Beruflich Dokumente

Kultur Dokumente

Design of A Prosthesis For Running in Composite Materials

Hochgeladen von

ginkenoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of A Prosthesis For Running in Composite Materials

Hochgeladen von

ginkenoCopyright:

Verfügbare Formate

1

DESIGN OF A PROSTHESIS FOR RUNNING IN COMPOSITE MATERIALS

1.Introduction

Today there exist different kinds of leg prosthesis, that are not only able to satisfy the basic functions of an amputated leg, but also to guarantee high locomotor performances. Prosthesis for running are ranked as belonging to this category of leg prosthesis. The design of these prosthesis is not univocal, because the requirements that they have to satisfy can vary in terms of amputation condition and performance. To give an example in Fig. 1.1 are reported some types of prosthesis present on the market: we can find prosthesis with an L-shape for transfemoral amputated athletes; prosthesis with a form of sickle for transtibial amputated athletes; prosthesis with a C-shape to cover long distances.

Fig. 1.1: Three kinds of prosthesis presented by Ossur; from left: L-shaped Flex Sprint, Flex-Foot Cheetah, Cshaped Flex Run.

Studies are currently focused on stiffness and form of the artificial leg, in order to optimize elastic and inertia features, and to increase the maximum attainable velocity. Prosthesis are designed with numerical analyses supported by experimental tests and field-tests to monitor the gait they give to amputated subjects. A further development is necessary in the research field of energetic efficiency, concerning especially the time of elastic response and the achievement of a walk as similar as possible to the non-pathological one. In this work we have designed a C-shaped prosthesis with form and dimensions referred to the specifications of Flexproduced by Ossur. In the first part of the project the object has been represented as a beam with three elbows and, in this 2D configuration, restraining reactions and internal actions have been calculated. In the second part the prosthesis has been modeled in 3D and submitted to a static analysis with the support of the software FEM Abaqus. In this part of the work the object has been projected in order to meet the strain requirements and to be safe in harder conditions than the normally expected ones. We have estimated the amount of energy that the artificial leg is able to store and the effect of each mechanical property of the unidirectional lamina used.

2. Bidimensional static analysis of a beam-based model: restraining reactions and internal actions.

The prosthesis has been represented as a beam with three elbows, to reproduce approximately the profile of the real model. The Fig. 2.1 shows the proportions of lengths and angles, that have been chosen in order to adjust the schematic representation of a beam-based model to real forms and dimensions. Length L corresponds to 10 cm, while angle is of 120. The model has been submitted to a static analysis: in Fig. 2.2 are shown the vertical load P, applied by the runner in the connection point of the prosthesis, and the three degrees of constraint, represented by the reactions of a sleeve and the ground reaction force. The sleeve is placed in the same connection point and allows only vertical displacement, so it acts with an horizontal force and a momentum. The ground reaction force acts normally to the horizontal part of the beam, that is oriented parallel to the ground, and it is conceived as a distributed load (q is a force per unit length). The equality between degrees of freedom and of constraint and the configuration of the constraints make the system isostatic. The Fig. 2.2 shows also the explicit values of the constraints, found with a simple static analysis.

Fig. 2.1: Form and proportions of a C-shaped prosthesis modeled as a beam with three elbows.

Fig. 2.2: Representation of the users load and the constraints acting on the prosthesis.

Internal actions has been also evaluated; results are showed in Figg. 2.3, 2.4, 2.5. We can obtain the order of magnitude of forces and momenta acting on the model using a suitable value for the force P. We have chosen 2850 N, that is the mean value transmitted on the prosthesis by an amputated leg during the athletic gesture [1]. We can notice that the maxima shear forces involve the two horizontal pieces of beam: in the upper the value is constant, while in the lower the value has a linear trend with the highest value present on the left end. The highest value coincides with P so it is equal to 2850 N. Normal forces act only on the two oblique parts, and have a constant value of about 2470 N. The momenta reach their maximum value, about 520 Nm, on the elbow formed by the two oblique parts.

3 P C P

CC

Fig. 2.3: Representation of the internal shear actions; words C and CC indicate clockwise and counterclockwise direction respectively.

Fig. 2.4: Representation of the internal axial actions; C indicates compressive direction.

Fig. 2.5: Representation of the bending momenta oriented towards the stretched fibers zone.

3. Creation of the model in Abaqus

The prosthesis has been devised as an unidirectional laminate in epoxy matrix reinforced with carbon fibers (volumetric fraction of 0,6). The Tab. 3.1 reports the properties of a single lamina.

(GPa) 148 (MPa) 1314

(GPa) 9,66 (MPa) 1220

0,3 (MPa) 43

(GPa) 4,55 (MPa) 168

(GPa) 4,55 (MPa) 48

(GPa) 2,95

Tab. 3.1: Mechanical properties of an unidirectional lamina T300/934 Carbon/Epoxy; E and G are the normal and the shear modulus respectively; is the Poissons coefficient; F is the ultimate strength.

The object has been modeled as a 3D deformable shell with an height of 35 cm and a width of 8 cm as showed in Figg. 3.1 and 3.2. A reference point, used to apply the vertical force, has been created within the upper horizontal portion of the profile; the Fig. 2.2 shows this point.

35 cm

15 cm 8 cm

Fig. 3.1: Profile view of the model with its dimensions.

Fig. 3.2: View with the width dimension; in the red circle is highlighted the application point of the force.

An additional rectangular element has been created with the function of reference plate for the application of ground constraints. Therefore an interaction has been imposed between the lower extremity of the prosthesis and the plate, neglecting the friction between the two elements; a vertex of the plate has been restrained as an encastre. Also the final edge of the prosthesis has been constrained allowing only vertical displacement and rotation respect to the axis in the direction of the width; Fig. 3.3 clarifies configuration and constraints. A last constraint, that permits only vertical displacement, has been applied to the reference point for the application of the force. For each analyzed case the direction of force is vertical. The profile of the prosthesis and the direction of the width generate the principal directions, 1 and 2 respectively, the orientation of plies are referred to. Both prosthesis and plate have been meshed by using quad structured elements of dimension 7 mm.

Encastre on a vertex of the plate Constraints for displacement and rotation on the final edge of the prosthesis

Fig. 3.3: Configuration of prosthesis and plate; the red arrows highlight the boundary conditions regarding the lower part of the system.

4. Choice of the lamination thickness

The prosthesis has been initially designed as a superposition of thirty unidirectional laminas, covering the entire object along its profile and all oriented in direction 1. The thickness of each lamina has been set in order to obtain a vertical displacement (of the point in which the force is applied) included in the range of the values considered optimal during running, i.e. between 35 and 55 mm [2]. The force value used for this aim is 2850 N, as explained in the second paragraph. The Fig. 4.1 shows how the displacement values vary respect to the thickness of a single lamina.

65 60

Vertical displacement (mm)

55 50 45 40 35 30 0,17 0,18 0,19 0,20 0,21 0,22 Thickness (mm)

Fig. 4.1: Trend of the vertical displacement respect to the thickness of a single lamina

6 We have chosen a thickness value of 0,21 mm, that corresponds to a displacement of 37,6 mm. In this way the total thickness of the laminate is of 6,3 mm.

5. Resistance verification

Fixed the thickness of the laminate, we have checked that the choice guaranteed an adequate degree of safety during working. The value of force applied for this verification is 5000 N, that results from increasing by 75% the working value of 2850 N (for precision the resulting value is 4987,5 N, that we have round up). The Tsai-Hill failure criterion (Eq. 5.1) has been used, considering only the stresses in the plane, since the laminate is very thin. ( ) ( ) ( ) ( )

To have a first indication about a possible fracture we have looked at the maximum mean values of tensile, compressive and shear stresses reached by the prosthesis; we have considered the first ply since the highest degree of stress is localized in the outermost plies, in a symmetric way (the maximum tensile value in the ply 1 is roughly equal to the maximum compressive value in the ply 30 and vice versa). The data are presented in the Tab. 5.1.

Minimum mean value

Type of stress

-1330 MPa -26 MPa -6 MPa

Maximum mean value 750 MPa 14 MPa 6 MPa

Tab. 5.1: Maximum mean values of stress obtained on ply 1, simulating the application of 5000 N on the prosthesis with thirty laminas, each of them with thickness of 0,21 mm.

is the most problematical type of stress; in fact on the ply 1 it reaches a compressive value of 1330 MPa, that overcomes the material strength = 1220 MPa; analogous question regards the ply 30 on which is the tensile value higher than the strength. The more stressed zone, in which reaches the highest value, is the blue region indicated in Fig. 5.1.

Fig. 5.1: Red arrows highlighted the blue zone, in which the ply 1.

reaches the maximum compressive value for

7 At first we have examined this zone; as for the other zones considered later, we have applied the equation 5.1 in the whole thickness, taking into account the variation of the stress values through it. Data in Tab. 5.2 show that, for the examined zone, the outermost plies break according to the Tsai-Hill criterion. (MPa) -1338,69 -1293,78 -1203,97 -1114,16 -1024,34 -934,53 -844,71 -754,90 -665,09 -575,27 -485,46 -395,64 -305,83 -216,02 -126,20 -36,39 53,43 143,24 233,06 322,87 412,68 502,50 592,31 682,13 771,94 861,76 951,57 1041,38 1131,20 1221,01 1310,83 1355,73 (MPa) -26,79 -25,89 -24,09 -22,30 -20,50 -18,70 -16,90 -15,11 -13,31 -11,51 -9,71 -7,92 -6,12 -4,32 -2,52 -0,73 1,07 2,87 4,67 6,46 8,26 10,06 11,86 13,65 15,45 17,25 19,04 20,84 22,64 24,44 26,23 27,13 -0,29 -0,28 -0,26 -0,24 -0,22 -0,20 -0,18 -0,16 -0,14 -0,12 -0,11 -0,09 -0,07 -0,05 -0,03 -0,01 0,01 0,03 0,05 0,07 0,09 0,11 0,13 0,15 0,17 0,19 0,21 0,23 0,24 0,26 0,28 0,29 Thickness (mm) 0,00 0,10 0,32 0,53 0,73 0,95 1,16 1,37 1,58 1,79 2,00 2,21 2,42 2,63 2,84 3,05 3,26 3,47 3,68 3,89 4,10 4,31 4,52 4,73 4,94 5,15 5,36 5,57 5,78 5,99 6,20 6,30 Values in compression 1,21 1,13 0,98 0,83 0,71 0,59 0,48 0,38 0,30 0,22 0,16 0,11 0,06 0,03 0,01 0,00 Values in traction

0,00 0,02 0,04 0,08 0,13 0,20 0,28 0,36 0,47 0,58 0,71 0,85 1,00 1,17 1,35 1,44

Tab. 5.2: Application of the Tsai-Hill equation (last two columns) on a square of the blue zone showed in Fig. 5.1. Red color highlights the exceeding (or the equaling) of the breaking threshold.

As consequence of these results, we have tried to increase the thickness of each lamina, going from 0,21 mm to 0,23 mm. Also in this case the object breaks in the ply 30, even if the limit value 1 in the equation 5.1 is not much exceeded.

8 Therefore we have decided to change strategy, in order to avoid an excessive increasing of thickness (and so of weight) of the prosthesis. Since we had already checked with thickness 0,21 mm that the only critical region is the showed one in Fig. 5.1, we have tried to use 30 plies, 0,21 mm thick, covering the entire profile of the proshtesis (as in the first choice) and to add four further plies, 0,28 mm thick, just in that region. To be more precise this zone is indicated in Fig. 5.2.

Fig. 5.2: With red color is showed the zone in which four plies 0,28 mm thick has been added.

This solution works well. At first we notice that the maximum mean values of stress are quite lower than the strength ones, as reported in Tab. 5.3.

Minimum mean value

Type of stress

-813 MPa -16 MPa -5 MPa

Maximum mean value 466 MPa 8 MPa 5 MPa

Tab. 5.3: Maximum mean values of stress obtained on the ply 1, simulating the application of 5000 N on the prosthesis with thirty laminas, 0,21 mm thick, covering all the profile and four laminas, 0,28 mm thick, added only in the region of Fig. 5.2 .

In the most critical zone the maximum value reached by using the equation 5.1 is 0,57. The Tsai-Hill criterion has been successfully satisfied also in the red region showed in Fig. 5.3, in which reaches the maximum tensile value in the ply 1; applying here the equation 5.1 the value 0,16 is not exceed. To do a complete check of the safety condition, we have also considered the more stressed region for and Confronting the Tabb. 3.1 and 5.3 an important indication is that the maximum mean values, for these two types of stress, are lower than the strength values of an order of magnitude. With regard to the more stressed regions are indicated in Fig. 5.4. They are the same zones (blue in compression and red in traction, for the ply 1) already checked since critical for . With regard to Fig. 5.5 shows that the maximum values are on the boundary of the critical zone, positive on one side and negative on the other side. Applying the equation 5.1 a value of 0,27 results, well lower than 1.

6. Energetic considerations

Storage and restitution of energy by materials used in sports application play, in general, a fundamental role with regard to the performance and the safety of the athletes. This fact posed a serious question about the possible disparity of performance condition between the

Fig. 5.3: Red color indicates the zone in which the maximum tensile values for the ply 1.

reaches

Fig. 5.4: Blue color indicates the zone in which reaches its maximum compressive values, while red color is associated to its maximum tensile values, for the ply 1.

10 runners competing with a prosthesis and the able-bodied ones. We have evaluated the energy restituted by the prosthesis, in static condition, under a working vertical force of 2850 N. For this and the following analysis we have obviously used the lamination configuration that satisfies the Tsai-Hill criterion. Since the materials forming the prosthesis are modeled as elastic, the restituted energy equals the stored energy, without any dissipation. The obtained value is about 47 J, that is consistent with the values obtained in a more accurate study in which, for a carbon/epoxy prosthesis, the different phases of running has been considered [3]. Positive

Negative

Fig. 5.5: Blue color indicates the zone in which reaches the maximum negative values, while red color is associated to the maximum positive values, for the ply 1.

7. Relation between force and vertical displacement

We have done some simulations with different values of force, in order to evaluate its influence on the vertical displacement of the point in which the force is applied. The results are presented in Fig. 7.1. The force values applied go from 1000 N to 5000 N, with increases of 500 N. The slope of the curve is obviously positive and tend to decrease slowly, but not in a regular way. The slope of a linear fitting on the whole interval is about 11 mm/kN.

8. Influence of the material properties

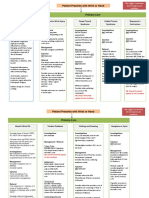

We have done simulations with the working force value of 2850 N, changing one by one the values of the elastic moduli and of the Poissons coefficient of 10% respect to the ones present in the Tab. 3.1. In this way we have estimated the effect of each property on the vertical displacement and on the energy storage of the prosthesis. The Tab. 8.1 shows that is the only property the variation of which has a significant effect on the prosthesis behavior.

11

60

50

Vertical displacement (mm)

40

30

20

10

0 0 1000 2000 3000 4000 5000

Force (N)

Fig. 7.1: Trend of the vertical displacement respect to the vertical force

Property

Property value 125,8 GPa 148 GPa 170,2 GPa 8,21 GPa 9,66 GPa 11,11 GPa 0,255 0,3 0,345 3,87 GPa 4,55 GPa 5,23 GPa

Displacement (mm) 42,57 37,03 33,77 37,04 37,03 37,025 37,05 37,03 37,01 37,11 37,03 36,98

Displacement variation (%) +15 -8,8 +0,03 -0,01 +0,05 -0,05 +0,2 -0,1

Energy (J) 55,07 47,42 44,54 47,43 47,42 47,42 47,43 47,42 47,41 47,52 47,42 47,35

Energy variation (%) +16,1 -6,1 +0,02 0 +0,02 -0,02 +0,2 -0,1

Fig. 8.1: Effect of each of the four principal mechanical properties on the prosthesis response in terms of displacement and energy storage.

12

9. Production technology

A suitable production technology for the prosthesis designed in this work is the hand layup and the autoclave molding. This technology allows a level of freedom, in the choice of geometry, quite higher respect to other technologies as pultrusion and filament winding. It permits also high volumetric fraction of fibers (that in this case is 0,6) and accurate control of their direction. However the working temperature doesnt overcome 40-50 C, so the temperature reached by the autoclave should not be much higher.

10. Conclusions

In this work we have designed a C-shaped prosthesis for running in carbon fibers and epoxy resin, modeled as an unidirectional laminate. A static analysis performed (with FEM method) applying a vertical force in the connection point with the human body has revealed that the most critical zone, in terms of stresses, is the first horizontal portion of the profile. In this zone we have inserted four further plies, 0,28 thick, in addition to the thirty others, 0,21 thick, covering the whole profile. The prosthesis has passed the resistance verification with a load increased by 75% the working one. The quantity of energy stored and restituted by the object in static conditions, under the typical working load, is about 47 J. The axial modulus in direction 1 has turned out to be the only mechanical property having significant effect on the displacement and the energetic responses. This suggests that it is the most important mechanical property that must be taken into account to obtain an optimization of performances.

Bibliography

[1] D. I. Miller, Biomechanical considerations in lower extremity amputee running and sports performance, Aust J Sports Med, 13, 55-67, 1981. [2] D. Pailler, P. Sautreuil, J.-B. Piera, M. Genty, H. Goujon, volution des prothses des sprinters amputs de membre infrieur, Annales de radaptation et de mdecine physique, 47, 374-381, 2004. [3] C. Colombo, A. Curti, Modellazione e ottimizzazione di una protesi transtibiale per attivit sportiva, XXXVIII Convegno Nazionale AIAS, 2009.

Das könnte Ihnen auch gefallen

- Gemstone and Crystal Reference Book EnglishDokument29 SeitenGemstone and Crystal Reference Book Englishsandu_livia100% (1)

- LowBackPain PDFDokument217 SeitenLowBackPain PDFBugis MuslimNoch keine Bewertungen

- Rehab Plans and Exercises Minor Rotator Cuff Repair Protocol For Physiotherapy Following SurgeryDokument11 SeitenRehab Plans and Exercises Minor Rotator Cuff Repair Protocol For Physiotherapy Following SurgeryTech How AssamNoch keine Bewertungen

- Jude's Quadriceps Plasty For Stiff KneeDokument6 SeitenJude's Quadriceps Plasty For Stiff KneeRaviNoch keine Bewertungen

- Surgical Incisions of Lower LimbDokument11 SeitenSurgical Incisions of Lower LimbcpradheepNoch keine Bewertungen

- APPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGDokument4 SeitenAPPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGKyle LoveNoch keine Bewertungen

- SM 10 - Knee Lesson 1Dokument4 SeitenSM 10 - Knee Lesson 1api-383568582Noch keine Bewertungen

- Soft tissue injury treatmentDokument2 SeitenSoft tissue injury treatmentThiruNoch keine Bewertungen

- Neck PainDokument1 SeiteNeck PainHasan RahmanNoch keine Bewertungen

- Orthotics Consensus Conference ReportDokument354 SeitenOrthotics Consensus Conference ReportAlec joshua RapadaNoch keine Bewertungen

- Knee Biomechanics: Mark Arthur Martinez Trauma 1 April 5, 2018Dokument7 SeitenKnee Biomechanics: Mark Arthur Martinez Trauma 1 April 5, 2018Juan Alvaro EstradaNoch keine Bewertungen

- Shoulder Arthroplasty WIC - Dr. LSDokument56 SeitenShoulder Arthroplasty WIC - Dr. LSDifitasari Cipta Perdana100% (1)

- Diagnosis and Treatment of Acute Essex-Lopresti inDokument11 SeitenDiagnosis and Treatment of Acute Essex-Lopresti inMỸ NGUYỄN CÔNGNoch keine Bewertungen

- Carbon CompositesDokument30 SeitenCarbon CompositesVIbhav GuptaNoch keine Bewertungen

- 04 Samss 005Dokument10 Seiten04 Samss 005ShojikuriakoseT100% (1)

- HumanBody - 3d Model and AnalysisDokument407 SeitenHumanBody - 3d Model and Analysissssq1Noch keine Bewertungen

- 9 InsulatorDokument39 Seiten9 InsulatorLeo KhkNoch keine Bewertungen

- Ijspt-Biomechanics and Pathomechanics of The Patellofemoral JointDokument11 SeitenIjspt-Biomechanics and Pathomechanics of The Patellofemoral JointDevi MigiekaNoch keine Bewertungen

- Clinicas de Endocrino. Pie Diabetico - Dic 2013Dokument15 SeitenClinicas de Endocrino. Pie Diabetico - Dic 2013Betzabeth RodriguezNoch keine Bewertungen

- MPFL ReconstructionDokument16 SeitenMPFL ReconstructiondrjorgewtorresNoch keine Bewertungen

- Management of Patellofemoral Chondral InjuriesDokument24 SeitenManagement of Patellofemoral Chondral InjuriesBenalNoch keine Bewertungen

- Clemens Attinger 10 Angiosomes and Wound Care in The Diabetic FootDokument26 SeitenClemens Attinger 10 Angiosomes and Wound Care in The Diabetic FootDorin DvornicNoch keine Bewertungen

- Introductio To OrthoticsDokument8 SeitenIntroductio To OrthoticsGopi Krishnan100% (1)

- Advances in Spinal Stabilization PDFDokument333 SeitenAdvances in Spinal Stabilization PDFMateo CortesNoch keine Bewertungen

- Transtibial Prosthetics 1 PDFDokument64 SeitenTranstibial Prosthetics 1 PDFAlfionita Wika100% (1)

- FEECO Rotary Dryers Coolers PDFDokument13 SeitenFEECO Rotary Dryers Coolers PDFFernando MilmanNoch keine Bewertungen

- Ispo-Who Training GuidelinesDokument59 SeitenIspo-Who Training GuidelinesAlfionita WikaNoch keine Bewertungen

- Clavicle Plate and Screw System Surgical TechniqueDokument12 SeitenClavicle Plate and Screw System Surgical TechniqueDrvijay Saradhara100% (1)

- 2012 Scapular-Focused Treatment in Patients With ShoulderDokument13 Seiten2012 Scapular-Focused Treatment in Patients With ShoulderIsrael Matías Chandia Ramírez100% (1)

- Hanger PDRDokument63 SeitenHanger PDRTetay JavierNoch keine Bewertungen

- Modelling and Analysis of A Prosthetic Runner BladeDokument11 SeitenModelling and Analysis of A Prosthetic Runner BladeIJRASETPublicationsNoch keine Bewertungen

- Shimadzu System GC CatalogDokument48 SeitenShimadzu System GC CatalogTerry Osenbach100% (1)

- Pediatric SplintingDokument51 SeitenPediatric SplintingNathalie Michelle HenriquezNoch keine Bewertungen

- P&O Elementary MathematicsDokument22 SeitenP&O Elementary MathematicsrrutayisireNoch keine Bewertungen

- Above-Knee Fitting and Alignment Tehniques PDFDokument18 SeitenAbove-Knee Fitting and Alignment Tehniques PDFsunsrayNoch keine Bewertungen

- How To Make A Prosthetic LimbDokument6 SeitenHow To Make A Prosthetic LimbMatt LawallNoch keine Bewertungen

- Prosthetic Knee Joints: Submitted By:-Ravi Mpo 1 YrDokument37 SeitenProsthetic Knee Joints: Submitted By:-Ravi Mpo 1 YrRavi KumarNoch keine Bewertungen

- Orthotics and ProstheticsDokument93 SeitenOrthotics and ProstheticsAwaisNoch keine Bewertungen

- EE3BA3 2013 OutlineDokument4 SeitenEE3BA3 2013 OutlineadiazNoch keine Bewertungen

- Steeper Prosthetic Best Practice GuidelinesDokument67 SeitenSteeper Prosthetic Best Practice GuidelinesMohammed Al-shamiriNoch keine Bewertungen

- Hand and Wrist PathwayDokument2 SeitenHand and Wrist PathwaydrsadafrafiNoch keine Bewertungen

- Biomechanical Basis of Foot Orthotic PrescriptionDokument6 SeitenBiomechanical Basis of Foot Orthotic PrescriptionDusan OrescaninNoch keine Bewertungen

- Joan Edelstein - Alex Moroz - Lower-Limb Prosthetics and Orthotics - Clinical Concepts-SLACK, Incorporated (2010)Dokument215 SeitenJoan Edelstein - Alex Moroz - Lower-Limb Prosthetics and Orthotics - Clinical Concepts-SLACK, Incorporated (2010)Andrei ȚîrleaNoch keine Bewertungen

- Amputee Course 2009Dokument6 SeitenAmputee Course 2009ptannenbaumNoch keine Bewertungen

- Biomechanics of The ElbowDokument16 SeitenBiomechanics of The ElbowAsmaa Ahmad SharawyNoch keine Bewertungen

- Pediatrics FracturesDokument14 SeitenPediatrics Fracturesخالد الغامديNoch keine Bewertungen

- Myoelectric ControlDokument15 SeitenMyoelectric ControlAbdullah AhmedNoch keine Bewertungen

- Patterns of Triangular Fibrocartilage Complex (TFCC) Injury Associated WithDokument7 SeitenPatterns of Triangular Fibrocartilage Complex (TFCC) Injury Associated WithCésarLópezNoch keine Bewertungen

- Prosthesis For Symes AmputationDokument24 SeitenProsthesis For Symes AmputationSHAIK SHABEENANoch keine Bewertungen

- 2.08 Brachial Region (Arm) - Compartments, Muscles, Nerves, and VesselsDokument3 Seiten2.08 Brachial Region (Arm) - Compartments, Muscles, Nerves, and VesselsDi CanNoch keine Bewertungen

- Journeyii CR 00344v1 UsDokument40 SeitenJourneyii CR 00344v1 UsSufyanNoch keine Bewertungen

- Understanding and Managing Chronic Wounds: Jasmine Kartiko Pertiwi Jurusan Fisioterapi Poltekkes Kemenkes SurakartaDokument13 SeitenUnderstanding and Managing Chronic Wounds: Jasmine Kartiko Pertiwi Jurusan Fisioterapi Poltekkes Kemenkes Surakartaamarilis sekarNoch keine Bewertungen

- Therapeutic Management of Knee Osteoarthritis: BY PT H N AbdullateefDokument96 SeitenTherapeutic Management of Knee Osteoarthritis: BY PT H N AbdullateefMaida FitrianiNoch keine Bewertungen

- Knee Biomechanics: Andrew CrosbyDokument32 SeitenKnee Biomechanics: Andrew CrosbyBhanu Pratap PangteyNoch keine Bewertungen

- Surgical Technique For Combined D Wyer Calcaneal Osteotomy and PeronealDokument6 SeitenSurgical Technique For Combined D Wyer Calcaneal Osteotomy and PeronealleahbayNoch keine Bewertungen

- Distal Biceps Repair Rehabilitation Protocol by Tendayi MutsopotsiDokument5 SeitenDistal Biceps Repair Rehabilitation Protocol by Tendayi MutsopotsiPhysiotherapy Care SpecialistsNoch keine Bewertungen

- P&O International Orthotic Solution DelhiDokument12 SeitenP&O International Orthotic Solution Delhineerajsaxena2018Noch keine Bewertungen

- Tennis Elbow JOSPT ArticleDokument11 SeitenTennis Elbow JOSPT ArticleHasan RahmanNoch keine Bewertungen

- The Relationship of Static Foot Structure To Dynamic Foot FunctionDokument8 SeitenThe Relationship of Static Foot Structure To Dynamic Foot FunctionminasNoch keine Bewertungen

- Indications and Clinical Outcomes of High Tibial Osteotomy A Literature ReviewDokument8 SeitenIndications and Clinical Outcomes of High Tibial Osteotomy A Literature ReviewPaul HartingNoch keine Bewertungen

- The Timed Up & Go - A Test of Basic Functional Mobility For Frail Elderly Persons. lAGSDokument7 SeitenThe Timed Up & Go - A Test of Basic Functional Mobility For Frail Elderly Persons. lAGSJose Fernando Díez ConchaNoch keine Bewertungen

- De Quervain SyndromeDokument5 SeitenDe Quervain Syndromebangla018Noch keine Bewertungen

- Introduction To Prosthetic & OrthoticDokument63 SeitenIntroduction To Prosthetic & OrthoticHassan Saifullah Khan AlisherzaiNoch keine Bewertungen

- THR 170717150826 PDFDokument50 SeitenTHR 170717150826 PDFTefera LeteboNoch keine Bewertungen

- Exercise 2 Activity 3 Muscle SummationDokument13 SeitenExercise 2 Activity 3 Muscle SummationElvira BasilioNoch keine Bewertungen

- GMFM (GMFM-66 & GMFM-88) User's Manual, 2nd editionVon EverandGMFM (GMFM-66 & GMFM-88) User's Manual, 2nd editionBewertung: 1 von 5 Sternen1/5 (1)

- Fresher Course Chemistry Practice ProblemsDokument2 SeitenFresher Course Chemistry Practice ProblemsHarsh Agarwal0% (1)

- Indonesian Journal of Chemical Science and Technology: State University of MedanDokument7 SeitenIndonesian Journal of Chemical Science and Technology: State University of Medanrizky bungaNoch keine Bewertungen

- Epsilon Echos 2 BDokument40 SeitenEpsilon Echos 2 BDaniel JoseNoch keine Bewertungen

- Caustic Potash SpecificationDokument1 SeiteCaustic Potash SpecificationJayakumar ANoch keine Bewertungen

- Maximizing Volumetric Efficiency of IC Engine Through Intake Manifold TuningDokument8 SeitenMaximizing Volumetric Efficiency of IC Engine Through Intake Manifold TuningMahtab GhummanNoch keine Bewertungen

- ISA-TR20.00.01 CD-ROM Table of Contents PDFDokument5 SeitenISA-TR20.00.01 CD-ROM Table of Contents PDFmegojasNoch keine Bewertungen

- Aqa Chm6x QP Jun12Dokument12 SeitenAqa Chm6x QP Jun12Georgiana CrivatNoch keine Bewertungen

- 5-1-14 Recueil Methodes Vol 1 en 2012Dokument488 Seiten5-1-14 Recueil Methodes Vol 1 en 2012James Quynh NguyenNoch keine Bewertungen

- IB Biology HL IA (MAY 2021)Dokument14 SeitenIB Biology HL IA (MAY 2021)Insiyah Huzefa BasraiNoch keine Bewertungen

- Black SandDokument2 SeitenBlack SandMinato100% (1)

- MEC102 Engineering Mechanics Course OverviewDokument1 SeiteMEC102 Engineering Mechanics Course OverviewVkrthirumalai RamanathanNoch keine Bewertungen

- Section 05 Block WorksDokument10 SeitenSection 05 Block WorksMarvin MessiNoch keine Bewertungen

- Ionization and Solubility of Chitosan Solutions Related To Thermosensitive ChitosanGlycerol-Phosphate SystemsDokument16 SeitenIonization and Solubility of Chitosan Solutions Related To Thermosensitive ChitosanGlycerol-Phosphate SystemstsujittoNoch keine Bewertungen

- SPE 37084 Horizontal Well Length: Drill Short or Long Wells?Dokument9 SeitenSPE 37084 Horizontal Well Length: Drill Short or Long Wells?Waleed Barakat MariaNoch keine Bewertungen

- Duracon Concrete DensifierDokument2 SeitenDuracon Concrete Densifiertejas_tNoch keine Bewertungen

- Millenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemDokument7 SeitenMillenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemgimenNoch keine Bewertungen

- Ipecacuanha Liquid Extract - British Pharmacopoeia 2017Dokument1 SeiteIpecacuanha Liquid Extract - British Pharmacopoeia 2017Social Service (V)Noch keine Bewertungen

- Geosynthetics Filter Codes of PracticeDokument42 SeitenGeosynthetics Filter Codes of PracticeyuNoch keine Bewertungen

- Mass Spectra and IRDokument7 SeitenMass Spectra and IRSyed FahimNoch keine Bewertungen

- Etruscan CeramicDokument18 SeitenEtruscan Ceramicapi-3850604100% (1)

- Determining Cation Exchange Capacity: A New Procedure For Calcareous and Gypsiferous SoilsDokument5 SeitenDetermining Cation Exchange Capacity: A New Procedure For Calcareous and Gypsiferous SoilsM. Yusuf HermawanNoch keine Bewertungen

- Specialized lubricants maximize steel industry productivityDokument16 SeitenSpecialized lubricants maximize steel industry productivitySioney MonteiroNoch keine Bewertungen

- 2DoorCatalogue 2012-0Dokument15 Seiten2DoorCatalogue 2012-0Akanksha GuptaNoch keine Bewertungen