Beruflich Dokumente

Kultur Dokumente

HYD01

Hochgeladen von

scrbdgharaviOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HYD01

Hochgeladen von

scrbdgharaviCopyright:

Verfügbare Formate

Opt. Hyd.

HYDRAULICS

OPTIMUM HYDRAULICS: The proper balance of hydraulic elements that will clean the hole below the bit, clean the bit and clean the bore hole above the bit with minimum horsepower. The balance of the hydraulic elements is influenced by: 1) lost circulation(ECD effect); 2) hole stability (turbulent erosion); 3) bit cleaning (cross flow); 4) cleaning hole below bit ( jet velocity) and cleaning the bore hole above the bit (annular velocity - flowrate - yield value and flow profile).

RULE: Balance flowrate between 25gpm and 50 gpm per inch of bit diameter. Jet velocity is influenced by formation drillability and mud overbalance chip hold down. The greater the overbalance the higher the jet velocity has to be to help free up the chip that is being differentially held below the bit. The jet velocity range is usually between 250 and 450 ft./sec.

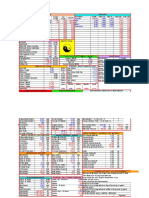

COMPUTER CALC.

inputs Bit dia. ROP 8.75 inches 60 ft per hr outputs G/B G Gmin Jv 40 gpm/in. 350 gpm 308 gpm 462 ft/sec

HAND CALC.

4 x Bit dia. =______ + 5 = _______ G/B Bit dia. x Bit dia x 4 = ____ + 5 x Bit dia = ____ G Bit dia ^ 1.47 = _____ x 12.72 =______ Gmin G/B = (4B)+5 G = ((4(B^2)+(5B)) Gmin = 12.72(B^1.47) Jv = ROP/(.01+.02)ROP WHERE: G/B = GPM/inch bit dia. G = GPM (flowrate, gpm) Gmin = For flowrate sensitive bits (PDC, etc) B = Bit diameter, inches Jv = Jet velocity, ft./sec. ROP = Penetration rate

ROP / (.01 + .02) x ROP = _______ Jv

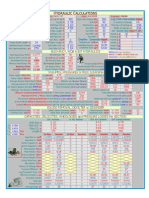

HYDRAULIC GUIDELINES Hydraulics can be optimized by concentrating on four main guidelines:1)Flowrate; 2)Jet horsepower; 3)Percent horsepower at the bit; 4)Jet velocity. The rules listed below are based on running optimum bit weight. RULE #1 Maintain flowrate 30 - 50 gpm/in. of bit diameter. The following ROP ranges are general guidelines for flowrates required. Range 1 - over 50 ft/hr 50 gpm/in Range 2 - 25 - 50 ft/hr 40 to 50 gpm/in Range 3 - 15 - 25 ft/hr 38 to 45 gpm/in Range 4 - 10 - 15 ft/hr 35 to 40 gpm/in Range 5 - 5 - 10 ft/hr 30 to 39 gpm/in RULE #2 Maintain jet horse power 2 1/2 to 5 HHP/in^2 (hydraulic horsepower per sq. in. of bit dia.).The rule is based on on the square root of the rate of penetration. In big hole (12 1/4 and greater size the HHP/in^2 could be allowed to go slightly above 5 (up to 6.5) if the drillability is good ( above 25 ft/hr).

RULE #3 Design hydraulics so that 50 to 65% of available pump pressure is across the bit jet nozzles. If optimized at midrange (55 to 60) the driller has more flexibility with the flowrate as influenced by formation drillability, ECD, and drilling operational factors. RULE #4 Maintain jet velocity between 350 and 450 ft/sec. Do not drop below 250 ft/sec. ROP and chip hold down influence optimum jet velocity as discussed in Optimum hydraulics above.

Page 1

Hyd. Calc.

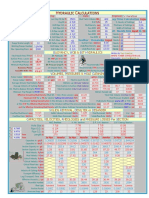

WELL NAME COTROPIA GAS UNIT # 1 COUNTY RO BIT# 5 Annular Velocity Dp (V) Annular Velocity Dc (V) Surface Pressure Loss Inside Pressure Loss (Dp) Inside Pressure Loss (Dc) Annular Pressure Loss (Dp) Annular Pressure Loss (Dc) Mud Motor Differential PSI TOTAL SYSTEM LOSSES Motor speed 218 369 7.3 1632.3 474.0 251.3 134.5 300.0 2799.5 94.5 ft/min ftmin psi psi psi psi psi psi

Circulation Rate (Q) 225 gpm. Diameter of Hole (Dh) 6.125 in. Outside Diameter of Pipe O.D.(Dp) 3.5 in. Inside Diameter of Pipe I.D.(Dp) 2.5 in. Length of pipe (Ldp) 8974 ft. Outside Diameter of Collars O.D.(Dc) 4 3/4 in. Inside Diameter of Collars I.D.(Dc) 2 in. Length of Collars (Ldc) 881 ft. Mud Weight (p) 10.8 ppg. Mud Motor Differential PSI 300 psi Motor Rpm per Gallon 0.42 rpm Surface Equip. Friction Factor(C) 0.15 TYPE 1(C)=1.00, TYPE 2(C)=.36, TYPE 3(C)=.22, TYPE 4(C)=.15 NOZZLE SELECTION Jet Nozzle #1 (32nds) Jet Nozzle #2 (32nds) Jet Nozzle #3 (32nds) Jet Nozzle #4 (32nds) Jet Nozzle #5 (32nds) Jet Nozzle #6 (32nds) (32nds) Decimal Equiv. 14 0.1503 14 0.1503 14 0.1503 0.0000 0.0000 0.0000

rpm

Jet Nozzle Pressure Loss Nozzle Velocity Estimated Stand Pipe Pressure Jet Impact Force Hydraulic Horse Power Hydraulic Horsepower per in^2 Calculated Standpipe Pressure

248 160.1 3047 200.7 32 1.1 3047

psi ft/sec psi lbf hp hsi psi

Surface Equip. Friction Factor (C) 1 1.00 2 0.36 3 0.22 4 0.15 This computer program is based on the Security Hydraulic Manual.

Page 2

Hyd. Worksheet

BIT HYDRAULIC ANALYSIS HAND CALCULATION WORKSHEET

Pb = GPM X^2 x MW x

156.5 / ( J1 X^2 + J2 X^2 + J3 X^2 ) X^2 =

HHPb = Pb

GPM

1714 =

HHPb/in^2 = HHPb

1.27 / BIT SIZE

X^2

Vn = GPM

417.2 /

J1 X^2

+ J2 X^2 + J3 X^2 =

I.F. = Vn

GPM

MW

1932

I.F/IN^2 =

I.F

1.27

/ BIT SIZE

X^2

%PSI b =

Pb

SURF. PSI

SYSTEM HHP =

SURF. PSI

x GPM /

1714

Page 3

Ann. Flow

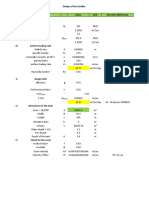

Hole Diameter Drill pipe O.D. Drill Pipe Length Flowrate Mud Wt. Plastic Viscosity Yeild Point. Cutting Diameter

8 1/4 4 1/2 6138 302 8.8 4 4 0.5

ANNULAR FLOW DYNAMICS in. 600 Vicomter reading in. 300 viscometer reading ft gpm N lb/gal K P.V. Annular Velocity "A.V." Y.P. SEC^-1 in "U" Lam "U" Turb. Use Larger "U" FRICTION LOSS "^P" REYNOLDS NO. "Rn" CRITICAL VEL. "Cv" CRITICAL VEL. "Cv" Cuttings Slip Velocity Cutting Rising Velocity Interval Transport Time ANN. TRANSPORT TIME

12 cps 8 cps 0.58 106.7 154.8 99.0 15.8 39.3 39.3 7.6 4995.1 2.35 141.0 66.2 88.5 39.7 flow index consistency index ft/min rate of shear apparent viscosity apparent viscosity psi/1000 ft ft/sec ft/min ft/min ft/min mins

43.2 mins 12 cps 8 cps 0.58 106.7 255.1 306.2 9.9 34.5 34.5 38.8 7019.1 2.47 148.5 69.2 186.0 3.5 flow index consistency index ft/min rate of shear apparent viscosity apparent viscosity psi/1000 ft ft/sec ft/min ft/min ft/min ft/min

Hole Diameter Drill Collar O.D. Drill Collar Length Flowrate Mud Wt. Plastic Viscosity Yeild Point. Cutting Diameter

8 1/4 6 1/4 655 302 8.8 4 4 0.5

in. in. ft gpm lb/gal P.V. Y.P. in

600 Vicomter reading 300 viscometer reading N K Annular Velocity "A.V." SEC^-1 "U" Lam "U" Turb. Use Larger "U" FRICTION LOSS "^P" REYNOLDS NO. "Rn" CRITICAL VEL. "Cv" CRITICAL VEL. "Cv" Cuttings Slip Velocity Cutting Rising Velocity Interval Transport Time

Note: Calculations based on Magobar's Annular Flow Dynamics and Bariod's Beingham Plastics Critical Velocity

Page 4

Cost per Ft.

BIT COST PER FOOT Rig Cost Additional Cost Bit Cost Rotating Time Connection Time Trip Time Footage Drilled $ 400.00 $ $ 5,000.00 31 0.1 6 538 per hour per hour hours hours hours feet Total cost $ 400.00 per hour Total Time 37.1 hours Bit Cost $ 36.88 per foot

Page 5

Sheet5

TUBING bha annulus

0.00579 0.0022 0.0143

9526 474 10000

55.2 1.0 56.2 143.0 199.2

Page 6

Das könnte Ihnen auch gefallen

- Horizontal Turn: 161277483.xls - Ms - Office Mitchell Engineering ProgramsDokument1 SeiteHorizontal Turn: 161277483.xls - Ms - Office Mitchell Engineering ProgramsscrbdgharaviNoch keine Bewertungen

- Drilling CalculationsDokument7 SeitenDrilling CalculationsBrahim LetaiefNoch keine Bewertungen

- Submersible Pump Cal. SheetDokument5 SeitenSubmersible Pump Cal. SheetIrfan Ahmed100% (1)

- Gas Line Sizing - Api 14E Input Description Unit: General DataDokument13 SeitenGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- Compressor Settle Out PressureDokument1 SeiteCompressor Settle Out PressureAhmed GattoufiNoch keine Bewertungen

- Fdocuments - in - Gas Boiler System Commissioning Checklist Gas Boiler System Commissioning ChecklistDokument2 SeitenFdocuments - in - Gas Boiler System Commissioning Checklist Gas Boiler System Commissioning Checklistkapster KannourNoch keine Bewertungen

- Design of Steel ConnectionsDokument34 SeitenDesign of Steel ConnectionsMashudha Sulthana100% (1)

- Liquid - Gas Phase SizingDokument12 SeitenLiquid - Gas Phase Sizingeke23Noch keine Bewertungen

- Circular TanksDokument8 SeitenCircular TanksMohamed Ehab100% (1)

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDokument7 SeitenPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryNoch keine Bewertungen

- Rheology Mud CalculatorDokument9 SeitenRheology Mud CalculatorShivaram SuppiahNoch keine Bewertungen

- Mud MixDokument2 SeitenMud MixscrbdgharaviNoch keine Bewertungen

- Separator Sizing and DesignDokument44 SeitenSeparator Sizing and DesignKay EenNoch keine Bewertungen

- Separator Sizing SpreadsheetDokument40 SeitenSeparator Sizing SpreadsheetWalid Ben Husein100% (2)

- PRO2000Dokument72 SeitenPRO2000scrbdgharaviNoch keine Bewertungen

- Anup Calculation SheetDokument33 SeitenAnup Calculation SheetAziz AndriyantoNoch keine Bewertungen

- Drilling Formulas Calculation Sheet Verson 1.3Dokument186 SeitenDrilling Formulas Calculation Sheet Verson 1.3Sarhad Ahmed100% (1)

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDokument20 SeitenExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNoch keine Bewertungen

- Hydraulics - Summary: Including Cutting Weight & Tool JointDokument5 SeitenHydraulics - Summary: Including Cutting Weight & Tool JointAnonymous U5t9NYzhLWNoch keine Bewertungen

- Pump Calculation SheetDokument4 SeitenPump Calculation SheetMuhammad BilalNoch keine Bewertungen

- Pump CalcDokument8 SeitenPump CalcMohamed FouadNoch keine Bewertungen

- Mud CalcDokument7 SeitenMud CalcmehrdadNoch keine Bewertungen

- Video Training Courses in Offshore Structures DesignDokument102 SeitenVideo Training Courses in Offshore Structures Designscrbdgharavi100% (2)

- FGCP Line Sizing CalculationsDokument86 SeitenFGCP Line Sizing CalculationsToyinNoch keine Bewertungen

- Pump SizingDokument31 SeitenPump SizingTuấn VũNoch keine Bewertungen

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDokument5 SeitenObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381Noch keine Bewertungen

- Thumb Rules For Chemical EngineerDokument44 SeitenThumb Rules For Chemical EngineerNallathambiNoch keine Bewertungen

- Slab Bridge 6m Span Superstructure DesignDokument12 SeitenSlab Bridge 6m Span Superstructure DesignEngineeri TadiyosNoch keine Bewertungen

- Engg. CalculationDokument5 SeitenEngg. CalculationVijaya PatilNoch keine Bewertungen

- Pressure Drop1Dokument15 SeitenPressure Drop1song LiNoch keine Bewertungen

- As 5100.5-2004 Bridge Design ConcreteDokument10 SeitenAs 5100.5-2004 Bridge Design ConcreteSAI Global - APAC0% (1)

- Pressure Loss - SwitchyardDokument1 SeitePressure Loss - Switchyardkarthikraja21Noch keine Bewertungen

- Hump Hydraulics CalculationsDokument13 SeitenHump Hydraulics CalculationsrutujaNoch keine Bewertungen

- Detailed Design Design of SlabDokument4 SeitenDetailed Design Design of Slabnandheeswaran rNoch keine Bewertungen

- Flare KOD SizingDokument4 SeitenFlare KOD SizingSaid Ahmed Salem100% (1)

- 0973r04 OKIOC Marine ManualDokument79 Seiten0973r04 OKIOC Marine ManualscrbdgharaviNoch keine Bewertungen

- CalculationDokument13 SeitenCalculationajit kumarNoch keine Bewertungen

- Drilling Formulas Calculation Sheet V1.2Dokument102 SeitenDrilling Formulas Calculation Sheet V1.2Jose Flores Hernandez100% (1)

- Nss CalculatorDokument4 SeitenNss CalculatorZoebair100% (1)

- Separator SizingDokument9 SeitenSeparator SizingTolstoy LeoNoch keine Bewertungen

- Hydraulic Calculations MudpumpDokument1 SeiteHydraulic Calculations MudpumpSudish BhatNoch keine Bewertungen

- Condensate Line SizingDokument2 SeitenCondensate Line SizingAnonymous oVRvsdWzfBNoch keine Bewertungen

- Design 3Dokument2 SeitenDesign 3JOY NATHNoch keine Bewertungen

- Hydraulic Calc by VassDokument1 SeiteHydraulic Calc by VassKyzak K. KeorkNoch keine Bewertungen

- Flow DataDokument5 SeitenFlow DataMiguel RodriguezNoch keine Bewertungen

- CO2 Condenser 02-03-2023-15 PMDokument37 SeitenCO2 Condenser 02-03-2023-15 PMahmad santosoNoch keine Bewertungen

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultDokument87 SeitenAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalNoch keine Bewertungen

- ParalDokument9 SeitenParalTahirJabbarNoch keine Bewertungen

- Calculation Title: Seagas Pipeline Design - MinervaDokument1 SeiteCalculation Title: Seagas Pipeline Design - Minerva秦东旺Noch keine Bewertungen

- Coastal Planning Management-Lesson4-Hydraulic StudyDokument47 SeitenCoastal Planning Management-Lesson4-Hydraulic StudyshirleyNoch keine Bewertungen

- Shell&Tube TEMAsheet 1Dokument1 SeiteShell&Tube TEMAsheet 1Rikiya FebriyanNoch keine Bewertungen

- Separator DesignDokument4 SeitenSeparator DesignTech ManagerNoch keine Bewertungen

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDokument7 SeitenQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Procees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetDokument17 SeitenProcees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetMagesh leoNoch keine Bewertungen

- Ydraulic Alculations: B W B HDokument1 SeiteYdraulic Alculations: B W B HhuangjlNoch keine Bewertungen

- Sludge Treatment: Total Solid in Raw Water 600 Kg/dayDokument12 SeitenSludge Treatment: Total Solid in Raw Water 600 Kg/dayThava ThavaNoch keine Bewertungen

- Master Calculation SheetDokument12 SeitenMaster Calculation SheetTanner BoydNoch keine Bewertungen

- Hyd. Calc of 43p17 Ab - As Per P&idDokument7 SeitenHyd. Calc of 43p17 Ab - As Per P&idAnindyaNoch keine Bewertungen

- Centrifugal Pump CurvesDokument2 SeitenCentrifugal Pump CurvesBesan LaduNoch keine Bewertungen

- MEPDG Manual of PracticesDokument209 SeitenMEPDG Manual of PracticesSri RamyaNoch keine Bewertungen

- Hydraulic Cal - Tanks Vent To FlareDokument1 SeiteHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JDokument1 SeiteSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiNoch keine Bewertungen

- Piping Pressure Drop and Pump Design Calculation Sheet: R-0 07-06-18 Issued For Information MRB MRBDokument2 SeitenPiping Pressure Drop and Pump Design Calculation Sheet: R-0 07-06-18 Issued For Information MRB MRBmoh. rusli bahtiarNoch keine Bewertungen

- Pump & Pressure Drop CalculationDokument42 SeitenPump & Pressure Drop CalculationMuhammad RizkyNoch keine Bewertungen

- Pipeline Hydraulics Modification ReqdDokument6 SeitenPipeline Hydraulics Modification ReqdchemtahirNoch keine Bewertungen

- 01 - General FormulaeDokument10 Seiten01 - General FormulaescrbdgharaviNoch keine Bewertungen

- Separator Design: Rev Description Date Prepared by Client ApprovalDokument18 SeitenSeparator Design: Rev Description Date Prepared by Client ApprovalUsɱâñ Måâñ100% (1)

- Valve Sizing Calculation8Dokument2 SeitenValve Sizing Calculation8PIDNoch keine Bewertungen

- Calculation and Specification of Bilge SystemDokument40 SeitenCalculation and Specification of Bilge SystemTegar LanangNoch keine Bewertungen

- Head LossDokument1 SeiteHead LossNghiaNoch keine Bewertungen

- Rig Technical DescriptionDokument17 SeitenRig Technical DescriptionAnonymous JMoXMYMnNoch keine Bewertungen

- Chapter 5Dokument7 SeitenChapter 5Harjith VaibavNoch keine Bewertungen

- Reference 18: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 18: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Reference 15: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 15: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Reference 19: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 19: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Ref 17Dokument1 SeiteRef 17scrbdgharaviNoch keine Bewertungen

- Reference 14: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 14: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Ref 4Dokument1 SeiteRef 4scrbdgharaviNoch keine Bewertungen

- Internal Cleaning and Coating of In-Place Pipelines: by C KleinDokument4 SeitenInternal Cleaning and Coating of In-Place Pipelines: by C KleinscrbdgharaviNoch keine Bewertungen

- Reference 16: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 16: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Reference 6: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 6: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Reference 3: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 3: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- Reference 2: Schedule 'D' Health, Safety, Environment and SecurityDokument1 SeiteReference 2: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNoch keine Bewertungen

- HSE Management - Guidelines For Working Together in A Contract EnvironmentDokument72 SeitenHSE Management - Guidelines For Working Together in A Contract EnvironmentscrbdgharaviNoch keine Bewertungen

- An Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferDokument8 SeitenAn Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferscrbdgharaviNoch keine Bewertungen

- Pigging Multi-Diameter Lines and Other Specialist TechniquesDokument6 SeitenPigging Multi-Diameter Lines and Other Specialist TechniquesscrbdgharaviNoch keine Bewertungen

- Pre On-Line Inspection Pigging: by C KershawDokument6 SeitenPre On-Line Inspection Pigging: by C KershawscrbdgharaviNoch keine Bewertungen

- Solutions To Unpiggable' Pipelines: by Allen A PenningtonDokument6 SeitenSolutions To Unpiggable' Pipelines: by Allen A PenningtonscrbdgharaviNoch keine Bewertungen

- A Comparison of CP Survey Techniques and Intelligent Pig InspectionDokument6 SeitenA Comparison of CP Survey Techniques and Intelligent Pig InspectionscrbdgharaviNoch keine Bewertungen

- U.S. Government Pipeline Safety Regulation: by J C CaldwellDokument6 SeitenU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviNoch keine Bewertungen

- Hor PlanDokument1 SeiteHor PlanscrbdgharaviNoch keine Bewertungen

- Cleaning and Geometry Inspection Prior To Corrosion InspectionDokument4 SeitenCleaning and Geometry Inspection Prior To Corrosion InspectionscrbdgharaviNoch keine Bewertungen

- New Developments in The Inspection of Gas Distribution MainsDokument6 SeitenNew Developments in The Inspection of Gas Distribution MainsscrbdgharaviNoch keine Bewertungen

- Engineering Technical ServicesDokument11 SeitenEngineering Technical ServicesscrbdgharaviNoch keine Bewertungen

- GTEDokument4 SeitenGTESridevi GNoch keine Bewertungen

- EjerciciosDokument14 SeitenEjerciciosmmontesmNoch keine Bewertungen

- CE 162 MidtermsDokument2 SeitenCE 162 MidtermsRoEm'z Suarez PaIlagoNoch keine Bewertungen

- New Generation Polycarboxylate Hyperplasticiser: Meets The Israeli Standards # 896Dokument2 SeitenNew Generation Polycarboxylate Hyperplasticiser: Meets The Israeli Standards # 896weamNoch keine Bewertungen

- Chapter-I-Stress-1 11 21 3Dokument5 SeitenChapter-I-Stress-1 11 21 3Joshua John JulioNoch keine Bewertungen

- Justmoh Procter Test So-11Dokument11 SeitenJustmoh Procter Test So-11Abu FalasiNoch keine Bewertungen

- Eurocode 8 EN1998-5 2003 - Faccioli LectureDokument34 SeitenEurocode 8 EN1998-5 2003 - Faccioli Lecturepaduco100% (1)

- Design Calculation: Donaldson Equipmentt ModelDokument49 SeitenDesign Calculation: Donaldson Equipmentt ModelmuratcanNoch keine Bewertungen

- Orifice Flowmeter Design: Chapter FourteenDokument8 SeitenOrifice Flowmeter Design: Chapter Fourteenjose mirandaNoch keine Bewertungen

- 34 - High Strength Concrete ColumnsDokument3 Seiten34 - High Strength Concrete ColumnsIan FloodNoch keine Bewertungen

- AISC DG02 Example 002Dokument6 SeitenAISC DG02 Example 002f tshNoch keine Bewertungen

- Choice of A Turbulence Model For Pump IntakesDokument15 SeitenChoice of A Turbulence Model For Pump IntakesBharath kumarNoch keine Bewertungen

- Mini Project Civil AbstractDokument1 SeiteMini Project Civil AbstractVidhun Ravindran100% (2)

- Yei Gen GD 07 PDFDokument1 SeiteYei Gen GD 07 PDFVishal KumarNoch keine Bewertungen

- University of ZimbabweDokument6 SeitenUniversity of ZimbabweTynash NyakatsapaNoch keine Bewertungen

- Beam Deflections and Stresses During LiftingDokument10 SeitenBeam Deflections and Stresses During LiftingharshadNoch keine Bewertungen

- Procedure Manual: FOR Underground FRP Storage TankDokument6 SeitenProcedure Manual: FOR Underground FRP Storage Tankravi yemmadiNoch keine Bewertungen

- How To Build A Small Vertical Shaft Lime Kiln: An Example of A Continuous Production, Mixed Feed Kiln From ZimbabweDokument8 SeitenHow To Build A Small Vertical Shaft Lime Kiln: An Example of A Continuous Production, Mixed Feed Kiln From ZimbabweMohammad Ali TaghdiriNoch keine Bewertungen

- DV ScheduleDokument12 SeitenDV SchedulePrasenjit MondalNoch keine Bewertungen

- Outdoor Kitchen r2 2510Dokument18 SeitenOutdoor Kitchen r2 2510chetanjtNoch keine Bewertungen

- Soil Mechanics Ce404Dokument5 SeitenSoil Mechanics Ce404Debasish DasNoch keine Bewertungen