Beruflich Dokumente

Kultur Dokumente

Relay Modification For Older Bikes

Hochgeladen von

Roberto Lopez RojasOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Relay Modification For Older Bikes

Hochgeladen von

Roberto Lopez RojasCopyright:

Verfügbare Formate

Relay modification for older bikes

Please read this in conjunction with the schematics at the end. All the options are shown, but you can opt to do any one or more as you wish. The electrical connections and switches on older bikes deteriorate over time and thus make poorer contact than when they were new and could lead to some erratic problems. These bikes also have very simple wiring diagrams, meant to take up very little space and thus do not have any relays installed to switch components. The fusing is also minimal. It is thus not unknown to have an accumulative voltage drop between the battery and the final component. Headlights can become duller, ignition coils may generate a weak spark and horns may work erratically. These are all items that are most easily affected if any resistance in the feed path is present due to bad contacts. A 12volt socket for cellphone charging is also shown for those who may be interested. Relays can be installed to switch such high currents closer to the item, the relay contacts are new and usually plated, heavier wire can be used for less loss. As extra fusing is being added, consideration should be given to replacing the complete stock fusebox with a later on with blade fuses and the extra fuses as per the modifications. Space and complexity of the wiring can become an issue and must be carefully determined before embarking on a relay project Relays There are many different types of relays that can be used, but must be 12volt DC operated, usually available for automotive use. These can be bought at most auto parts stores and are usually used for fog light and horn installations. There are a couple of configurations, some have only 4 pins with two for the internal relay coil and two for the contacts (internal switch) and could provide an on/off function when the relay is operated and released. Others could have a 5 pin configuration with 3 pins for the contacts which can provide an on and off function if only two pins are used or a change over function if all three are used. Be careful, as there are also 5 pin relays that only have an on/off function as two of the contacts are internally bridged to allow two wires out without joining, such as for two fog lights or two horns. See the schematics of the relays with the pin numbers further below. Horns The horn button that directly switches the horns are notoriously prone to erratic working and a relay can be installed, the horn button then is used to operate the relay. The relay then switches a battery feed directly via a fuse to the horns. Additionally you can also install two diodes connected to the left and right flashers and all your flashers will come on when you blow the horn, making you more visible! Headlights Unfortunately the headlights on older bikes are a bit lacking and can also become weaker as the bike ages. Any voltage drop between the battery and the globe can cause the lamp to not do its best. The other unfortunate thing is that the charging system usually does not allow for any extra lights to be installed due to its design limitations on maximum output. The first thing to do is to replace the globe with a high light output one. The H4 Osram Silverstar gives up to 50% more light than a standard H4 globe and is still rated at 55/60W which means it draws the same amount of current as the standard globe, this is the easiest upgrade. The second option is to install one or two relays, one for the high beam and the other for the low beam. With two relays both the Hi and Lo beam can be on simultaneously when switched to Hi. The dimmer switch will then operate the relays and these will switch battery directly to the globes via a new direct heavier wire and fuse from the battery. This greatly reduces the path the wire follows in the standard configuration and gets the maximum voltage and at the globe. A simpler method using one relay, which makes mounting easier is also shown, but does not provide both beams on.

Ignition coils People with older bikes are also finding that some bikes are difficult to start. Especially if the lights are on or if the battery is partially charged, but still turning the starter. In other cases they think they have carburettor trouble, but actually have misfiring due to a weak spark and go to great expense to have high performance after market coils fitted. A quick tests usually shows that the coils are not getting the full 12v from the battery and on some bikes it is not unusual to find 2 to 3 volts lost along the way. Usually a temporary direct wire to the battery can confirm this problem. In such cases it is again easier to wire a relay in to switch battery voltage directly to the coils via a separate fused wire to the battery. The 12 volt originally to the coils then operates the relay which switches 12v directly from the battery via a heavier wire and fuse. Starter Some bikes have wiring for headlight always on and when starting the bike problems can be experienced. A relay can be fitted to disable the headlights while the starter is turning, thus allowing full voltage from the battery for the starter and coils and may solve some hard starting problems. This relay operates only while the starter button is pushed and disconnects the earth (negative) to the lights, horn and accessory plug, to allow maximum voltage to the starter and coils. 12Volt accessory socket A 12volt accessory socket is also very useful as cellphone chargers, GPS's, radios etc may need to be plugged in at times. A separate fuse with a direct negative and positive is wired to a weatherproof 12v socket mounted in a convenient location. It can also double as a connection for a battery tender. These sockets have a rubber weatherproof cover and a short adapter can easily be made for an cigarette lighter type socket if required. How to do this: Have a look at the two attached schematics at the end. They give the option of installing relays for any or all of the above scenarios. The idea is also to keep these additional wires separate from the existing wiring and keep the existing wiring as intact or stock as possible, so that fault finding is easier. It may also be easier for an owner to do all the mods simultaneously rather than doing one and coming back to the others later. The guide will assume all the mods are done at the same time. Material list 12V 35A Motor Vehicle Relays with a C/O (changeover) or M (make) contact (4 or 5 pin) Relay female bases with pigtails You can also use female spade connectors directly in place of the relay bases with pigtails Fuse Holders for coloured blade fuses (these holders have a cover and can be stacked together) 10A fuses 15A fuses H4 headlamp globe type male plug with pigtails H4 headlamp globe type female socket with pigtails 12volt socket 12volt plug for socket Various connectors, spade, bullet, holes lugs Vehicle wire Red and Black Heavy guage Orange, Green, White, Yellow, Blue or available colours Shrink sleeving Solder Cable ties

Installing the components; Remove the tank, light, side covers and seat. Make sure you have a proper wiring diagram for your model bike at hand in case you need to check something on the existing wiring. First of all find/make a location for the relays. It is suggested that the horn and coil relays are mounted under the tank and the headlight relays inside the headlamp base or fairing. Attach the female relay bases to the relays before locating a mounting point as this affects size or use female spade terminals. Some headlamp shrouds may be too small for additional relays with bases. Keep in mind that the existing globe socket is going to be retained and another male plugged into it additionally. You can mount the relays with cable ties or a self tapper if no other existing screw will do. This positioning must also allow for the wires as well and careful checks should be made that nothing will be pinched or damaged and that nothing just flops around and is exposed directly to the elements as far as possible. The next step is to find a suitable position for the fuses. These are best fitted under the seat or under a side cover near the existing ones, so that they are easily accessible. You also need to keep the feed between the battery and the fuses as short as possible. The individual fuse holders should clip together, so try and fit them as a unit. They would also need to be mounted securely and a screw or a bracket would help. An opportunity for the adventurous is to replace your old stock fuse holder with a later blade fuse type with the additional fuses you require. Now you have to find a spot for your 12 volt accessory come battery tender socket. A small black plastic box will easily do, but even fitting it through the headlamp plastic base may be an option, just remember that space inside the headlight base is usually quite crowded. Wiring It is assumed that you have the facilities and skills to solder wires, apply shrink sleeving, use a multimeter and crimp fit connectors. If not, invite a friend over to help. This guide does not give an exact description, so you need to either follow it while using the schematic or work out the process for your specific bike. 1) The cluster of fuses now need to have one side of each fuse connected to a heavy red wire that gets a lug to fit on the positive terminal of the battery or starter solenoid. If your cluster of fuses have red pigtails on one side, cut and solder then together as close to the fuse as possible then connect that soldered group to a piece of heavy red wire. Cover with shrink sleeving to insulate. Measure the heavy red wire carefully up to the battery side of the starter solenoid screw and crimp a lug on the end, shrink sleeve over the crimped part for safety. Do not connect at this stage! Your new 12v power feed to the new fuses is ready. 2) Now make up a short heavy black lead with two lugs on either end, to reach from your negative battery terminal to a screw on the frame in the side cover. You if you already have such a lead just replace it with your heavier one with brand new terminals. 3) Now run another heavy black wire, from the screw mentioned in point 2 above, all the way along the frame up to and past the relays under the tank passing each relay with some working slack, allowing some slack near the horns and starter headlamp relay and right into the headlamp. This is the first wire of your new loom. All the others will follow this path as far as possible. From the steering neck make sure that these new slightly heavier wires allow for enough slack when turning the handle bars. Remember we are using heavier wires than stock and these are slightly stiffer and may need a slightly larger loop to allow this. Leave enough slack as when you cut, it is easier to shorten a wire, but not if it needs to be longer! 4) Now connecting this black negative wire. Assuming the first relay it passes is the one for the coils. Find the pigtail from the relay negative coil side, usually black as well, crimp a female spade connector to the end, cut a piece of thinner black wire, measure it to the heavy black and leave a little slack, strip one end and crimp a male spade connector to the other end. Cut

4 mm of the black insulation of the heavy black wire without damaging or cutting any copper strands. Now take the stripped end of the black wire from the relay and wrap it around this bare copper part of the heavy wire. Slip a piece of shrink sleeving on from the front free end, solder the joint and slip the shrink sleeving over it and shrink it. You now have a heavy black wire passing through the tube of shrink sleeving and a thinner one going out on one side and plugged into a spade connector going to the relay base. Your new earth for your coil relay is done. 5) Now move along the heavy black wire to close proximity of your horns. Again strip a small piece of insulation off. Now take about 400mm of thinner gauge black wire and strip the insulation off for about 10mm of the thin black wire in the center. Wrap this copper part of the thinner wire around the copper part of the heavier black wire. Solder this joint and again slip a piece of shrink sleeving from the front over this joint and shrink. You should now have two back wire tails of about 200mm each route these to the outside tag on each horn, crimp a female spade connector on each and push onto a lug of each horn. The new earthing for your horns are done. 6) If you have opted to put the headlamp cutoff relay inside the headlamp base then this heavy black wire is connected to the pigtail of the relay terminal 30 and another shorter piece on terminal 87a allowing the negative to the headlamp to be disconnected when the relay is operated. 7) Now pick up the end of the heavy black wire inside the headlamp shroud and solder it to the pigtail from the new female socket for the headlamp. Prepare a bit of shrink sleeving beforehand and shrink it over the joint. The Black/White wire on the H4 socket you pulled off the headlight should indicate where the connection is on the new H4 socket. Your headlamp now has its new earth connected. 8) Now plug a new male H4 plug into the original female headlamp socket which has been unplugged from the headlamp to prepare the wiring back to the relays. The old wiring to the headlamp here is re-used to operate the relays. 9) Assuming that the new headlamp relays are inside the headlamp base, find the two headlamp relay negative coil tag pigtails, usually they will be the black ones, prepare some shrink sleeving and connect them to the black pigtail from the new H4 male plug that you plugged into the original old H4 globe socket. This uses the old negative wire (Black/White) to the globe to operate the relays. 10) Now lengthen (if required) the pigtails for the Hi and Low beam that are still free on the female globe H4 socket to reach the relays and join (solder) them to the pigtails of the make contact of each relay (make sure you have labeled which is Hi and which is Lo beam) 11) Next locate the two pigtails on the new male H4 plug that you plugged into the old headlamp socket, that are still free, one is the Hi beam (goes to yellow wire) and the other is the Lo beam (goes to white wire), connect these to the corresponding pigtails of the coils on the two relays. This is now the connection that operates the Hi and Lo beam relays when the switch is thrown as before. 12) Now run a length of white wire plus a length of yellow wire from the new H4 female socket on the globe following the path of the heavy back earth wire back to the new fuse cluster. Check that you have enough slack and terminate on the two new fuses for the Hi and Lo beam and also on the pigtails inside the headlight for the Hi and Lo filaments of the globe.

You have now completed the new battery feed to the headlamp. 13) Next locate the green wires that ran to each horn, lengthen any one of these by plugging a male spade connector with a piece of green wire crimped to it into the female spade connector. You may have to replace the old female with a new one as those are usually quite corroded, or just solder a piece on. Then slip a piece of shrink sleeving over the joint and shrink. Now do the same for the Orange/Green wire, lengthen it with a piece of orange wire or Orange/Green if you have. Now cover the other 2 old horn connectors with a piece of shrink sleeving and tie all 4 of then to the loom and tape up leaving only the pieces of lengthened green and orange wire free. Connect the green and orange wires to the pigtails for the coil of the relay on the horn relay socket. This relay will now operate when you push the horn button. You have already wired the negative in step 5. For the positive run a red wire from the pigtail on the contact of the horn relay back along with the headlight and earth wires to the top new fuse, solder shrink sleeve. Go back to the horn relay and run two blue wires from the pigtail on the make side of the contact to each horn positive or inside tag, crimp an insulated female spade connector and fit to horn. Solder and shrink sleeve at the relay. Your horn positive is now also completed. 14) Now move to your coil relay. The earth or negative for the relay has already been wired in step 4. Locate the existing connector plugs that have the Orange/White wires going to each coil, this is the wire that as stock supplies 12v via the ignition to the coils. Disconnect this wire and connect the Orange/White side coming from the ignition to the pigtail positive (usually red) of the socket of the relay coil. Try not to cut off connectors if possible, rather terminate with a male or female into an old connector or if the old one is too damaged replace with same and shrink sleeve the connection. This method allows little intrusion to the original wiring and keeps it as original as possible. Connect the other side from the coils of the Orange/White wire to the make side of the relay contact pigtail. You may need to lengthen these if they cannot reach the relay. Now run a red wire from the coil relay contact pigtail all the way back to the new fuse cluster and connect to the bottom fuse. New battery 12v connection for coil is now complete. Testing: Leave all the new fuses out. At the battery the new earth wires should already be screwed down on the frame and the new short black can be connected to the negative post of the battery. Double check all your wiring and make sure nothing is touching anywhere. Connect up the positive battery wires including the new heavy red wire (if you did not opt for the solenoid point as in step1). If there is no smoke, sparks of flashes you are safe! 1) Make sure the killswitch is off and the light switch is also off. 2) Turn on the ignition and see if neutral and oil pressure light comes on 3) Now physically check that no other lights came on as well, if so switch off, disconnect battery and recheck your work. 4) If all seems well test stoplight, if it works you can move on. 5) Push a 15A fuse into the new horn fuse holder 6) Push horn and test, if it does not work check negative present on horns Black wires, then listen for click if relay operates when horn button is pushed. If so then confirm that positive is present on the contact side and is put out on the make side of the contact when the relay operates. If so check if it is reaching the horns. If this works and horns sound you are doing well. Switch off ignition. 7) Push in a 10A fuse into the first headlight fuse holder, ensure light switch is off. Switch on ignition. Check to see if any headlight comes on when light switch is switched on. Toggle between Hi and Lo. If all is well push in next headlight 10A fuse and see if both Hi and Lo

beams work. Also check the rear and instrument lights. Ensure that you have not reversed the Hi and Lo beams as per your switch. 8) If the headlight does not work, unplug the globe and first listen if a relay clicks if you put lights on and clicks as you change from Hi to Lo and back. If not then first check the negative (Black wire) on both relays and then check that positive is applied to the other side of each relay coil when the lights are on and the beams are changed. If both relays operate properly then you have to ensure that negative is reaching the back of the globe (Black wire) and that positive from each fuse is reaching the contact side of each relay and that the make side is correctly wired and sending positive to the globe. If the lights work you are nearly a genius! 9) Put a 15A fuse in the coils fuse holder. Make sure light switch is off or even remove the new light fuses. Put the ignition on and flick the killswitch to on and listen for the relay click. If it does not click, check out the positive from the killswitch Orange/White wire to the relay coil side and the negative black on the other side of the coil.If the relay clicks, then check with your voltmeter that 12v is present on the coils on the Orange/White wires, if not check it on the contact side of the relay and on the make side going to the coils. Use the killswitch to switch it on and off. If this works you are nearly ready to start the bike. 10) Next is to test the headlight cut off. Put you headlights on and push the starter button, if the headlights go off wile the button is pressed that part is working. 11) The next step is now to disconnect the battery and tape up the wires and cable tie your beautiful new wiring properly and refit the tank etc and you are on the road!!! Extra A little extra that may be of some interest is that someone suggested that he would like all four of his flashers come on when he presses the horn, that makes him audible and visible! With the relay fitted this can be easily done. Additionally you will need two diodes of about a 3 to 5amp rating, solder some pigtails to both sides and shrink sleeve the whole diode right over the connections. Connect the two anode sides together and to the switched positive wire (new orange wire) to your horns and connect one of the cathode sides to the right flasher positive side (Black) and the other cathode to the left flasher positive side (Light green) Now every time you push the horn button the horn will sound and the flashers will flash! Some people also would like both the Hi and Lo beam to be on when they switch to hi for better visibility. This could give rise to more load on the battery than what the alternator can supply so check this out first on your bike. To do this a diode is fitted between the two headlight relays which operated bot relays on Hi and only the low relay when on Lo. Matchless 2008/03/26

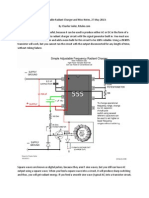

Two typical 30A 12volt Relays with isolated casing, 4 or 5 pin type with a normally open, make contact. Pin 85 to negative, pin 86 to positive, pin 30 input voltage to switch, pin 87 out from pin 30 when relay is operated. The right hand one has two pin 87's for a double output.

Some typical variations of12V relays available for these modifications, with the schematic showing pin numbers and location as seen from the bottom.

Here are typical blade fuse holders and fuses, each colour represents a value. The red lead just gets cut and joined to the wires being run.

Here you have a typical 12volt weatherproof and robust socket and plug. These can be used to drive accessories and fitted in a convenient spot or even double up as you battery tender socket. An adapter to plug a cigarette lighter type socket can easily be made up as well, using the make plug and a short wire with female cigarette type socket.

Das könnte Ihnen auch gefallen

- VL1500 Charging System Wiring Upgrades PDFDokument8 SeitenVL1500 Charging System Wiring Upgrades PDFPachu 99Noch keine Bewertungen

- Distribution Block Power RelayDokument5 SeitenDistribution Block Power Relaymichael rose100% (3)

- Headlight Relay Wiring - GTSparkplugsDokument4 SeitenHeadlight Relay Wiring - GTSparkplugsShubham KaklijNoch keine Bewertungen

- Utomotive Wiring TipsDokument138 SeitenUtomotive Wiring TipsEngine Tuning UP0% (1)

- Automotive Wiring Diagrams: Electrical SchematicsDokument5 SeitenAutomotive Wiring Diagrams: Electrical SchematicsJeffrey Constantino PatacsilNoch keine Bewertungen

- V-Strom Wiring ProjectsDokument8 SeitenV-Strom Wiring ProjectsthingumybobNoch keine Bewertungen

- Popular Mechanics - Curing A Clicking StarterDokument4 SeitenPopular Mechanics - Curing A Clicking StarterGeorgiana MarinNoch keine Bewertungen

- Fitting Footwell Lights To Your CarDokument3 SeitenFitting Footwell Lights To Your CarAlexandru-Mihai NitaNoch keine Bewertungen

- Low Cost Led Headlight For Lucas BPF p36dDokument4 SeitenLow Cost Led Headlight For Lucas BPF p36dapi-274594300Noch keine Bewertungen

- Rough Guide To DIY Luxeon Bike LightsDokument6 SeitenRough Guide To DIY Luxeon Bike LightsAitch PebbleNoch keine Bewertungen

- Alternator Description and TestingDokument11 SeitenAlternator Description and TestingadillukNoch keine Bewertungen

- Contact Less JawaMoped Electrics - IgnitionDokument5 SeitenContact Less JawaMoped Electrics - IgnitionVishal AdNoch keine Bewertungen

- Capacitor Discharge Ignition Extends Points and Plug LifeDokument0 SeitenCapacitor Discharge Ignition Extends Points and Plug LifeJose De Jesus MoralesNoch keine Bewertungen

- New Adjustable Frequency Radiant Charger PDFDokument5 SeitenNew Adjustable Frequency Radiant Charger PDFlancerdoom1100% (6)

- Circuit Blocks in The ClassroomDokument14 SeitenCircuit Blocks in The ClassroomrichromeroNoch keine Bewertungen

- BMW 6-Series Lighting Guide: Running Accessory Power To The Engine CompartmentDokument6 SeitenBMW 6-Series Lighting Guide: Running Accessory Power To The Engine CompartmentTudor SecretNoch keine Bewertungen

- 3 Dollar Battery ChargerDokument6 Seiten3 Dollar Battery ChargerbelmopanNoch keine Bewertungen

- Doble Bobina GS 125Dokument5 SeitenDoble Bobina GS 125ROBINSON FERNEYNoch keine Bewertungen

- P LampsDokument25 SeitenP Lampsicon6970Noch keine Bewertungen

- Mini Power Supply 33v 5A ScriptDokument8 SeitenMini Power Supply 33v 5A ScriptIlago BenignoNoch keine Bewertungen

- DC Voltage Testing: Nodal AnalysisDokument7 SeitenDC Voltage Testing: Nodal Analysisseshubabu_999Noch keine Bewertungen

- Polaris Ignition SystemDokument3 SeitenPolaris Ignition Systemluvmaine2Noch keine Bewertungen

- Low Voltage & Automotive Circuit ProtectionDokument7 SeitenLow Voltage & Automotive Circuit ProtectionTim schroderNoch keine Bewertungen

- Headlight Relays - To Do or Not To DoDokument3 SeitenHeadlight Relays - To Do or Not To DoRoyal ENoch keine Bewertungen

- Updated Mod-3 For The C90Dokument14 SeitenUpdated Mod-3 For The C90Leonardo Halon100% (1)

- Chapter 5 - Wiring PointsDokument15 SeitenChapter 5 - Wiring PointsAnthony FarrellNoch keine Bewertungen

- Coil Gun Kit Instructions From Disposable CameraDokument3 SeitenCoil Gun Kit Instructions From Disposable CameraPhilip Henson0% (1)

- Ducati Kickstand ModDokument4 SeitenDucati Kickstand ModTim de JongNoch keine Bewertungen

- Encontrar Cortos Facil EnglishDokument4 SeitenEncontrar Cortos Facil EnglishCarlos AlbertoNoch keine Bewertungen

- Relays in AutomobilesDokument8 SeitenRelays in AutomobilesTesfahun TegegneNoch keine Bewertungen

- Yamaha RXS100 12 Volt ConversionDokument2 SeitenYamaha RXS100 12 Volt Conversionjohnnyhawk2002Noch keine Bewertungen

- Build Your Own Portable Power Station: An Arfcom Tutorial (Very Pic Heavy)Dokument10 SeitenBuild Your Own Portable Power Station: An Arfcom Tutorial (Very Pic Heavy)John MillerNoch keine Bewertungen

- E46 HID InstallDokument10 SeitenE46 HID Installsonic100% (1)

- Heater Fan Switch WorkaroundDokument3 SeitenHeater Fan Switch WorkaroundJack MarlowNoch keine Bewertungen

- Arduino Bedini Charger Guide Setup Replication TestsDokument8 SeitenArduino Bedini Charger Guide Setup Replication TestsBastien Gall de Sillé0% (1)

- AccuSpark Fault FindingDokument2 SeitenAccuSpark Fault FindingMshiboniumNoch keine Bewertungen

- Electrical SystemDokument283 SeitenElectrical Systemzed shop73100% (1)

- Aliner Ext Porch Light ProjectDokument5 SeitenAliner Ext Porch Light ProjectthriftytravelNoch keine Bewertungen

- How To Rewire A Car - The Easy WayDokument13 SeitenHow To Rewire A Car - The Easy WayLucas BrownNoch keine Bewertungen

- The Big 3 UpgradeDokument2 SeitenThe Big 3 UpgradekanzazzNoch keine Bewertungen

- Split Charge InstructionsDokument4 SeitenSplit Charge InstructionsAugusto ZanlungoNoch keine Bewertungen

- Build a low-drop trailer stop and turn signal converterDokument5 SeitenBuild a low-drop trailer stop and turn signal converterTim schroderNoch keine Bewertungen

- Tail Light Installation InstructionsDokument2 SeitenTail Light Installation InstructionsNick rytychNoch keine Bewertungen

- RelayDokument5 SeitenRelayShafiq AmierNoch keine Bewertungen

- 5 V Power SplyDokument13 Seiten5 V Power SplyShahid SiddiquiNoch keine Bewertungen

- Automotive Electrical SystemDokument6 SeitenAutomotive Electrical SystemLuke Scofield100% (1)

- Understanding RelaysDokument75 SeitenUnderstanding RelaysAnonymous vMzbUJNoch keine Bewertungen

- Click No StartDokument3 SeitenClick No StartAnonymous 5tSwulWNoch keine Bewertungen

- Alternator ModDokument28 SeitenAlternator ModinsulatedNoch keine Bewertungen

- Basic Tips, Tricks & Tools For Wiring Your VehicleDokument10 SeitenBasic Tips, Tricks & Tools For Wiring Your VehicleConrad SternNoch keine Bewertungen

- Bad Stator Fix - Don't Buy A New Stator For Your Engine! Create A Battery-Op Ignition System For Less Than $50Dokument13 SeitenBad Stator Fix - Don't Buy A New Stator For Your Engine! Create A Battery-Op Ignition System For Less Than $50Onelove ManNoch keine Bewertungen

- Proper Relay Circuit UseDokument4 SeitenProper Relay Circuit Useex14himanshuNoch keine Bewertungen

- Homebrew Lead Acid Battery DesulfatorDokument5 SeitenHomebrew Lead Acid Battery Desulfatorrosslovelady100% (1)

- A Simple Inverter For Flourescent LampsDokument5 SeitenA Simple Inverter For Flourescent Lampstenk_manNoch keine Bewertungen

- Remote Bird Launcher Project PlansDokument16 SeitenRemote Bird Launcher Project PlansLê Trindad TrinNoch keine Bewertungen

- Building Circuits On BreadboardsDokument23 SeitenBuilding Circuits On Breadboardsniyop4allNoch keine Bewertungen

- 12V, 5 Amp SMPS Battery Charger Circuit - Homemade Circuit ProjectsDokument103 Seiten12V, 5 Amp SMPS Battery Charger Circuit - Homemade Circuit Projectsmohamed lamine elbiskriNoch keine Bewertungen

- Coaxial Power ConnectorDokument12 SeitenCoaxial Power ConnectorSo BorathNoch keine Bewertungen

- Redes DisponiblesDokument1 SeiteRedes DisponiblesRoberto Lopez RojasNoch keine Bewertungen

- Garage Door Opener Model 3265 1/2 HP: Owner's ManualDokument36 SeitenGarage Door Opener Model 3265 1/2 HP: Owner's ManualJairo Enrique Rojas TorresNoch keine Bewertungen

- Redes DisponiblesDokument1 SeiteRedes DisponiblesRoberto Lopez RojasNoch keine Bewertungen

- Redes DisponiblesDokument1 SeiteRedes DisponiblesRoberto Lopez RojasNoch keine Bewertungen

- BT50 QT-9 Parts Diagram: WWW - Chinesescooterclub.co - UkDokument38 SeitenBT50 QT-9 Parts Diagram: WWW - Chinesescooterclub.co - UkRoberto Lopez RojasNoch keine Bewertungen

- Illustrated Parts List 31A700: Model SeriesDokument12 SeitenIllustrated Parts List 31A700: Model SeriesRoberto Lopez RojasNoch keine Bewertungen

- Resistors: Resistors in Series Resistors in ParallelDokument3 SeitenResistors: Resistors in Series Resistors in ParallelRoberto Lopez RojasNoch keine Bewertungen

- GAL16V8Dokument22 SeitenGAL16V8Esaú RojasNoch keine Bewertungen

- Garage Door Opener Model 3265 1/2 HP: Owner's ManualDokument36 SeitenGarage Door Opener Model 3265 1/2 HP: Owner's ManualJairo Enrique Rojas TorresNoch keine Bewertungen

- Mikuni SBN ManualDokument22 SeitenMikuni SBN ManualAdrian C.Noch keine Bewertungen

- Significado de Las Letras de La BujiaDokument1 SeiteSignificado de Las Letras de La BujiaBelfor Luis Vilca LecarosNoch keine Bewertungen

- 5L40EDokument5 Seiten5L40EjaeszNoch keine Bewertungen

- Significado de Las Letras de La BujiaDokument1 SeiteSignificado de Las Letras de La BujiaBelfor Luis Vilca LecarosNoch keine Bewertungen

- Mikuni CarbsDokument1 SeiteMikuni Carbsserg_bushNoch keine Bewertungen

- Mikuni SBN ManualDokument22 SeitenMikuni SBN ManualAdrian C.Noch keine Bewertungen

- Linelazer 3400 Airless Line Striper: RepairDokument26 SeitenLinelazer 3400 Airless Line Striper: RepairRoberto Lopez RojasNoch keine Bewertungen

- 83-97 FORD RANGER, BRONCO II 4” LIFT KIT INSTRUCTIONSDokument4 Seiten83-97 FORD RANGER, BRONCO II 4” LIFT KIT INSTRUCTIONSRoberto Lopez RojasNoch keine Bewertungen

- Horsepower and TorqueDokument9 SeitenHorsepower and TorqueRoberto Lopez RojasNoch keine Bewertungen

- Ford Ranger, Mazda TrucksDokument1 SeiteFord Ranger, Mazda TrucksRoberto Lopez RojasNoch keine Bewertungen

- 83-97 FORD RANGER, BRONCO II 4” LIFT KIT INSTRUCTIONSDokument4 Seiten83-97 FORD RANGER, BRONCO II 4” LIFT KIT INSTRUCTIONSRoberto Lopez RojasNoch keine Bewertungen

- Illustrated Parts List 31A700: Model SeriesDokument12 SeitenIllustrated Parts List 31A700: Model SeriesRoberto Lopez RojasNoch keine Bewertungen

- Universal Rear 4-Link Instructions: Trim Crossmembers To Fit Your ChassisDokument8 SeitenUniversal Rear 4-Link Instructions: Trim Crossmembers To Fit Your ChassisRoberto Lopez RojasNoch keine Bewertungen

- EolicoDokument3 SeitenEolicoRoberto Lopez RojasNoch keine Bewertungen

- Resistors: Resistors in Series Resistors in ParallelDokument3 SeitenResistors: Resistors in Series Resistors in ParallelRoberto Lopez RojasNoch keine Bewertungen

- Common Tuning IssuesDokument12 SeitenCommon Tuning IssuesRoberto Lopez RojasNoch keine Bewertungen

- Instructions For Linbar and Multibar Part # 901-1, 13901Dokument1 SeiteInstructions For Linbar and Multibar Part # 901-1, 13901Roberto Lopez RojasNoch keine Bewertungen

- Horsepower and TorqueDokument9 SeitenHorsepower and TorqueRoberto Lopez RojasNoch keine Bewertungen

- Cavitation and Pump NPSHRDokument39 SeitenCavitation and Pump NPSHRRicardo BarrosNoch keine Bewertungen

- MATHEMATICAL MODELLING OF TUBULAR AIR HEATERSDokument50 SeitenMATHEMATICAL MODELLING OF TUBULAR AIR HEATERSBalaji NatarajanNoch keine Bewertungen

- CT00022379 28288Dokument48 SeitenCT00022379 28288Salim AshorNoch keine Bewertungen

- YOKOGAWA Exa Fc400g (Ing)Dokument91 SeitenYOKOGAWA Exa Fc400g (Ing)biotech666Noch keine Bewertungen

- Concrete Coating of Line Pipe PDFDokument19 SeitenConcrete Coating of Line Pipe PDFZadeh Norman100% (1)

- Cathodic Protection Specification - Takoradi Oil Terminal 27.02.2018 rv1 PDFDokument12 SeitenCathodic Protection Specification - Takoradi Oil Terminal 27.02.2018 rv1 PDFRaynus Arhin100% (1)

- KNOC - Surface Pre and Painting ProcedureDokument32 SeitenKNOC - Surface Pre and Painting Procedureminhhieu.qc100% (1)

- Sno Pro Diagnostic Troubleshooting Guide 72 520 1Dokument72 SeitenSno Pro Diagnostic Troubleshooting Guide 72 520 1papamatt100% (1)

- CCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)Dokument10 SeitenCCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)ManafNoch keine Bewertungen

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDokument36 SeitenRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456Noch keine Bewertungen

- Finite Element Analysis of The Stability of Tunnel Surrounding Rock With Weak Rock LayerDokument6 SeitenFinite Element Analysis of The Stability of Tunnel Surrounding Rock With Weak Rock LayerVahid ShariatyNoch keine Bewertungen

- Total Water Management in Thermal Power StationsDokument8 SeitenTotal Water Management in Thermal Power StationsSarah FrazierNoch keine Bewertungen

- API 650 Tank Design CalculationDokument9 SeitenAPI 650 Tank Design CalculationSunday PaulNoch keine Bewertungen

- Pellitization Vs SinteringDokument4 SeitenPellitization Vs SinteringBin YameenNoch keine Bewertungen

- DS DT 02 Standard TraysDokument4 SeitenDS DT 02 Standard TraysAhmet Samet ÖzdilekNoch keine Bewertungen

- Disclaimer Document Supplier ListDokument30 SeitenDisclaimer Document Supplier ListAmin AzadNoch keine Bewertungen

- Auxiliary Machines and Equipments in Electric LocomotivesDokument9 SeitenAuxiliary Machines and Equipments in Electric LocomotivesJanmejay SaxenaNoch keine Bewertungen

- Topray Tpsm5u 185w-200wDokument2 SeitenTopray Tpsm5u 185w-200wThanh Thai LeNoch keine Bewertungen

- 8.1prob Sheet Vapor Power CyclesDokument3 Seiten8.1prob Sheet Vapor Power CyclesAnonymous mXicTi8hB100% (1)

- CHS Waste Disposal GuideDokument37 SeitenCHS Waste Disposal GuideFazal RaheemNoch keine Bewertungen

- Advantages of Precast Concrete ConstructionDokument12 SeitenAdvantages of Precast Concrete Constructionvalerie samarNoch keine Bewertungen

- Filtro Bacteriologico Puritan BennetDokument24 SeitenFiltro Bacteriologico Puritan BennetRonald David ReyesNoch keine Bewertungen

- Unit Operation Lesson 1Dokument4 SeitenUnit Operation Lesson 1رائد عبد العزيز فرحانNoch keine Bewertungen

- Anchorage To Concrete - Means and MethodsDokument28 SeitenAnchorage To Concrete - Means and MethodsMustafaNoch keine Bewertungen

- I Clean - The ManualDokument71 SeitenI Clean - The ManualChristelle Van Ende100% (2)

- Allotropes of Phosphorus (White and Red)Dokument3 SeitenAllotropes of Phosphorus (White and Red)Mayette Rose SarrozaNoch keine Bewertungen

- M-DS31 Filcor Eps Data Sheet Cordek v1Dokument2 SeitenM-DS31 Filcor Eps Data Sheet Cordek v1ShamaNoch keine Bewertungen

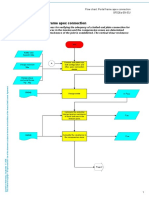

- SF026a-Flow Chart Portal Frame Apex ConnectionDokument3 SeitenSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevNoch keine Bewertungen

- Grillage Analogy C.S.surana R.agrawal - For WordDokument283 SeitenGrillage Analogy C.S.surana R.agrawal - For WordMohak Nagrani100% (1)

- LG AC Service ManualDokument80 SeitenLG AC Service ManualFrengky RmNoch keine Bewertungen