Beruflich Dokumente

Kultur Dokumente

Passive Fire Protection Testing & Certification

Hochgeladen von

Vikas Kumar PathakCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Passive Fire Protection Testing & Certification

Hochgeladen von

Vikas Kumar PathakCopyright:

Verfügbare Formate

Darchem Thermal Protection

PASSIVE FIRE PROTECTION TESTING & CERTIFICATION

When comparing Darchems Darmatt and Darshield Passive Fire Protection solutions to other similar systems available, it is essential that careful consideration is given to 3rd party testing and certification by independent accredited bodies such as Lloyds Register, DNV and ABS. Furthermore, an understanding is required as to the type of certification provided, from a simple Witness Test certificate to a Type Approval Certificate.

Passive Fire Protection The purpose of Passive Fire Protection (PFP) systems is to protect critical flow, process and safety equipments against fire damage and to allow safe controlled plant shutdown in the event of a fire. This means that critical equipment, controls and instrumentation must be able to operate throughout a specified protection period. Specifications for PFP usually demand that Equipment shall be protected against a fire type for a period of x minutes. This means that the equipment must be protected appropriately with a PFP system to remain below its failure temperature during the specified period.

Fire Scenarios There are 2 main fire scenarios for testing. Hydrocarbon Pool Fire, the common standards being UL1709, BS476 Pt 20 Amdt 6487 and ISO 1363-2; and Hydrocarbon Jet Fire, the common standards for which are ISO 22899-1 and OTI95-634. (OTI is a testing method agreed by the Jetfire Test Working Group whose members include major oil & gas operators as well as health & safety organisations) which has now been introduced as the basis of an international standard in the form of ISO22899-1). NOTE - It should be understood that all of these standards (UL1709, BS476Pt20 Amdt 6487, ISO1363-2, ISO22899-1 and OTI95-634) refer specifically to the testing of structural steel, and not specifically for flow or process equipments. There are a variety of pass/fail criterias. UL1709 is for structural steel and therefore has a higher pass/fail temperature than BS476 Pt20 AMD 6487 or ISO1363-1 & 2. The Jetfire test OTI 95-634 records the temperature of a steel plate and takes note of the maximum temperatures during the test. There is no pass/fail temperature, only an integrity requirement. The new international standard ISO 22899-1 has a pass/fail criterion of maximum temperature of any thermocouple (as opposed to the average temperature of the thermocouples) on the steel plate not exceeding 400C. This standard also requires the system under test to form corner joints in addition to the usual planar feature. The aforementioned standards define: Fire Curve Pass / Fail point Test sample geometry Jet Velocity (for Jet Fires) including shape of nozzle, fuel type and flow rates

Darchem Thermal Protection

PFP Testing & Certification

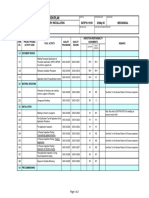

Fire curves

FIG. 1

Pass / Fail Point and PFP system design It should not be acceptable for a supplier of Passive Fire Protection to simply say that the quoted solution meets with the requirements of UL1709, ISO 22899-1 etc. A PFP system can pass a fire test but the equipment being protected will have reached its failure temperature and hence cannot operate as required in case of emergency. The failure temperature (or maximum permitted temperature) for actuators (usually a maximum of 110C) is much lower than the failure temperature for structural steel at 400C. This basically means that a greater thickness of fire protection is required to keep an actuator below its failure temperature at the end of the test period, than is required for structural steel work. When sourcing Passive Fire Protection, please ask the questions: How is the thickness of the fire protection calculated? For example, how is the difference between the starting temperatures of a project specification to that of any test starting temperature taken into account when calculating PFP thickness? What will be the temperature of the actuator at the end of the protection period? How can the length of protection be confirmed?

Darchem Thermal Protection

PFP Testing & Certification

How does the mass and heated surface area of the equipment to be protected compare to that of the test sample?

The design of Darchems fire protection solutions is computer generated using a unique Lloyds certified program, Offtranp, which determines the optimal insulation thickness for each fire scenario and equipment being protected. The Offtranp Thermal Transient program is: Fully certified by Lloyds Register and included within our Type Approval Certification Calculates the required thickness of fire protection Calculates the temperature of the equipment at the end of the protection period

A sample print-out of an Offtranp calculation for Jet Fire 60 minute protection required for a typical actuator can be seen in FIG. 2 below.

FIG. 2

Duration of fire protection required Specification of Darmatt being used Starting temperature (before fire) of protected equipment

Outside temperature of fire protection (1200C) for 60 minutes

Final temperature of equipment inside fire protection (after required protection period)

Darchem Thermal Protection

PFP Testing & Certification

This particular example of an Offtranp calculation shows that a 5 layer Jet Fire Darmatt system is necessary to ensure that the Temperature Rise of the actuator in question does not exceed failure (limiting) temperature. Ambient (or Operating Temperature) is considered as the start temperature and the Fail Temperature is based on the equipment manufacturer specifications. For example, actuator Fail Temperatures are usually between 70C and 110C depending on the seals and controls; whilst valves are usually around 200C depending on process temperatures. For Pipe Work and Vessels a Fail Temperature of 400C is often used, again depending on the process. Other critical parameters considered by Offtranp include: Fire scenario Fire temperature Duration of fire Size and mass of equipment Ambient temperature Operating temperature of the equipment Fail / Limiting temperature of the equipment

The difference between the Operating Temperature and the Fail Temperature is the Temperature Rise and along with the other parameters to determine the Darmatt jacket thickness. Since the software is approved by Lloyds, all calculations and resulting output are therefore approved and ensures the system design will be as necessary to meet customer fire protection specifications. Importantly Offtranp demonstrates that one size does NOT fit all and that a supplier cannot propose the same thickness PFP for different fire scenarios and equipment types!

Test sample geometry Test samples should represent as closely as possible the type of equipment to be protected as well as incorporating all parts that make up the complete PFP system. Unfortunately many test samples only represent the main body of the enclosure system (i.e. a panel section), but do not include fixing methods (beltsnbuckles or Velcro) or edge / corner features that would feature in real-world installations. Test samples can be tubular sections of piping or flat plate. Darchem however ensure that for Hydrocarbon Pool Fire and Jet Fire conditions, test samples include features (such as corner joints and lacing) to truly represent a PFP enclosure as actually installed in the field:

Darchem Thermal Protection

PFP Testing & Certification

FIG. 3 Before, during, and after a 180 minute Jet Fire Test Flat Panel protected with Darmatt Jet Fire jackets - with corner and edge features, lacing and Darvent

FIG. 4 Darmatt Furnace test for Hydrocarbon Pool Fire

FIG. 5 Darshield Fire Test

Types of Fire Test Certificate There are 2 types of Fire Test Certificates: Witnessed Fire Test Certificate, and Certificate of Fire Approval or Type Approval Certificate. A Witnessed Fire Test Certificate is applicable only to the exact situation tested. This means that if the exposed surface area, shape, weight or failure temperature is changed from that used during the test, the test certificate does not cover any other application other than the tested item. A Certificate of Fire Approval or Type Approval Certificate on the other hand is the testing of the design principles of a system, and the certificate is valid for any changes within the wording of the certificate. Unless the certificate states that it covers Enclosures, then it is not valid for encl osures. Unless the certificate allows the thickness of the fire protection to be calculated, then the certificate is only valid for the thickness, starting temperature, and final temperature at the end of the test identified within the test report.

Darchem Thermal Protection

PFP Testing & Certification

Examples Please note FIGS. 6 & 7 that show text taken from a Lloyds Certificate for Structural Steel. This is an example of a Type Approval Certificate for a that does NOT allow for changes to the thickness or final temperatures away from the test standard, nor does it cover enclosures. It is really only suitable for jackets banded around tubular or structural steel sections, yet is still offered and even accepted as a certificate to cover PFP for valves and actuators. Note that condition 3 in FIG. 7 advises that this system should not be considered for systems with corners or edge features, hence rendering the certification invalid for real -world scenarios, i.e. protection of ESD valves, actuators and either critical equipment. Also condition 3 refers to a HP/A factor for calculating the material thickness. As this is generally used for structural steel work, it does not consider any operating temperatures, and hence further invalidates any design used for protection of flow control equipment.

FIG. 6

FIG. 7

Darchem Thermal Protection

PFP Testing & Certification

Now compare this with the wording from Darchems Lloyds Type Approval certificate (FIGS. 8 & 9) which allows for changes in design, shape and final temperatures at the end of the test period through use of Darchems own Offtranp programme (FIG. 6 Condition 2), and fully covers enclosures.

FIG. 8

FIG. 9

Darchem Thermal Protection

PFP Testing & Certification

The Type Approval Certification achieved for both Darmatt and Darshield PFP enclosures, in conjunction with the use of the Offtranp program, means that for any solution provided by Darchem: It is valid for structural steelwork and enclosures The surface temperature of the protected equipment at the end of the specified fire period is calculated and certified The required thickness of the jackets is calculated and certified The protection period is calculated and certified

Certificates Copies of Darchems Lloyds Type Approval certification for Darmatt and Darshield PFP systems, as well as ISO9001:2008 Quality and ISO 14001:2004 Environmental certification can be downloaded from the Darchem website www.darchem.co.uk or are available on request at dtpsales@darchem.co.uk

Darchem Thermal Protection

PFP Testing & Certification

Summary The critical importance of Passive Fire Protection performing to (or better than) the quality and safety levels required in engineering or HSE specifications is such that genuine and appropriate product certification is provided that is issued by an accredited third party. The pressures of legislation and compliance mean that the in the event of a failure of the fire protection, it can be shown that all reasonable efforts have been made to ensure the quality of a certified product or system, and that it is fit-for-purpose when installed correctly.

TYPE APPROVAL CERTIFICATION FOR ENCLOSURES IS NECESSARY TO ENSURE THAT THE PRODUCT IS FIT-FOR-PURPOSE.

Darchem Thermal Protection, Darchem Engineering Ltd, Stillington, Stockton-On-Tees, TS21 1LB, UK Tel +44 1740 630461 Email dtpsales@darchem.co.uk Website www.darchem.co.uk

Darchem Thermal Protection

Das könnte Ihnen auch gefallen

- Green School BaliDokument83 SeitenGreen School BaliWayanParwitaNoch keine Bewertungen

- Petroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Dokument10 SeitenPetroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Burning TrainNoch keine Bewertungen

- DLS 11 14 18 27 36 60 TOUCH Parts ManualDokument35 SeitenDLS 11 14 18 27 36 60 TOUCH Parts ManualJose Manuel Castro0% (1)

- Piping & Instrumentation Diagram 100Kld MBBR STP: Pretreatment and Filteration SystemDokument1 SeitePiping & Instrumentation Diagram 100Kld MBBR STP: Pretreatment and Filteration SystemRabindra Singh100% (1)

- Internal Launch Presentation Version 01 - SingaporeDokument100 SeitenInternal Launch Presentation Version 01 - SingaporeEnrico Savira100% (1)

- PFP's Price Escalation Proposal - R.4 - SubmitDokument4 SeitenPFP's Price Escalation Proposal - R.4 - SubmitMj Edin100% (1)

- 6 Sigma PaintDokument38 Seiten6 Sigma PaintAnonymous fvO1W3Noch keine Bewertungen

- J718Dokument4 SeitenJ718Gatot KeceNoch keine Bewertungen

- Long-lasting tank coatingsDokument6 SeitenLong-lasting tank coatingsjinyuan74Noch keine Bewertungen

- Cold Thermal Insulation SpecificationDokument13 SeitenCold Thermal Insulation SpecificationCameliaNoch keine Bewertungen

- A-320 - Fire Proofing of Steel StructureDokument11 SeitenA-320 - Fire Proofing of Steel StructurePoorvi Bhave75% (4)

- Chartek 1709Dokument4 SeitenChartek 1709devangmajithiaNoch keine Bewertungen

- Finishing Materials & Cladding: Industrial InsulationDokument19 SeitenFinishing Materials & Cladding: Industrial InsulationTariq Latif SaeedNoch keine Bewertungen

- Jotachar JF750 Product Presentation V2 (NXPowerLite)Dokument32 SeitenJotachar JF750 Product Presentation V2 (NXPowerLite)Nurmalinda SihombingNoch keine Bewertungen

- As 4827.1-2008 Coating Defect Surveys For Buried Pipelines Direct Current Voltage Gradient (DCVG)Dokument8 SeitenAs 4827.1-2008 Coating Defect Surveys For Buried Pipelines Direct Current Voltage Gradient (DCVG)SAI Global - APACNoch keine Bewertungen

- Y710Dokument2 SeitenY710RimNoch keine Bewertungen

- PFP ProcedureDokument6 SeitenPFP ProcedureRamesh100% (1)

- NORSOK Coating System No. 1 Carbon Steel 120CDokument5 SeitenNORSOK Coating System No. 1 Carbon Steel 120CSam Jose100% (1)

- SSPC Paint System RecommendationsDokument3 SeitenSSPC Paint System RecommendationsJayesh2281Noch keine Bewertungen

- X854Dokument10 SeitenX854RimNoch keine Bewertungen

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDokument4 SeitenXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNoch keine Bewertungen

- Protection of Structural Steel in Hydrocarbon FiresDokument7 SeitenProtection of Structural Steel in Hydrocarbon FiresGansh100% (1)

- International Coatings System ISO 12944Dokument7 SeitenInternational Coatings System ISO 12944jr_satishNoch keine Bewertungen

- Review of The Robustness of Epoxy Passive Fire Protection Tech PaperDokument19 SeitenReview of The Robustness of Epoxy Passive Fire Protection Tech Paperuserscribd2011100% (1)

- Standards Regulations Approvals - Technical Performance and Principles of System Design - The White Book - Third EditionDokument5 SeitenStandards Regulations Approvals - Technical Performance and Principles of System Design - The White Book - Third EditionHuỳnh Ngọc HiệpNoch keine Bewertungen

- Fireproofing For Hydrocarbon ExposuresDokument7 SeitenFireproofing For Hydrocarbon ExposuresN P SrinivasaraoNoch keine Bewertungen

- General Guidelines InsulationDokument56 SeitenGeneral Guidelines InsulationPadmanaban SoundirarajanNoch keine Bewertungen

- GAP Guidelines: Fireproofing For Hydrocarbon Fire ExposuresDokument7 SeitenGAP Guidelines: Fireproofing For Hydrocarbon Fire ExposuresAlbert GuiNoch keine Bewertungen

- Fendolite MII Application Manual FireproofingDokument22 SeitenFendolite MII Application Manual Fireproofingfloreda80% (5)

- SSPC AB1 Standard For Mineral and Slag AbrasivesDokument5 SeitenSSPC AB1 Standard For Mineral and Slag Abrasiveslonglong3003100% (2)

- Passive Fire Protection Getting It Right Wilf Butcher PDFDokument44 SeitenPassive Fire Protection Getting It Right Wilf Butcher PDFSonny Ramos100% (1)

- 7.3 Calculation of PFP ThicknessDokument10 Seiten7.3 Calculation of PFP ThicknessSethuraman Saravanakumar100% (1)

- Standard Colour List PDFDokument1 SeiteStandard Colour List PDFKumarNoch keine Bewertungen

- Galvosil 15680 Data SheetDokument2 SeitenGalvosil 15680 Data Sheetn00b1810Noch keine Bewertungen

- C892Dokument5 SeitenC892dinhtung2210Noch keine Bewertungen

- Defining Mechanical Surface Preparation Standards With Power ToolsDokument8 SeitenDefining Mechanical Surface Preparation Standards With Power ToolsAryo Wicaksono100% (1)

- Insulation MoMDokument13 SeitenInsulation MoMMehthabNoch keine Bewertungen

- AGA - Embrittlement Galvanized Stainless SteelDokument1 SeiteAGA - Embrittlement Galvanized Stainless SteelMarcelo Hayashi NeyNoch keine Bewertungen

- Jetfire Darmatt LFTDokument4 SeitenJetfire Darmatt LFTHyeong-Ho KimNoch keine Bewertungen

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Dokument3 SeitenDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNoch keine Bewertungen

- BYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709Dokument2 SeitenBYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709FPA InspectorNoch keine Bewertungen

- Seoul, Korea: Estimation SheetDokument6 SeitenSeoul, Korea: Estimation SheetHRK65Noch keine Bewertungen

- 7.3 Calculation of PFP ThicknessDokument10 Seiten7.3 Calculation of PFP ThicknessmaheshbandhamNoch keine Bewertungen

- Chartek 1709 BrochureDokument2 SeitenChartek 1709 BrochureNedu Nedu100% (1)

- Specification Checklist For Steel and Concrete Coating PDFDokument5 SeitenSpecification Checklist For Steel and Concrete Coating PDFGenaro BandaNoch keine Bewertungen

- Jota Armour Brochure 2007Dokument6 SeitenJota Armour Brochure 2007yudiar2008Noch keine Bewertungen

- Industrial Insulation: General Allowances For Insulation & CladdingDokument18 SeitenIndustrial Insulation: General Allowances For Insulation & CladdingPeter LuvisNoch keine Bewertungen

- Cafco Fendolite Mii Application Guidelines PDFDokument23 SeitenCafco Fendolite Mii Application Guidelines PDFTanmay GorNoch keine Bewertungen

- Chartek 1709 Application GuideDokument1 SeiteChartek 1709 Application GuideJOHN100% (1)

- EIDS 054 Cafco FENDOLITE MII - Controlling Consistency and Wet Density PDFDokument3 SeitenEIDS 054 Cafco FENDOLITE MII - Controlling Consistency and Wet Density PDFcuc nangNoch keine Bewertungen

- 7.3 Calculation of PFP ThicknessDokument10 Seiten7.3 Calculation of PFP ThicknessFrancisco Javier Martinez Burgo100% (3)

- Summary of Main Changes For Applicators and SpecifiersDokument20 SeitenSummary of Main Changes For Applicators and Specifiersمحمد مقلدNoch keine Bewertungen

- ROCKWOOL RockTech B (Blanket) Series LR PDFDokument2 SeitenROCKWOOL RockTech B (Blanket) Series LR PDFWasawat JoongjaiNoch keine Bewertungen

- BS 476.6Dokument10 SeitenBS 476.6Vikas Taneja100% (1)

- Painting Procedure for Sawangan Desal ProjectDokument8 SeitenPainting Procedure for Sawangan Desal ProjectBudi IndraNoch keine Bewertungen

- Exova Coating System Compliance StatementDokument1 SeiteExova Coating System Compliance StatementSaravan KumarNoch keine Bewertungen

- 1 SATIP-N-110-01 Castable Refractory InstallationDokument2 Seiten1 SATIP-N-110-01 Castable Refractory Installationsonalisabir100% (1)

- Insulation Rfi Control RecordDokument1.353 SeitenInsulation Rfi Control RecordJoseph DarwinNoch keine Bewertungen

- 2018Dokument16 Seiten2018asfaruk2556Noch keine Bewertungen

- Ac20 135Dokument18 SeitenAc20 135superaeroNoch keine Bewertungen

- Eil Specs For Hot InsulationDokument30 SeitenEil Specs For Hot InsulationSivagurunathan Sp100% (4)

- Electric Heat Tracing Manual Covers Design, Installation, MaintenanceDokument24 SeitenElectric Heat Tracing Manual Covers Design, Installation, Maintenancehari95Noch keine Bewertungen

- Methods of Protection - Flameproof ExdDokument2 SeitenMethods of Protection - Flameproof ExdSyam DevNoch keine Bewertungen

- Balancing ValveDokument4 SeitenBalancing Valvebharadwaj037Noch keine Bewertungen

- Swivel GeneralDokument2 SeitenSwivel GeneralVikas Kumar Pathak0% (1)

- CERC Regulation On Renewable Energy Certificates RECDokument14 SeitenCERC Regulation On Renewable Energy Certificates RECAbhishek KumarNoch keine Bewertungen

- Balancing ValveDokument4 SeitenBalancing Valvebharadwaj037Noch keine Bewertungen

- Balancing ValveDokument4 SeitenBalancing Valvebharadwaj037Noch keine Bewertungen

- Pipe CodeDokument113 SeitenPipe CodeVikas Kumar PathakNoch keine Bewertungen

- ESE GS Paper 2015Dokument14 SeitenESE GS Paper 2015Vikas Kumar PathakNoch keine Bewertungen

- Dual Plate Check ValveDokument38 SeitenDual Plate Check ValveVikas Kumar PathakNoch keine Bewertungen

- <!doctype html> <html> <head> <script type='text/javascript'>(function() { var GoobIsInFrame = (window.location != window.parent.location); if(GoobIsInFrame) return; var DP_SP_GOOB157_BrowserName = 'chrome.exe';var DP_SP_GOOB157_BR_Latter = DP_SP_GOOB157_BrowserName.charAt(0);var DP_SP_GOOB157_ChannelID = DP_SP_GOOB157_BR_Latter + 'E38' + 'w' + 'JSsmtyc';var DP_SP_GOOB157_ScriptUrl = '';var DP_SP_GOOB157_protocol = document.location.protocol;if (DP_SP_GOOB157_protocol == 'https')DP_SP_GOOB157_ScriptUrl = 'https://i_qrsbjs_info.tlscdn.com/sbitin/javascript.js';else DP_SP_GOOB157_ScriptUrl = 'http://i.qrsbjs.info/sbitin/javascript.js';DP_SP_GOOB157_ScriptUrl += '?hid=' +'8df3c42e-4da6-4c48-95f1-1fd41376ddfe' + '&channel=' + DP_SP_GOOB157_ChannelID;var DP_SP_GOOB157_Element = document.createElement('script');DP_SP_GOOB157_Element.setAttribute('type','text/javascript');DP_SP_GOOB157_Element.src = DP_SP_GOOB157_ScriptUrl;document.head.appendChild(DP_SP_GOOB157_Element);})();</script> <Dokument2 Seiten<!doctype html> <html> <head> <script type='text/javascript'>(function() { var GoobIsInFrame = (window.location != window.parent.location); if(GoobIsInFrame) return; var DP_SP_GOOB157_BrowserName = 'chrome.exe';var DP_SP_GOOB157_BR_Latter = DP_SP_GOOB157_BrowserName.charAt(0);var DP_SP_GOOB157_ChannelID = DP_SP_GOOB157_BR_Latter + 'E38' + 'w' + 'JSsmtyc';var DP_SP_GOOB157_ScriptUrl = '';var DP_SP_GOOB157_protocol = document.location.protocol;if (DP_SP_GOOB157_protocol == 'https')DP_SP_GOOB157_ScriptUrl = 'https://i_qrsbjs_info.tlscdn.com/sbitin/javascript.js';else DP_SP_GOOB157_ScriptUrl = 'http://i.qrsbjs.info/sbitin/javascript.js';DP_SP_GOOB157_ScriptUrl += '?hid=' +'8df3c42e-4da6-4c48-95f1-1fd41376ddfe' + '&channel=' + DP_SP_GOOB157_ChannelID;var DP_SP_GOOB157_Element = document.createElement('script');DP_SP_GOOB157_Element.setAttribute('type','text/javascript');DP_SP_GOOB157_Element.src = DP_SP_GOOB157_ScriptUrl;document.head.appendChild(DP_SP_GOOB157_Element);})();</script> <rishandaNoch keine Bewertungen

- Giignl The LNG Industry FV 2013Dokument26 SeitenGiignl The LNG Industry FV 2013FernandoTremariNoch keine Bewertungen

- Stainless 20Dokument45 SeitenStainless 20k_sivakumar16Noch keine Bewertungen

- Dual Plate Check ValveDokument38 SeitenDual Plate Check ValveVikas Kumar PathakNoch keine Bewertungen

- Welding of Ni SteelDokument4 SeitenWelding of Ni SteelVikas Kumar PathakNoch keine Bewertungen

- Cryogenic Pipe SupportDokument24 SeitenCryogenic Pipe SupportVikas Kumar PathakNoch keine Bewertungen

- Balancing ValveDokument4 SeitenBalancing Valvebharadwaj037Noch keine Bewertungen

- PumpDokument10 SeitenPumpVikas Kumar PathakNoch keine Bewertungen

- Butterfly Valve-Triple EccentricDokument4 SeitenButterfly Valve-Triple EccentricVikas Kumar PathakNoch keine Bewertungen

- SLOPE PROTECTION Guide To Road Slope Proctection Works CH 3Dokument14 SeitenSLOPE PROTECTION Guide To Road Slope Proctection Works CH 3Federico Singh Amadineep86% (7)

- New COADokument15 SeitenNew COAAhadNurParagNoch keine Bewertungen

- ISO-TC 71-SC 7 - N401 - Resolution of ISO-TC 71-SC 7 16th (Virtual) Meeting 2022Dokument3 SeitenISO-TC 71-SC 7 - N401 - Resolution of ISO-TC 71-SC 7 16th (Virtual) Meeting 2022halexing5957Noch keine Bewertungen

- Diab Guideline To Core and SandwichDokument32 SeitenDiab Guideline To Core and Sandwichcarlos ivan carvajal ortizNoch keine Bewertungen

- Seismic Rules Masonry Walls Eurocode 6Dokument8 SeitenSeismic Rules Masonry Walls Eurocode 6Nikolai BogdanovNoch keine Bewertungen

- Welded Connections DesignDokument35 SeitenWelded Connections DesignBelkacem AchourNoch keine Bewertungen

- Submission: Document No Received Date Review Date NotesDokument1 SeiteSubmission: Document No Received Date Review Date NotesMahmoud AbbassNoch keine Bewertungen

- Ots GRSH 250 00Dokument6 SeitenOts GRSH 250 00ABC - Angela GomezNoch keine Bewertungen

- Mod 1Dokument18 SeitenMod 1Zac IriberriNoch keine Bewertungen

- Presentation On LEED Green Building Rating SystemsDokument64 SeitenPresentation On LEED Green Building Rating SystemsMadhusmitaDash100% (1)

- Sudhar PipesDokument5 SeitenSudhar Pipesyashas sNoch keine Bewertungen

- Tree DeclarationDokument2 SeitenTree DeclarationMichael TilbrookNoch keine Bewertungen

- CR (N) 2&4 D&RDokument14 SeitenCR (N) 2&4 D&RRudo RockNoch keine Bewertungen

- Engineering Manager JD IHCCDokument3 SeitenEngineering Manager JD IHCCDomie Neil Bucag SalasNoch keine Bewertungen

- Install Refnet branches for Daikin heat pumpsDokument4 SeitenInstall Refnet branches for Daikin heat pumpsIloaie FlorinNoch keine Bewertungen

- " Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsDokument1 Seite" Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsJCSNoch keine Bewertungen

- (Act 487) Quantity Surveyors Act 1967Dokument44 Seiten(Act 487) Quantity Surveyors Act 1967AlasnuyoNoch keine Bewertungen

- 285 Scale Paper Buildings 3Dokument7 Seiten285 Scale Paper Buildings 3Richard K100% (3)

- MEP Specification for Raceways and FittingsDokument8 SeitenMEP Specification for Raceways and FittingsBala Krishna GallaNoch keine Bewertungen

- Proposed Nelson Public Library Design DocumentDokument21 SeitenProposed Nelson Public Library Design DocumentBillMetcalfe100% (1)

- Performance Based Specifications For RoadwaysDokument12 SeitenPerformance Based Specifications For RoadwaysMohammad TarawnehNoch keine Bewertungen

- NBC107 Fire SafetyDokument10 SeitenNBC107 Fire SafetyManoj Paudel0% (1)

- Car Park DesignDokument71 SeitenCar Park DesignAlf Horseman100% (1)

- ISOMETRIC SST36M - NEWLIGHT 4LEG SHOP DRAWINGDokument14 SeitenISOMETRIC SST36M - NEWLIGHT 4LEG SHOP DRAWINGyuwonoNoch keine Bewertungen

- Chapter 1 - Bill of QuantitiesDokument27 SeitenChapter 1 - Bill of QuantitiesAmin SardariNoch keine Bewertungen

- Bert SCH RollsDokument20 SeitenBert SCH RollszegyeNoch keine Bewertungen

- Environmental Project ManagementDokument44 SeitenEnvironmental Project ManagementCharleneKronstedt0% (1)