Beruflich Dokumente

Kultur Dokumente

DLW Linoleum With LPX Surface: Cleaning and Care Recommendation

Hochgeladen von

Dan George IIIOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DLW Linoleum With LPX Surface: Cleaning and Care Recommendation

Hochgeladen von

Dan George IIICopyright:

Verfügbare Formate

DLW Linoleum with LPX Surface

Cleaning and Care Recommendation

Adequately dimensioned textile-based clean walkway zones at least 2 to 3 paces long) protect the floor covering against fine dust and moisture. If the clean walkway zones are regularly cleaned, they protect the floor covering, thus increasing its utility and reducing cleaning costs in the property.

Type of cleaning

Completion of installation cleaning

Machine cleaning of floor covering Rinse with clean water

Cleaning materials and equipment

Single-disk machine, 150 180 RPM max. Scrubbing brush or red 3M pad Neutral or alcohol-based cleaner with pH < 9 as required

Factory-applied LPX may not be removed.

Maintenance

Principally not necessary* -----

Routine cleaning

Low degree of contamination and/or loose-lying dirt Remove by vacuum cleaning/ brushing and/or by moist mopping Vacuum cleaner Disposable mopping pads Mop and mop head covering Mopping cleaning agent

Heavy, strongly sticking contamination Smaller areas: Spray until moist and collect loosened dirt with cleaning cloths

Mop and mop head covering Mopping cleaning agent and spray bottle

Larger areas: use the twin-bucket mopping method or a suitable scouring vacuum cleaning machine Regular polishing seals the surface and improves the durability of the floor covering, as well as providing better protection against most scuffing agents.

Twin bucket and mop head covering Mopping cleaning agent Disinfectant cleaner (see "Special property requirements") Scouring vacuum cleaning machine Automatic cleaning machine for linoleum

Scuff marks, heel marks First treat affected floor covering areas with spray cleaner Then machine polish

Spray cleaner Single-disk machine, 300 1000 RPM. Polishing pad, e.g. beige or red 3M pad

As of: 02 / 2008 Telephone: 071 42 / 71 340 www.armstrong.eu service_germany@armstrong.com

DLW Linoleum with LPX Surface

Cleaning and Care Recommendation

Protective film restoration

Covering areas are partially or fully buffed to give an even matt surface to the existing protective film / coating

Single-disk machine (e.g. Nilfisk 545) with at least 300 RPM. Polishing pad, e.g. blue or green 3M pad

Remove dust Apply a protective film

Mop Polymer dispersion / Maintenance emulsion

If application is only partial, the cross-over areas must be matched up by polishing

Single-disk machine with at least 300 RPM. Polishing pad, e.g. beige or red 3M pad

Special property requirements*

Twice-applied polymer dispersion, disinfectant-resistant if necessary Sufficient drying time must be allowed between applications Polymer dispersion, surface disinfectant-resistant if necessary Mop and mop head covering

*The appearance of a floor covering is affected by property-specific environmental conditions (such as the frequency of use) and may be subject to property-specific requirements (applicable hygiene standards for instance). For this reason it may sometimes be necessary to take further measures, for example the application of an additional surface protection agent. The suitability of the dispersion / emulsion, particularly for electrically conducting linoleum, must be checked with the manufacturer. Special notes: During routine cleaning, care should be taken that a complete protective film is always present on the floor covering surface. If necessary, the factory-applied surface protection should be restored by using a mopping cleaning agent or polymer dispersion. After completing laying work, the floor covering areas should be protected against damage, contamination and scratching in areas that are heavily frequented during the building phase by using protective coverings. The compatibility of adhesive tape with linoleum should be checked with the tape manufacturer before use. Sufficiently dimensioned textile-based clean walkway zones (at least 2 to 3 paces long) protect the floor covering against fine dust and moisture. If the clean walkway zones are regularly cleaned, they protect the floor covering, thus increasing its utility and reducing cleaning costs in the property. Raised floors are treated by wet mopping or with disposable mopping pads and the spray cleaner method used if necessary. To avoid damage to the floor, we recommend that, in accordance with EN 12529, chair castors of type "W" and soft furniture gliders (felt or soft light-coloured plastic) be used. Chair and furniture floor contact areas must not have sharp edges. Prolonged contact with coloured rubber, particularly if black, can cause colouration of elastic floor coverings, which cannot be removed. To avoid this, we recommend the use of underlay plates or suitable rollers (PUR or another suitable material). The anti-slip properties of a floor covering are significantly affected by the amount of dirt present, the frequency of cleaning as well as the cleaning and care materials used. A reduction in cleaning activity can therefore lead to various potential hygiene and safety issues.

For installation recommendation please have a look in www.armstrong.eu

**DLWPDF03** lino_uk

As of: 02 / 2008 Telephone: 071 42 / 71 340 www.armstrong.eu service_germany@armstrong.com

Das könnte Ihnen auch gefallen

- Afpe Maint Linoleum UkDokument6 SeitenAfpe Maint Linoleum UkAt YugovicNoch keine Bewertungen

- The New LPX Finish For DLW Linoleum LPX Finish - The BenefitsDokument2 SeitenThe New LPX Finish For DLW Linoleum LPX Finish - The BenefitsDan George IIINoch keine Bewertungen

- Primo SD Cleaning MaintenanceDokument2 SeitenPrimo SD Cleaning MaintenanceEric Vergel de DiosNoch keine Bewertungen

- Care and Maintenance Instructions: Initial Cleanup After Installation (Once)Dokument2 SeitenCare and Maintenance Instructions: Initial Cleanup After Installation (Once)Nilesh NarkhedeNoch keine Bewertungen

- All-Purpose Adhesive: Technical DataDokument3 SeitenAll-Purpose Adhesive: Technical DataMuraleedharanNoch keine Bewertungen

- Anticorossive Epoxy FlooringDokument2 SeitenAnticorossive Epoxy Flooringtejas_tNoch keine Bewertungen

- Maintenance GuideDokument2 SeitenMaintenance GuideVinka PrintNoch keine Bewertungen

- MasterTop SRS Cleaning InstructionsDokument3 SeitenMasterTop SRS Cleaning InstructionsEngTamerNoch keine Bewertungen

- V13 DV Ls MSL 5-Steps Guide Aftercare OWF 180x180 1015Dokument16 SeitenV13 DV Ls MSL 5-Steps Guide Aftercare OWF 180x180 1015Dan George IonescuNoch keine Bewertungen

- MOS For Bituminous Protective Coating Water ProofingDokument5 SeitenMOS For Bituminous Protective Coating Water ProofingHussam WaleedNoch keine Bewertungen

- Forbo Floor Care - Marmoleum: Forbo Flooring Cleaning and Maintenance AdviceDokument2 SeitenForbo Floor Care - Marmoleum: Forbo Flooring Cleaning and Maintenance AdviceDoutor InácioNoch keine Bewertungen

- Cork Linoleum CleaningDokument2 SeitenCork Linoleum CleaningFloorkitNoch keine Bewertungen

- Dulux Promise Smartchoice Exterior PdsDokument3 SeitenDulux Promise Smartchoice Exterior PdsJohn AbhishekNoch keine Bewertungen

- Conrema Repair Material Steelcord BeltsDokument24 SeitenConrema Repair Material Steelcord BeltsPetros IosifidisNoch keine Bewertungen

- V5 Ls MSL 5-Steps Guide Aftercare 148x148 0315Dokument16 SeitenV5 Ls MSL 5-Steps Guide Aftercare 148x148 0315Dan George IonescuNoch keine Bewertungen

- Application Guide For Ultra-Ever Dry SE 7.6.110: Instructional Video Available atDokument1 SeiteApplication Guide For Ultra-Ever Dry SE 7.6.110: Instructional Video Available atqwertykingzNoch keine Bewertungen

- InstallationInstruction Purebamboo en LQDokument1 SeiteInstallationInstruction Purebamboo en LQAnonymous JR3wU5eeNoch keine Bewertungen

- Cleaning & MaintenanceDokument2 SeitenCleaning & MaintenanceFloorkitNoch keine Bewertungen

- 1 DT 2.8 Preparation FillercoatDokument4 Seiten1 DT 2.8 Preparation Fillercoatyoxan25808Noch keine Bewertungen

- Uzin L 3 Gold: Product Data SheetDokument2 SeitenUzin L 3 Gold: Product Data SheetFloorkitNoch keine Bewertungen

- Elemental Installation GuideDokument3 SeitenElemental Installation GuidesymonpatenNoch keine Bewertungen

- Road Safety Booklet 30-10-2019Dokument18 SeitenRoad Safety Booklet 30-10-2019Salman AsadNoch keine Bewertungen

- Nitoproof 30 - Water Proofing CompoundDokument2 SeitenNitoproof 30 - Water Proofing CompoundChethan BhatNoch keine Bewertungen

- Weberfloor 514 SL TDS SelflevelDokument3 SeitenWeberfloor 514 SL TDS SelflevelMusab yassinNoch keine Bewertungen

- Technology of Spot Repairs - ENDokument4 SeitenTechnology of Spot Repairs - ENVilius BukysNoch keine Bewertungen

- Uzin NC 152Dokument2 SeitenUzin NC 152FloorkitNoch keine Bewertungen

- Nitoproof 30Dokument2 SeitenNitoproof 30Balasubramanian Ananth0% (1)

- Uzin NC 110Dokument4 SeitenUzin NC 110FloorkitNoch keine Bewertungen

- TDS - Mastertop 100Dokument3 SeitenTDS - Mastertop 100Venkata RaoNoch keine Bewertungen

- PC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540Dokument3 SeitenPC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540onshore purchase100% (1)

- 1 DT 6.4 Speciality HichemepoxyenamelDokument5 Seiten1 DT 6.4 Speciality Hichemepoxyenamelyoxan25808Noch keine Bewertungen

- Milliken-Maintenance GuideDokument6 SeitenMilliken-Maintenance GuideNoraishah Mohd IsmailNoch keine Bewertungen

- Coating Problem Solver: Adhesion (Blocking) : DescriptionDokument24 SeitenCoating Problem Solver: Adhesion (Blocking) : DescriptionKiran Kumar JhaNoch keine Bewertungen

- Dulux Trade Ecosure MattDokument6 SeitenDulux Trade Ecosure Mattyoxan25808Noch keine Bewertungen

- TDS - Mastertop 230Dokument2 SeitenTDS - Mastertop 230Venkata RaoNoch keine Bewertungen

- Onboard Maintenance Paint Guide Tcm40 67407Dokument9 SeitenOnboard Maintenance Paint Guide Tcm40 67407Costas AggelidisNoch keine Bewertungen

- Uzin PE 360Dokument2 SeitenUzin PE 360FloorkitNoch keine Bewertungen

- Cemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmDokument4 SeitenCemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmBalasubramanian AnanthNoch keine Bewertungen

- Floor Types and Their CareDokument93 SeitenFloor Types and Their CareArundeep Singh100% (1)

- Nitoproof 230Dokument2 SeitenNitoproof 230Balasubramanian Ananth50% (2)

- Kaltreparatur-Textil WT2332 enDokument20 SeitenKaltreparatur-Textil WT2332 enFerAK47aNoch keine Bewertungen

- FlotopDokument2 SeitenFlotoppravi3434Noch keine Bewertungen

- BTL BTS-P System 12-07 enDokument10 SeitenBTL BTS-P System 12-07 enlutherblackNoch keine Bewertungen

- 1 Manual Limpieza Marmol Digital ENG 05-1Dokument7 Seiten1 Manual Limpieza Marmol Digital ENG 05-1charbel mechaalaniNoch keine Bewertungen

- Dulux Universal UndercoatDokument5 SeitenDulux Universal UndercoatEnock ChinakaNoch keine Bewertungen

- Housekeeping 101Dokument481 SeitenHousekeeping 101Micaella JoannaNoch keine Bewertungen

- Asian Apcodur Epoxy Mio PaintDokument3 SeitenAsian Apcodur Epoxy Mio PaintPrinceRaghavNoch keine Bewertungen

- Euco TopDokument2 SeitenEuco Toppravi3434Noch keine Bewertungen

- L3 Gold System Primer GB 01Dokument2 SeitenL3 Gold System Primer GB 01FloorkitNoch keine Bewertungen

- Method Statement For Waterproofing Treatment of Wet Areas.1Dokument4 SeitenMethod Statement For Waterproofing Treatment of Wet Areas.1shakeelNoch keine Bewertungen

- Toli Carpet Maintenance GuidelinesDokument5 SeitenToli Carpet Maintenance GuidelinesRicky Ricky Rbg0% (1)

- Plywood TechnologyDokument37 SeitenPlywood TechnologyDr.E.Sreenivasan80% (5)

- Uk RailwayDokument61 SeitenUk RailwayKatrina MartinNoch keine Bewertungen

- Dip PDFDokument27 SeitenDip PDFolenin64Noch keine Bewertungen

- Waterproofing Torch On MethodologyDokument2 SeitenWaterproofing Torch On MethodologyErwin Obenza100% (1)

- Advance ServicesDokument20 SeitenAdvance Servicesashitha bodduNoch keine Bewertungen

- Weberfloor - 630 - TSC - 01 (1) - 221109 - 183928Dokument3 SeitenWeberfloor - 630 - TSC - 01 (1) - 221109 - 183928Pacific CoastNoch keine Bewertungen

- Uzin KE 603Dokument2 SeitenUzin KE 603FloorkitNoch keine Bewertungen

- SOP-PVC FlooringDokument7 SeitenSOP-PVC FlooringNitish Singh (Monty)Noch keine Bewertungen

- Burmatex Presentation TSB PDFDokument11 SeitenBurmatex Presentation TSB PDFDan George IIINoch keine Bewertungen

- Load Bearing CapacityDokument1 SeiteLoad Bearing CapacityDan George IIINoch keine Bewertungen

- Emco DIPLOMAT With Ribbed Carpet Insert - RDokument1 SeiteEmco DIPLOMAT With Ribbed Carpet Insert - RDan George IIINoch keine Bewertungen

- Vetromagic Tutorial Ok 1Dokument2 SeitenVetromagic Tutorial Ok 1Dan George IIINoch keine Bewertungen

- Datenblatt Consul 02 GB - KV1Dokument2 SeitenDatenblatt Consul 02 GB - KV1Dan George IIINoch keine Bewertungen

- CONIPURHGDokument3 SeitenCONIPURHGDan George IIINoch keine Bewertungen

- Warranty Tivoli24Dokument1 SeiteWarranty Tivoli24Dan George IIINoch keine Bewertungen

- Model Sm/Smc-100 Thru 400 Installation Instructions: Important InformationDokument4 SeitenModel Sm/Smc-100 Thru 400 Installation Instructions: Important InformationDan George IIINoch keine Bewertungen

- APF Series - Product Page APF 25 To APF 150Dokument1 SeiteAPF Series - Product Page APF 25 To APF 150Dan George IIINoch keine Bewertungen

- WelcomeFolder BasicDokument4 SeitenWelcomeFolder BasicDan George IIINoch keine Bewertungen

- Vorwerk CARPET CAREDokument5 SeitenVorwerk CARPET CAREDan George IIINoch keine Bewertungen

- Create Your Own Enia DesignDokument1 SeiteCreate Your Own Enia DesignDan George IIINoch keine Bewertungen

- 2tec2 FloorsDokument25 Seiten2tec2 FloorsDan George IIINoch keine Bewertungen

- CS CouvraneufDokument28 SeitenCS CouvraneufDan George IIINoch keine Bewertungen

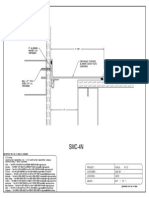

- SMC-4N: Scale: Project: Customer: Location: Job No.: - N.T.S.Dokument1 SeiteSMC-4N: Scale: Project: Customer: Location: Job No.: - N.T.S.Dan George IIINoch keine Bewertungen

- Linopro Sport: Specification According To DIN V 18032-2 / EN 548 Linopro 4.0Dokument1 SeiteLinopro Sport: Specification According To DIN V 18032-2 / EN 548 Linopro 4.0Dan George IIINoch keine Bewertungen

- Cataloog Versie 2009Dokument76 SeitenCataloog Versie 2009Dan George IIINoch keine Bewertungen

- Fixing Our Broken Economy v2Dokument6 SeitenFixing Our Broken Economy v2Dan George IIINoch keine Bewertungen

- 04AF0BD9d01 PDFDokument84 Seiten04AF0BD9d01 PDFDan George IIINoch keine Bewertungen

- Water Treatment UniversalDokument19 SeitenWater Treatment UniversalDan George IIINoch keine Bewertungen

- Inspiration: Inspiration. Creations To Make You Feel at HomeDokument2 SeitenInspiration: Inspiration. Creations To Make You Feel at HomeDan George IIINoch keine Bewertungen

- Faculty of AyurvedaDokument9 SeitenFaculty of AyurvedaKirankumar MutnaliNoch keine Bewertungen

- Menu Planning in HospitalDokument4 SeitenMenu Planning in HospitalERva Soelkarnaen100% (1)

- UVEX - Helmets & Eyewear 2009Dokument19 SeitenUVEX - Helmets & Eyewear 2009Ivica1977Noch keine Bewertungen

- Jungbluth Main Catalogue-LanacDokument60 SeitenJungbluth Main Catalogue-LanacMilenkoBogdanovicNoch keine Bewertungen

- Questionnaire OriginalDokument6 SeitenQuestionnaire OriginalJAGATHESANNoch keine Bewertungen

- Bachelors of Engineering: Action Research Project - 1Dokument18 SeitenBachelors of Engineering: Action Research Project - 1manasi rathiNoch keine Bewertungen

- California Academy For Lilminius (Cal) : Lesson PlanDokument4 SeitenCalifornia Academy For Lilminius (Cal) : Lesson Plandarryl franciscoNoch keine Bewertungen

- Diagnostic Test - Tle8Dokument2 SeitenDiagnostic Test - Tle8rose mae marambaNoch keine Bewertungen

- REM630 Broch 756825 LRENdDokument6 SeitenREM630 Broch 756825 LRENdsihamuNoch keine Bewertungen

- Wapda CSR 2013 Zone 3Dokument245 SeitenWapda CSR 2013 Zone 3Naveed Shaheen91% (11)

- Grand Chapter Mentor ProgramDokument13 SeitenGrand Chapter Mentor ProgramJulius Wright100% (1)

- Citadel Securities Australia Pty LTD - Company DetailsDokument5 SeitenCitadel Securities Australia Pty LTD - Company DetailsBrendan OswaldNoch keine Bewertungen

- Beyond The Breech Trial. Maggie BanksDokument4 SeitenBeyond The Breech Trial. Maggie Bankspurpleanvil100% (2)

- AromatherapyDokument15 SeitenAromatherapymurrmurreNoch keine Bewertungen

- Solow 5e Web SolutionsDokument58 SeitenSolow 5e Web SolutionsOscar VelezNoch keine Bewertungen

- Liquid Process Piping - Part 1 General Piping Design PDFDokument33 SeitenLiquid Process Piping - Part 1 General Piping Design PDFnitin guptaNoch keine Bewertungen

- Safe Motherhood Ao2016-0035 Quality Antenatal Care PDFDokument9 SeitenSafe Motherhood Ao2016-0035 Quality Antenatal Care PDFGa B B OrlonganNoch keine Bewertungen

- IRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthDokument32 SeitenIRAQ Reproductive Maternal, Newborn, Child and Adolescent HealthbejarhasanNoch keine Bewertungen

- Resume LittletonDokument1 SeiteResume Littletonapi-309466005Noch keine Bewertungen

- Device InfoDokument3 SeitenDevice InfoGrig TeoNoch keine Bewertungen

- T HR El 20003 ST PDFDokument20 SeitenT HR El 20003 ST PDFAngling Dharma100% (1)

- 8 TH Linear Equations DBDokument1 Seite8 TH Linear Equations DBParth GoyalNoch keine Bewertungen

- Directorate of Technical Education, Maharashtra StateDokument47 SeitenDirectorate of Technical Education, Maharashtra StatePandurang GunjalNoch keine Bewertungen

- The Names of Allah and Their ReflectionsDokument98 SeitenThe Names of Allah and Their ReflectionsSuleyman HldNoch keine Bewertungen

- Operations Management Stevenson 11th Edition Test BankDokument10 SeitenOperations Management Stevenson 11th Edition Test BankAries Gonzales Caragan50% (2)

- Lesson 7Dokument6 SeitenLesson 7Jeya Plays YTNoch keine Bewertungen

- Soal PTS Vii BigDokument6 SeitenSoal PTS Vii Bigdimas awe100% (1)

- Attitude Scale For Mental IllnessDokument6 SeitenAttitude Scale For Mental IllnessSyed Faizan100% (7)

- 56257375851Dokument3 Seiten56257375851Anneliese FernandesNoch keine Bewertungen

- Solutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriDokument5 SeitenSolutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriMarkib Singh AdawitahkNoch keine Bewertungen