Beruflich Dokumente

Kultur Dokumente

Study of Lathe

Hochgeladen von

kb210538Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Study of Lathe

Hochgeladen von

kb210538Copyright:

Verfügbare Formate

STUDY OF LATHE

INTRODUCTION Lathe is the father of all machine tool. It is a basic machine tool probably the most important one of all, lathe was actually the first machine tool. Lathe is a particular type of machine tool in

which the work is held and rotated against a suitable cutting tool for the purpose of producing surface of revolution in any material.

LATHE SPECIFICATIONS: In order to specify a lathe, a number of parameters could be used on the specific applications. However, the major elements used for specifications should invariably be based on the components that would be manufactured in the lathe. The sum of lathe specifications is, L=Distance between centers. A=Swing diameter over bed. B=Swing diameter over carriage. R=Radius. H=Height of center from bed DISTANCE BETWEEN CENTERS (L): This would be specifying the maximum length of the job that can be turned in the lathe. SWING DIAMETER OVER BED (A): This specifies the maximum diameter of the job that can be turned in the lathe machine generally restricted to small length jobs. SWING DIAMETER OVER CARRIAGE (B): This specifies the maximum diameter of job that can be turned in the lathe machines with the job across the cross slide. Other factors should also be specified to fully describe the lathe machine. 1. 2. 3. 4. 5. 6. Horse power of the motor Feed range Accuracy achieved Cutting speed range Screw cutting capacity Spindle nose diameter

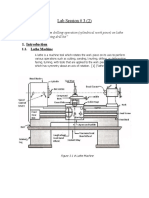

PARTS OF ENGINE LATHE OR CENTER LATHE: The principal parts of an engine lathe are, 1. Bed, 2. Head stock, 3. Tail stock, 4. Carriage, 4.1. 4.2. 4.3. 4.4. 4.5. Saddle, Cross slide, Compound rest, Tool post, Apron.

5. Feed Mechanism, 6. Thread cutting mechanism. CARRIERS AND CATCH PLATES: Carriers and catch plates are used to drive a work piece when it is held between two centers. Carriers or driving dogs are attached to the end of the work piece by a setscrew, and catch plates are either screwed or bolted to the nose of the headstock spindle. CHUCK: A chuck is one of the most important devices for holding and rotating a piece of work in a lathe. Work piece of short length, and large diameter or irregular shapes, which cannot be conveniently mounted between centers, are held quickly and rigidly in a chuck. TYPES OF CHUCKS: 1. Four jaw independent chuck 2. Three jaw universal chuck 3. Air or hydraulic operated chuck 4. Magnetic chuck 5. Collet chuck 6. Combination chuck 7. Drill chuck

FACE PLATE: A faceplate consists of a circular disk bored out and threaded to fit the nose of the lathe spindle. This has the radial, plain and T slots for holding work by bolts and clamps. ANGLE PLATE: This is a cast iron plate having two faces machined to make them absolutely at right angles to each other. Holes and slots are provided on both faces so that it may be clamped on a faceplate and can hold the work piece on the face by bolts and clamps. MANDRELS: A mandrel is a device for holding and rotating a hollow piece of work that has been previously drilled or bored. The work revolves with the mandrel which is mounted between two centers. PLAIN MANDREL: The plain mandrel this type of mandrel is most commonly used in shops and finds wide application where a large number of identical pieces having standard size holes are required to be mounted on it. STEP MANDREL: A step mandrel having steps of different diameters may be employed to drive different work pieces having different sizes of holes without replacing the mandrel each time. This type of mandrel is suitable for turning collars, washers and odd size jobs used in repairing workshops. COOLER MANDREL: A cooler mandrel having solid coolers is used for turning work pieces having holes of larger diameter, usually above 100 mm. This construction reduces weight and fits better than a solid mandrel of equal size. SCREWED MANDREL: A screwed mandrel is threaded at one end with a collar. Work pieces having internal threads are screwed on to it against the collar for machining. CONE MANDREL: A cone mandrel consists of a solid attached to the one end of the body, and a sliding cone, which can be adjusted by turning a nut at a threaded end.

GANG MANDREL: This has a fixed collar at one end and a movable collar at the threaded end, which may be adjusted, to this position by a nut. The mandrel is used to hole a set of hollow work piece between two collars by tightening the nut. EXPANSION MANDREL: There are different types of expansion mandrels. The mandrel consists of tapered pin, which is driven into a sleeve that is parallel outside and tapered inside the sleeve has three longitudinal slots, two of which are cut nearly through, and the third splits it completely. RESTS: A rest is a mechanical device which supports a long slender work piece, which is turned between centers or by a clutch, at some intermediate point to prevent bending of the work piece due to its own weight and vibrations set up due to the cutting force that acts on it. STEADY REST: A steady rest shown in Fig consists of a cast iron base, which may be made to slide on the loath bed ways and clamped at any desired position where a support is necessary.

Das könnte Ihnen auch gefallen

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsVon EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNoch keine Bewertungen

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsVon EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsBewertung: 5 von 5 Sternen5/5 (1)

- Lathe Machine Parts and FunctionDokument58 SeitenLathe Machine Parts and Functionjas081603Noch keine Bewertungen

- Lathe AccessoriesDokument4 SeitenLathe AccessoriesBOT-X GAMING100% (1)

- Lathe Machine ToolDokument59 SeitenLathe Machine ToolSiva BhaskarNoch keine Bewertungen

- Lathe Machine IntroDokument7 SeitenLathe Machine IntroHirenNoch keine Bewertungen

- Lathe Machine AssignmentDokument23 SeitenLathe Machine AssignmentChristopher Rohrer100% (1)

- Lec. 2,3 PDFDokument52 SeitenLec. 2,3 PDFAwad M. El ArabyNoch keine Bewertungen

- Lathe MachineDokument6 SeitenLathe MachineJuno Eron TalamayanNoch keine Bewertungen

- Machine Shop: Principal Parts of A LatheDokument7 SeitenMachine Shop: Principal Parts of A LatheArchika YaduNoch keine Bewertungen

- TurningDokument6 SeitenTurningShivshankar Singh0% (1)

- Study and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeDokument9 SeitenStudy and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeSazzadNoch keine Bewertungen

- Chapter 2 Different Types of FixturesDokument20 SeitenChapter 2 Different Types of FixturesaragawNoch keine Bewertungen

- Chucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheDokument14 SeitenChucks: Clamp Radial Symmetry Cylindrical Drill Bit Power Tool Bar Spindle LatheIrtaza Husnain100% (1)

- FixingDokument13 SeitenFixingPR projectNoch keine Bewertungen

- Machine WorskopDokument20 SeitenMachine WorskopnaemaNoch keine Bewertungen

- Unit-4 Machine ToolsDokument77 SeitenUnit-4 Machine ToolsSOURABH GANGWARNoch keine Bewertungen

- Lathe MachineDokument13 SeitenLathe Machinemboniface763Noch keine Bewertungen

- Lecture No. 9: Drilling Machines, Nomenclature, Types, Operations and PrecautionsDokument47 SeitenLecture No. 9: Drilling Machines, Nomenclature, Types, Operations and PrecautionsMuhammad IrfanNoch keine Bewertungen

- Lathe Machine OperationDokument68 SeitenLathe Machine OperationKarthick N100% (8)

- Chapter 11Dokument32 SeitenChapter 11Mark Angelo M. BubanNoch keine Bewertungen

- Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFDokument20 SeitenLathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFMark Angelo M. BubanNoch keine Bewertungen

- Machine Shop Manual 27112020Dokument9 SeitenMachine Shop Manual 27112020Jeevan MandalaNoch keine Bewertungen

- Machine ShopDokument6 SeitenMachine ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)Noch keine Bewertungen

- Impetus Metalmaster LatheDokument19 SeitenImpetus Metalmaster LatheIan Foreman100% (1)

- c5 Lathe 120203152613 Phpapp02Dokument30 Seitenc5 Lathe 120203152613 Phpapp02Preavin Kutty Thamotharan100% (1)

- Machining Processes - I MT 164: LatheDokument45 SeitenMachining Processes - I MT 164: LatheMusab LatifNoch keine Bewertungen

- Workshop Technology-II, Unit I: TurningDokument8 SeitenWorkshop Technology-II, Unit I: TurningRamkrishnaSutharNoch keine Bewertungen

- Machine Tools Lab Manual (13-14)Dokument39 SeitenMachine Tools Lab Manual (13-14)Krishna Murthy100% (1)

- Diagram of Lathe Machine: Explanation of The Standard Components of Most LathesDokument5 SeitenDiagram of Lathe Machine: Explanation of The Standard Components of Most LathesKaushik SreenivasNoch keine Bewertungen

- Me2207 Manufacturing Technology I Lab ManualDokument71 SeitenMe2207 Manufacturing Technology I Lab ManualKarthick N91% (11)

- Machine Tool SDokument14 SeitenMachine Tool Ssiri.pogulaNoch keine Bewertungen

- Lathe MachineDokument16 SeitenLathe MachineM Arslan AshrafNoch keine Bewertungen

- Lab 3Dokument6 SeitenLab 3Khurram SattarNoch keine Bewertungen

- MSJF Mod-1Dokument20 SeitenMSJF Mod-1abithek03Noch keine Bewertungen

- MTM Lab ManualDokument23 SeitenMTM Lab ManualMian Abdul Rehman100% (1)

- Cbe-241rev Quad Processing MachineDokument12 SeitenCbe-241rev Quad Processing MachineVigneshMurugesh ANoch keine Bewertungen

- Lathe MachineDokument18 SeitenLathe MachineCRAZY INDIAN XYZ100% (1)

- Lab Session Operations of Lathe Machine Part 1Dokument2 SeitenLab Session Operations of Lathe Machine Part 1Aqib ZamanNoch keine Bewertungen

- LatheDokument76 SeitenLathebmm16957Noch keine Bewertungen

- M AchingDokument10 SeitenM AchingSnehasishNoch keine Bewertungen

- Lathe Machine Lab ReportDokument8 SeitenLathe Machine Lab ReportJasmine_lai00Noch keine Bewertungen

- Diploma Workshop Practice IIDokument30 SeitenDiploma Workshop Practice IISagir Musa SaniNoch keine Bewertungen

- Lathes and Lathe Machining OperationsDokument18 SeitenLathes and Lathe Machining Operationssarasrisam100% (1)

- Machine Lab - ReportDokument11 SeitenMachine Lab - Reportsaiq kamranNoch keine Bewertungen

- Project Report 360 Degree Drilling MachineDokument11 SeitenProject Report 360 Degree Drilling MachineSumit Bijwe80% (5)

- Workshop AssignmentDokument23 SeitenWorkshop AssignmentMr. NasrullahNoch keine Bewertungen

- Unit - 2 (Lathes)Dokument17 SeitenUnit - 2 (Lathes)suryaNoch keine Bewertungen

- Mohamed Baksh 1036007 Assignment 6Dokument11 SeitenMohamed Baksh 1036007 Assignment 6Mohamed BakshNoch keine Bewertungen

- Activity #9Dokument2 SeitenActivity #9Mariella Alyzza InciongNoch keine Bewertungen

- WORKSHOP PRACTICE-B.Tech IIDokument46 SeitenWORKSHOP PRACTICE-B.Tech IIrawat7233abhayNoch keine Bewertungen

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingVon EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNoch keine Bewertungen

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversVon EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversBewertung: 5 von 5 Sternen5/5 (2)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheVon EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Practical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsVon EverandPractical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsNoch keine Bewertungen

- Tables BookDokument1 SeiteTables Bookkb210538Noch keine Bewertungen

- EDM Advantages PDFDokument1 SeiteEDM Advantages PDFkb210538Noch keine Bewertungen

- EDM Advantages PDFDokument1 SeiteEDM Advantages PDFkb210538Noch keine Bewertungen

- EDM Advantages PDFDokument1 SeiteEDM Advantages PDFkb210538Noch keine Bewertungen

- EDM Advantages PDFDokument1 SeiteEDM Advantages PDFkb210538Noch keine Bewertungen

- EDM Advantages PDFDokument1 SeiteEDM Advantages PDFkb210538Noch keine Bewertungen

- Edm PDFDokument2 SeitenEdm PDFkb210538Noch keine Bewertungen

- Ie End SemDokument1 SeiteIe End Semkb210538Noch keine Bewertungen

- DocumentDokument1 SeiteDocumentkb210538Noch keine Bewertungen

- Greeting CardDokument1 SeiteGreeting Cardkb210538Noch keine Bewertungen

- 18ed62 - Geometric ModellingDokument2 Seiten18ed62 - Geometric Modellingkb210538Noch keine Bewertungen

- SyllabusDokument4 SeitenSyllabuskb210538Noch keine Bewertungen

- Full Page PhotoDokument1 SeiteFull Page Photokb210538Noch keine Bewertungen

- Drawing1 ModelDokument1 SeiteDrawing1 Modelkb210538Noch keine Bewertungen

- A Key To New Arabic Grammer by NahammedDokument1 SeiteA Key To New Arabic Grammer by Nahammedkb210538Noch keine Bewertungen

- EMM Lesson Plan UNIT I 6 Hours Phase Diagrams and Constitution of AlloysDokument1 SeiteEMM Lesson Plan UNIT I 6 Hours Phase Diagrams and Constitution of Alloyskb210538Noch keine Bewertungen

- IE QbankDokument1 SeiteIE Qbankkb210538Noch keine Bewertungen

- Hibiscus Flower (Shoe Flower) A Visual Illustration For Easy UnderstandingDokument1 SeiteHibiscus Flower (Shoe Flower) A Visual Illustration For Easy Understandingkb210538Noch keine Bewertungen

- IE Qbank PDFDokument1 SeiteIE Qbank PDFkb210538Noch keine Bewertungen

- SunflowerDokument1 SeiteSunflowerkb210538Noch keine Bewertungen

- Ie QBDokument1 SeiteIe QBkb210538Noch keine Bewertungen

- Fundamentals of Fluid Mechanics by Munson Good Book To ReferDokument1 SeiteFundamentals of Fluid Mechanics by Munson Good Book To Referkb210538Noch keine Bewertungen

- Unit-2 Metrology and MeasurementsDokument1 SeiteUnit-2 Metrology and Measurementskb210538Noch keine Bewertungen

- SDT Time TableDokument1 SeiteSDT Time Tablekb210538Noch keine Bewertungen

- Mechatronics Laboratory: List of ExperimentsDokument7 SeitenMechatronics Laboratory: List of ExperimentsratchagarajaNoch keine Bewertungen

- Unit-3 Metrology and MeasurementsDokument1 SeiteUnit-3 Metrology and Measurementskb210538Noch keine Bewertungen

- Casting TypesDokument1 SeiteCasting Typeskb210538Noch keine Bewertungen

- Train Numbe R Train Name From Station Destination Station Runs From Source OnDokument1 SeiteTrain Numbe R Train Name From Station Destination Station Runs From Source Onkb210538Noch keine Bewertungen

- Unit-1 Metrology and MeasurementsDokument1 SeiteUnit-1 Metrology and Measurementskb210538Noch keine Bewertungen

- CastingDokument1 SeiteCastingkb210538Noch keine Bewertungen

- Topic 5 - Cost AnalysisDokument8 SeitenTopic 5 - Cost AnalysistoytoyNoch keine Bewertungen

- Assignment Operations Management II 2019Dokument4 SeitenAssignment Operations Management II 2019Indah Widoningtyas100% (1)

- Gantt Chart PDFDokument1 SeiteGantt Chart PDFIrish CPNoch keine Bewertungen

- The NASA - Exercise: Teambuilding Amsterdam, 08/12/2001Dokument4 SeitenThe NASA - Exercise: Teambuilding Amsterdam, 08/12/2001Anonymous 8mSGlNHNoch keine Bewertungen

- Competency Requirements and Record Form (Example)Dokument2 SeitenCompetency Requirements and Record Form (Example)srihari kallaNoch keine Bewertungen

- Dian Zhang: Porter's Five Forces Analysis and Value Chain Analysis of AUX Air-Conditioning Co., LTDDokument5 SeitenDian Zhang: Porter's Five Forces Analysis and Value Chain Analysis of AUX Air-Conditioning Co., LTDMangesh SarjeNoch keine Bewertungen

- Parker Products Filtration Process-LDokument190 SeitenParker Products Filtration Process-Lkamal_muralikumarNoch keine Bewertungen

- Knauf TCDM 2013 V3Dokument163 SeitenKnauf TCDM 2013 V3Santosh PatilNoch keine Bewertungen

- JAIIB Principles of Banking Module C NewDokument16 SeitenJAIIB Principles of Banking Module C News1508198767% (3)

- Project Planning QuestionsDokument8 SeitenProject Planning QuestionsAntokaNoch keine Bewertungen

- Iocl Shell & Tube He's Spec Ea-601 Rev 0Dokument5 SeitenIocl Shell & Tube He's Spec Ea-601 Rev 0Rama Krishna Reddy DonthireddyNoch keine Bewertungen

- Blue Light Blue Color Blocks Flight Attendant CVDokument2 SeitenBlue Light Blue Color Blocks Flight Attendant CVahmed mezNoch keine Bewertungen

- Quality BasicsDokument16 SeitenQuality BasicskamaleshaiahNoch keine Bewertungen

- Analytical Modelling For Vibration Analysis of Partially Cracked Orthotropic Rectangular PlatesDokument34 SeitenAnalytical Modelling For Vibration Analysis of Partially Cracked Orthotropic Rectangular PlatesHamid M SedighiNoch keine Bewertungen

- TM Appendix 6C Torque Sequences S9086 CJ STM 010 NSTM075 Rev 4Dokument236 SeitenTM Appendix 6C Torque Sequences S9086 CJ STM 010 NSTM075 Rev 4Ricardo Jorge Horta PequenoNoch keine Bewertungen

- PeristalticDokument12 SeitenPeristalticAnonymous ItzBhUGoiNoch keine Bewertungen

- Q'Max Solutions Inc CommercialDokument22 SeitenQ'Max Solutions Inc Commercialanup_mbmNoch keine Bewertungen

- Hyperlynx High-Speed Serial Interface Analysis: Student WorkbookDokument6 SeitenHyperlynx High-Speed Serial Interface Analysis: Student WorkbookPawanNoch keine Bewertungen

- T&D March 2011Dokument118 SeitenT&D March 2011refherreraNoch keine Bewertungen

- As 1289.3.6.3-2003 Methods of Testing Soils For Engineering Purposes Soil Classification Tests - DeterminatioDokument2 SeitenAs 1289.3.6.3-2003 Methods of Testing Soils For Engineering Purposes Soil Classification Tests - DeterminatioSAI Global - APAC0% (1)

- Ufgs 33 52 90.00 20Dokument22 SeitenUfgs 33 52 90.00 20pradanangkpNoch keine Bewertungen

- Manual Quick TrailingDokument2 SeitenManual Quick TrailingDaniels JackNoch keine Bewertungen

- Flow Chart - Production SystemDokument30 SeitenFlow Chart - Production Systemmatthew mafaraNoch keine Bewertungen

- Breaker SeriesDokument6 SeitenBreaker SeriesDeno Manuel LudzanNoch keine Bewertungen

- Manual de Uso Datazen-3.0Dokument177 SeitenManual de Uso Datazen-3.0Davi Demétrio VieiraNoch keine Bewertungen

- Chancadora Secundaria OSBORNDokument12 SeitenChancadora Secundaria OSBORNfaviojjglNoch keine Bewertungen

- Everything About Diaper Production Machinezjady PDFDokument2 SeitenEverything About Diaper Production Machinezjady PDFbeercrush71Noch keine Bewertungen

- Transport Economics by Kenneth ButtonDokument520 SeitenTransport Economics by Kenneth ButtonHadi100% (6)

- Saarthi - Excel AssignmentDokument17 SeitenSaarthi - Excel AssignmentBHUMIT KATARIANoch keine Bewertungen

- APSC150 - Lecture 3.5 - Mine Rescue at UBCDokument50 SeitenAPSC150 - Lecture 3.5 - Mine Rescue at UBCRahul Verma RVNoch keine Bewertungen