Beruflich Dokumente

Kultur Dokumente

L12 - Kill Sheets (Compatibility Mode)

Hochgeladen von

Laxmi Kant PrasadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

L12 - Kill Sheets (Compatibility Mode)

Hochgeladen von

Laxmi Kant PrasadCopyright:

Verfügbare Formate

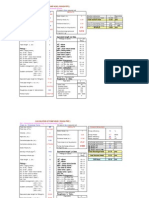

Lecture 12: Well Control Kill Sheet Calculations for Well Control

Arun S Chandel

Assistant Professor aschandel@ddn upes ac in aschandel@ddn.upes.ac.in 09997200339

Data required for Kill Procedures

All kill procedures require data concerning drillstring geometry, hole geometry, mud density, pump rates, pressure losses, and fracture pressure.

Important data that is required prior to initiating kill procedures include:

1) Circulating pressure at kill rate 2) Surface to bit time at kill rate (in strokes and minutes) 3) Bit to surface time at kill rate (in strokes and minutes) 4) Maximum Ma im m allowable allo able annular ann la pressure p ess e 5) Formula for calculating the kill mud density 6) Formula for calculating the change in circulating pressure due d t the to th effect ff t of f the th heavier h i mud d 7) The clients policies on safety factors and trip margins

2

Formulas Used in Kick and Kill Procedures

1) Hydrostatic Pressure (psi)= MW x TVD x 0.052 where: MW = Mud Density (lb/gal) TVD = True Vertical Depth (ft) 2) Circulating Pressure (psi)= (MW x TVD x 0.052) + Pla where: Pla = Annular Pressure Loss (psi) 3) ) Initial Circulating g Pressure (p (psi)= ) SPR + SIDP where: SPR = System pressure loss at kill rate (psi) SIDP= Shut-in Drillpipe Pressure (psi) 4) Final Circulating Pressure (psi)= (KMW / MW) x SPR where: KMW = Kill Mud Density (lb/gal) 5) Kill Mud Weight (lb/gal)= MW + (SIDP / (TVD x 0.052))

6) Formation Pressure (psi)= SIDP + (MW x TVD x 0.052) 7) Density of influx (ppg)= MW - [(SICP - SIDP)/(L x 0.052)] where: SICP= Shut in casing gp pressure (p (psi) ) L = Length of influx (ft) 8) Length of kick around drill collars (ft)= Pit Gain (bbls)/ Annular Volume around collars (bbls/ft) 9) ) Length g of kick, drill collars and drill p pipe p ( (ft)= ) Collar Length + [(Pit Gain - Collar Annular Volume) / (D12 - D22 x 0.000971)] where: D1 = hole diameter (inches) D2 = drillpipe diameter (inches) 10) Gas bubble migration rate (psi/hr)= Pa / (0.052 x MW) where:Pa = pressure change over time interval / time interval (hr)

11) Volume increase caused by weighting up = 100 x (KMW - MW) / (35.8 (35 8 - KMW) The drill pipe pressure can be used as a downhole pressure gauge, while the casing pressure is affected by the type and amount of fluid influx. When the density of the kick fluid is known, the composition may be estimated; Influx Density (psi/ft) 0.05 - 0.2 0.2 - 0.4 0 4 - 0.5 0.4 05 Influx Type gas combination of gas/oil and or seawater oil il or seawater t

Das könnte Ihnen auch gefallen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- QA-RD7AE-V8 English API Formula SheetDokument4 SeitenQA-RD7AE-V8 English API Formula SheetYogesh GavaliNoch keine Bewertungen

- Security Hydraulics ConversionsDokument2 SeitenSecurity Hydraulics ConversionsayushiNoch keine Bewertungen

- I WCF Formula SheetDokument4 SeitenI WCF Formula Sheethamdi1000Noch keine Bewertungen

- Mud HydraulicsDokument5 SeitenMud HydraulicsFares NaceredineNoch keine Bewertungen

- 1.QA-RD7A - IWCF Formula Sheet - API Field UnitsDokument4 Seiten1.QA-RD7A - IWCF Formula Sheet - API Field UnitsExequiel Plaza100% (3)

- 671 - BP Well Control Tool Kit 2002Dokument20 Seiten671 - BP Well Control Tool Kit 2002gplese0Noch keine Bewertungen

- Calculation For Pressure DropDokument2 SeitenCalculation For Pressure DropNakul AhirraoNoch keine Bewertungen

- قوانين الحفرDokument4 Seitenقوانين الحفرibrahim familyNoch keine Bewertungen

- Wave Equation ApplicationsDokument26 SeitenWave Equation ApplicationsUmdpmg Ursa100% (1)

- MJAE Volume 37 Issue 2 Pages 185-212Dokument28 SeitenMJAE Volume 37 Issue 2 Pages 185-212Bop AlberthaNoch keine Bewertungen

- Calculation Validation ReportDokument18 SeitenCalculation Validation Reportvijay10484Noch keine Bewertungen

- PV 1390 Cal R1Dokument44 SeitenPV 1390 Cal R1namasralNoch keine Bewertungen

- Calculation Manufacturing ProcessDokument18 SeitenCalculation Manufacturing ProcessEncik MaaNoch keine Bewertungen

- QA-RD7A Formula Sheet Rev 3 - 2006Dokument4 SeitenQA-RD7A Formula Sheet Rev 3 - 2006wandersaquaNoch keine Bewertungen

- Total Middle East New Bitumen Terminal in TlbuDokument25 SeitenTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Hydraulic Fracturing DesignDokument49 SeitenHydraulic Fracturing Designcrown21260% (5)

- PETE 411: Well DrillingDokument41 SeitenPETE 411: Well Drillingshanecarl100% (1)

- Useful Formulas in Drilling Well EngineeringDokument5 SeitenUseful Formulas in Drilling Well EngineeringDuu haaNoch keine Bewertungen

- Tappi 0502-17 Papermaker FormulaDokument19 SeitenTappi 0502-17 Papermaker FormulaMulyadi Moel85% (20)

- Hydraulics CalculationDokument1 SeiteHydraulics CalculationSudish BhatNoch keine Bewertungen

- Formula Sheet - MetricDokument4 SeitenFormula Sheet - MetricAlexander KlmNoch keine Bewertungen

- Design center crank shaft dimensionsDokument8 SeitenDesign center crank shaft dimensionsSagarias AlbusNoch keine Bewertungen

- 671 - BP Well Control Tool Kit 2002Dokument20 Seiten671 - BP Well Control Tool Kit 2002Uok Ritchie100% (1)

- Die Casting CalculationDokument4 SeitenDie Casting CalculationBožidar GaćinovićNoch keine Bewertungen

- Kill Sheet Formula GuideDokument4 SeitenKill Sheet Formula GuideAwani Kester100% (1)

- Seminar On Split Cavity MouldDokument43 SeitenSeminar On Split Cavity MouldasgrutuNoch keine Bewertungen

- Common Rig MathDokument17 SeitenCommon Rig MathSanjay Mishra86% (7)

- PRO2000Dokument72 SeitenPRO2000scrbdgharaviNoch keine Bewertungen

- LPG STORAGE TANK DESIGN CALCULATIONSDokument2 SeitenLPG STORAGE TANK DESIGN CALCULATIONSRamesh GanapathyNoch keine Bewertungen

- M45 Design 1000Dokument7 SeitenM45 Design 1000Landon MitchellNoch keine Bewertungen

- Typ-Base PlateDokument11 SeitenTyp-Base PlateManoj Jaiswal100% (2)

- Formation strength data and surface BOP kill sheetDokument0 SeitenFormation strength data and surface BOP kill sheetjosesito_amoroso2005Noch keine Bewertungen

- Bit Hydraulics With Rig Pumping TestDokument2 SeitenBit Hydraulics With Rig Pumping Testvazzoleralex6884Noch keine Bewertungen

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDokument4 Seiten1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- Discharge PR Drop Pipe SizeDokument5 SeitenDischarge PR Drop Pipe SizemohdnazirNoch keine Bewertungen

- Well Control CalculationsDokument2 SeitenWell Control CalculationsDian SikumbangNoch keine Bewertungen

- IWCF Kick SheetDokument3 SeitenIWCF Kick SheetKathryn SmithNoch keine Bewertungen

- CALCULATION OF PUMP HEAD AND POWER REQUIREDDokument2 SeitenCALCULATION OF PUMP HEAD AND POWER REQUIREDlutfi awn100% (1)

- Typ Base PlateDokument19 SeitenTyp Base PlateumeshNoch keine Bewertungen

- Continue: Textile Spinning Calculation PDFDokument2 SeitenContinue: Textile Spinning Calculation PDFAkhtar AbassiNoch keine Bewertungen

- HYD01Dokument6 SeitenHYD01scrbdgharaviNoch keine Bewertungen

- 3 - Penilaian Formasi (Mud Logging)Dokument33 Seiten3 - Penilaian Formasi (Mud Logging)Andi SusetioNoch keine Bewertungen

- Diesel Tank TaluksangayDokument70 SeitenDiesel Tank TaluksangayBert EngNoch keine Bewertungen

- Process Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENDokument42 SeitenProcess Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENSwarnim RajNoch keine Bewertungen

- RISER SPAN ANALYSIS CALCULATIONSDokument9 SeitenRISER SPAN ANALYSIS CALCULATIONSfirmansyahperdanaNoch keine Bewertungen

- Geotechnical Engineering: Testing ManualsVon EverandGeotechnical Engineering: Testing ManualsBewertung: 5 von 5 Sternen5/5 (1)

- Pressuremeter Testing: Methods and InterpretationVon EverandPressuremeter Testing: Methods and InterpretationBewertung: 5 von 5 Sternen5/5 (2)

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsVon EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNoch keine Bewertungen

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportVon EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNoch keine Bewertungen

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesVon EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNoch keine Bewertungen

- SonicDokument26 SeitenSonicSutanu SarkarNoch keine Bewertungen

- L2-Floating Platforms (Compatibility Mode)Dokument22 SeitenL2-Floating Platforms (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- ch10 7Dokument5 Seitench10 7Laxmi Kant PrasadNoch keine Bewertungen

- Micro-Spherically Focused Log (MSFL™) and Microlog (ML) : Wireline and Perforating ServicesDokument2 SeitenMicro-Spherically Focused Log (MSFL™) and Microlog (ML) : Wireline and Perforating ServicesLaxmi Kant PrasadNoch keine Bewertungen

- Well Control Causes of Kicks Detection Techniques EquipmentsDokument49 SeitenWell Control Causes of Kicks Detection Techniques EquipmentsLaxmi Kant PrasadNoch keine Bewertungen

- L17-Wave Loading On Risers (Compatibility Mode)Dokument19 SeitenL17-Wave Loading On Risers (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- L13-Intro To Subsea (Compatibility Mode)Dokument26 SeitenL13-Intro To Subsea (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- L16-Wind Loading On Offshore Structures (Compatibility Mode)Dokument12 SeitenL16-Wind Loading On Offshore Structures (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- DIRECTIONAL DRILLING LECTURE: JETTING & DOWNHOLE MOTORSDokument32 SeitenDIRECTIONAL DRILLING LECTURE: JETTING & DOWNHOLE MOTORSLaxmi Kant Prasad100% (1)

- L13-Intro To Subsea (Compatibility Mode)Dokument26 SeitenL13-Intro To Subsea (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- Well Control Causes of Kicks Detection Techniques EquipmentsDokument49 SeitenWell Control Causes of Kicks Detection Techniques EquipmentsLaxmi Kant PrasadNoch keine Bewertungen

- L8-Drill String Design in Directional WellsDokument25 SeitenL8-Drill String Design in Directional WellsLaxmi Kant PrasadNoch keine Bewertungen

- Well Control Leak-Off Test & Kick Circulation MethodsDokument45 SeitenWell Control Leak-Off Test & Kick Circulation MethodsLaxmi Kant PrasadNoch keine Bewertungen

- L14-Multiphase Pumping & Subsea Processing (Compatibility Mode)Dokument26 SeitenL14-Multiphase Pumping & Subsea Processing (Compatibility Mode)Laxmi Kant Prasad100% (1)

- L9 - Oilfield Pressures & D-Exponent (Compatibility Mode)Dokument42 SeitenL9 - Oilfield Pressures & D-Exponent (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- L6-DD Fundamentals and Directional Well PlanningDokument31 SeitenL6-DD Fundamentals and Directional Well PlanningLaxmi Kant Prasad100% (1)

- Chenab JhelumDokument12 SeitenChenab JhelumLaxmi Kant PrasadNoch keine Bewertungen

- L8-Drill String Design in Directional WellsDokument25 SeitenL8-Drill String Design in Directional WellsLaxmi Kant PrasadNoch keine Bewertungen

- L4-Platform Installation (Compatibility Mode)Dokument37 SeitenL4-Platform Installation (Compatibility Mode)Laxmi Kant PrasadNoch keine Bewertungen

- Palaeoenvironmental Interpretation of The EarlyDokument1 SeitePalaeoenvironmental Interpretation of The EarlyLaxmi Kant PrasadNoch keine Bewertungen

- Drilling - FormulasDokument1 SeiteDrilling - FormulasLaxmi Kant PrasadNoch keine Bewertungen

- Drill Collars Size - Weight PDFDokument1 SeiteDrill Collars Size - Weight PDFLaxmi Kant PrasadNoch keine Bewertungen

- Calibrating Hart ProtokolDokument11 SeitenCalibrating Hart ProtokolKenon FlemingsNoch keine Bewertungen

- IndexDokument9 SeitenIndexLaxmi Kant PrasadNoch keine Bewertungen

- Geotechnical Design Manual M 46-03 Soil and Rock Classification and Logging September 2005 Chapter 4-1Dokument22 SeitenGeotechnical Design Manual M 46-03 Soil and Rock Classification and Logging September 2005 Chapter 4-1Ruby Dela CruzNoch keine Bewertungen

- EarthworksDokument24 SeitenEarthworksLaxmi Kant PrasadNoch keine Bewertungen

- Coal IndiaDokument24 SeitenCoal IndiaReshmi ShenoyNoch keine Bewertungen

- Geology Dept JournalDokument16 SeitenGeology Dept JournalLaxmi Kant PrasadNoch keine Bewertungen

- CS 122subtestdescriptionDokument12 SeitenCS 122subtestdescriptionLaxmi Kant PrasadNoch keine Bewertungen

- Fight The LightDokument11 SeitenFight The LightBryan Núñez LugoNoch keine Bewertungen

- Climate Adaptations in Tropical RainforestsDokument9 SeitenClimate Adaptations in Tropical Rainforestshweta173Noch keine Bewertungen

- Made in China Farming Tigers To ExtinctionDokument25 SeitenMade in China Farming Tigers To ExtinctionInternational Fund for Animal WelfareNoch keine Bewertungen

- Assessment I (Soal Dan Jawab)Dokument6 SeitenAssessment I (Soal Dan Jawab)AlyNoch keine Bewertungen

- Chapter Four: Analysis and Interpretation: Number Percentage Sample Size 50 100 % Response Rate 50 100%Dokument9 SeitenChapter Four: Analysis and Interpretation: Number Percentage Sample Size 50 100 % Response Rate 50 100%Mukhtaar CaseNoch keine Bewertungen

- The Evaluation of The Design Flood Hydrographs Determined With The Hydroproject Method in The Gauged CatchmentsDokument12 SeitenThe Evaluation of The Design Flood Hydrographs Determined With The Hydroproject Method in The Gauged CatchmentsArkadiusz ŚrodulaNoch keine Bewertungen

- Marketing Practices of Falcata Growers in Tagbina, Surigao Del Sur, PhilippinesDokument8 SeitenMarketing Practices of Falcata Growers in Tagbina, Surigao Del Sur, PhilippinesWyzty DelleNoch keine Bewertungen

- IELTS Listening Test0012Dokument8 SeitenIELTS Listening Test0012catalin_albu_4Noch keine Bewertungen

- Weathering and Erosion Web-QuestDokument3 SeitenWeathering and Erosion Web-Questapi-268569185Noch keine Bewertungen

- Badac Action Plan: Barangay San Isidro Atimonan, QuezonDokument26 SeitenBadac Action Plan: Barangay San Isidro Atimonan, QuezonEyaNoch keine Bewertungen

- Design and Construction of An Automatic Sand Separation System - Final Year Project Report by Job Lazarus OkelloDokument77 SeitenDesign and Construction of An Automatic Sand Separation System - Final Year Project Report by Job Lazarus OkelloOKELLO JOB LAZARUS83% (12)

- The Amazon Rainforest Internet Assignment: - SurinameDokument4 SeitenThe Amazon Rainforest Internet Assignment: - Surinameapi-278203839Noch keine Bewertungen

- Real Estate in Dubai - PresentationDokument75 SeitenReal Estate in Dubai - PresentationPiotr BartenbachNoch keine Bewertungen

- Final Programme of The XXXVIII IAH CongressDokument60 SeitenFinal Programme of The XXXVIII IAH Congress4outdoor.plNoch keine Bewertungen

- SCRA Usurpation LGU PD705 PDFDokument29 SeitenSCRA Usurpation LGU PD705 PDFAlin ZivuanuNoch keine Bewertungen

- Integrated Coastal Zone Management A Case Study From Goa PDFDokument70 SeitenIntegrated Coastal Zone Management A Case Study From Goa PDFosei yorke100% (1)

- Orchard DesignDokument28 SeitenOrchard DesignMarilou TagarinoNoch keine Bewertungen

- Design of WeederDokument26 SeitenDesign of Weederarsojol100% (2)

- Fitoremediasi KelDokument8 SeitenFitoremediasi KelYahya AdjaNoch keine Bewertungen

- Rain Bird Catalogo 2017Dokument112 SeitenRain Bird Catalogo 2017cajosopaNoch keine Bewertungen

- Can An Island Economy Be More Sustainable - A Comparative Study of Indonesia, Malaysia, and The PhilippinesDokument9 SeitenCan An Island Economy Be More Sustainable - A Comparative Study of Indonesia, Malaysia, and The PhilippinesFaiza LatifNoch keine Bewertungen

- On Killing A TreeDokument12 SeitenOn Killing A TreearavNoch keine Bewertungen

- Results and DiscussionDokument6 SeitenResults and DiscussionCharlie65129Noch keine Bewertungen

- Natural Science Word SearchDokument2 SeitenNatural Science Word Searchpepac414Noch keine Bewertungen

- 88 Civil Code Book IV Title I, Obligations, Chapter 2.nature and EffectsDokument159 Seiten88 Civil Code Book IV Title I, Obligations, Chapter 2.nature and EffectsAron MenguitoNoch keine Bewertungen

- Viewpoint Calculating Depletion Units of Production Method Oil Gas June 2016Dokument7 SeitenViewpoint Calculating Depletion Units of Production Method Oil Gas June 2016KCNoch keine Bewertungen

- Is Human Progress or Progress of Society Possible Without Abusing The Environment?Dokument2 SeitenIs Human Progress or Progress of Society Possible Without Abusing The Environment?Gwenny PieNoch keine Bewertungen

- The Rivers: The 2010 Umpqua Edition Features Stories About The North, South and Main UmpquaDokument24 SeitenThe Rivers: The 2010 Umpqua Edition Features Stories About The North, South and Main UmpquaNews-Review of Roseburg OregonNoch keine Bewertungen

- 19 Stone ColumnsDokument12 Seiten19 Stone Columnsalexjos1Noch keine Bewertungen

- Artificial Reefs Indian Experience Coastrack - July - Dec - 2010Dokument24 SeitenArtificial Reefs Indian Experience Coastrack - July - Dec - 2010pjgomezdNoch keine Bewertungen