Beruflich Dokumente

Kultur Dokumente

4 3 SS24 Panels

Hochgeladen von

mojeebmashalCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4 3 SS24 Panels

Hochgeladen von

mojeebmashalCopyright:

Verfügbare Formate

STEEL BUILDINGS

SS24

PANEL SPECIFICATIONS

PRODUCT NAME SS24 Roof system for new roofing or retrofit roofing. MANUFACTURER CBC Steel Buildings 1700 E. Louise Avenue Lathrop, CA 95330 Phone: 209-983-0910 PRODUCT DESCRIPTION Basic Use: For roofing new buildings or reroofing existing ones of any construction type. Specially designed roof panels are secured to the structural system with concealed clips. A mechanical seaming tool locks the seam securely to insure against leaks. Sliding clips provide for thermal expansion along the slope. SS24 panels have 2" high (3" high with seam) by 4-3/4" wide ribs on 24" centers. Net width coverage of each panel is 2', and panels are available in standard lengths up to 45'. Longer lengths are available upon request. Materials: SS24 panels are 24 or 22 gage 50,000 psi steel. Exterior finish is either AZ50 aluminum-zinc alloy-coated, pre-painted G90 zinc-coated (galvanized) or pre-painted AZ50 aluminum-zinc alloy-coated. Pre-painted panels have CBCs Premier Pacific Kynar 500 Finish. The SS24 clip is a two part assembly. The tab portions are 2-1/2" wide, die formed of SAE 1050 high carbon spring steel and heat treated to Rockwell 45C to 50C with fluorocarbon coating for corrosion resistance, or 301 stainless steel. The base portion of the clip is 2-1/4" or 3-1/4" (for thermal blocks) in height. It is die formed from 12 gage, zinc-coated (galvanized) steel. Total expansion capability of the clip assembly is 2-1/2". SS24 sidelaps have factory applied mastic, Sika Sika Caulk 501 or equal. Its composition is 91% solids by weight. Service temperature range is -60F to +250F. The material meets or surpasses requirements of Federal Specification TT-C-1796A, Type I, Class A. Endlaps, roof flashing laps, ridges and eave closures are sealed with tape mastic, Sika Sika Tape TC-95 or equal. The material is non-staining, non-corrosive, non-toxic and non-volatile. Composition is 100% solid ethylene propylene copolymer tape. Service temperature is -60F to +212F. The material meets or surpasses Federal Specification TTC-1796A, Type II, Class B. Caulk: Eaves, endlaps, ridge and eave closures are sealed with non-skinning butyl caulk, Sika, Sika Caulk 501 or equal. Its composition is 91% solids by weight. Service temperature range is -60F to +250F. The material meets or surpasses requirements of Federal Specification TT-C-1796A, Type I, Class A. All gutter and downspout joints, and roof accessories are sealed with polyurethane caulk, Sika SikaFlex 219LM or equal. It meets or surpasses Federal Specification TT-S00230C, Type II, Class A. SS24 roof panel fasteners shall be No. 12 x 1-1/4" selfdrilling carbon steel screws with an assembled EPDM bond seal washer hex head. SS24 panel clips are attached to the purlins with selfdrilling carbon steel No. 12 hex head, cadmium or zinc plated screws. TECHNICAL DATA The SS24 panel has received a Class 90 Wind Uplift rating by Underwriters Laboratories when tested in accordance with test procedure UL 580. This panel has also been tested in accordance with Air Infiltration, ASTM E1680 and Water Penetration, ASTM E1646. This panel has received a Class A fire rating when tested in accordance with test procedure ASTM E108. INSTALLATION Panels are joined at the sidelap with an interlocking seam standing one inch above the major rib. Panel sidelaps are seamed by a special mechanical seaming tool. Sidelap sealer is factory applied. Roof systems are installed by CBC Authorized Builders. Installation may be incorporated with a light gage structural system. AVAILABILITY For availability, contact Estimating Department CBC Steel Buildings Phone: 209-983-0910 WARRANTY Twenty-year material, and thirty five-year paint finish warranties are available. Twenty-year weathertightness warranties can be ordered. MAINTENANCE Only normal routine maintenance is required over the life of the panels.

STEEL BUILDINGS

SS24

PANEL SPECIFICATIONS

TECHNICAL SERVICES For information contact CBC Steel Buildings 1700 E. Louise Avenue Lathrop, CA 95330 Phone: 209-983-0910 PRODUCT NOTES A certain amount of waviness called "oilcanning" may exist in this panel. Minor waviness of the panel is not sufficient cause for rejection, because oilcanning does not affect the structural integrity of the panel. Standing Seam Panels in general are known for their tendency to rumble in high winds if insulation is not used. SS24 is no different. Under no circumstances should SS24 be used without blanket insulation between the panel and the purlin/bar joist. NOTE: R-19 maximum insulation suggested with Thermo Spacer. R-12 maximum insulation suggested without Thermo Spacer. CBC Steel Buildings reserves the right to revise all standard specifications and information.

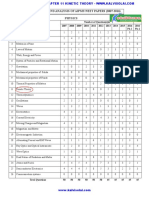

Engineering Properties of CBC's SS24 Panel Base Total Metal Thickness Thickness (Inches) (Inches) 0.0224 0.0242 0.030 0.0318 Panel Weight Square Ft. 1.20 1.59 Top In Compression Ix Sx In4/ft. In3/ft. 0.121 0.076 0.165 0.105 Bottom In Compression Ix Sx In4/ft. In3/ft. 0.122 0.077 0.178 0.107 Fb ksi

24 Gage 22 Gage

30 30

Maximum Total Uniform Load in PSF Number of Spans L = 3'-0" 3'-4" 4'-0" 4'-6" 5'-0" 1 169 137 95 75 61 24 Gage 2 171 139 96 76 62 Steel 3 214 173 120 95 77 4 200 162 112 89 72 1 233 189 131 104 84 22 Gage 2 238 193 134 106 86 Steel 3 297 241 167 132 107 4 278 225 156 123 100 1. Section properties have been calculated in accordance with the 1996 AISI specification for the design of cold-formed steel structural members. 2. Minimum yield strength of steel is 50,000 psi. 3. Steel panels are either aluminum-zinc alloy or G-90 coated. The base metal thickness shown is the minimum design thickness and was used in determining section properties. 4. For loads shown, deflections are less than L/150. 5. For wind loads the tabulated values can be multiplied by 1.33.

Das könnte Ihnen auch gefallen

- Experimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFDokument7 SeitenExperimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFmojeebmashalNoch keine Bewertungen

- Worktips 25 Geotextile Reinforced Sprayed SealsDokument2 SeitenWorktips 25 Geotextile Reinforced Sprayed SealsmojeebmashalNoch keine Bewertungen

- Effect of GeotextileDokument10 SeitenEffect of GeotextileHendra SaputraNoch keine Bewertungen

- Technical Note TN 014 Geotextile Reinforced SealsDokument4 SeitenTechnical Note TN 014 Geotextile Reinforced SealsmojeebmashalNoch keine Bewertungen

- Functions and Installation of Paving Geosynthetics: S.K. ShuklaDokument8 SeitenFunctions and Installation of Paving Geosynthetics: S.K. ShuklamojeebmashalNoch keine Bewertungen

- Chapter Forty-Six Pavement Rehabilitation: Bureau of Local Roads and Streets ManualDokument60 SeitenChapter Forty-Six Pavement Rehabilitation: Bureau of Local Roads and Streets ManualmojeebmashalNoch keine Bewertungen

- Technical Note TN 014 Geotextile Reinforced SealsDokument4 SeitenTechnical Note TN 014 Geotextile Reinforced SealsmojeebmashalNoch keine Bewertungen

- Effective Maintenance Using Geotextile Reinforced Spray SealsDokument11 SeitenEffective Maintenance Using Geotextile Reinforced Spray SealsmojeebmashalNoch keine Bewertungen

- Functions and Installation of Paving Geosynthetics: S.K. ShuklaDokument8 SeitenFunctions and Installation of Paving Geosynthetics: S.K. ShuklamojeebmashalNoch keine Bewertungen

- Technical Note TN 014 Geotextile Reinforced SealsDokument4 SeitenTechnical Note TN 014 Geotextile Reinforced SealsmojeebmashalNoch keine Bewertungen

- Effective Maintenance Using Geotextile Reinforced Spray SealsDokument11 SeitenEffective Maintenance Using Geotextile Reinforced Spray SealsmojeebmashalNoch keine Bewertungen

- Chapter Forty-Six Pavement Rehabilitation: Bureau of Local Roads and Streets ManualDokument60 SeitenChapter Forty-Six Pavement Rehabilitation: Bureau of Local Roads and Streets ManualmojeebmashalNoch keine Bewertungen

- 12pr PDFDokument2 Seiten12pr PDFAlban TabakuNoch keine Bewertungen

- Effective Maintenance Using Geotextile Reinforced Spray SealsDokument11 SeitenEffective Maintenance Using Geotextile Reinforced Spray SealsmojeebmashalNoch keine Bewertungen

- Correlation Between Soil Bearing Capacity and Modulus of Subgrade ReactionDokument5 SeitenCorrelation Between Soil Bearing Capacity and Modulus of Subgrade ReactionCristian Camilo Londoño PiedrahítaNoch keine Bewertungen

- Guide to Jointed Plain Concrete Pavement ConstructionDokument10 SeitenGuide to Jointed Plain Concrete Pavement ConstructionmojeebmashalNoch keine Bewertungen

- Effective Maintenance Using Geotextile Reinforced Spray SealsDokument11 SeitenEffective Maintenance Using Geotextile Reinforced Spray SealsmojeebmashalNoch keine Bewertungen

- Retrofitting of Existing RCC Buildings BDokument25 SeitenRetrofitting of Existing RCC Buildings BAhetesham Uddin Ahmed TipuNoch keine Bewertungen

- Ahsanullah University of Science & Technology Dept. of Civil EngineeringDokument14 SeitenAhsanullah University of Science & Technology Dept. of Civil EngineeringmojeebmashalNoch keine Bewertungen

- Correlation Between Soil Bearing Capacity and Modulus of Subgrade ReactionDokument5 SeitenCorrelation Between Soil Bearing Capacity and Modulus of Subgrade ReactionCristian Camilo Londoño PiedrahítaNoch keine Bewertungen

- Joints in Pavements PDFDokument2 SeitenJoints in Pavements PDFmojeebmashalNoch keine Bewertungen

- Factors that determine time for cold joints in concrete and treatment methodsDokument1 SeiteFactors that determine time for cold joints in concrete and treatment methodsmojeebmashalNoch keine Bewertungen

- Mathcad Worksheet 4Dokument8 SeitenMathcad Worksheet 4Ryan Negreanu RajmoolieNoch keine Bewertungen

- Hot - Weather Creaton 2Dokument7 SeitenHot - Weather Creaton 2Pankaj PriyadarshiNoch keine Bewertungen

- 12pr PDFDokument2 Seiten12pr PDFAlban TabakuNoch keine Bewertungen

- Mathcad - Graphing Summing ArraysDokument3 SeitenMathcad - Graphing Summing ArraysmojeebmashalNoch keine Bewertungen

- Mcad 1Dokument2 SeitenMcad 1Tang B. LinNoch keine Bewertungen

- Intro LabDokument3 SeitenIntro LabmojeebmashalNoch keine Bewertungen

- Mathcad - Graphing Summing ArraysDokument3 SeitenMathcad - Graphing Summing ArraysmojeebmashalNoch keine Bewertungen

- Mcad 1Dokument2 SeitenMcad 1Tang B. LinNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sciences An Integrated Approach 8th Edition by James Trefil Ebook PDFDokument41 SeitenThe Sciences An Integrated Approach 8th Edition by James Trefil Ebook PDFcrystal.wright360100% (32)

- القطعDokument11 Seitenالقطعcam spiderNoch keine Bewertungen

- Grade 12 FT Sample Paper 2 QPDokument13 SeitenGrade 12 FT Sample Paper 2 QPsafaaNoch keine Bewertungen

- Hydro TestDokument11 SeitenHydro TestSachinNoch keine Bewertungen

- Alternate Mekton Zeta Weapon CreationDokument7 SeitenAlternate Mekton Zeta Weapon CreationJavi BuenoNoch keine Bewertungen

- ColorimetryDokument21 SeitenColorimetryM.PRASAD NAIDUNoch keine Bewertungen

- Electronic Controls in KnittingDokument20 SeitenElectronic Controls in KnittingProfessorTextechNoch keine Bewertungen

- Visual Function ExperimentDokument3 SeitenVisual Function Experimentim. EliasNoch keine Bewertungen

- Dwss Part1 Basics of HydraulicsDokument97 SeitenDwss Part1 Basics of HydraulicsGJ CCNoch keine Bewertungen

- Class 6 Assignment 15 2022-23Dokument27 SeitenClass 6 Assignment 15 2022-23Debaprasad MukherjeeNoch keine Bewertungen

- Laser Welding Steel Wheel RimsDokument5 SeitenLaser Welding Steel Wheel RimsSamanthaPereraNoch keine Bewertungen

- # 1. Neet 2017 - Physics - Chapter 11 Kinetic TheoryDokument19 Seiten# 1. Neet 2017 - Physics - Chapter 11 Kinetic TheoryTamilaruviNoch keine Bewertungen

- Light Weight ConcreteDokument15 SeitenLight Weight ConcreteGia 2k17Noch keine Bewertungen

- Nissin Di700 ManualDokument24 SeitenNissin Di700 ManualVladimir TodorovićNoch keine Bewertungen

- 271 Introduction To Process Control Course PreviewDokument17 Seiten271 Introduction To Process Control Course PreviewAdrian Reyes0% (1)

- LF Solar Panels Datasheet - July 2022 - Preview FileDokument9 SeitenLF Solar Panels Datasheet - July 2022 - Preview FileMayur HiwarkarNoch keine Bewertungen

- Uranium Mining in Tanzania - Are We ReadyDokument31 SeitenUranium Mining in Tanzania - Are We ReadyStephen MsechuNoch keine Bewertungen

- Emulsifiers!: Prof. Abd Karim Alias Universiti Sains MalaysiaDokument9 SeitenEmulsifiers!: Prof. Abd Karim Alias Universiti Sains MalaysiaKhaled Abu-AlruzNoch keine Bewertungen

- JEE Main Sample Paper 5Dokument13 SeitenJEE Main Sample Paper 5SK.KaleshaNoch keine Bewertungen

- Telescope Design 1Dokument6 SeitenTelescope Design 1JimNoch keine Bewertungen

- Catalog 2011Dokument84 SeitenCatalog 2011Marlou RabinaNoch keine Bewertungen

- Ductile LinkDokument19 SeitenDuctile LinksuvraNoch keine Bewertungen

- CR Modulation TheoryDokument78 SeitenCR Modulation Theory_the_bridge_Noch keine Bewertungen

- Tolc I Sinavi Ornek SorulariDokument50 SeitenTolc I Sinavi Ornek SorulariborabasmaciNoch keine Bewertungen

- Theory of Hydraulic ModelsDokument283 SeitenTheory of Hydraulic ModelsEdward Julian Sanchez TrujilloNoch keine Bewertungen

- Converters and InterfacesDokument140 SeitenConverters and InterfacesMartin LundeenNoch keine Bewertungen

- Exclusive or InclusiveDokument30 SeitenExclusive or InclusiveMary Christine IgnacioNoch keine Bewertungen

- Smart ValveDokument4 SeitenSmart ValveCoordinadorIngNoch keine Bewertungen

- Coulombs Law Worksheet Answers3Dokument2 SeitenCoulombs Law Worksheet Answers3Jack Daniel CandelarioNoch keine Bewertungen

- Vert Heater TreaterDokument2 SeitenVert Heater TreaterJaveed KhanNoch keine Bewertungen