Beruflich Dokumente

Kultur Dokumente

Unit II Hydro Electric Power Plants

Hochgeladen von

karthikeyanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Unit II Hydro Electric Power Plants

Hochgeladen von

karthikeyanCopyright:

Verfügbare Formate

UNIT II

HYDRO ELECTRIC POWER PLANTS

UNIT II

Unit II Course material

EE1252-POWER PLANT ENGINEERING UNIT II HYDRO ELECTRIC POWER PLANTS

N.KARTHIKEYAN

Layout Dams Selection of water turbines Types Pumped storage hydel plants.

Hydraulic Power Plants Rainwater which falls over the earths surface possesses potential energy in relation to mean sea level. This energy can be converted into mechanical energy and finally to electric energy. The development of power from flowing water depends on the volume of flow and the differential pressure. The branch of science which discusses these aspects is known as hydrology. The rainfall, flow of water and evaporation forms a cycle known as hydrological cycle.

Depending on the capacity, hydel power plants are divided into the following categories:

Hydrological Cycle Hydel power is a renewable source of energy which is the cheapest form of energy available in the world. Hydel power is superior to any other power source, because of their long plant life, low operating cost and pollution free nature. Other factors like renewability and utilization of discharge for irrigation purpose made it a superior energy source where it is environmentally feasible.

Power = W.Q.H. watts. Where W = Specific weight of water, N/m3 Q = rate of water flow, m3/sec. H = Height of fall or head, m = efficiency of conversion of potential energy into mechanical energy.

1

UNIT II

HYDRO ELECTRIC POWER PLANTS

Hydro projects are developed for the following purposes:

1. 2. 3. 4. To control the floods in the rivers. Generation of power. Storage of irrigation water. Storage of the drinking water supply.

Advantages of hydraulic power plants

1. Operating cost is very low, 2. Less Maintenance cost and less manpower required, 3. Pollution free 4. Quick to start and easy to synchronize, 5. Part load efficiency is very high, 6. Can be used for irrigation and flood control, 7. Long plant life.

Disadvantages of Hydraulic Power Plants

1. 2. 3. 4. Initial cost of total plant is comparatively high Power generation depends on availability of water Cost of transmission is high since most of the plants are in remote areas Project duration is long.

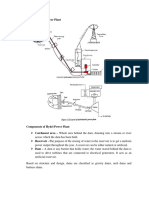

General layout of Hydro-Power Plant

A hydro power plant the energy of water is utilized for power generation may Kinetic or potential. The general layout of a hydro electric power plant is given in figure. The main

2

UNIT II

HYDRO ELECTRIC POWER PLANTS

components of a hydro plant include the storage reservoir, dam, penstock, surge tank, turbines, generator and transformers. a) Reservoir

Reservoirs ensure supply of water throughout the year, by storing water during rainy season and supplying the same during dry season. b) Dam

The function of the dam is to increase the reservoir capacity and to increase the working head of the turbine. c) Penstock

A pipe between dam and turbine is known as penstock. It will carry the water from dam to turbine. Penstock is commonly made of steel pipes covered with RCC. d) Surge tank

When the rate of water flow through the penstock is suddenly decreased, the pressure inside the penstock will increase suddenly due to water hammer and thereby damage the penstock. Surge tank is constructed between the dam and turbine. It will act as a pressure regulator during variable loads. e) Turbine/Prime Mover

Turbines convert the kinetic and potential energy of water into mechanical energy to produce electric power. Major types of turbines used in hydro power stations are a. Pelton wheel b. Francis turbine c. Kaplan turbine Low discharge, high head Medium discharge, Medium head High discharge, Low head.

(Head is the elevation difference of reservoir water level and downstream water level, and discharge is the volume flow of water per unit time) f) Generator and Transformer Electric generator converts mechanical energy into electrical energy. A step up transformer will increase the voltage for loss free transmission.

UNIT II

HYDRO ELECTRIC POWER PLANTS

Turbine

The turbine is a device which converts the hydraulic power from the water to rotating mechanical energy. There are several turbines that have been developed for specific purposes. Turbines are classified into 1. Impulse turbines for high heads. 2. Reaction turbines for low heads. 3. Submersible propeller turbines. Some of the turbines are Elton, cross flow, turbo, Francis, Harris etc.

Generator

Generally, induction generators and synchronous generators are used to produce the power. Induction generators are especially suited for providing electricity in remote areas because they are rugged and reliable. However, synchronous generators and dc generators have also been used for some applications. The three phase induction motors can be used as generators. These are easily available and quite inexpensive. For most home applications, a single phase supply is required. It is required to produce a single phase supply from a three phase motor. This is done by connecting unequal amounts of excitation capacitance across the windings of the machine.

Load Control

The speed of the turbine changes when the load connected to the generator changes. Since this change of speed affects the voltage and frequency, the load on the generator must be kept constant or the flow of water through the nozzle must be adjusted. The most reliable method of controlling the load and keeping the voltage and frequency constant is by using an electronic load controller. The unused power of the induction generator is sent to a ballast or

4

UNIT II

HYDRO ELECTRIC POWER PLANTS

dummy load so that the total load on the generator remains constant. For example if the generator produces 1000W and the total load connected is 700W, then the remaining 300W will be dissipated in the ballast load.

RUN OFF

Rain fall (used in a general sense) or precipitation may be defined as the total condensation of moisture that reaches the earth in any form. It includes all forms of rains, ice, snow, hail or sleet etc. Evaporation represents practically that entire portion of the rainfall that does not reach the point of ultimate use as stream flow. So, evaporation includes all the rainfall that is returned to the atmosphere from land and water surfaces. Thus total evaporation is: 1. Evaporation from land and water surfaces. 2. Evaporation by transpiration which is the vaporization of water from the breathing pores of vegetable matter. 3. Atmospheric evaporation (evaporation while precipitation is falling). Rain-fall is measured in terms of centimetres of water over a given area and over a given period (usually one year). The portion of the total precipitation that flows through the catchment area is known as Run-off. The catchment area of a hydro site is the total area behind the dam, draining water into the reservoir. Thus, Run-off = Total precipitation Total evaporation Part of the precipitation is absorbed by the soil and seeps or percolates into ground and will ultimately reach the catchment area through the underground channels. Thus. Total run-off = Direct run off over the land surface T Run-off through seepage. The unit of run-off are m3/s or day-second meter. Day-second meter = Discharge collected in the catchment area at the rate of 1 in 3/S for one day = 1 24 3600 = 86400 m3/day. The flow of run-off can also be expressed in cms. of water on the drainage area feeding the river site for a stated period, or km, cm of water per unit of time. Factors Affecting Runoff 1. Nature of Precipitation. Short, hard showers may produce relatively little run-off. Rains lasting a longer time results in larger run-off. The soil tends to become saturated and the rate of seepage decreases. Also, the humid atmosphere lowers evaporation, resulting in increased run-off. 2. Topography of Catchments Area. Steep, impervious areas will produce large percentage of total run-off. The water will flow quickly and absorption and evaporation losses will be small.

5

UNIT II

HYDRO ELECTRIC POWER PLANTS

3. Geology of Area. The run-off is very much affected by the types of surface soil and subsoil, type of rocks etc. Rocky areas will give more run-off while pervious soil and sub-soil and soft and sandy area will give lesser run-off. 4. Meteorology. Evaporation varies with temperature, wind velocity and relative humidity. Runoff increases with low temperature, low wind velocity and high relative humidity and vice versa. 5. Vegetation. Evaporation and seepage are increased by cultivation. Cultivation opens and roughens the hard, smooth surface and promotes seepage. Thick vegetation like forests consumes a portion of the rain fall and also acts as obstruction for run-off. 6. Size and Shape of Area. Large areas will give more run-off. A wide area like a fan will give greater run-off; whereas, a narrow area like a leaf will give lesser run-off. In an area whose length is more than its width, the flow along its width will give more run-off than if the flow is along its length, since in the former case, seepage and evaporation will be less. SELECTION OF SITE FOR A HYDRO-ELECTRIC POWER PLANT While selecting a suitable site, if a good system of natural storage lakes at high altitudes and with large catchment areas can be located, the plant will be comparatively economical. Anyhow the essential characteristics of a good site are: large catchment areas, high average rainfall and a favourable place for constructing the storage or reservoir. The following factors should be given careful consideration while selecting a site for a hydroelectric power plant: 1. Water Available. To know the available energy from a given stream or river, the discharge flowing and its variation with time over a number of years must be known. Preferably, the estimates of the average quantity of water available should be prepared on the basis of actual measurements of stream or river flow. The recorded observation should be taken over a number of years to know within reasonable, limits the maximum and minimum variations from the average discharge. the river flow data should be based on daily, weekly, monthly and yearly flow ever a number of years. Then the curves or graphs can be plotted between tile river flow and time. These are known as hygrographs and flow duration curves. The plant capacity and the estimated output as well as the need for storage will be governed by the average flow. The primary or dependable power which is available at all times when energy is needed will depend upon the minimum flow. Such conditions may also fix the capacity of the standby plant. The, maximum of flood flow governs the size of the headwords and dam to be built with adequate spillway. 2. Water-Storage. As already discussed, the output of a hydropower plant is not uniform due to wide variations of rain fall. To have a uniform power output, a water storage is needed so that excess flow at certain times may be stored to make it available at the times of low flow. To select the site of the dam ; careful study should be made of the geology and topography of the catchment area to see if the natural foundations could be found and put to the best use. 3. Head of Water. The level of water in the reservoir for a proposed plant should always be within limits throughout the year. 4. Distance from Load Centre. Most of the time the electric power generated in a hydroelectric power plant has to be used some considerable distance from the site of plant. For this reason, to be economical on transmission of electric power, the routes and the distances should be carefully considered since the cost of erection of transmission lines and their maintenance will depend upon the route selected.

6

UNIT II

HYDRO ELECTRIC POWER PLANTS

5. Access to Site. It is always a desirable factor to have a good access to the site of the plant. This factor is very important if the electric power generated is to be utilized at or near the plant site. The transport facilities must also be given due consideration.

RUN-OF-RIVER POWER PLANTS These plants can be classified as either without pondage or with pondage. A run-ofriver plant without pondage has no control over river flow and uses the water as it comes. These plants usually supply peak load. During floods, the tail water level may become excessive rendering the plant inoperative. A run-of-river plant with pondage may supply base load or peak load power. At times of high water flow it may be base loaded and during dry seasons it may be peak loaded. PUMPED STORAGE POWER PLANTS 1. These plants supply the peak load for the base load power plants and pump all or a portion of their own water supply. 2. The usual construction would be a tail water pond and a head water pond connected through a penstock. The generating pumping plant is at the lower end.

PUMPED STORAGE POWER PLANTS

3. During off peak hours, some of the surplus electric energy being generated by the base load plant is utilized to pump the water from tail water pond into the head water pond and this energy will be stored there. 4. During times of peak load, this energy will be released by allowing the water to flow from the head water pond through the water turbine of the pumped storage plant.

7

UNIT II

HYDRO ELECTRIC POWER PLANTS

5. These plants can be used with hydro, steam and i.e. engine plants. This plant is nothing but a hydraulic accumulator system and is shown in Fig. 6. These plants can have either vertical shaft arrangement or horizontal shaft arrangement. In the older plants, there were separate motor driven pumps and turbine driven generators. 7. The improvement was the pump and turbine on the same shaft with the electrical element acting as either generator or motor. The latest design is to use a Francis turbine which is just the reverse of centrifugal pump. 8. When the water flows through it from the head water pond it will act as a turbine and rotate the generator. 9. When rotated in the reverse direction by means of an electric motor, it will act as a pump to shunt the water from the tail water pond to the head water pond. 10. The efficiency of such a plant is never 100 per cent. Some water may evaporate from the head water pond resulting in the reduction in the stored energy or there might be run off through the soil. PRIME-MOVERS OR TURBINES, HYDRAULIC TURBINES

The prime-mover in the hydraulic power plant converts the energy of water into mechanical energy and further into electrical energy. These machines are classified on the basis of the action of water and moving blades. As per the action of water on the prime-mover, they are classified as impulse turbine and reaction turbine. IMPULSE TURBINE 1. In impulse type turbine, the pressure energy of the water is converted into kinetic energy when passed through the nozzle and forms the high velocity jet of water. 2. The formed water jet is used for driving the wheel. 3. The casing of the impulse turbine operates at atmospheric pressure. REACTION TURBINE 1. In case of reaction turbine, the water pressure combined with the velocity works on the runner. 2. The power in this turbine is developed from the combined action of pressure and velocity of water that completely fills the runner and water passage. 3. The casing of the reaction turbine operates under high pressure. Types of turbines

1. Pelton Turbine. 2. Francis Turbine. 3. Kaplan Turbine. 1. PELTON TURBINE.

1. Figure shows the layout of the Pelton turbine. This was discovered by Pelton in 1880. 2. This is a special type of axial flow impulse turbine generally mounted on horizontal shaft. A number of buckets are mounted round the periphery of the wheel as shown in Fig. 3. The water is directed towards the wheel through a nozzle or nozzles. The flow of water through the nozzle is generally controlled by special regulating system. 4. The water jet after impinging on the buckets is deflected through an angle of 160 and flows axially in both directions thus avoiding the axial thrust on the wheel. 5. The hydraulic efficiency of Peltan wheel lies between 85 to 95%. Now-a-days, Pelton wheels are used for very high heads upto 2000 meters.

UNIT II

HYDRO ELECTRIC POWER PLANTS

UNIT II

HYDRO ELECTRIC POWER PLANTS

Arrangement of jets. 1. In most of the Pelton wheel plants, single jet with horizontal shaft is used. The number of the jets adopted depends upon the specific speed required. 2. Any impulse turbine achieves its maximum efficiency when the velocity of the bucket at the centre line of the jet is slightly under half the jet velocity. 3. Hence, for maximum speed of rotation, the mean diameter of the runner should be as small as possible. There is a limit to the size of the jet which can be applied to any impulse turbine runner without seriously reducing the efficiency. 4. In early twenties, a normal ratio of D/d was about 10: I. In a modern Turbo impulse turbine, it is reduced up to 4.5: I. 5. The basic advantage of Turbo impulse turbine is that a much larger jet could be applied to a runner of a given mean diameter. 6. The jet of pelton turbine strikes the splitter edge of the bucket, bifurcates and is discharged at either side. 7. With the turbo impulse turbine, the jet is set at an angle to face the runner, strikes the buckets at the front arid discharges at opposite side. 8. The basic difference between the two is shown in Fig. The Turbo impulse turbine bridges the gap of specific speed between the Pelton wheel and Francis turbine. 9. Two turbo impulse turbines are used in a power house at Poonch which is 320 km from Jalnmu. The reaction turbines are further divided into two general types as Francis and Propeller Type. 10. The propeller turbines are further subdivided into fixed blade propeller type and the adjustable blade type as Kaplan Turbine.

2. FRANCIS TURBINE

In Francis turbine, the water enters into a casing with a relatively low velocity, passes through guide vanes located around the circumference and flows through the runner and finally discharges into a draft tube sealed below the tail water level. The water passage from the headrace to tail race is completely filled with water which acts upon the whole circumference of the runner. Two types of Francis turbines i. open flume type

10

UNIT II

HYDRO ELECTRIC POWER PLANTS

ii. closed type

Open flume type

In open flume type, the turbine is immersed under water of the headrace in a concrete chamber and discharges into the tailrace through the draft tube. The main disadvantage of this type is that runner and guide-vane mechanism is under the water and they are not open either for inspection or repair without draining the chamber.

Closed type

In the closed type, the water is led to the turbine through the penstock whose end is connected to the spiral casing of the turbine. The open flume type is used for the plants of 10 meters head whereas; closed type is preferred above 30 meters head. The guide vanes are provided around the runner to regulate the water flowing through the turbine The guide vanes provide gradually decreasing area of flow for all gate openings, so that no eddies are formed, and efficiency does not suffer much even at part load conditions. The majority of the Francis turbines are inward radial flow type and most preferred for medium heads. The inward flow turbine has many advantages over outward flow turbine as listed below: 1. The chances of eddy formation and pressure loss are reduced as the area of flow becomes gradually convergent.

11

UNIT II

HYDRO ELECTRIC POWER PLANTS

2. The runaway speed of the turbine is automatically checked as the centrifugal force acts outwards while the flow is inward. 3. The guide vanes can be located on the outer periphery of the runner; therefore, better regulation is possible. 4. The frictional losses are less as the water velocity over the vanes is reduced. 5. The inward flow turbine can be used for fairly high heads without increasing the speed of the turbine as centrifugal head supports considerable part of supply head.

3. KAPLAN TURBINE.

Great strides are made in last few decades to improve the performance of propeller turbine at part load conditions. The Kaplan turbine is a propeller type having a movable blade instead of fixed one. This turbine was introduced by Dr. Vitkor Kaplan. This turbine has attained popularity and rapid progress has been made in recent years in the design and construction of this turbine:

1. The rotor of the Kaplan turbine is shown in Fig. The blades are rotated to the most efficient angle by a hydraulic servo-motor. 2. A cam on the governor is used to change the blade angle with the gate position so that high efficiency is always obtained at almost any percentage of full loads. 3. These turbines are constructed to run at speeds varying from 60 to 220 r.p.m. and to work under varying head from 2 to 60 meters. 4. These are particularly suitable for variable heads and for variable flows and where the ample quantity of water is available.

12

UNIT II

HYDRO ELECTRIC POWER PLANTS

5. The specific speed of Kaplan lies in the range of 400 to 1500 so that the speed of the rotor is 6. much higher than that of Francis Turbine for the same output and head or Kaplan turbine having the same size as Francis develops more power under the same head and flow quantity. 7. The velocity of water flowing through Kaplan turbine is high as the flow is large and, therefore, the cavitation is more serious problem in Kaplan than Francis Turbine. 8. The propeller type turbines have an outstanding advantage of higher speed which results in lower cost of runner, generator and smaller power house substructure and superstructure. 9. The capital and maintenance cost of Kaplan turbine is much higher than fixed blade propeller type units operated at a point of maximum efficiency. 10. For a low head development with fairly constant head and requiring a number of units, it is always advisable to install fixed blade propeller type runners for most of them and Kaplan type for only one or two units. 11. With this combination, the fixed blade units could be operated at point of maximum efficiency and Kaplan units could take the required variations in load. 12. Such combination is particularly suitable to a large power system containing a multiplicity of the units.

Cavitation and Limitation of Turbine Height above Tailrace Level.

1. The formation of water vapour and air bubbles on the water surface due to the reduction of pressure is known as "Capitation". 2. When the pressure on the water reduces below the saturation pressure corresponding to the temperature of the water, the rapid formation of water vapour and air bubbles starts. 3. The bubbles suddenly collapse with the violent action and collapsing pressure will be very high. 4. The rapid formation and collapsing of the bubbles causes the pitting of the metallic surface. 5. It also reduces the efficiency of the hydraulic prime mover causing honeycombing of runner and blade contours which reduces the power output. METHODS TO AVOID CAVITATION Installation of Turbine below Tailrace Level. 1. The danger of cavitations increases in case of low head and high speed propeller runner as the value of (V02 Vd2)/g is considerably large as mentioned earlier. 2. In order to keep the value of pc within the cavitation limit, the value of h is made negative keeping the runner below tailrace level. 3. For such installations, the turbines remain always under water. It is riot advisable as the inspection and repair of the turbine is difficult. 4. The other method to avoid cavitation zone without keeping the runner under water is to use the runner of low specific speed as mentioned earlier.

Cavitation Free Runner.

13

UNIT II

HYDRO ELECTRIC POWER PLANTS

1. The cavitation free runner can be designed to fulfill the given conditions with extensive research. 2. The shape of the blade, the angle of the blade, the thickness of the blade can be changed and experiments can be conducted to find out the best dimensions of the blade (shape, size, angle. etc. Use of Material. 1. The cavitation effect can be reduced by selecting materials which can resist better the cavitation effect. 2. The cast steel is better than cast iron and stainless steel or alloy steel is still 3. better than cast steel. 4. The pitting effect of cavitation on cast steel can be repaired more economically by ordinary welding. 5. It has been observed that the welded parts are more resistant to cavitation than ordinary ones. Polishing. The cavitation effect is less on polished surfaces than ordinary one. Mat, is why the cast steel runners and blades are coated with stainless steel. UNDERGROUND POWER HOUSE. The conventional hydro-electric power stations are usually located over-ground at the foot of a dam or a hill slope on the banks of a river. The first underground power station Nerayaz was built in 1897 in Switzerland. The high capacity underground power plants were built only after Second World War. The idea of locating powerhouse underground was suggested not only with the intention of protecting them against air attack but also technical and economical considerations were mainly considered. After Second World War, the immunity against air attacks was unquestionably regarded as an important. Advantage-of underground power stations, a large number of underground power stations have been installed in U.K., U.S.A., Russia, Canada, and Japan after Second World War and recently in India also.

The considerations supporting the construction of underground power stations are stated below : 1. Non-availability of a suitable site for a conventional surface station and good slope for penstock. 2. Danger of falling rocks and snow avalanches particularly in narrow valleys. 3. Availability of underground sound rock and avoidance of a long pressure tunnel and facility 14

UNIT II

HYDRO ELECTRIC POWER PLANTS

for a convenient tail-race outlet. 4. Possibility of elimination of surge tank required for surface station due to long pressure tunnel 5. The rugged topographical features and the difficulties in finding a suitable short and steep slope for pipe lines make it more economical to install the water conduit, the machine, and transformer hall and tailrace system underground. 6. Foundation costs for over ground power house become excessive in case of poor quality surface layers.

ADVANTAGES 1. The reduced length of the pressure conduit reduced the pressures developed due to water hammer. Therefore, smaller surge tank is also sufficient. 2. For the economical arrangement, the ratio of the pressure conduit to the tail-race tunnel is also significant. The overall cost of the system is lower if the tail-race tunnel length is relatively large. 3. The construction work at underground power station can continue uninterrupted even under severest winter conditions. The overall construction cost and period of construction is reduced due to continuity of work. 4. The construction of underground conduit instead of penstock results in considerable saving in steel, the internal pressure is carried partly by the rock if it is of good quality. 5. Much care is devoted today in many countries to preserve landscape features such as picturesque rock walls, canyons, valleys and river banks in their original beauty against spoiling by exposed penstocks, canal basins and machine halls. 6. The regular maintenance and repair costs are lower for underground stations as the maintenance required for rock tunnels is less. 7. The power plant is free from landslides, avalanches, heavy snow and rainfall. 8. The useful life of the structures excavated in rock is considerably longer than that of concrete and reinforced concrete structures. 9. The construction period is reduced mainly due to the possibility of full-scale construction work in winter. DISADVANTAGES 1. The operational cost of the power plant increases due to following reasons : a) The lighting cost. b) The running cost of air-conditioned plant. c) The removal of water seeping may be more costly than for the surface arrangement.

2. The construction cost of the underground power house is more compared with the over ground power house: a) The excavation of the caverns required for housing the turbine generator units and auxiliary equipments (machine hall of Koyna project is $00 120 60in dimensions) is very expensive. b) The costs of access tunnels are considerable. c) The separate gallery excavated for the inlet valves adds the extra cost. d) The construction of air ducts and bus galleries also adds in total construction costs. e) Special ventilation and air-conditioning equipment required for underground adds in the constructional costs.

15

Das könnte Ihnen auch gefallen

- Polymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental ImpactsVon EverandPolymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental ImpactsSanjay Mavinkere RangappaNoch keine Bewertungen

- Demonstration of Hydro Power StationDokument5 SeitenDemonstration of Hydro Power Stationsmh khanNoch keine Bewertungen

- Performance Test of Mini-Hydroelectric Power PlantDokument8 SeitenPerformance Test of Mini-Hydroelectric Power PlantKram YnarNoch keine Bewertungen

- Steam Turbine Internal InspectionDokument8 SeitenSteam Turbine Internal InspectionVenkat DoraNoch keine Bewertungen

- Francis Turbine Formulas - enDokument10 SeitenFrancis Turbine Formulas - ensivakumar subramanianNoch keine Bewertungen

- Classification of Hydroelectric Power PlantsDokument6 SeitenClassification of Hydroelectric Power PlantsvenkatNoch keine Bewertungen

- "Maintenance Procedure For Hydro Power Plant": A Microproject OnDokument12 Seiten"Maintenance Procedure For Hydro Power Plant": A Microproject OnAnshul JangaleNoch keine Bewertungen

- Pump Hydro Storage PlantsDokument14 SeitenPump Hydro Storage PlantsRisa RianiNoch keine Bewertungen

- 02 Pumps, Turbines - Graphical Representation of BEEDokument27 Seiten02 Pumps, Turbines - Graphical Representation of BEEMatsu FerrerasNoch keine Bewertungen

- Procedimiento de Reparación TurbinaDokument4 SeitenProcedimiento de Reparación Turbinajaime huertasNoch keine Bewertungen

- AGR558 Lab Drip Irrigation SystemDokument3 SeitenAGR558 Lab Drip Irrigation SystemNoor Syazwan NasirNoch keine Bewertungen

- 4 MsDokument19 Seiten4 MsMaryrose VasquezNoch keine Bewertungen

- Advantages of High Speed BalancingDokument29 SeitenAdvantages of High Speed BalancingAkshayNoch keine Bewertungen

- Runner Casted-Vs-Microguss Wangdi DDokument0 SeitenRunner Casted-Vs-Microguss Wangdi DsapkotamonishNoch keine Bewertungen

- 10 Pump CalculationDokument4 Seiten10 Pump CalculationVivekka Olivia JohnNoch keine Bewertungen

- Test Plan Piano Di Collaudo: Stamp Reserved SpaceDokument4 SeitenTest Plan Piano Di Collaudo: Stamp Reserved SpaceJuan GaunaNoch keine Bewertungen

- National Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryDokument11 SeitenNational Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryBaishnaba KumbharNoch keine Bewertungen

- Membrance CleaningDokument23 SeitenMembrance CleaningsaaroomaniNoch keine Bewertungen

- 4 - Brochure Francis-TurbinesDokument5 Seiten4 - Brochure Francis-Turbinesmamok supraptoNoch keine Bewertungen

- 49 - Refurbishment of Eastern Cape Mini Hydro SchemesDokument17 Seiten49 - Refurbishment of Eastern Cape Mini Hydro Schemesskerminkel100% (1)

- Steam-Turbines 2 PDFDokument2 SeitenSteam-Turbines 2 PDFGaneshsikarwarNoch keine Bewertungen

- List of Hydroelectric Power Station FailuresDokument4 SeitenList of Hydroelectric Power Station FailuresFlorentina SuduNoch keine Bewertungen

- Alignment Technique - The Steam TurbineDokument2 SeitenAlignment Technique - The Steam TurbineRajeswar KulanjiNoch keine Bewertungen

- Abebe HandoutDokument113 SeitenAbebe HandoutFasika Tegegn100% (1)

- STR 3 2010 18 20 Romero en Low PDFDokument3 SeitenSTR 3 2010 18 20 Romero en Low PDFBradley Nelson100% (2)

- REYNOLDS NUMBER ENERGY LOSSES DUE TO FRICTION (Topic 4)Dokument25 SeitenREYNOLDS NUMBER ENERGY LOSSES DUE TO FRICTION (Topic 4)Gurlz Wawa100% (1)

- Effect of Alkali Treatment On The Mechanical Properties of Raffia Palm Fibres/Oil Bean Pod Shell Reinforced Epoxy Hybrid CompositeDokument6 SeitenEffect of Alkali Treatment On The Mechanical Properties of Raffia Palm Fibres/Oil Bean Pod Shell Reinforced Epoxy Hybrid CompositePremier PublishersNoch keine Bewertungen

- Damper Winding Influence On UMPDokument8 SeitenDamper Winding Influence On UMPSrinivas KamarsuNoch keine Bewertungen

- Hydro Power Calculation:: Power Head X Flow X GravityDokument2 SeitenHydro Power Calculation:: Power Head X Flow X GravityIzaz Rahman100% (1)

- Rainfall As An Energy SourceDokument3 SeitenRainfall As An Energy SourceSagar KumarNoch keine Bewertungen

- Generator Protection XZCDokument25 SeitenGenerator Protection XZCblaagica100% (1)

- Steam Turbines Generators PDFDokument13 SeitenSteam Turbines Generators PDFPrince ChaudharyNoch keine Bewertungen

- THYRIPOL Operating InstructionsDokument310 SeitenTHYRIPOL Operating InstructionsCristian VillalbaNoch keine Bewertungen

- Fluid Flow TerminologyDokument15 SeitenFluid Flow Terminologyboxe80Noch keine Bewertungen

- On Pelton Efficiency and CavitationDokument10 SeitenOn Pelton Efficiency and CavitationJohn RobinsonNoch keine Bewertungen

- Process Management of Membrane Filtration SystemsDokument2 SeitenProcess Management of Membrane Filtration SystemsNur Hazirah Sadon100% (1)

- Francis Turbine and Generator Machine Fo PDFDokument6 SeitenFrancis Turbine and Generator Machine Fo PDFAdarsh Kumar ManwalNoch keine Bewertungen

- Chapter3 1Dokument234 SeitenChapter3 1mspd2003Noch keine Bewertungen

- Maintenance Transformer at Pahlawan PowerDokument6 SeitenMaintenance Transformer at Pahlawan PowerSyer Khomainie Mohamad YakopNoch keine Bewertungen

- Steam TurbinesDokument76 SeitenSteam Turbinesgunawan eko wardoyo100% (1)

- NDTDokument9 SeitenNDTrajbubl23Noch keine Bewertungen

- Efficiency Testing of Medium Induction Motors-A Comment On IEEE STD 112-1991Dokument5 SeitenEfficiency Testing of Medium Induction Motors-A Comment On IEEE STD 112-1991Aviv AlRasyidNoch keine Bewertungen

- VSHP090041 Pelton T3341e 72dpiDokument8 SeitenVSHP090041 Pelton T3341e 72dpiJose Fuentes MendezNoch keine Bewertungen

- Nuclear 2Dokument37 SeitenNuclear 2Dan NiloNoch keine Bewertungen

- Parts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentDokument15 SeitenParts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentsatishNoch keine Bewertungen

- CVE 471 - 5 Water Supply 2Dokument57 SeitenCVE 471 - 5 Water Supply 2MEME123Noch keine Bewertungen

- Analysis of Electrical MachineryDokument66 SeitenAnalysis of Electrical Machineryzabig100% (1)

- Pelton TurbineDokument9 SeitenPelton TurbinenikNoch keine Bewertungen

- 60 Steam Turbine ManagementDokument25 Seiten60 Steam Turbine ManagementLTE002100% (1)

- Kaplan DesignDokument2 SeitenKaplan DesignruralworldNoch keine Bewertungen

- Irjet V5i5381 PDFDokument4 SeitenIrjet V5i5381 PDFAjay Kumar GantiNoch keine Bewertungen

- Hydraulic Machines MR Raman GahlautDokument44 SeitenHydraulic Machines MR Raman GahlautEyob AdNoch keine Bewertungen

- ThrustBearing Orion PDFDokument13 SeitenThrustBearing Orion PDFFarzadNoch keine Bewertungen

- TurbomachinesDokument2 SeitenTurbomachinesThesinghNoch keine Bewertungen

- Ae Mod 1Dokument12 SeitenAe Mod 1Sarath SudarsanNoch keine Bewertungen

- Slide Hepp 001Dokument25 SeitenSlide Hepp 001CiitHarappaNoch keine Bewertungen

- Hydraulic Power Plant PPE-UNIT-IIIDokument15 SeitenHydraulic Power Plant PPE-UNIT-IIISacet 2003Noch keine Bewertungen

- Chapter 7-Hydroelectric Power PlantDokument72 SeitenChapter 7-Hydroelectric Power PlantbaseakelNoch keine Bewertungen

- PPE Unit 4Dokument21 SeitenPPE Unit 4Krishna RockNoch keine Bewertungen

- Ps-1 Unit 3Dokument21 SeitenPs-1 Unit 3Prathap VuyyuruNoch keine Bewertungen

- EE6352-Electrical Engineering and Instrumentation Unit II Question Bank NewDokument2 SeitenEE6352-Electrical Engineering and Instrumentation Unit II Question Bank NewkarthikeyanNoch keine Bewertungen

- UNIT I Energy SenarioDokument33 SeitenUNIT I Energy Senariosanthosiyal751Noch keine Bewertungen

- Question Bank-Ee 1006 - Electric Safety and QualityDokument4 SeitenQuestion Bank-Ee 1006 - Electric Safety and Qualitykarthikeyan50% (2)

- UNIT V Power Plant Engineering NON - CONVENTIONAL POWER GENERATIONDokument51 SeitenUNIT V Power Plant Engineering NON - CONVENTIONAL POWER GENERATIONkarthikeyanNoch keine Bewertungen

- Construction of Circle DiagramDokument4 SeitenConstruction of Circle DiagramkarthikeyanNoch keine Bewertungen

- E C E SyllabusDokument1 SeiteE C E SyllabuskarthikeyanNoch keine Bewertungen

- Electrical Machines Lab QuestionsDokument2 SeitenElectrical Machines Lab Questionskarthikeyan75% (4)

- Stepper MotorDokument27 SeitenStepper Motorjena_anshumanNoch keine Bewertungen

- E C E SyllabusDokument1 SeiteE C E SyllabuskarthikeyanNoch keine Bewertungen

- R 2008 M.E. Power System SyllabusDokument24 SeitenR 2008 M.E. Power System SyllabuskarthikeyanNoch keine Bewertungen

- Training Report ElectricalDokument73 SeitenTraining Report ElectricalAkash KumarNoch keine Bewertungen

- Wind Turbine Emulator With DC MotorDokument6 SeitenWind Turbine Emulator With DC MotormatiastielliNoch keine Bewertungen

- 05 KKS Engl TSDokument23 Seiten05 KKS Engl TSImam Syarifudin100% (1)

- GTDokument33 SeitenGTowais_36100% (4)

- Dakhni Gas Processing Plant Report: Oil and Gas Development Company Muhammad UsmanDokument49 SeitenDakhni Gas Processing Plant Report: Oil and Gas Development Company Muhammad UsmanAnonymous HjB1bhmNoch keine Bewertungen

- Mech AeeDokument18 SeitenMech AeeDemudu DonkaNoch keine Bewertungen

- Factsheet78 - 129 - D361 Faqs 071609Dokument2 SeitenFactsheet78 - 129 - D361 Faqs 071609Oscar Reyes RodríguezNoch keine Bewertungen

- Nergy and Nvironment: A Numerical Investigation of Flow Profile and Performance of A Low Cost Crossflow TurbineDokument22 SeitenNergy and Nvironment: A Numerical Investigation of Flow Profile and Performance of A Low Cost Crossflow TurbineAnonymous h3huS5DlNoch keine Bewertungen

- Horizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewDokument18 SeitenHorizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewHavaldar, SanjayNoch keine Bewertungen

- Applied Thermodynamics Second Semester 2020Dokument24 SeitenApplied Thermodynamics Second Semester 2020NARE EDMUNDNoch keine Bewertungen

- Turbine Protection & EmergenciesDokument28 SeitenTurbine Protection & EmergenciesAmit Chauhan96% (23)

- FAG Motion Guard - The Intelligent Lubricators: Compact, Champion, Concept 6Dokument6 SeitenFAG Motion Guard - The Intelligent Lubricators: Compact, Champion, Concept 6Renzo Jo LaurentNoch keine Bewertungen

- Gas Turbine Performance by Rainer KurzDokument16 SeitenGas Turbine Performance by Rainer KurzSulzerRuudNoch keine Bewertungen

- 1961 - 0077 BR 945Dokument1 Seite1961 - 0077 BR 945dagger21Noch keine Bewertungen

- Owc Wave Energy TopicsDokument91 SeitenOwc Wave Energy TopicskeethanNoch keine Bewertungen

- Broc Energyfog - Fogging System For GTDokument4 SeitenBroc Energyfog - Fogging System For GTapi-27411749100% (1)

- ANDRITZ Hydro Summer Training ReportDokument43 SeitenANDRITZ Hydro Summer Training ReportStuti Shrivastava0% (1)

- Hydroelectric Power PlantDokument3 SeitenHydroelectric Power Plantpalani kumarNoch keine Bewertungen

- AHE NotesDokument35 SeitenAHE NotesmynameisgunaNoch keine Bewertungen

- Adrc PMSG JeetDokument14 SeitenAdrc PMSG JeetDileep VarmaNoch keine Bewertungen

- Air Sep Era TorsDokument18 SeitenAir Sep Era Torssridhar4seven100% (1)

- Abstract Wind PowerDokument2 SeitenAbstract Wind PoweresskaydhakarNoch keine Bewertungen

- Group Project 1: Drilling Hydraulics (Pcb4223) : Rotor Speed (RPM) Dial Reading (Degree)Dokument16 SeitenGroup Project 1: Drilling Hydraulics (Pcb4223) : Rotor Speed (RPM) Dial Reading (Degree)Syed DzafeerNoch keine Bewertungen

- 3.design and Analysis of Gas Turbine Rotor BladeDokument22 Seiten3.design and Analysis of Gas Turbine Rotor BladeBalaji BeliveNoch keine Bewertungen

- TurbomachineryDokument26 SeitenTurbomachineryfauzNoch keine Bewertungen

- Concept Paper Windmill Power PlantDokument40 SeitenConcept Paper Windmill Power PlantNoe S. Elizaga Jr.100% (1)

- Processes 10 00874Dokument20 SeitenProcesses 10 00874recaiNoch keine Bewertungen

- Fabrication of Vertical Axis Wind Turbine and ApplicationDokument5 SeitenFabrication of Vertical Axis Wind Turbine and ApplicationIJRASETPublicationsNoch keine Bewertungen

- Section 6 Technical Specification & DrawingsDokument168 SeitenSection 6 Technical Specification & Drawingspavankumar001Noch keine Bewertungen

- L12-Design of Pelton TurbineDokument15 SeitenL12-Design of Pelton TurbineRohan GuptaNoch keine Bewertungen