Beruflich Dokumente

Kultur Dokumente

ER420 - MS of Road Construction - r1

Hochgeladen von

Wr ArOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ER420 - MS of Road Construction - r1

Hochgeladen von

Wr ArCopyright:

Verfügbare Formate

ULT CORPORATION PTE LTD

7E PIONEER SECTOR 1 SINGAPORE 628446 TEL: 64153078 FAX: 68631928

ER420-NEW ROAD LINK BETWEEN UPPER CHANGI ROAD AND UPPER CHANGI ROAD EAST

METHOD STATEMENT

ROAD CONSTRUCTION

PREPARED BY APPROVED BY SAFETY OFFICER DATE OF SUBMISSION REVISION

: HARIRAM MANOHARAN : GOO KIANG TIONG, JIMMY : STEVEN LIM : :0

ER420_MS_Road Construction_r1

TABLE OF CONTENTS: 1. 2. 3. 4. 5. 6. 7. 8. 9. Back ground Scope of work Person responsible for work Manpower Construction tools and equipments Material specifications Construction Procedures Quality Control Safety Precautions

ER420_MS_Road Construction_r1

1)Background This method statement describes the work procedures for the construction of New road link between Upper Changi road and Upper Changi road East. The type of road construction is TYPE 1, Flexible pavement as per LTA/RD/SD99/PAV/2A. 2)Scope of work The project ER420 is for the construction of New road link between Upper Changi road and Upper Changi road East. The link road has a total of 4 lanes (2 northbound and 2 southbound), 3.7m each. The total length of the link road is roughly 180 metres. Two new bus stops are also to be constructed on either side of the link road. 3)Persons responsible for work Name Jimmy Goo Hariram Mani Fong Muni Designation Project Manager Site Engineer Pavement Supervisor Site Supervisor Safety supervisor Contact No. 96957413 94477749 84332276 84025141 82590048

4)Manpower Project Manager Site Engineer Safety Supervisor Lifting Supervisor Signal man Site Supervisor Operator Worker -1 -1 -1 -1 -1 -1 -1 -5

Pavement Supervisor - 1

ER420_MS_Road Construction_r1

5)Construction Tools and Equipment Typical equipment for carrying out pavement works are listed as below, i) ii) iii) iv) Mechanical Paver Vibratory Roller Milling machine Excavator

6)Material Specifications: The construction of road

shall

be

in

accordance

to

the

details

in

LTA/RD/SD99/PAV/2A, Type 1 pavement for the main road. The elements of the road consist of 1. Standard road kerb (Type K2) 2. Sub grade 3. Sub-base 4. Base Course (B1 asphalt mix) 5. Wearing course (W3B asphalt mix) 7)Construction Procedures: 7.1) Detection of Underground Services a) Prior to commencement of the works, Contractor shall identify any services that are likely to be in the way of the proposed road to be constructed. b) Trial trenches shall be excavated to determine the exact location of these services. c) Once determined that no services are obstructing the construction, work shall proceed. 7.2) Risk And Hazard Analysis The risk and hazard analysis for construction of road is to be conducted. 7.3) Precaution On Utilities And Services a) Prior to construction of roads, supervisor is to check for services on surrounding of the kerb. E.g. LV cable for streetlights, water pipes, manhole cover and/or valve cover for culverts and others services. b) Precaution for services under or surrounding the road, esp. LV cable, should be taken during the process of breaking up existing road furniture. c) Determine the road furniture that will be affected during widening of the roads, eg. Lamp posts, OG boxes, traffic counter etc.

ER420_MS_Road Construction_r1

7.4) Setting out a) Site Land Surveyor shall set out all the alignment and levels for the road edge as per the Drawings.

7.5) Site Work- Proposed Road by Type 1 Flexible Pavement Structure a) Detection of Underground services will be carried out by Licensed Cable Detection Worker (LCDW). Trial trench will be carried out before excavation to determine the exact location of the services and liaise with relevant authority for diversion if affected by the road raising works. b) Excavation / filling will proceed once confirm there is no underground obstruction or affected services are removed. Earthworks shall be completed up to the subgrade level of the final road level/ c) Sub-grade compaction will be carried out from MC01 Ch:30 to Ch:175 with 10-ton roller to achieve the required standard. d) Once the sub-grade is compacted it will be covered with the thin layer of Mill Waste to protect it from bad weather conditions. e) Surface drainage will also be provided to prevent any stagnant water on the Sub-grade area. f) After subgrade construction the sub-base material (mill waste) 300mm thick will be laid and compacted to the required standard using excavator and 10 tons roller. g) The sequence of laying the sub-base will be to start at the bus bay area (MC01 Ch: 60 to Ch:100) and then on the remaining areas. h) Once the sub-base is ready, Construction of permanent kerb will be started. The sequence of kerb construction will follow the same sequence as Sub-base construction. i) After completion of kerb construction laying and compaction of graded granite aggregate base course (RCA) 250mm thick shall be carried out in two layers. The first layer (150mm to 175mm) will be laid with the help of exacavator. The second layer (75mm to 100mm) will be laid by Mechanical paver. j) After completion of Base course, using the same mechanical paver, asphaltic base course 120mm thick shall be laid in two operations. Each operation of 60mm thick shall be rolled smooth and compacted before proceeding with the next layer.

ER420_MS_Road Construction_r1

k) Once the asphalitic base course works are completed, remaining road related works like application of temporary traffic road marking, Installation of temporary signage and warning signs will be completed l) Once all the said works are completed,Inspection by Traffic Management review team prior to the opening of road diversion will be carried out. m) Arrangement of meeting with relevant Authorities before road opening and informed the Public on the intention. The summary of the site works are as following: a) Cut the existing ground to the propose subgrade levels. b) Carry out sub-grade compaction with 10-ton roller to achieve the required standard. c) Laying and compaction of sub-base material (mill waste)to the required standard by means of an excavator. d) Construction of permanent kerb / divider. e) Using a mechanical paver, laying and compaction of graded granite aggregate and layer shall be rolled smooth and compacted. f) Using the same mechanical paver, asphaltic base course shall be laid in one operation. g) After the asphaltic base course has been rolled smooth and compacted. The final wearing course shall then be laid.

8. Quality control

8.1) Material i) Asphalt concrete a. Extraction Test and Field Density Tests must comply with the requirements set out in LTA Materials and Worksmanship Specifications. ii) Sub-base Materials a. Batch samples shall be taken and tested to meet the requirements set out in LTA Materials and Worksmanship Specifications Clause 10.3.2.2

9. Precautions of Safety

a) Safety precautions are implemented and adhered to strictly for work areas which are in close proximity to the man on the street. b) The supervisor is wholly in-charge of safety, supervision and traffic control and in work areas. c) Work should be cordon up with safety netting or plastic barricade to prevent pedestrian entering the work area.

ER420_MS_Road Construction_r1

Das könnte Ihnen auch gefallen

- Revit KHMER PDFDokument222 SeitenRevit KHMER PDFSereyponleu KhunNoch keine Bewertungen

- Construction of Road EmbankmentsDokument39 SeitenConstruction of Road EmbankmentsOsman Mukhtar MohamedNoch keine Bewertungen

- Bridge Construction Manual - Falsework and FormsDokument81 SeitenBridge Construction Manual - Falsework and FormsRocky ChoNoch keine Bewertungen

- NO.08Bmethod Statement For Culverts Upper PortionREV.ADokument11 SeitenNO.08Bmethod Statement For Culverts Upper PortionREV.AAmila Priyadarshana DissanayakeNoch keine Bewertungen

- Retaining Wall StandardsDokument3 SeitenRetaining Wall StandardssowjichNoch keine Bewertungen

- Constuction of Embankment/ Preparation of Subgrade: Highway ConstructionDokument11 SeitenConstuction of Embankment/ Preparation of Subgrade: Highway ConstructionMohan Mylarappa100% (1)

- Road BOQDokument129 SeitenRoad BOQSunil Kumar GeraNoch keine Bewertungen

- S86088-LKA-C07CE-MS-004 - Sub & Superstructure (Rev0)Dokument47 SeitenS86088-LKA-C07CE-MS-004 - Sub & Superstructure (Rev0)Stephen David Gozun100% (1)

- Specification of D-Wall and Bored PilesDokument34 SeitenSpecification of D-Wall and Bored PilesdonnyNoch keine Bewertungen

- Intelligent Transportation Systems 7409 LCfgAlfDokument21 SeitenIntelligent Transportation Systems 7409 LCfgAlfChetan HalladNoch keine Bewertungen

- Bim For Road Works 1702098608Dokument119 SeitenBim For Road Works 1702098608Samuel TibebuNoch keine Bewertungen

- Moment Distribution MethodDokument25 SeitenMoment Distribution Methodosbo1611Noch keine Bewertungen

- In-Situ Concrete CulvertDokument3 SeitenIn-Situ Concrete CulvertBenjamin IpeNoch keine Bewertungen

- FOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005Dokument28 SeitenFOUNDATION DESIGN & CONSTRUCTION IN HONG KONG - PRESENT & BEYOND, Daman Lee HK-Taiwan 2005M Mushanif MuktiNoch keine Bewertungen

- Overlay and Asphalt Pavement Rehabilitation ManualDokument47 SeitenOverlay and Asphalt Pavement Rehabilitation ManualMike NderituNoch keine Bewertungen

- Fischer Technical DataDokument6 SeitenFischer Technical DataAnonymous CgJzschNoch keine Bewertungen

- Bar Bending Schedule TemplateDokument2 SeitenBar Bending Schedule TemplateKung'u GithachuriNoch keine Bewertungen

- Hoardings Good PracticeDokument46 SeitenHoardings Good PracticeVincent TengNoch keine Bewertungen

- Stage 1 Demolition Method StatementDokument27 SeitenStage 1 Demolition Method StatementPaul OchiengNoch keine Bewertungen

- Site Acceptance Testing (S.A.T) : Quality Control DepartmentDokument2 SeitenSite Acceptance Testing (S.A.T) : Quality Control Departmentefmartin21100% (1)

- Erection Methodology PreCast Boundary Wall Vedanta Aluminium LTD and Sterlite Energy LTDDokument1 SeiteErection Methodology PreCast Boundary Wall Vedanta Aluminium LTD and Sterlite Energy LTDkavi_prakash6992Noch keine Bewertungen

- Formwork Structure & Concreting - Flowchart & Checklist - FINAL PDFDokument4 SeitenFormwork Structure & Concreting - Flowchart & Checklist - FINAL PDFNURLINURLINDA100% (1)

- Pages From Australian Standards AS1428 Stair TreadsSINGLE PAGEDokument1 SeitePages From Australian Standards AS1428 Stair TreadsSINGLE PAGEYogaditya ModukuriNoch keine Bewertungen

- 3-Type of Retaining WallsDokument3 Seiten3-Type of Retaining Wallsone engNoch keine Bewertungen

- Method Statement For Reinforced Concrete PoursDokument6 SeitenMethod Statement For Reinforced Concrete Poursselva1965Noch keine Bewertungen

- Lo 2 - DemolitionDokument29 SeitenLo 2 - DemolitionEng Stephen ArendeNoch keine Bewertungen

- MS For Excavation at Choti ChauparDokument11 SeitenMS For Excavation at Choti ChauparvikasNoch keine Bewertungen

- Construction Management and Civil Engineering Practice in HongKongDokument133 SeitenConstruction Management and Civil Engineering Practice in HongKongJo TamNoch keine Bewertungen

- MOS Trial Trench WorkDokument20 SeitenMOS Trial Trench Workg.chandra mohanNoch keine Bewertungen

- Demolishen Work NoteDokument40 SeitenDemolishen Work NoteTeacher IshaNoch keine Bewertungen

- Sample Precast Project SetupDokument9 SeitenSample Precast Project SetupPrateek ModyNoch keine Bewertungen

- Section J: Structural Steel and Metal Works: @hakcipta JKR MalaysiaDokument8 SeitenSection J: Structural Steel and Metal Works: @hakcipta JKR MalaysiaZAHRUDIN ZAHIRUDDIN DAUD MoeNoch keine Bewertungen

- Drainage and Water Management: Concrete PipesDokument60 SeitenDrainage and Water Management: Concrete PipesThierry100% (1)

- Specifications For Erection of Precast Prestressed Concrete GirdersDokument7 SeitenSpecifications For Erection of Precast Prestressed Concrete Girdersmoh4mm4d100% (1)

- Boutique Build Australia: Risk Management PlanDokument3 SeitenBoutique Build Australia: Risk Management PlanSubash UpadhyayNoch keine Bewertungen

- BG Shirke Construction Iit Dharwad InternshipDokument89 SeitenBG Shirke Construction Iit Dharwad InternshipShravan Patil100% (1)

- LGS Erection Methodology by Nabeel AmjadDokument14 SeitenLGS Erection Methodology by Nabeel AmjadNabeel SheikhNoch keine Bewertungen

- Concrete LiningDokument17 SeitenConcrete LiningEtha MargarethaNoch keine Bewertungen

- 2-Design For Action Effects - M & P (2011)Dokument34 Seiten2-Design For Action Effects - M & P (2011)Omar RileyNoch keine Bewertungen

- DemolitionDokument4 SeitenDemolitionLjupka VukicNoch keine Bewertungen

- WORKS METHOD STATEMENT Ceiling WorksDokument3 SeitenWORKS METHOD STATEMENT Ceiling WorksSyafiq ZakiNoch keine Bewertungen

- EC7 Slopes NIGS Seminar 11th Apr 2013 AP FINALDokument33 SeitenEC7 Slopes NIGS Seminar 11th Apr 2013 AP FINALRoshanRSVNoch keine Bewertungen

- Method of Statement - Junction ChamberDokument9 SeitenMethod of Statement - Junction ChamberLaksri JayathilakeNoch keine Bewertungen

- Latest Trends in ConstructionDokument9 SeitenLatest Trends in Constructiondcsekhar100% (1)

- Cross - Section: Section Design For Crack Widths: Default ExampleDokument2 SeitenCross - Section: Section Design For Crack Widths: Default ExampleAbdallahNoch keine Bewertungen

- Seismic Analysis and Structural Design of Multi-Storied RCC Framed Commercial BuildingDokument55 SeitenSeismic Analysis and Structural Design of Multi-Storied RCC Framed Commercial BuildingYugenNoch keine Bewertungen

- Method Statement For Asphalt WorksDokument29 SeitenMethod Statement For Asphalt Workskhalid mohamedNoch keine Bewertungen

- Diaphragm WallDokument8 SeitenDiaphragm Wall08DALVI PRASHANINoch keine Bewertungen

- Concrete StandardsDokument48 SeitenConcrete StandardsDejana AnaNoch keine Bewertungen

- Technical Manual PDFDokument39 SeitenTechnical Manual PDFMatumbi NaitoNoch keine Bewertungen

- Demolition: Medan Ikan Bakar Sabar Awor, Bandar Maharani, Muar, Johor Darul TakzimDokument10 SeitenDemolition: Medan Ikan Bakar Sabar Awor, Bandar Maharani, Muar, Johor Darul TakzimShafiek IsmailNoch keine Bewertungen

- Demolition of StructuresDokument15 SeitenDemolition of Structuresashok sutharNoch keine Bewertungen

- High Rise Building Calculation SheetDokument29 SeitenHigh Rise Building Calculation SheetmannshiNoch keine Bewertungen

- Vario GT 24 Girder Wall Formwork Instructions For Assembly and UseDokument96 SeitenVario GT 24 Girder Wall Formwork Instructions For Assembly and UsePaul LadjarNoch keine Bewertungen

- Appendix D Construction Method StatementDokument43 SeitenAppendix D Construction Method StatementEngr EhsanNoch keine Bewertungen

- Method Statement For Earth WorksDokument3 SeitenMethod Statement For Earth WorksMin Min Soe0% (1)

- Method Statement For Maintenance National RoadDokument11 SeitenMethod Statement For Maintenance National RoadBasem DoniaNoch keine Bewertungen

- Method Statement For DBST Road MaintenanceDokument20 SeitenMethod Statement For DBST Road Maintenanceroldski90% (10)

- Method Statement For Bridge Deck PoursDokument6 SeitenMethod Statement For Bridge Deck Poursabdulrehman73186% (7)

- Method Statement For Production and Laying of Cement Concrete Kerb and Kerb With ChannelDokument5 SeitenMethod Statement For Production and Laying of Cement Concrete Kerb and Kerb With ChannelKeerti Bongu100% (1)

- Welcome: Ahsanullah University of Science & TechnologyDokument69 SeitenWelcome: Ahsanullah University of Science & TechnologyWr ArNoch keine Bewertungen

- 6 July 2015 Sunlove Building ProjectDokument42 Seiten6 July 2015 Sunlove Building ProjectWr ArNoch keine Bewertungen

- DAFLOU BATIS VpCI - 2Dokument6 SeitenDAFLOU BATIS VpCI - 2Wr ArNoch keine Bewertungen

- IR Asphalt PremixDokument2 SeitenIR Asphalt PremixWr ArNoch keine Bewertungen

- @MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneDokument1 Seite@MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneWr ArNoch keine Bewertungen

- BCM Anna University NotesDokument112 SeitenBCM Anna University NotesaruchellamNoch keine Bewertungen

- Rebar Arrangement in SlabDokument12 SeitenRebar Arrangement in Slableovorig100% (2)

- Beam Rebar ArrangementDokument10 SeitenBeam Rebar Arrangementme_decent28457100% (2)

- Calculations of Unit Weight of Rebar PDFDokument1 SeiteCalculations of Unit Weight of Rebar PDFWr ArNoch keine Bewertungen

- GeneralTechnicalInformation RebarSplicingDokument7 SeitenGeneralTechnicalInformation RebarSplicingSarakikenpachiNoch keine Bewertungen

- Cross Section Analysis and Design - Worked ExamplesDokument148 SeitenCross Section Analysis and Design - Worked ExamplesWr ArNoch keine Bewertungen

- Calculations of Unit Weight of Rebar PDFDokument1 SeiteCalculations of Unit Weight of Rebar PDFWr ArNoch keine Bewertungen

- Seismic Rebar DetailingDokument11 SeitenSeismic Rebar DetailingWr ArNoch keine Bewertungen

- Concrete SlabsDokument15 SeitenConcrete SlabsWr ArNoch keine Bewertungen

- Permit To Work On Public StreetsDokument27 SeitenPermit To Work On Public StreetsWr ArNoch keine Bewertungen

- Permit To Work On Public StreetsDokument27 SeitenPermit To Work On Public StreetsWr ArNoch keine Bewertungen

- Cross Section Analysis and DesignDokument158 SeitenCross Section Analysis and DesignWr ArNoch keine Bewertungen

- YAMAHA Blaster (Parts) PDFDokument65 SeitenYAMAHA Blaster (Parts) PDFAlberto VegaNoch keine Bewertungen

- Ibm 3592 Tape Cartridge CatalogueDokument4 SeitenIbm 3592 Tape Cartridge CatalogueamsfibNoch keine Bewertungen

- VEH MB ML320 EAM Extended Activity Module TaskDokument1 SeiteVEH MB ML320 EAM Extended Activity Module Taskd9d100% (1)

- Ds Lm5006 en Co 79839 Float Level SwitchDokument7 SeitenDs Lm5006 en Co 79839 Float Level SwitchRiski AdiNoch keine Bewertungen

- Gautam Buddha University: ID Card Form (Please Fill Up The Form in Block Letters)Dokument1 SeiteGautam Buddha University: ID Card Form (Please Fill Up The Form in Block Letters)ATUL SAXENANoch keine Bewertungen

- Riviera Sponsorship LetterDokument7 SeitenRiviera Sponsorship LetterAnirudh Reddy YalalaNoch keine Bewertungen

- Arc Welding ProcessesDokument153 SeitenArc Welding Processespratap biswasNoch keine Bewertungen

- Karcher Quotation List - 2023Dokument12 SeitenKarcher Quotation List - 2023veereshmyb28Noch keine Bewertungen

- Desktop 10 QA Exam Prep Guide PDFDokument16 SeitenDesktop 10 QA Exam Prep Guide PDFShiva RungtaNoch keine Bewertungen

- JIS B 01801 - 000 - 000 - 1997 - e - pr10 - I4Dokument27 SeitenJIS B 01801 - 000 - 000 - 1997 - e - pr10 - I4Flavio ShiratoNoch keine Bewertungen

- An 4160Dokument8 SeitenAn 4160aurumstar2000Noch keine Bewertungen

- David T History Rev 26032019Dokument18 SeitenDavid T History Rev 26032019David TaleroNoch keine Bewertungen

- Mitac 6120N ManualDokument141 SeitenMitac 6120N ManualLiviu LiviuNoch keine Bewertungen

- The Butt Joint Tool: Product InformationDokument8 SeitenThe Butt Joint Tool: Product InformationElias de Souza RezendeNoch keine Bewertungen

- ACCY225 Tri 1 2017 Tutorial 3 Business Processes-2Dokument3 SeitenACCY225 Tri 1 2017 Tutorial 3 Business Processes-2henryNoch keine Bewertungen

- Application of Pinnipedvibrissae To AeropropulsionDokument31 SeitenApplication of Pinnipedvibrissae To AeropropulsionShahzadNoch keine Bewertungen

- R10 On XPDokument182 SeitenR10 On XPadenihun Adegbite100% (1)

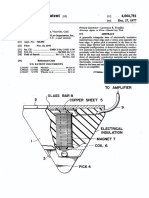

- U.S. Patent 4,064,781, Guitar Pick, Issued 1977.Dokument3 SeitenU.S. Patent 4,064,781, Guitar Pick, Issued 1977.Anonymous a7S1qyXNoch keine Bewertungen

- Item 3 Ips C441u c441r Ieb Main ListDokument488 SeitenItem 3 Ips C441u c441r Ieb Main Listcristian De la OssaNoch keine Bewertungen

- 7GCBC PohDokument75 Seiten7GCBC PohEyal Nevo100% (1)

- Vi35 San GuideDokument43 SeitenVi35 San Guideapi-3824328Noch keine Bewertungen

- BMC ProactiveNetDokument202 SeitenBMC ProactiveNetfranc_estorsNoch keine Bewertungen

- NCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsDokument26 SeitenNCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsAhmed Sherif CupoNoch keine Bewertungen

- CR 55 AaaehqqeDokument7 SeitenCR 55 AaaehqqesigithvacNoch keine Bewertungen

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDokument4 SeitenBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniNoch keine Bewertungen

- Digital Design Course FileDokument191 SeitenDigital Design Course FileCharan NethaNoch keine Bewertungen

- BextexDokument14 SeitenBextexBishawnath RoyNoch keine Bewertungen

- EMT Tooth Saver Data SheetDokument5 SeitenEMT Tooth Saver Data SheetTerry FarmakisNoch keine Bewertungen

- Teaching and Learning With Technology: An IntroductionDokument4 SeitenTeaching and Learning With Technology: An IntroductionAphril Joy LlorenteNoch keine Bewertungen