Beruflich Dokumente

Kultur Dokumente

Stress-Strain Diagram - Strength of Materials Review

Hochgeladen von

imrancenakkOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stress-Strain Diagram - Strength of Materials Review

Hochgeladen von

imrancenakkCopyright:

Verfügbare Formate

7/15/13

Stress-strain Diagram | Strength of Materials Review

Stress-strain Diagram

Tags: stress-strain diagram proportinal limit elastic limit yield point ultimate strength rupture strength

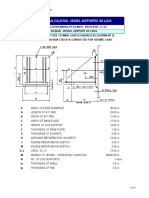

Suppose that a metal specimen be placed in tension-compression-testing machine. As the axial load is gradually increased in increments, the total elongation over the gauge length is measured at each increment of the load and this is continued until failure of the specimen takes place. Knowing the original cross-sectional area and length of the specimen, the normal stress and the strain can be obtained. The graph of these quantities with the stress along the y-axis and the strain along the x-axis is called the stress-strain diagram. The stress-strain diagram differs in form for various materials. The diagram shown below is that for a medium-carbon structural steel. Metallic engineering materials are classified as either ductile or brittle materials. A ductile material is one having relatively large tensile strains up to the point of rupture like structural steel and aluminum, whereas brittle materials has a relatively small strain up to the point of rupture like cast iron and concrete. An arbitrary strain of 0.05 mm/mm is frequently taken as the dividing line between these two classes.

Stress-strain diagram of a medium-carbon structural steel Proportional Limit (Hooke's Law) From the origin O to the point called proportional limit, the stress-strain curve is a straight line. This linear relation between elongation and the axial force causing was first noticed by Sir Robert Hooke in 1678 and is called Hooke's Law that within the proportional limit, the stress is directly proportional to strain or or The constant of proportionality k is called the Modulus of Elasticity E or Young's Modulus and is equal to the slope of the stress-strain diagram from O to P. Then

Elastic Limit The elastic limit is the limit beyond which the material will no longer go back to its original shape when the load is removed, or it is the maximum stress that may e developed such that there is no permanent or residual deformation when the load is entirely removed. Elastic Limit The elastic limit is the limit beyond which the material will no longer go back to its original shape when the load is removed, or it is the maximum stress that may e developed such that there is no permanent or residual deformation when the load is entirely removed. Elastic and Plastic Ranges The region in stress-strain diagram from O to P is called the elastic range. The region from P to R is called the plastic range.

www.mathalino.com/reviewer/mechanics-and-strength-of-materials/stress-strain-diagram

1/3

7/15/13

Stress-strain Diagram | Strength of Materials Review

Yield Point Yield point is the point at which the material will have an appreciable elongation or yielding without any increase in load. Ultimate Strength The maximum ordinate in the stress-strain diagram is the ultimate strength or tensile strength. Rapture Strength Rapture strength is the strength of the material at rupture. This is also known as the breaking strength. Modulus of Resilience Modulus of resilience is the work done on a unit volume of material as the force is gradually increased from O to P, in Nm/m3. This may be calculated as the area under the stress-strain curve from the origin O to up to the elastic limit E (the shaded area in the figure). The resilience of the material is its ability to absorb energy without creating a permanent distortion. Modulus of Toughness Modulus of toughness is the work done on a unit volume of material as the force is gradually increased from O to R, in Nm/m3. This may be calculated as the area under the entire stress-strain curve (from O to R). The toughness of a material is its ability to absorb energy without causing it to break. Working Stress, Allowable Stress, and Factor of Safety Working stress is defined as the actual stress of a material under a given loading. The maximum safe stress that a material can carry is termed as the allowable stress. The allowable stress should be limited to values not exceeding the proportional limit. However, since proportional limit is difficult to determine accurately, the allowable tress is taken as either the yield point or ultimate strength divided by a factor of safety. The ratio of this strength (ultimate or yield strength) to allowable strength is called the factor of safety.

Submitted by Romel Verterra on October 27, 2008 - 8:38pm

SPONSORED LINKS

Stress Engineering Yield Stress Stress Strain Measurement

Strain Stress and Fatigue Strain Gauge Transducer

Recent Updates

MATHalino.com is now offering tutorials for Engineering Mathematics 026 Review Problem - Find the diameter of a wooden ball 025 Review Problem - Time required to fill a reservoir of water 024 Review Problem - Will the pail hold all the water in the pipe? 023 Review Problem - Lead pipe melt into a cube 022 Review Problem - Tin required to create a funnel 020 Review Problem - Volume of a factory chimney 021 Review Problem - Finding the volume of a stone 019 Review Problem - Which buy is more economical? 018 Review Problem - Volume of Stone Bridge 017 Review Problem - Amount of water to fill the large network of city pipes 016 Review Problem - Mammoth Dredges Used in Panama Canal 015 Review Problem - Volume of spherical shell 014 Review Problem - Weight of concrete surge chamber when full of water 013 Review Problem - Volume of water inside the Venturi meter 012 Review Problem - Lake for household water supply 011 Review Problem - Cutting the strongest square timber 010 Review Problem - Volume of a stick 006 Review Problem - Area illuminated by light placed in front of the globe 007 Review Problem - Length of wire

www.mathalino.com/reviewer/mechanics-and-strength-of-materials/stress-strain-diagram

2/3

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Self-Taught ProgrammerDokument299 SeitenThe Self-Taught Programmerimrancenakk100% (1)

- Skirt Support DesignDokument8 SeitenSkirt Support Designimrancenakk100% (2)

- Shaft DeflectionDokument15 SeitenShaft Deflectionfreek_jamesNoch keine Bewertungen

- Lug Support DesignDokument11 SeitenLug Support Designimrancenakk100% (6)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- NSPM 12 Guidelines Guidelines For Assessment, Audit and Accreditation of Fumigation Agencies For Undertaking Methyl Bromide FumigationDokument46 SeitenNSPM 12 Guidelines Guidelines For Assessment, Audit and Accreditation of Fumigation Agencies For Undertaking Methyl Bromide FumigationimrancenakkNoch keine Bewertungen

- 10 Secrets To A Great BodyDokument16 Seiten10 Secrets To A Great BodyimrancenakkNoch keine Bewertungen

- Design Calculations For AgitatorsDokument5 SeitenDesign Calculations For AgitatorsimrancenakkNoch keine Bewertungen

- Agitator Vessel (Design&Costing)Dokument34 SeitenAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Castor Wheel CatalogueDokument12 SeitenCastor Wheel CatalogueimrancenakkNoch keine Bewertungen

- Valves & Fittings Catalog 2015Dokument20 SeitenValves & Fittings Catalog 2015imrancenakkNoch keine Bewertungen

- NSK CAT E1102m B304-325Dokument11 SeitenNSK CAT E1102m B304-325dassoumennNoch keine Bewertungen

- A Continuum Damage Mechanics Framework For Modeling Micro-Damage HealingDokument22 SeitenA Continuum Damage Mechanics Framework For Modeling Micro-Damage HealingimrancenakkNoch keine Bewertungen

- Problem 03 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewDokument2 SeitenProblem 03 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Solitons in Elastic SolidsDokument9 SeitenSolitons in Elastic SolidsimrancenakkNoch keine Bewertungen

- A Thermo-Viscoelastic-Viscoplastic-Viscodamage Constitutive Model Forasphaltic MaterialsDokument17 SeitenA Thermo-Viscoelastic-Viscoplastic-Viscodamage Constitutive Model Forasphaltic MaterialsimrancenakkNoch keine Bewertungen

- Assessment of Local Strain Field in Adhesive Layer of An Unsymmetrically Repaired CFRP Panel Using Digital Image CorrelationDokument13 SeitenAssessment of Local Strain Field in Adhesive Layer of An Unsymmetrically Repaired CFRP Panel Using Digital Image CorrelationimrancenakkNoch keine Bewertungen

- Rectilinear Translation - Moving Vessel - Advance Engineering Mathematics ReviewDokument2 SeitenRectilinear Translation - Moving Vessel - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Towards Optimization of Patch Shape On The Performance of Bonded Composite Repair Using FEMDokument11 SeitenTowards Optimization of Patch Shape On The Performance of Bonded Composite Repair Using FEMimrancenakkNoch keine Bewertungen

- Problem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewDokument1 SeiteProblem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Energy and Head - Advance Engineering Mathematics ReviewDokument4 SeitenEnergy and Head - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Problem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewDokument2 SeitenProblem 04 - Bernoulli's Energy Theorem - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Discharge - Flow Rate - Advance Engineering Mathematics ReviewDokument2 SeitenDischarge - Flow Rate - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Manometers - Advance Engineering Mathematics ReviewDokument2 SeitenManometers - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- 03 Pressure Below The Surface of The Ocean - Advance Engineering Mathematics ReviewDokument1 Seite03 Pressure Below The Surface of The Ocean - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Analysis of Gravity Dam - Advance Engineering Mathematics ReviewDokument3 SeitenAnalysis of Gravity Dam - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- Relative Equilibrium of Liquids - Advance Engineering Mathematics ReviewDokument1 SeiteRelative Equilibrium of Liquids - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- 05 Depth of Water in Which Pressure Is 200 Kpa - Advance Engineering Mathematics ReviewDokument1 Seite05 Depth of Water in Which Pressure Is 200 Kpa - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- 02 Pressure On The Face of A Dam - Advance Engineering Mathematics ReviewDokument1 Seite02 Pressure On The Face of A Dam - Advance Engineering Mathematics ReviewimrancenakkNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Moparm Action - December 2014 USADokument100 SeitenMoparm Action - December 2014 USAenricoioNoch keine Bewertungen

- Sika Saudi Arabia: Safety Data SheetDokument4 SeitenSika Saudi Arabia: Safety Data Sheetusman khalid100% (1)

- CW February 2013Dokument60 SeitenCW February 2013Clint FosterNoch keine Bewertungen

- Key Features of A Company 1. Artificial PersonDokument19 SeitenKey Features of A Company 1. Artificial PersonVijayaragavan MNoch keine Bewertungen

- Process Synchronization: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionDokument26 SeitenProcess Synchronization: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionKizifiNoch keine Bewertungen

- Ambient Lighting Vol 6 CompressedDokument156 SeitenAmbient Lighting Vol 6 Compressedadvait_etcNoch keine Bewertungen

- Tax Accounting Jones CH 4 HW SolutionsDokument7 SeitenTax Accounting Jones CH 4 HW SolutionsLolaLaTraileraNoch keine Bewertungen

- 2 and 3 Hinged Arch ReportDokument10 Seiten2 and 3 Hinged Arch ReportelhammeNoch keine Bewertungen

- Brother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDokument123 SeitenBrother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDuplessisNoch keine Bewertungen

- Global Review Solar Tower Technology PDFDokument43 SeitenGlobal Review Solar Tower Technology PDFmohit tailorNoch keine Bewertungen

- h6811 Datadomain DsDokument5 Seitenh6811 Datadomain DsChristian EstebanNoch keine Bewertungen

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonDokument8 SeitenRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietNoch keine Bewertungen

- 7373 16038 1 PBDokument11 Seiten7373 16038 1 PBkedairekarl UNHASNoch keine Bewertungen

- Adjectives With Cork English TeacherDokument19 SeitenAdjectives With Cork English TeacherAlisa PichkoNoch keine Bewertungen

- S SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesDokument3 SeitenS SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesMohan PreethNoch keine Bewertungen

- Singapore Electricity MarketDokument25 SeitenSingapore Electricity MarketTonia GlennNoch keine Bewertungen

- Pediatric Skills For OT Assistants 3rd Ed.Dokument645 SeitenPediatric Skills For OT Assistants 3rd Ed.Patrice Escobar100% (1)

- Manulife Health Flex Cancer Plus Benefit IllustrationDokument2 SeitenManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNoch keine Bewertungen

- SCHEDULE OF FEES - FinalDokument1 SeiteSCHEDULE OF FEES - FinalAbhishek SunaNoch keine Bewertungen

- MNO Manuale Centrifughe IngleseDokument52 SeitenMNO Manuale Centrifughe IngleseChrist Rodney MAKANANoch keine Bewertungen

- 11 TR DSU - CarrierDokument1 Seite11 TR DSU - Carriercalvin.bloodaxe4478100% (1)

- Saic-M-2012 Rev 7 StructureDokument6 SeitenSaic-M-2012 Rev 7 StructuremohamedqcNoch keine Bewertungen

- Tech Mahindra Sample Verbal Ability Placement Paper Level1Dokument11 SeitenTech Mahindra Sample Verbal Ability Placement Paper Level1Madhav MaddyNoch keine Bewertungen

- Catalog enDokument292 SeitenCatalog enSella KumarNoch keine Bewertungen

- Step-7 Sample ProgramDokument6 SeitenStep-7 Sample ProgramAmitabhaNoch keine Bewertungen

- Math 1 6Dokument45 SeitenMath 1 6Dhamar Hanania Ashari100% (1)

- Colibri - DEMSU P01 PDFDokument15 SeitenColibri - DEMSU P01 PDFRahul Solanki100% (4)

- 14 CE Chapter 14 - Developing Pricing StrategiesDokument34 Seiten14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalNoch keine Bewertungen

- Spine Beam - SCHEME 4Dokument28 SeitenSpine Beam - SCHEME 4Edi ObrayanNoch keine Bewertungen

- Company Law Handout 3Dokument10 SeitenCompany Law Handout 3nicoleclleeNoch keine Bewertungen