannapandit832Noch keine Bewertungen

- Welding Electrodes SelectionDokument19 SeitenWelding Electrodes SelectionjerickNoch keine Bewertungen

- Using CHEMCAD For Piping Network Design and AnalysisDokument51 SeitenUsing CHEMCAD For Piping Network Design and AnalysisRawlinsonNoch keine Bewertungen

- Drafting Sanitary and Plumbing Layout and DetailsDokument17 SeitenDrafting Sanitary and Plumbing Layout and DetailsStewart MagayanoNoch keine Bewertungen

- Towards 4.0: The Smelter of The FutureDokument4 SeitenTowards 4.0: The Smelter of The FutureShyamal VermaNoch keine Bewertungen

- Exercises On Fracture MechanicsDokument33 SeitenExercises On Fracture Mechanicsyaswanth199260% (5)

- Monthly ReportDokument15 SeitenMonthly ReportMae Ann GonzalesNoch keine Bewertungen

- A Simple Aico Carbon Monoxide Alarms LeafletDokument1 SeiteA Simple Aico Carbon Monoxide Alarms LeafletSparks Electrical Wholesalers LtdNoch keine Bewertungen

- Triple Star Fire Catalogue Price List v2.5Dokument16 SeitenTriple Star Fire Catalogue Price List v2.5pastorgeeNoch keine Bewertungen

- Ipc TM 650 Test Methods ManualDokument3 SeitenIpc TM 650 Test Methods ManualPiere Salas HerreraNoch keine Bewertungen

- Eew Longitudinally Welded Double Seam Lwds Pipes PDFDokument4 SeitenEew Longitudinally Welded Double Seam Lwds Pipes PDFktsnlNoch keine Bewertungen

- L1103ADokument4 SeitenL1103Ac131508Noch keine Bewertungen

- 800D SeriesDokument3 Seiten800D Seriesvkeie0206Noch keine Bewertungen

- Center Pivot: End Gun ApplicationDokument2 SeitenCenter Pivot: End Gun ApplicationdonnynkNoch keine Bewertungen

- Ime34070m 2 Far FR2835SDokument80 SeitenIme34070m 2 Far FR2835Ssrinu1984Noch keine Bewertungen

- Pages From ASME B31.3 - 2016Dokument5 SeitenPages From ASME B31.3 - 2016Gulzar AliNoch keine Bewertungen

- The Detection of Alpha Prime in Duplex Stainless SteelsDokument10 SeitenThe Detection of Alpha Prime in Duplex Stainless Steelsapply19842371Noch keine Bewertungen

- Material Reconciliation - PDF REVISEDDokument32 SeitenMaterial Reconciliation - PDF REVISEDSrinivasan RanganathanNoch keine Bewertungen

- NUST Journal of Engineering Science (NJES) PDFDokument97 SeitenNUST Journal of Engineering Science (NJES) PDFjasim aliNoch keine Bewertungen

- en 10213 2007 Steel Castings For Pressure Purposes PDFDokument29 Seitenen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNoch keine Bewertungen

- T10A Secondary Cells: Chapter - 1Dokument15 SeitenT10A Secondary Cells: Chapter - 1lvsaruNoch keine Bewertungen

- Glass Data - v4 Low ResDokument15 SeitenGlass Data - v4 Low ResPatrick SyNoch keine Bewertungen

- Sonalika Training ReportDokument64 SeitenSonalika Training Report3drohit100% (4)

- Choke Specification - CCI PDFDokument4 SeitenChoke Specification - CCI PDFAakashRanjan100% (1)

- Construction of A Low Cost Drip Irrigation System For ProductionDokument4 SeitenConstruction of A Low Cost Drip Irrigation System For ProductionBaba shehu Abba kyariNoch keine Bewertungen

- Flaechendicht k435 de 0216 0 Eng ScreenDokument2 SeitenFlaechendicht k435 de 0216 0 Eng ScreenAlexandru IonescuNoch keine Bewertungen

- CFBC SHORT NOTESDokument8 SeitenCFBC SHORT NOTESanbarasanNoch keine Bewertungen

- Fundamentals Hvac R Carter StanfieldDokument3 SeitenFundamentals Hvac R Carter Stanfieldzvonkomihajlovic48910% (1)

- Project Proposal (Urban Gardening)Dokument2 SeitenProject Proposal (Urban Gardening)Geanne Antoinette BasilioNoch keine Bewertungen

- Tim Hieu Qua Trinh Loc Tach Dau KhiDokument838 SeitenTim Hieu Qua Trinh Loc Tach Dau KhiNem Chua RánNoch keine Bewertungen