Beruflich Dokumente

Kultur Dokumente

Interrupting Capacity Vs Interrupting Rating

Hochgeladen von

Arnel Pascual LaquindanumOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Interrupting Capacity Vs Interrupting Rating

Hochgeladen von

Arnel Pascual LaquindanumCopyright:

Verfügbare Formate

Applying Interrupting Rating: Circuit Breakers

Interrupting Rating Vs. Interrupting Capacity

Interrupting Rating

It is the maximum short-circuit current that an overcurrent protective device can safely interrupt under standard test conditions. The phrase under standard test conditions means it is important to know how the overcurrent protective device is tested in order to assure it is properly applied. This can be very important when it comes to the application of circuit breakers, mainly ratings of 100A and less.

Standard Test Conditions - Circuit Breakers

This is not the case with circuit breakers. Because of the way circuit breakers are short circuit tested (with additional conductor impedance), their interrupting capacity can be less than their interrupting rating. When the test circuit is calibrated for the circuit breaker interrupting rating tests, the circuit breaker is not in the circuit. After the test circuit has been verified to the proper level of short-circuit current, the circuit breaker is placed into the circuit. However, in addition to the circuit breaker, significant lengths of conductor are permitted to be added to the circuit after the calibration. This additional conductor impedance can result in a significantly lower short-circuit current. So a circuit breaker marked with an interrupting rating of 22,000A may in fact have an interrupting capacity of only 9,900A. To better understand this, it is necessary to review the standard interrupting rating test procedures for circuit breakers: Molded Case Circuit Breakers - UL 489 and CSA 5 Test Procedures. UL 489 requires a unique test set-up for testing circuit breaker interrupting ratings. The diagram below illustrates a typical calibrated test circuit waveform for a 20A, 240V, 2-pole molded case circuit breaker, with a marked interrupting rating of 22,000A, RMS symmetrical.

Interrupting Capacity

The highest current at rated voltage that the device can interrupt. This definition is from the IEEE Standard Dictionary of Electrical and Electronic Terms.

Standard Test Conditions - Fuses

Branch circuit fuses are tested without any additional conductor in the test circuit. For instance, if a fuse has an interrupting rating of 300,000A, the test circuit is calibrated to have at least 300,000A at the rated fuse voltage. During the test circuit calibration, a bus bar is used in place of the fuse to verify the proper short-circuit current. Then the bus bar is removed and the fuse is inserted; the test is then conducted. If the fuse passes the test, the fuse is marked with this interrupting rating (300,000A). In the procedures just outlined for fuses, there are no extra conductors inserted into the test circuit after the short-circuit current is calibrated. A major point is that the fuse interrupts an available short-circuit current at least equal to or greater than its marked interrupting rating. In other words, because of the way fuses are short-circuit tested (without additional conductor impedance), their interrupting capacity is equal to or greater than their marked interrupting rating.

26

2005 Cooper Bussmann

Applying Interrupting Rating: Circuit Breakers

Interrupting Rating Vs. Interrupting Capacity

The diagram below illustrates the test circuit as allowed by UL 489. Standard interrupting rating tests for a 22,000A sym. RMS interrupting rated circuit breaker will allow for a maximum 4 feet rated wire on the line side for each lead, and 10 inch rated wire on the load side for each lead of the circuit breaker. See the following diagrams and table, that provide a short circuit analysis of this test circuit as seen by the circuit breaker.

S.C.P .F. = 20% S.C. A vail. = 22,000A

R LINE RS XS XLINE

20A

R CB XCB R LOAD XLOAD

Conclusion (refer to table above and graphs below)

This 22,000A (with short circuit power factor of 20%) interrupting rated circuit breaker has an interrupting capacity of 9900A at a short circuit power factor of 88%. Unless there is a guarantee that no fault will ever occur at less than 4 feet 10 inches from the load terminals of the circuit breaker, this circuit breaker must only be applied where there are 9,900A or less available on its line side. A graphic analysis of this actual short circuit follows.

SOURCE:

4' Rated W ire (12 AWG Cu)

10" Rated Wire (12 AWG Cu)

Note: For calculations, R CB and X CB are assum ed negligible.

Test station source impedance is adjusted to achieve a calibrated 22,000 RMS symmetrical amps at 20% or less power factor. This circuit can achieve a peak current of 48,026 amps. For the calibration test, a bus bar (shorting bar) is inserted between the test station terminals.

Test station source leads Shorting bar

After the circuit calibration is verified, the shorting bar is removed and the circuit breaker is inserted. In addition, lengths of rated conductor are permitted to be added as shown. This extra rated conductor has a high impedance and effectively restricts the current to 9900 RMS symmetrical amps. The power factor increases to 88% due to small conductor high resistance versus its reactance. This circuit can now only achieve a peak current of 14,001 amps.

Test station source leads

Shorting bar removed, circuit breaker & conductors added

Each 4 feet 12 AWG

Agency standards allow for a random close during the short circuit test, so the peak available current may be as low as 1.414 times the RMS symmetrical current. Thus, the circuit breaker is actually tested to interrupt 9900A at 88% power factor, not 22,000A at 20% power factor. The following graph shows the waveforms superimposed for comparison. Henceforth, this RMS test value will be identified as the circuit breaker interrupting capacity. (Dont confuse this with the circuit breaker marked interrupting rating.)

20 A

20A, 240V, 2-Pole Circuit Breaker marked 22,000 A.I.R.

Each 10 inches 12 AWG

2005 Cooper Bussmann

27

Applying Interrupting Rating: Circuit Breakers

Interrupting Rating Vs. Interrupting Capacity

Equally important, the short circuit power factor is greatly affected due to the high R values of the small, rated wire. This results in a lower peak value that the circuit breaker must tolerate during the first one-half cycle. Following is an example of a partial table showing the actual Ip and IRMS values to which circuit breakers are tested.

Bus Bar Conditions- Circuit Breakers

Beginning October 31, 2000, UL 489 requires circuit breakers rated 100A and less to additionally be tested under bus bar conditions. However, this does not assure that the circuit breakers interrupting capacity equals its interrupting rating nor even that the circuit breaker is reusable. In this test, line and load terminals are connected to 10 inches of rated conductor. For single pole circuit breakers, these 10 inch leads are then connected to 4 feet of 1 AWG for connection to the test station. For multi-pole circuit breakers, the 10 inch line side leads are connected to the test station through 4 feet of 1 AWG. The load side is shorted by 10 inch leads of rated conductor per pole. These bus bar condition tests still do not fully address the situation where a fault can occur less than 4 feet 10 inches from the circuit breaker. One point to be made is that acceptable bus shot test results per the product standard do not meet the NEC definition for a circuit breaker. For example, 7.1.11.6.3.1 of UL 489 states The inability to relatch, reclose, or otherwise reestablish continuity ... shall be considered acceptable for circuit breakers which are tested under bus bar conditions. In practical terms, this means the circuit breaker doesnt have to work after a fault near the circuit breaker occurs. This is in violation of the NEC definition for a circuit breaker: A device designed to open and close a circuit by nonautomatic means and to open the circuit automatically on a predetermined overcurrent without damage to itself when properly applied within its rating. In addition, under bus bar condition tests the circuit breaker is required to only interrupt one short-circuit current. For this one short circuit test shot, the circuit breaker is in its closed position and the short-circuit current is initiated by the test station switch closing randomly. The bus bar conditions test procedures do not evaluate the circuit breaker for closing-on the short circuit. Closing-on a short circuit is an important criteria for safety.

28

2005 Cooper Bussmann

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Guidelines For Temperature Profiling For Mass Soldering Processes (Reflow & Wave)Dokument3 SeitenGuidelines For Temperature Profiling For Mass Soldering Processes (Reflow & Wave)Selvakumar100% (2)

- ASCEN SMT Conveyor List 0Dokument22 SeitenASCEN SMT Conveyor List 0Igur EuiNoch keine Bewertungen

- Protection Question and AnswerDokument26 SeitenProtection Question and AnswerKanda VelanNoch keine Bewertungen

- Schneider Earthing SystemsDokument30 SeitenSchneider Earthing SystemsSimon WrightNoch keine Bewertungen

- Schneider Earthing SystemsDokument30 SeitenSchneider Earthing SystemsSimon WrightNoch keine Bewertungen

- Cable Test Sheet On DrumDokument2 SeitenCable Test Sheet On DrumAhmad Dagamseh100% (1)

- Bus Switching Configurations in Air Insulated Substations AISDokument5 SeitenBus Switching Configurations in Air Insulated Substations AISArnel Pascual LaquindanumNoch keine Bewertungen

- Pages From 241-1990 Gray Book Power Systems Commercial BuildingsDokument1 SeitePages From 241-1990 Gray Book Power Systems Commercial BuildingsArnel Pascual LaquindanumNoch keine Bewertungen

- K Factor RefDokument54 SeitenK Factor RefNamki LeeNoch keine Bewertungen

- PSH 1 HarmonicsDokument44 SeitenPSH 1 HarmonicsArnel Pascual Laquindanum0% (1)

- What Is The Difference Between Momentary DutyDokument1 SeiteWhat Is The Difference Between Momentary DutyArnel Pascual LaquindanumNoch keine Bewertungen

- Physics Worksheet Electromagnetic Induction Section: NameDokument1 SeitePhysics Worksheet Electromagnetic Induction Section: NameArnel Pascual LaquindanumNoch keine Bewertungen

- Fluke 1587 PDFDokument48 SeitenFluke 1587 PDFArnel Pascual LaquindanumNoch keine Bewertungen

- Fluke 1587 PDFDokument48 SeitenFluke 1587 PDFArnel Pascual LaquindanumNoch keine Bewertungen

- Differences Between Earthed and Unearthed CablesDokument4 SeitenDifferences Between Earthed and Unearthed Cableskash30Noch keine Bewertungen

- Harmonic Effects On Power System EquipmentDokument12 SeitenHarmonic Effects On Power System EquipmentCalin AvramescuNoch keine Bewertungen

- Port1050 - SiemensFreeCourses - Basics of Safety SwitchesDokument76 SeitenPort1050 - SiemensFreeCourses - Basics of Safety Switchesmahesh_sali2003Noch keine Bewertungen

- Animal Deterrents and Security in SubstationDokument3 SeitenAnimal Deterrents and Security in SubstationArnel Pascual LaquindanumNoch keine Bewertungen

- IV. Harmonics in Power SystemsDokument17 SeitenIV. Harmonics in Power SystemsArnel Pascual LaquindanumNoch keine Bewertungen

- IV. Harmonics in Power SystemsDokument17 SeitenIV. Harmonics in Power SystemsArnel Pascual LaquindanumNoch keine Bewertungen

- 220V DC System at Thermal Power StationDokument5 Seiten220V DC System at Thermal Power StationArnel Pascual LaquindanumNoch keine Bewertungen

- Determining Correction Factor of Power Cable SizingDokument40 SeitenDetermining Correction Factor of Power Cable SizingawsifzNoch keine Bewertungen

- The Cage Induction Motor Explained in DetailsDokument3 SeitenThe Cage Induction Motor Explained in DetailsArnel Pascual LaquindanumNoch keine Bewertungen

- How To Protect Capacitor BanksDokument5 SeitenHow To Protect Capacitor BanksArnel Pascual LaquindanumNoch keine Bewertungen

- Purpose of Shielded Isolation TransformerDokument3 SeitenPurpose of Shielded Isolation TransformerArnel Pascual LaquindanumNoch keine Bewertungen

- Purpose of Shielded Isolation TransformerDokument3 SeitenPurpose of Shielded Isolation TransformerArnel Pascual LaquindanumNoch keine Bewertungen

- Arc Flash Protection LV HV Switching Suits For Racking in & OutDokument2 SeitenArc Flash Protection LV HV Switching Suits For Racking in & OutArnel Pascual LaquindanumNoch keine Bewertungen

- Electrical Engineering Portal - Com Arrangement of Hydropower PlantsDokument4 SeitenElectrical Engineering Portal - Com Arrangement of Hydropower Plantsrajitha5633Noch keine Bewertungen

- Ais Air Insulated SubstationsDokument1 SeiteAis Air Insulated SubstationsArnel Pascual LaquindanumNoch keine Bewertungen

- Wind Power Applications Grid Connected or NotDokument5 SeitenWind Power Applications Grid Connected or NotArnel Pascual LaquindanumNoch keine Bewertungen

- About Permeability and PermitivityDokument3 SeitenAbout Permeability and PermitivityArnel Pascual LaquindanumNoch keine Bewertungen

- AC Adjustable Speed Drive ASD An OverviewDokument4 SeitenAC Adjustable Speed Drive ASD An OverviewArnel Pascual LaquindanumNoch keine Bewertungen

- Introduction To Instrument TransformersDokument4 SeitenIntroduction To Instrument TransformersArnel Pascual LaquindanumNoch keine Bewertungen

- Application of Piezoelectric Transducer in Energy Harvesting in PavementDokument8 SeitenApplication of Piezoelectric Transducer in Energy Harvesting in PavementvisionNoch keine Bewertungen

- Eds3400 Plus VdmaDokument4 SeitenEds3400 Plus VdmasunhuynhNoch keine Bewertungen

- Basic Elements of KnittingDokument3 SeitenBasic Elements of KnittingMd.Shoeb Alom RoxyNoch keine Bewertungen

- LV - Switchgear, Controlgear & Power Quality Solutions: Price List W.E.F 21st July 2021Dokument92 SeitenLV - Switchgear, Controlgear & Power Quality Solutions: Price List W.E.F 21st July 2021ShashankNoch keine Bewertungen

- Eyc Ege SKM 420 GR 20190315Dokument1 SeiteEyc Ege SKM 420 GR 20190315zaki abbasNoch keine Bewertungen

- PCE Indutrial Switch Socket (2,12)Dokument14 SeitenPCE Indutrial Switch Socket (2,12)Kelvin LiewNoch keine Bewertungen

- Answer:: 4. Question 4. Define CMRR?Dokument8 SeitenAnswer:: 4. Question 4. Define CMRR?শ্রী লিমন চন্দ্র মোহন্তNoch keine Bewertungen

- TS27M2, TS27M2A, TS27M2B: Low-Power CMOS Dual Operational AmplifiersDokument15 SeitenTS27M2, TS27M2A, TS27M2B: Low-Power CMOS Dual Operational AmplifiersMihai Butnaru-PaladeNoch keine Bewertungen

- Ferrite Core Analysis For DC-DC Flyback Converter: Maliki@pwr - Elect.itm - Edu.myDokument5 SeitenFerrite Core Analysis For DC-DC Flyback Converter: Maliki@pwr - Elect.itm - Edu.mymohon_eee03Noch keine Bewertungen

- Abb-Dtr Current Transformers en 11-01a PDFDokument48 SeitenAbb-Dtr Current Transformers en 11-01a PDFkhai100% (1)

- Module Electricity and MagnetismDokument21 SeitenModule Electricity and MagnetismNoorain PurhanudinNoch keine Bewertungen

- WWW - Iranswitching.Ir: Ac/Dc Switch Mode Power Supply Design GuideDokument1 SeiteWWW - Iranswitching.Ir: Ac/Dc Switch Mode Power Supply Design GuidedraNoch keine Bewertungen

- Book ListDokument6 SeitenBook ListKhandaker Khairul AlamNoch keine Bewertungen

- Logic Families: Designed By: Asadullah JamalovDokument6 SeitenLogic Families: Designed By: Asadullah JamalovAsadullah JamalovNoch keine Bewertungen

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffDokument1 Seite(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroNoch keine Bewertungen

- 4158AS0840Dokument51 Seiten4158AS0840Ronhal LozanoNoch keine Bewertungen

- Valve EquivalentsDokument608 SeitenValve EquivalentsPeeters GuyNoch keine Bewertungen

- Serti Plat Hitam 3,2mm...Dokument1 SeiteSerti Plat Hitam 3,2mm...AGSMotoVlog 06Noch keine Bewertungen

- a8cd09f2ef69793dff843b1397494446 (1)Dokument24 Seitena8cd09f2ef69793dff843b1397494446 (1)vishal.nithamNoch keine Bewertungen

- 2.7 Lampu Tanda 'Keluar' LedDokument1 Seite2.7 Lampu Tanda 'Keluar' Ledenergy empireNoch keine Bewertungen

- Data Sheet Py2 PDFDokument3 SeitenData Sheet Py2 PDFErik HenriqueNoch keine Bewertungen

- JNTUH 2-2 ECE May 2016Dokument13 SeitenJNTUH 2-2 ECE May 2016mushahedNoch keine Bewertungen

- KV Adjustment: Use and Disclosure Is Subject To The Restrictions On The Title Page of This CPI DocumentDokument14 SeitenKV Adjustment: Use and Disclosure Is Subject To The Restrictions On The Title Page of This CPI DocumentFoued MbarkiNoch keine Bewertungen

- Distance Protection: 70 KV Overhead LineDokument1 SeiteDistance Protection: 70 KV Overhead Lineandi mulyanaNoch keine Bewertungen

- 2019 Summer Model Answer Paper (Msbte Study Resources)Dokument16 Seiten2019 Summer Model Answer Paper (Msbte Study Resources)juber mullaNoch keine Bewertungen

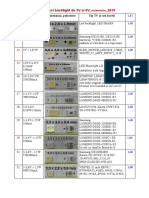

- Oferta Leduri Backlight de 3V Si 6V - Noiembrie - 2019Dokument20 SeitenOferta Leduri Backlight de 3V Si 6V - Noiembrie - 2019piciNoch keine Bewertungen