Beruflich Dokumente

Kultur Dokumente

DHSL-05 en

Hochgeladen von

Neagu LaurentiuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DHSL-05 en

Hochgeladen von

Neagu LaurentiuCopyright:

Verfügbare Formate

Linear gantries

Movements in 2D: a linear gantry consists of a gantry axis and a yoke drive. High mechanical rigidity and sturdy design Pneumatic and electrical components freely combinable As electrical solution variable positioning/any desired intermediate positions Range of application: Ideal for long gantry strokes Often used for feeding applications Workpiece masses up to 5 kg (effective load up to 10 kg) Long gantry strokes up to 3 m and heavy loads up to 10 kg High requirements on system resistance to torsion

Example: construction materials industry Handling, palletising and packing of ceramic tiles

Requirements High dynamic response Gentle acceleration and braking Jerk-free movement Good positioning flexibility Solution Linear gantry with toothed belt axes and cantilever axis Complete solution, including vacuum gripper

12

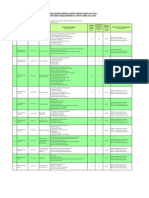

Handling system overview Subject to change 2009/09

Type

Important characteristics

Axis design Y: Gantry axes Z: Slide Cantilever axis

Effective load Max. effective strokes Components

Linear gantry High process reliability thanks as mono axis to installation integration Free movement Pneumatic and electric drives of the Z-axis (with freely programmable in the vertical positions) plane (2D) Repetition-accurate, centralised direct axis connections Mini slide on the Z-axis for maximum precision See above See above, points 1 3 Pneumatic cantilever axis on the Z-axis with high repetition accuracy, high dynamic response and intermediate positions See above See above, points 1 3 Pneumatic handling axis on the Z-axis with high rigidity and intermediate positions

Mono: 0 to 6 kg

Y: Up to 5000 mm Z: Up to 300 mm

Y: DGC/EGC Z: DGSL EGSA

Y: Gantry axes Z: Handling axis

Mono: 0 to 5 kg

Y: Up to 5000 mm Z: Up to 200 mm

Y: DGC/EGC Z: HMPL

Y: Gantry axes Z: Handling axis

Mono: Y: 0 to 10 kg* Up to 5000 mm Z: Up to 400 mm

Y: DGC/EGC Z: HMP

See above, points 1 3 Linear gantry as mono or Electric cantilever axis on the duo axis Z-axis for large strokes, high Free movement dynamic response and low of the Z-axis in moving dead weight the vertical plane (2D) Higher effective loads of up to 50 kg on request

Y: Gantry axes Z: Cantilever axis

Mono: 0 to 15 kg Duo: 0 ... 25 kg

Y: Up to 5000 mm Z: Up to 900 mm

Y: DGC/EGC Z: DGEA

* With the pneumatic drive DGC, can be used as duo axis

2009/09 Subject to change Handling system overview

13

Standard linear gantry LP 0.5

Effective load up to 0.5 kg

Motor controller package on electric axes Servo motor: EMMS-AS Controller: CMMS/P-AS (CMMD)

Technical data Stroke/mm Z-axis P Y-axis ZR P 1xEGC-50-TB-KF 1x DGC-12-KF 0 1900 0 1900 Any 0.08 0.02* 0.08 DGSL-8 0 100 Intermed. position Repetition accuracy/mm End position 0.01** Intermediate position

* With shock absorber YSR/YSRW ** With cushioning P1/Y3 Grey shading: drive components in the illustration

14

Handling Guide Subject to change 2010/2011

Reference for cycle times Note

Selection matrix Types of handling units

Cycle time [s]

Z-axis

0,6 0,5 0,4 0,3 DGSL-8 0,2 0,1 0,0 0 20 40

Stroke [mm]

Pages 6 to 9 Handling components Page 95 Gripping/rotating Adaptation options

60 80 100

Page 71 Control cabinets Page 92

Y-axis

4,0 3,5

Cycle time [s]

Frames Page 78 CAD drawings/ CAD hotline 2D and 3D drawings

EGC-50 DGC-12-KF

3,0 2,5 2,0 1,5

Tel. +49 (0)711 347-4667 Individual project engineering and cycle time

1,0

0,5 0,0 0 200 400 600 800 1000 1200

calculation Tel. +49 (0)711 347-4381 Fax enquiry Form Page 101

Stroke [mm]

Note An operating pressure of 6 bar is assumed for all the pneumatic drives shown here.

2010/2011 Subject to change Handling Guide

15

Overview of Festo control products

FED-CEC CPX terminal

Integrated controller FED-CEC

CoDeSys controller CPX-CEC-C1

Motion controller CPX-CEC-M1

FED-CEC

FED

CAN-Bus

CAN-Bus

CAN-Bus

SFC-DC MTR-DCI CMMx

CMMx

SFC-DC MTR-DCI CMMx

Single axis (point-to-point asynchronous) Maximum number Recommended: 8 axes Note: one axis is treated as a of possible axes CANopen node. 128 nodes are possible (as defined by CANopen specifications).

C1: single axis M1: interpolation Recommended: 8 axes Note: one axis is treated as a CANopen node. 128 nodes are possible (as defined by CANopen specifications).

C1: single axis M1: interpolation Recommended: 8 axes Note: one axis is treated as a CANopen node. 128 nodes are possible (as defined by CANopen specifications).

Motion

Point-to-point asynchronous Every axis moves with its own pre-defined parameter The axes do not reach their end positions at the same time and the path is not defined 2.5D interpolation PLC Open Integrated controller in a display screen Function integration on the CPX valve platform

Special features

CNC editor DXF import Cam disk editor

Application examples

Handling systems Pick & place, palletising

Path control, bonding, cutting, handling, flying saw, cam disk

Programming environment

CoDeSys

CoDeSys

CoDeSys + Softmotion

2010/2011 Subject to change Handling Guide

81

Modular control

CMXR robotic controller Modular controller CECX-C1 Motion controller CECX-M1 CMXR-C1 (Basic) CMXR-C2 (Advanced)

FED FED TeachPanel

CAN-Bus

CAN-Bus

CAN-Bus

CAN-Bus

SFC-DC MTR-DCI CMMx

SFC-DC MTR-DCI CMMx

CMMx

CMMx

Single axis (point-to-point asynchronous)

Interpolation (2.5D)

Robotics (3D)

Robotics (3D)

Recommended: 8 axes Note: one axis is treated as a CANopen node. 128 nodes are possible (as defined by CANopen specifications).

Max. 6 interpolated axes, of which max. 3 basic axes and 1 orientation axis and max. 3 dependent auxiliary axes that are interpolated together with the kinematics system. Additional single axes (not interpolated together with others) can be controlled via the integrated CoDeSys PLC. Recommended: 16 axes. 3D contour interpolation with an orientation axis for kinematics systems with up to 4 degrees of freedom. E.g. 3D gantry with an axis of rotation on the front end.

2.5D interpolation PLC Open Powerful PLC Encoder interface Interrupt function Fast clock pulse inputs Profibus master Two Canbus masters RS 232/ RS 485-A/422-A

CoDeSys control: point-to-point asynchronous Economical design and configuration with the Festo Configuration Tool (FCT) Simple programming of motions with Festo Teach Language (FTL), no specialist expertise required Optional teach pendant with 2-channel permission button Reduced speed in manual override mode Automatic repositioning when continuing interrupted motions Simple teaching of positions Definition of tools, allowing easy use of multiple grippers Real orientation axes on the front end Integrated kinematics models e.g. for Cartesian systems, tripod, H- and T-gantries

CNC editor DXF import Cam disk editor

Increased flexibility with the integrated CoDeSys PLC, e.g. for the integration of vision systems Tracking function for applications involving selecting items from a conveyor belt Speed-independent path switching points with time compensation, e.g. for bonding applications Complete automation of a cell is possible Tracking applications such as proHandling, palletising, bonding, metered dispensing, painting, cutting cessing of moving parts on a conveyor belt or synchronised kinematics movement with up to 6D Festo Teach Language (FTL) FTL + CoDeSys

Handling systems Pick & place, palletising

Path control, bonding, cutting, handling, flying saw, cam disk

CoDeSys

CoDeSys + Softmotion

82

Handling Guide Subject to change 2010/2011

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Rf-31 Mill Drill Manual GuideDokument2 SeitenRf-31 Mill Drill Manual GuideAhmad Krisna0% (1)

- CoCom Lists - 1991 MarchDokument100 SeitenCoCom Lists - 1991 MarchSamuel Evans100% (1)

- CNC Machine Safety RulesDokument6 SeitenCNC Machine Safety RuleskarthikkandaNoch keine Bewertungen

- Century Star CNC System Programming Guide For Milling Machines PDFDokument147 SeitenCentury Star CNC System Programming Guide For Milling Machines PDFDiego Steven Pulido AriasNoch keine Bewertungen

- 10 Series CNC OSAI Programming Manual (Rev 18 - 4457k)Dokument587 Seiten10 Series CNC OSAI Programming Manual (Rev 18 - 4457k)kwood94xjNoch keine Bewertungen

- B-64602en - 01 - 0if DescriptionsDokument416 SeitenB-64602en - 01 - 0if DescriptionsSergioNoch keine Bewertungen

- Plasma Arc Voltage Torch Height Controller: Operation Manual Vision 1404Dokument23 SeitenPlasma Arc Voltage Torch Height Controller: Operation Manual Vision 1404BoroDragovicNoch keine Bewertungen

- M64 RS-232 SetupDokument9 SeitenM64 RS-232 Setupsunhuynh67% (3)

- CNC MagDokument14 SeitenCNC MagraghavsaNoch keine Bewertungen

- Introduction to PowerMill Robot in Subtractive ManufacturingDokument20 SeitenIntroduction to PowerMill Robot in Subtractive ManufacturingGauravNoch keine Bewertungen

- Soft ServoDokument16 SeitenSoft ServotuanNoch keine Bewertungen

- Program CNC Lanjut-Kurniawan-5202421003Dokument47 SeitenProgram CNC Lanjut-Kurniawan-5202421003kurniawanofficial06Noch keine Bewertungen

- FAGOR General FeedbackDokument36 SeitenFAGOR General FeedbackPaun AlNoch keine Bewertungen

- Union e PDFDokument33 SeitenUnion e PDFGuillermo RamirezNoch keine Bewertungen

- NCSIMUL MACHINE CNC Machine VerificationDokument2 SeitenNCSIMUL MACHINE CNC Machine Verificationnnn766Noch keine Bewertungen

- Feed Drive Simulator: Ryuta SatoDokument2 SeitenFeed Drive Simulator: Ryuta SatoAmazingTransNoch keine Bewertungen

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDokument40 SeitenMachining Processes Used To Produce Round Shapes: Turning and Hole MakingAnonymous rYwUkp100% (1)

- NC & CNC MachinesDokument12 SeitenNC & CNC MachinesRenjith RajendraprasadNoch keine Bewertungen

- Mechanical Engineering Syllabus - B.tech - SRM UniversityDokument19 SeitenMechanical Engineering Syllabus - B.tech - SRM UniversityAditya MakineniNoch keine Bewertungen

- To Temporarily Remove A 4 Axis From A Vertical Machining CenterDokument1 SeiteTo Temporarily Remove A 4 Axis From A Vertical Machining CenterPham LongNoch keine Bewertungen

- Connor Jensen Mechanical Engineer ResumeDokument2 SeitenConnor Jensen Mechanical Engineer ResumeArth PatelNoch keine Bewertungen

- Short Term Courses Offered at Adtec Taiping 2014/2015Dokument2 SeitenShort Term Courses Offered at Adtec Taiping 2014/2015Safar BrolyNoch keine Bewertungen

- Turbocnc Driver PDFDokument3 SeitenTurbocnc Driver PDFElizabethNoch keine Bewertungen

- F-14-082 Vision Part Programming ManualDokument74 SeitenF-14-082 Vision Part Programming Manualgefelix vasquezNoch keine Bewertungen

- Kern Pyramid eDokument6 SeitenKern Pyramid ejacksonholland8335Noch keine Bewertungen

- Company Profile Pt. SSJDokument25 SeitenCompany Profile Pt. SSJoganuluNoch keine Bewertungen

- CTS Turner 2017 PDFDokument74 SeitenCTS Turner 2017 PDFgiti kalpiNoch keine Bewertungen

- Implant Training ReportDokument5 SeitenImplant Training ReportLogeshNoch keine Bewertungen

- APEM1 1 - 13 22 AIbased Cam:cncDokument10 SeitenAPEM1 1 - 13 22 AIbased Cam:cncTahir AbbasNoch keine Bewertungen

- COFMOW CompendiumDokument22 SeitenCOFMOW CompendiumRajiv Mahajan100% (1)