Beruflich Dokumente

Kultur Dokumente

Helical Gear Teeth PDF

Hochgeladen von

kumaras1Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Helical Gear Teeth PDF

Hochgeladen von

kumaras1Copyright:

Verfügbare Formate

In Figure 5-2 the gear train has a difference of numbers of teeth of only 1; z1 = 30 and z2 = 31.

This results in a reduction ratio of 1/30.

ax

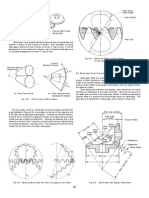

plane is unwrapped, analogous to the unwinding taut string of the spur gear in Figure 2-2. On the plane there is a straight line AB, which when wrapped on the base cylinder has a helical trace AoBo. As the taut plane is unwrapped, any point on the line AB can be visualized as tracing an involute from the base cylinder. Thus, there is an innite series of involutes generated by line AB, all alike, but displaced in phase along a helix on the base cylinder. Again, a concept analogous to the spur gear tooth development is to imagine the taut plane being wound from one base cylinder on to another as the base cylinders rotate in opposite directions. The result is the generation of a pair of conjugate helical involutes. If a reverse direction of rotation is assumed and a second tangent plane is arranged so that it crosses the rst, a complete involute helicoid tooth is formed.

6.2 Fundamentals Of Helical Teeth In the plane of rotation, the helical gear tooth is involute and all of the relationships governing spur gears apply to the helical. However, the axial twist of the teeth introduces a helix angle. Since the helix angle varies from the base of the tooth to the outside radius, the helix angle B is dened as the angle between the tangent to the helicoidal tooth at the intersection of the pitch cylinder and the tooth prole, and an element of the pitch cylinder. See Figure 6-3. The direction of the helical twist is designated as either left or right. The direction is dened by the right-hand rule. For helical gears, there are two related pitches one in the plane of Tangent to Helical Tooth Element of Pitch Cylinder (or gear's axis)

Fig. 5-2

The Meshing of Internal Gear and External Gear in which the Numbers of Teeth Difference is 1 (z2 z1 = 1) HELICAL GEARS

SECTION 6

The helical gear differs from the spur gear in that its teeth are twisted along a helical path in the axial direction. It resembles the spur gear in the plane of rotation, but in the axial direction it is as if there were a series of staggered spur gears. See Figure 6-1. This design brings forth a number of different features relative to the spur gear, two of the most important being as follows:

B Helix Angle

Pitch Cylinder

Fig. 6-1

Helical Gear

1. Tooth strength is improved because of the elongated helical wraparound tooth base support. 2. Contact ratio is increased due to the axial tooth overlap. Helical gears thus tend to have greater load carrying capacity than spur gears of the same size. Spur gears, on the other hand, have a somewhat higher efciency. Helical gears are used in two forms: 1. Parallel shaft applications, which is the largest usage. 2. Crossed-helicals (also called spiral or screw gears) for connecting skew shafts, usually at right angles. 6.1 Generation Of The Helical Tooth The helical tooth form is involute in the plane of rotation and can be developed in a manner similar to that of the spur gear. However, unlike the spur gear which can be viewed essentially as two dimensional, the helical gear must be portrayed in three dimensions to show changing axial features. Referring to Figure 6-2, there is a base cylinder from which a taut Twisted Solid Involute A A0 B0 B

Fig. 6-3

Denition of Helix Angle

rotation and the other in a plane normal to the tooth. In addition, there is an axial pitch. Referring to Figure 6-4, the two circular pitches are dened and related as follows: pn = pt cosB = normal circular pitch (6-1) The normal circular pitch is less than the transverse radial pitch, pt, in the plane of rotation; the ratio between the two being equal to the cosine of the helix angle. Consistent with this, the normal module is less than the transverse (radial) module. The axial pitch of a helical gear, px, is the distance between corresponding points of adjacent teeth measured parallel to the gear's axis see Figure 6-5. Axial pitch is related to pt

pn B

Fig. 6-4

Relationship of Circular Pitches

px Taut Plane Fig. 6-5 Base Cylinder Fig. 6-2 Generation of the Helical Tooth Prole Axial Pitch of a Helical Gear

T25

Das könnte Ihnen auch gefallen

- Gears: Classification, profiles, advantagesDokument18 SeitenGears: Classification, profiles, advantagesSharthak GhoshNoch keine Bewertungen

- Helical GearDokument18 SeitenHelical GearNitin B maskeNoch keine Bewertungen

- 3 TYPES OF GEARS & Gear TrainsDokument17 Seiten3 TYPES OF GEARS & Gear TrainsabinmwangiNoch keine Bewertungen

- Gear Mechanisms IntroductionDokument9 SeitenGear Mechanisms Introductionsteve ogagaNoch keine Bewertungen

- Screw Propellers ExplainedDokument25 SeitenScrew Propellers ExplainedAkashDudi100% (1)

- Bevel Gears GeometryDokument12 SeitenBevel Gears GeometryGabriel IulianNoch keine Bewertungen

- Presentation 1 EvolutesandinvolutesDokument15 SeitenPresentation 1 EvolutesandinvolutesPrajwal P Churi100% (1)

- Algo For Involute Octoidal Bevel Gear GenerationDokument9 SeitenAlgo For Involute Octoidal Bevel Gear GenerationTanmay MathurNoch keine Bewertungen

- DESIGN OF HELICAL & BEVEL GEARSDokument53 SeitenDESIGN OF HELICAL & BEVEL GEARSPRANAY SHRIDHAR100% (1)

- Ch-5 Toothed Gears_1Dokument40 SeitenCh-5 Toothed Gears_1Samar GuptaNoch keine Bewertungen

- GearsDokument43 SeitenGearsshristikushram2003Noch keine Bewertungen

- MdII 1Dokument18 SeitenMdII 1Kamran ShakeelNoch keine Bewertungen

- Chapter 8. Other MechanismsDokument8 SeitenChapter 8. Other MechanismsAshish SinglaNoch keine Bewertungen

- Kom Unit-4Dokument68 SeitenKom Unit-4G GaneshNoch keine Bewertungen

- The Synthesis of Elliptical Gears Generated by Shaper-CuttersDokument9 SeitenThe Synthesis of Elliptical Gears Generated by Shaper-CuttersBen TearleNoch keine Bewertungen

- Find the Right Database ProductDokument11 SeitenFind the Right Database Productmanish_umdNoch keine Bewertungen

- Bevel Gear Transmission AnglesDokument6 SeitenBevel Gear Transmission AnglesNabende UmarNoch keine Bewertungen

- Section 8 Bevel Gearing DesignDokument5 SeitenSection 8 Bevel Gearing DesignLiniel de JesusNoch keine Bewertungen

- 1959 Lawrencea. WeinberDokument12 Seiten1959 Lawrencea. Weinber謎超人Noch keine Bewertungen

- Proyección HexagonalDokument17 SeitenProyección HexagonalHenry Castro ArandaNoch keine Bewertungen

- Internal GearsDokument4 SeitenInternal GearsBranislav DjordjevicNoch keine Bewertungen

- Machinery's - Reference - Series - No - 15 Spur GearingDokument49 SeitenMachinery's - Reference - Series - No - 15 Spur GearingJohnNoch keine Bewertungen

- MIT Manipal Document on Toothed GearingDokument18 SeitenMIT Manipal Document on Toothed GearingAbhishek MishraNoch keine Bewertungen

- Cams Design & Kinematic Analysis: According To The Surface in ContactDokument13 SeitenCams Design & Kinematic Analysis: According To The Surface in ContactFaisal MaqsoodNoch keine Bewertungen

- Tom-Assignment 1Dokument2 SeitenTom-Assignment 1jamunaa83Noch keine Bewertungen

- Introduction To Mechanisms: 7 GearsDokument15 SeitenIntroduction To Mechanisms: 7 GearsgauravthamanNoch keine Bewertungen

- Cam Profile AnalysisDokument4 SeitenCam Profile AnalysisPremjeetSingh100% (1)

- MTM 2Dokument28 SeitenMTM 2RajendrakumarNoch keine Bewertungen

- Bearing Component Motions and Speeds: SS 2006 by Taylor & Francis Group, LLCDokument22 SeitenBearing Component Motions and Speeds: SS 2006 by Taylor & Francis Group, LLCIvelin ValchevNoch keine Bewertungen

- Cameron Browne - Taiji Variations: Yin and Yang in Multiple DimensionsDokument17 SeitenCameron Browne - Taiji Variations: Yin and Yang in Multiple DimensionsGremnDLNoch keine Bewertungen

- Gear Couplings PDFDokument8 SeitenGear Couplings PDFroberto_perraciniNoch keine Bewertungen

- Introduction To Mechanisms: 7 GearsDokument15 SeitenIntroduction To Mechanisms: 7 GearsDezert EagleNoch keine Bewertungen

- Boston Gear Helical GearsDokument14 SeitenBoston Gear Helical GearssandchiNoch keine Bewertungen

- Machine Elements 2 (Introduction)Dokument12 SeitenMachine Elements 2 (Introduction)Melinda100% (2)

- Gear TrainsDokument16 SeitenGear Trainsraju100% (1)

- Gear Types and Uses ExplainedDokument38 SeitenGear Types and Uses ExplainedM HarmanNoch keine Bewertungen

- 7 Gears: 7.1 Gear ClassificationDokument10 Seiten7 Gears: 7.1 Gear ClassificationAshish SinglaNoch keine Bewertungen

- Gear KnowledgeDokument24 SeitenGear KnowledgebabublsNoch keine Bewertungen

- Kom Unit 5 - Question Bank Answers: Skip To ContentDokument24 SeitenKom Unit 5 - Question Bank Answers: Skip To ContentMohammed Al-OdatNoch keine Bewertungen

- Gears: Looking For GATE Preparation Material? Join & Get Here Now!Dokument8 SeitenGears: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNoch keine Bewertungen

- GearsDokument37 SeitenGearsذوالفقار علي حسينNoch keine Bewertungen

- GearsDokument110 SeitenGearsBujjibabu KattaNoch keine Bewertungen

- Other Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Dokument7 SeitenOther Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNoch keine Bewertungen

- 7 Gears: 7.1 Gear ClassificationDokument15 Seiten7 Gears: 7.1 Gear ClassificationSimrit Kaur MakanNoch keine Bewertungen

- Gearabc BDokument40 SeitenGearabc Bvadi100% (1)

- 6 Stereo ProjectionDokument12 Seiten6 Stereo ProjectionGustavo AraújoNoch keine Bewertungen

- Me III II DMM II LnotesDokument33 SeitenMe III II DMM II LnotesChandu MallamNoch keine Bewertungen

- For The Gear-Like Device Used To Drive A Roller Chain, See - This Article Is About Mechanical Gears. For Other Uses, SeeDokument25 SeitenFor The Gear-Like Device Used To Drive A Roller Chain, See - This Article Is About Mechanical Gears. For Other Uses, SeeNasir HadranNoch keine Bewertungen

- Ars and CamsDokument85 SeitenArs and CamsHariharan MNoch keine Bewertungen

- The Basics of Gear TheoryDokument12 SeitenThe Basics of Gear TheoryChandrasekaranNoch keine Bewertungen

- A. Basic Concepts 1.0 Velocities in Gear TrainsDokument76 SeitenA. Basic Concepts 1.0 Velocities in Gear TrainsLuis Balducci80% (5)

- Helical GearsDokument5 SeitenHelical GearsMihir RathodNoch keine Bewertungen

- Kinematic Differential Geometry and Saddle Synthesis of LinkagesVon EverandKinematic Differential Geometry and Saddle Synthesis of LinkagesNoch keine Bewertungen

- 507 Mechanical Movements: Mechanisms and DevicesVon Everand507 Mechanical Movements: Mechanisms and DevicesBewertung: 4 von 5 Sternen4/5 (28)

- The Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesVon EverandThe Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesNoch keine Bewertungen

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsVon EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNoch keine Bewertungen

- Watch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyVon EverandWatch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyNoch keine Bewertungen

- 14 / Gear Materials, Properties, and Manufacture: Casting, Forming, and Forging ProcessesDokument1 Seite14 / Gear Materials, Properties, and Manufacture: Casting, Forming, and Forging Processeskumaras1Noch keine Bewertungen

- M2000 PDFDokument1 SeiteM2000 PDFkumaras1Noch keine Bewertungen

- Chapter 1: Basic Understanding of Gears / 3: Schematic of Gear Backlash. Source: Ref 1Dokument1 SeiteChapter 1: Basic Understanding of Gears / 3: Schematic of Gear Backlash. Source: Ref 1kumaras1Noch keine Bewertungen

- Nylon MTRL PDFDokument1 SeiteNylon MTRL PDFkumaras1Noch keine Bewertungen

- Gear Report PDFDokument1 SeiteGear Report PDFkumaras1Noch keine Bewertungen

- Accuracy GradeDokument1 SeiteAccuracy Gradekumaras1Noch keine Bewertungen

- Steel Rope Technical Information: Pressures Between Ropes and Sheaves or DrumsDokument1 SeiteSteel Rope Technical Information: Pressures Between Ropes and Sheaves or Drumskumaras1Noch keine Bewertungen

- Cooling Curve of Pure Iron Diagram: Figure 4 Shrager, M. 1961Dokument1 SeiteCooling Curve of Pure Iron Diagram: Figure 4 Shrager, M. 1961kumaras1Noch keine Bewertungen

- GM PDFDokument1 SeiteGM PDFkumaras1Noch keine Bewertungen

- d24 PDFDokument1 Seited24 PDFkumaras1Noch keine Bewertungen

- Components of a Typical AircraftDokument1 SeiteComponents of a Typical Aircraftkumaras1Noch keine Bewertungen

- Icd PDFDokument1 SeiteIcd PDFkumaras1Noch keine Bewertungen

- Instability PDFDokument1 SeiteInstability PDFkumaras1Noch keine Bewertungen

- Virtual Product Development: VPD and Simulation SoftwareDokument1 SeiteVirtual Product Development: VPD and Simulation Softwarekumaras1Noch keine Bewertungen

- T& W = Cc - d I dx dx U = Н Cccc = Cc Н Ccccccc d - d L L - d U = W, then &Dokument1 SeiteT& W = Cc - d I dx dx U = Н Cccc = Cc Н Ccccccc d - d L L - d U = W, then &kumaras1Noch keine Bewertungen

- t11 PDFDokument1 Seitet11 PDFkumaras1Noch keine Bewertungen

- Section 1: 2010 MSC - Software CorporationDokument1 SeiteSection 1: 2010 MSC - Software Corporationkumaras1Noch keine Bewertungen

- Engineering Fracture Mechanics Elective CourseDokument1 SeiteEngineering Fracture Mechanics Elective Coursekumaras1Noch keine Bewertungen

- T& W = Cc - d I dx dx U = Н Cccc = Cc Н Ccccccc d - d L L - d U = W, then &Dokument1 SeiteT& W = Cc - d I dx dx U = Н Cccc = Cc Н Ccccccc d - d L L - d U = W, then &kumaras1Noch keine Bewertungen

- t11 PDFDokument1 Seitet11 PDFkumaras1Noch keine Bewertungen

- Shaft Twist PDFDokument1 SeiteShaft Twist PDFkumaras1Noch keine Bewertungen

- STEEL Strength PDFDokument1 SeiteSTEEL Strength PDFkumaras1Noch keine Bewertungen

- Gear View PDFDokument1 SeiteGear View PDFkumaras1Noch keine Bewertungen

- Dmap Parameters PDFDokument1 SeiteDmap Parameters PDFkumaras1Noch keine Bewertungen

- Backlash Theory PDFDokument1 SeiteBacklash Theory PDFkumaras1Noch keine Bewertungen

- Rack Teeth PDFDokument1 SeiteRack Teeth PDFkumaras1Noch keine Bewertungen

- Wing Box Design PDFDokument1 SeiteWing Box Design PDFkumaras1Noch keine Bewertungen

- Metric Gear Equivalent PDFDokument1 SeiteMetric Gear Equivalent PDFkumaras1Noch keine Bewertungen

- Strain Theory PDFDokument1 SeiteStrain Theory PDFkumaras1Noch keine Bewertungen

- Review Pp. 232-233 PDFDokument4 SeitenReview Pp. 232-233 PDFStella SmithNoch keine Bewertungen

- Mensuration 1st ChapterDokument23 SeitenMensuration 1st ChaptersanthoshNoch keine Bewertungen

- Set A: Model Question - 2079 Sifal Secondary School Subject: Mathematics Full Marks: 75 Time: 3 HrsDokument23 SeitenSet A: Model Question - 2079 Sifal Secondary School Subject: Mathematics Full Marks: 75 Time: 3 HrsShreejesh Raj JoshiNoch keine Bewertungen

- Electric Fux WorksheetDokument1 SeiteElectric Fux Worksheetjovsky015Noch keine Bewertungen

- UTA015: Learn Engineering DrawingDokument2 SeitenUTA015: Learn Engineering DrawingSHIVA THAVANINoch keine Bewertungen

- ME 2131 Module PDFDokument64 SeitenME 2131 Module PDFGreen Brain0% (1)

- Magnus, W. - Oberhettinger, F. - Formulas & Theorems For The Functions of Mathematical Physics. CheDokument178 SeitenMagnus, W. - Oberhettinger, F. - Formulas & Theorems For The Functions of Mathematical Physics. CheMiku Fourier AlvaradoNoch keine Bewertungen

- Mixed CV Motion and UA Motion Review-1Dokument4 SeitenMixed CV Motion and UA Motion Review-1juliannlevine445Noch keine Bewertungen

- Lecture Notes 6: The Method of ImagesDokument20 SeitenLecture Notes 6: The Method of ImagesZoricaNoch keine Bewertungen

- CV - Pramod Kumar Das - April - 2019 PDFDokument4 SeitenCV - Pramod Kumar Das - April - 2019 PDFPramodNoch keine Bewertungen

- Introduction To Super String Theory by PeskinDokument132 SeitenIntroduction To Super String Theory by PeskinAvinanda ChaudhuriNoch keine Bewertungen

- GD&T Reference ChartDokument1 SeiteGD&T Reference ChartWang MbaoNoch keine Bewertungen

- SMT1108 Engineering Mathematics I exam questionsDokument3 SeitenSMT1108 Engineering Mathematics I exam questionsThiyaga RajanNoch keine Bewertungen

- Polygons WorksheetDokument3 SeitenPolygons WorksheetMen Keo RathaNoch keine Bewertungen

- Curriculum MNG 09 Mining1Dokument201 SeitenCurriculum MNG 09 Mining1Papadasu Srinivasa Reddy100% (2)

- Addition and Multiplication of Vectors (PS - 2) - BDokument11 SeitenAddition and Multiplication of Vectors (PS - 2) - BAnurag KasaudhanNoch keine Bewertungen

- CSEC Mathematics June 2017 Paper 1 Solution 2017Dokument9 SeitenCSEC Mathematics June 2017 Paper 1 Solution 2017steve hope75% (8)

- Mathematics 10-A4Dokument5 SeitenMathematics 10-A4Ronalyn LimNoch keine Bewertungen

- Structural Parameters of Trabecular Bone Measured by Skyscan Micro-CT - SkyscanDokument9 SeitenStructural Parameters of Trabecular Bone Measured by Skyscan Micro-CT - SkyscanrhinemineNoch keine Bewertungen

- Math IB Revision Vectors SLDokument14 SeitenMath IB Revision Vectors SLmykiri79100% (1)

- Quantitative Ability 1Dokument23 SeitenQuantitative Ability 1Akhil SinglaNoch keine Bewertungen

- Iit Jee StudyDokument955 SeitenIit Jee StudyGarlapati Srinivasa Rao88% (16)

- CNC AlphabetDokument23 SeitenCNC AlphabetБоривоје Спасојевић50% (2)

- The Sparkcharts Algebra IDokument4 SeitenThe Sparkcharts Algebra IMuhammad Fariz Mohamed Zain88% (8)

- Speed-II Question Bank for IITJEE Mathematics from JEEMAIN.GURUDokument18 SeitenSpeed-II Question Bank for IITJEE Mathematics from JEEMAIN.GURUAmruta PoojaryNoch keine Bewertungen

- MA1521 Solution3Dokument5 SeitenMA1521 Solution3Ray TanNoch keine Bewertungen

- Quantum Mechanics As A Classical TheoryDokument8 SeitenQuantum Mechanics As A Classical TheoryNeha ZaidiNoch keine Bewertungen

- G. E. Society'S H. P. T. Arts and R. Y. K. Science College, Nasik. T.Y.B.Sc. (Mathematics) Semester Iv MT 341: Complex Analysis Question Bank Multiple Choice QuestionsDokument6 SeitenG. E. Society'S H. P. T. Arts and R. Y. K. Science College, Nasik. T.Y.B.Sc. (Mathematics) Semester Iv MT 341: Complex Analysis Question Bank Multiple Choice QuestionsKadam KartikeshNoch keine Bewertungen

- JIMS TemplateDokument2 SeitenJIMS TemplateKresnha PangadiNoch keine Bewertungen

- EMDokument227 SeitenEMfaizu_ibmNoch keine Bewertungen