Beruflich Dokumente

Kultur Dokumente

Cooling Tower Modification Project

Hochgeladen von

rashm006ranjanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cooling Tower Modification Project

Hochgeladen von

rashm006ranjanCopyright:

Verfügbare Formate

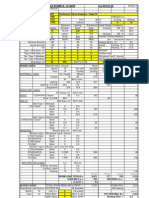

Improvement Item

Productivity

No.

38

Budget (x 1000 Php )

2000

Project No.

AFC Forge Main Cooling Tower

Purpose: To be able to justify for Forge Main Cooling Tower Modification To be able to set standard of Cooling Tower Pipe line. To be able to reduce Vibration on motor and Header pipe. To improve productivity and Reduce Breakdown Maintenance.

Prepared by:

Checked by:

Approved by:

Aichi Forging Co. of Asia Inc.

Date:

R. Pedrigal

J. Fajardo

K. Kondo

4/19/2010 Date:

Date:

Current Situation :

CRACK PART

Planning and Scheduling

2010 Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 MAY Description PIC 1wk 2wk 3wk 4wk 1wk 2wk JUNE 3wk 4wk 1wk 2wk JULY 3wk 4wk 1wk AUGUST 2wk 3wk 4wk

FIX TYPE

FIX TYPE

CRACK PART

PROBLEM ANALYSIS

Problem: Crack Weld portion of piping from ( desiel pump line to header pipe line

No Good foundation

App. Of proposal Inq. And qoutation request Submition of qoutation Check specs. Of qoutatio and design App. Of contractor design PR. And monitoring of p.o Checking of Contractors schedule Approval of schedule Starting of project

why?

Not so good welding at the pipe Big Vibration why? ( Due to fix type of piping why?

Target date of Completion

K. Kondo James Contractor James K. Kondo Ronald James K. Kondo Contractor Contractor Contractor Contractor Contractor Contractor Contractor Contractor Contractor Contractor Contractor Contractor

why? Due to only one side is weld not totally weld )

Due to foundation of Motor is not good why?

Already damage and not fix

Due to no ( shock absorber ) ex. Rubber billow connection

why? L (500~1M ) Due to hard to weld coz electrode cannot reach. why?

due to flange very long from connection weld point.

CHECKING AND EVALUATION

MAY 1wk NO. 1 2 3 ITEM TO BE CHECK SAFETY PROJECT QUALITY VIBRATION LEVEL PIC ROY JAMES RONALD 2wk 3wk 4wk 1wk 2wk JUNE 3wk 4wk 1wk 2wk JULY 3wk 4wk 1wk AUGUST 2wk 3wk 4wk

EVALUATION : LEGEND: SAFETY: COST : PROD PERMIT: (iso) Very Good

TOTAL:

Recommendation: Not so good No Good

ok

TARGET FOR VIBRATION LEVEL = REDUCE 15%~30% AFTER INSTALLATION OF COUNTERMEASURE TARGET FOR PRODUCTIVITY = NO BREAKDOWN MAINTENANCE RELATED TO PIPING CONNECTION TARGET FOR SAFETY = ZERO ACCIDENT

VIBRATION LEVEL MONITORING

Counter Measure : PROPOSAL

>100 L

Spare line for Future plan ( additional pump )

can be weld inside

mm/sec

SEPTEMBER OCTOBER NOVEMBER DECEMBER SAFETY PROJECT QUALITY NOISE LEVEL

RUBBER BILLOW ( VIBRATION ABSORBER )

SEPTEMBER

FLANGE ( FOR EASY MAINTENANCE

Modify foundation

OCTOBER MONTH

NOVEMBER

DECEMBER

SAFETY

PROJECT QUALITY

NOISE LEVEL

EVALUATION : LEGEND: SAFETY: COST : PROD PERMIT: (iso) Very Good ok Not so good No Good

Recommendation:

Das könnte Ihnen auch gefallen

- Dd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Dokument1 SeiteDd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Muhammad IshtiaqueNoch keine Bewertungen

- SME Air Calculation and Makeup Air Analysis by ZoneDokument33 SeitenSME Air Calculation and Makeup Air Analysis by ZoneAshiq NishmaNoch keine Bewertungen

- Humidity and Cooling Tower FundamentalsDokument11 SeitenHumidity and Cooling Tower FundamentalsMuhammed AfnazNoch keine Bewertungen

- Aero Ducts IDokument31 SeitenAero Ducts ImanhngoducNoch keine Bewertungen

- Fabrication and Working of a Cooling Tower ThesisDokument21 SeitenFabrication and Working of a Cooling Tower ThesisNoorul BabaNoch keine Bewertungen

- 4.11.4 Steam Pipe Sizing and DesignDokument3 Seiten4.11.4 Steam Pipe Sizing and DesignSaurabh VijNoch keine Bewertungen

- CIS7:2014Dokument66 SeitenCIS7:2014Ken ChuahNoch keine Bewertungen

- FAHU Cooling Load and Condensate RatesDokument4 SeitenFAHU Cooling Load and Condensate RatesSundar DAACNoch keine Bewertungen

- Expansion Tank SizingDokument1 SeiteExpansion Tank Sizinghaysam0% (2)

- Air cooler size estimation parametersDokument1 SeiteAir cooler size estimation parametersmacielNoch keine Bewertungen

- Drain Flow CalculatorDokument4 SeitenDrain Flow CalculatorarcelitasNoch keine Bewertungen

- LP Gas CalculationDokument4 SeitenLP Gas Calculationlutfi awnNoch keine Bewertungen

- Pump power and sizing calculationDokument1 SeitePump power and sizing calculationVIVEKZI0Noch keine Bewertungen

- Yazd-System Description For Clean Drain System PDFDokument7 SeitenYazd-System Description For Clean Drain System PDFace-winnieNoch keine Bewertungen

- Steam Boiler Spec.Dokument17 SeitenSteam Boiler Spec.bandithaguru6338100% (1)

- Pharmaceutical Facility DesignDokument27 SeitenPharmaceutical Facility Designmdalt9180Noch keine Bewertungen

- Ashrae - 2009 I-P - F09 - AddDokument2 SeitenAshrae - 2009 I-P - F09 - AddSergio SemmNoch keine Bewertungen

- Atrium Natural Smoke CalculationsDokument5 SeitenAtrium Natural Smoke CalculationsRamiAl-fuqahaNoch keine Bewertungen

- External Pumping StationDokument10 SeitenExternal Pumping Stationabdullah sahibNoch keine Bewertungen

- Arzel Zoning Bypass CalculatorDokument6 SeitenArzel Zoning Bypass CalculatorVíctor RojasNoch keine Bewertungen

- Vent CalculationDokument60 SeitenVent Calculationnazile_05Noch keine Bewertungen

- Optimizing Central Chilled Water SystemsDokument56 SeitenOptimizing Central Chilled Water Systemsapi-328841994Noch keine Bewertungen

- Flow Meter Orifice CalculationDokument27 SeitenFlow Meter Orifice CalculationLaksono BudiNoch keine Bewertungen

- Chiller Water Pressure DropDokument4 SeitenChiller Water Pressure DropCử NguyễnNoch keine Bewertungen

- 08-Electric Water HeaterDokument3 Seiten08-Electric Water Heatermohamed IbrahemNoch keine Bewertungen

- Plumbing Calculation - Rev 140113Dokument4 SeitenPlumbing Calculation - Rev 140113Paijo TejoNoch keine Bewertungen

- Exhaust System Back Pressure CalculationDokument1 SeiteExhaust System Back Pressure Calculationmazumdar_satyajitNoch keine Bewertungen

- Chilled Water and Condensor Water Pump Head CalculaitonDokument3 SeitenChilled Water and Condensor Water Pump Head CalculaitonYusuf RampNoch keine Bewertungen

- Ductwork Sizing Calculation StudyDokument2 SeitenDuctwork Sizing Calculation StudyNghia Huynh NgocNoch keine Bewertungen

- Kitchen Hoods: As 1668.2 - Conventional FryingDokument2 SeitenKitchen Hoods: As 1668.2 - Conventional Fryingamo3330Noch keine Bewertungen

- Data Sheet For Spray NozzleDokument3 SeitenData Sheet For Spray Nozzlebecpavan100% (1)

- Exhaust HoodsDokument4 SeitenExhaust HoodsMohammed MustafaNoch keine Bewertungen

- Copper Pipes (Based On Silver Book) : Purpose AssumptionsDokument3 SeitenCopper Pipes (Based On Silver Book) : Purpose AssumptionscesNoch keine Bewertungen

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Dokument1 SeiteRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNoch keine Bewertungen

- Esp Pu-1Dokument1 SeiteEsp Pu-1Abdul Majeed KottaNoch keine Bewertungen

- Commercial Kitchen Exhaust System Design CalculationsDokument2 SeitenCommercial Kitchen Exhaust System Design CalculationsJomyJoseNoch keine Bewertungen

- S&W CalculationDokument10 SeitenS&W CalculationSameera LakmalNoch keine Bewertungen

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDokument3 SeitenTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omONoch keine Bewertungen

- Psychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DDokument13 SeitenPsychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DKarl WeierstrassNoch keine Bewertungen

- Air Conditioning Equipment Noise Level NEA SingaporeDokument7 SeitenAir Conditioning Equipment Noise Level NEA SingaporeChalla Venu Kumar ReddyNoch keine Bewertungen

- Project:: Chilled Water Pump Head CalculationDokument1 SeiteProject:: Chilled Water Pump Head CalculationClarkFedele27Noch keine Bewertungen

- Selection Sheet - 30XA452 Screw ChillerDokument1 SeiteSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Noch keine Bewertungen

- Halton Design Guide enDokument54 SeitenHalton Design Guide enimtiyaz94Noch keine Bewertungen

- Rain Water Calculation (300mmh)Dokument6 SeitenRain Water Calculation (300mmh)MechanicalLatestNoch keine Bewertungen

- PEERLEES Fire Pump PDFDokument175 SeitenPEERLEES Fire Pump PDFN. AndradeNoch keine Bewertungen

- Pump Sizing CalculationDokument18 SeitenPump Sizing CalculationChaitanya BhattNoch keine Bewertungen

- Estimating Exteranl and Internal Pressure Drop For AHU and FCUDokument6 SeitenEstimating Exteranl and Internal Pressure Drop For AHU and FCUfghabboonNoch keine Bewertungen

- Chilled Water Flow, Pipe SizeDokument3 SeitenChilled Water Flow, Pipe SizeSatya N.GNoch keine Bewertungen

- Sanitary Accessories Calculator for Building ProjectsDokument1 SeiteSanitary Accessories Calculator for Building Projectskumar123rajuNoch keine Bewertungen

- Steam Pipe Sizing VGDokument39 SeitenSteam Pipe Sizing VGSolooloo Kebede NemomsaNoch keine Bewertungen

- Halton - KSK Grease Filter (Catalog)Dokument6 SeitenHalton - KSK Grease Filter (Catalog)picnarukNoch keine Bewertungen

- Area Calculation 4 Elbow$ReducerDokument9 SeitenArea Calculation 4 Elbow$ReducerLemack Paul0% (3)

- Testing and Balancing AcsDokument10 SeitenTesting and Balancing Acsroshan jaiswalNoch keine Bewertungen

- System Duct Pressure Loss CalculationDokument6 SeitenSystem Duct Pressure Loss Calculationthanh_79Noch keine Bewertungen

- 012 QualityNewsLetter - January2012Dokument8 Seiten012 QualityNewsLetter - January2012ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDokument11 SeitenPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900Noch keine Bewertungen

- OETC-74 - 400kV Tower Design Inputs To AL-BABTAINDokument146 SeitenOETC-74 - 400kV Tower Design Inputs To AL-BABTAINMohamed Gad67% (3)

- BOQ (Structural & Archetectural)Dokument222 SeitenBOQ (Structural & Archetectural)pdkprabhath_66619207Noch keine Bewertungen

- TBE Pumps CP 16Dokument21 SeitenTBE Pumps CP 16ivomNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Irjet V3i11206Dokument8 SeitenIrjet V3i11206rashm006ranjanNoch keine Bewertungen

- APH Efficiency 1Dokument12 SeitenAPH Efficiency 1Debabrata TantubaiNoch keine Bewertungen

- MCDokument4 SeitenMCViral PatelNoch keine Bewertungen

- Quality ControlDokument32 SeitenQuality ControlvignanarajNoch keine Bewertungen

- ExamineeGuide May 2019Dokument36 SeitenExamineeGuide May 2019Hemanth UsNoch keine Bewertungen

- Geared Up For SuccessDokument32 SeitenGeared Up For Successrashm006ranjanNoch keine Bewertungen

- Earned Value Management (EVM)Dokument8 SeitenEarned Value Management (EVM)rashm006ranjanNoch keine Bewertungen

- 9Dokument8 Seiten9armin heidariNoch keine Bewertungen

- Earned Value Management (EVM)Dokument8 SeitenEarned Value Management (EVM)rashm006ranjanNoch keine Bewertungen

- Correlation Example 1 Output PDFDokument1 SeiteCorrelation Example 1 Output PDFrashm006ranjanNoch keine Bewertungen

- 3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom ListDokument2 Seiten3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom Listrashm006ranjanNoch keine Bewertungen

- Ansys - Simply Supported BeamDokument12 SeitenAnsys - Simply Supported Beamrashm006ranjanNoch keine Bewertungen

- 03 - Confined Space EntryDokument18 Seiten03 - Confined Space Entryrashm006ranjanNoch keine Bewertungen

- AmountDokument62 SeitenAmountrashm006ranjanNoch keine Bewertungen

- Mr. A. K. Sinha - Energy Efficiency Industrial Utilities - Boiler SystemsDokument63 SeitenMr. A. K. Sinha - Energy Efficiency Industrial Utilities - Boiler Systemsjanakiram2010Noch keine Bewertungen

- Maximize Machine Reliability Through Precision Lubrication SkillsDokument12 SeitenMaximize Machine Reliability Through Precision Lubrication Skillsrashm006ranjan50% (2)

- New Book Launch Schedule 36 Days: Planning Complete!Dokument1 SeiteNew Book Launch Schedule 36 Days: Planning Complete!rashm006ranjanNoch keine Bewertungen

- NCQC 2016 RaipurDokument8 SeitenNCQC 2016 Raipurrashm006ranjanNoch keine Bewertungen

- New Book Launch Schedule 36 Days: Planning Complete!Dokument1 SeiteNew Book Launch Schedule 36 Days: Planning Complete!rashm006ranjanNoch keine Bewertungen

- Project Launch OverviewDokument1 SeiteProject Launch Overviewrashm006ranjanNoch keine Bewertungen

- PR Approval Request for Digital Thermometer and AnemometerDokument1 SeitePR Approval Request for Digital Thermometer and Anemometerrashm006ranjanNoch keine Bewertungen

- Hourly temperature readings of TSE casing and HP shaftDokument12 SeitenHourly temperature readings of TSE casing and HP shaftrashm006ranjan0% (1)

- 790Dokument5 Seiten790rashm006ranjanNoch keine Bewertungen

- Hourly temperature readings of TSE casing and HP shaftDokument12 SeitenHourly temperature readings of TSE casing and HP shaftrashm006ranjan0% (1)

- Steam Ejector CalculationsDokument11 SeitenSteam Ejector Calculationsrashm006ranjanNoch keine Bewertungen

- Coal Mill Heat Balance SheetDokument2 SeitenCoal Mill Heat Balance Sheetrashm006ranjanNoch keine Bewertungen

- Energy Audit For Electric MotorDokument4 SeitenEnergy Audit For Electric Motorrashm006ranjanNoch keine Bewertungen

- HyperGraph3D TutorialsDokument41 SeitenHyperGraph3D Tutorialsrashm006ranjanNoch keine Bewertungen

- User ManualDokument87 SeitenUser ManualebinjozerNoch keine Bewertungen

- Development Centre - Know It AllDokument2 SeitenDevelopment Centre - Know It Allrashm006ranjanNoch keine Bewertungen

- Mitsubishi forklift manual pdf downloadDokument3 SeitenMitsubishi forklift manual pdf downloadDwi Putra33% (12)

- Notice No.8: Rules and Regulations For TheDokument40 SeitenNotice No.8: Rules and Regulations For TherickNoch keine Bewertungen

- Remeha Gas 310 ECO: Technical InformationDokument59 SeitenRemeha Gas 310 ECO: Technical InformationAdrian Blazquez MolinaNoch keine Bewertungen

- Dual vs Core 2 DuoDokument5 SeitenDual vs Core 2 Duomahisharma123456Noch keine Bewertungen

- Lab 3 - Series and Parallel CircuitsDokument7 SeitenLab 3 - Series and Parallel CircuitsHảo PhùngNoch keine Bewertungen

- Nonwoven Material StandardsDokument5 SeitenNonwoven Material StandardsRajesh Dwivedi0% (1)

- Maximo Sandbox SettingsDokument6 SeitenMaximo Sandbox SettingsChandra SekharNoch keine Bewertungen

- Computer Science & Engineering Department ElectivesDokument13 SeitenComputer Science & Engineering Department Electivesnitro gtnaNoch keine Bewertungen

- Pass4sure 200-120 PDF DownloadDokument8 SeitenPass4sure 200-120 PDF DownloadEleanor19Noch keine Bewertungen

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDokument1 SeiteMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiNoch keine Bewertungen

- Detailed Lesson Plan in Science IVDokument12 SeitenDetailed Lesson Plan in Science IVAgnes DumlaoNoch keine Bewertungen

- Brocade Ciscomds Cli ComparisonDokument17 SeitenBrocade Ciscomds Cli ComparisonprocomphysNoch keine Bewertungen

- EC2151 Electric Circuit Important QuestionsDokument47 SeitenEC2151 Electric Circuit Important QuestionschitragowsNoch keine Bewertungen

- Gaspardo MAESTRA 2004-02 (19530520)Dokument78 SeitenGaspardo MAESTRA 2004-02 (19530520)costelchelariuNoch keine Bewertungen

- MCP HistoryDokument18 SeitenMCP HistoryStanciu VladNoch keine Bewertungen

- My Oracle Support - Knowledge Browser - 1441364Dokument9 SeitenMy Oracle Support - Knowledge Browser - 1441364Aman Khan Badal KhanNoch keine Bewertungen

- Hitachi Sumitomo Scx1500 2 Hydraulic Crawler Crane SpecificationsDokument2 SeitenHitachi Sumitomo Scx1500 2 Hydraulic Crawler Crane Specificationsmargeret100% (50)

- Tender Evaluation FormDokument1 SeiteTender Evaluation FormbkimaxNoch keine Bewertungen

- G100-G102-Chassis-Manual #1Dokument151 SeitenG100-G102-Chassis-Manual #1Daihatsu Charade BanjarnegaraNoch keine Bewertungen

- PM IS - 12818 June2021Dokument10 SeitenPM IS - 12818 June2021Mahendra AhirwarNoch keine Bewertungen

- Francis Turbines PDFDokument12 SeitenFrancis Turbines PDFabbas bilal100% (1)

- TMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyDokument30 SeitenTMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyjdaoukNoch keine Bewertungen

- EN 12663-1 - 2010 - IndiceDokument6 SeitenEN 12663-1 - 2010 - IndiceOhriol Pons Ribas67% (3)

- Coverage of Quiz 1Dokument24 SeitenCoverage of Quiz 1Ben RileyNoch keine Bewertungen

- Tank Size CalculatorDokument6 SeitenTank Size CalculatorVijayakumar Chandrasekaran100% (2)

- Assist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Dokument49 SeitenAssist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Hundee HundumaaNoch keine Bewertungen

- Load Case CombinationsDokument5 SeitenLoad Case CombinationsFrancisco UgarteNoch keine Bewertungen

- Bondek Design & Construct ManualDokument131 SeitenBondek Design & Construct ManualAkuma.Gokai7328100% (12)

- PC Pump ManualDokument540 SeitenPC Pump ManualtelephonicaNoch keine Bewertungen

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Dokument2 SeitenElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262Noch keine Bewertungen