Beruflich Dokumente

Kultur Dokumente

32-626 Sdasd Asda Dasd Sadasd Ad

Hochgeladen von

Hatem AbdelrahmanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

32-626 Sdasd Asda Dasd Sadasd Ad

Hochgeladen von

Hatem AbdelrahmanCopyright:

Verfügbare Formate

An Experimental Study on the Self-recovery Regulation System of

Centrifugal Compressor Axial Displacement Fault

Yan Li, Weimin Wang, J inji Gao, Shuangxi Li

Diagnosis and Self-recovering Research Center

Beijing university of Chemical Technology

15 Beisanhuan East Road, Chaoyang District, Beijing, 100029

P R China

happy523_2000@163.com

Abstract: The axial displacement fault has very little indication before taking place and the fracture of oil film

between thrust disk and tilt pads mainly contributes to this breakdown. Usually this fracture was caused by the

contamination of oil or decrease of oil supply pressure which result in losing load bearing capacity of oil film.

Also the increase of axial force caused by fluctuation of operation condition can result in the oil film fracture.

Both of the above reasons can lead to tilt pads abrasion and emergency shutdown of machine. The method

presented in this paper monitors the stiffness of oil film and identifies the reason of axial displacement

increasing. By introducing the mechanism of axial displacement fault self-recovering and taking the axial

displacement as the control objectives, the axial forces on rotor was controlled on-line and the minimum oil

film thickness was ensured in real time. The experiment indicated that the mechanism can realize the axial fault

self-recovery effectively, and with this system, the centrifugal compressor doesnt need to be shut down

immediately when the axial displacement fault happens.

Keywords: centrifugal compressor, axial displacement, thrust bearing, fault self-recovery, PID controller, axial

stiffness

1 Introduction

Large-scale centrifugal compressor is the central

equipment of process industry such as petrochemical

industry and metallurgical industry etc. It is closely

related to the production process and contributed to

be a huge system. The fault of this type of system

may cause casualty and brings great pecuniary loss.

International engineers and scientists have developed

monitoring equipment and fault diagnostic technique

from 1960s. Predictive maintenance and intelligent

maintenance have been promoted into industrial

enterprises, and the Emergency Shutdown (ESD)

have been adopted extensively as well. The

diagnostic technique has played an important role in

safe production and obtained significant economical

benefit.

However, the solution of equipment faults

depends on ESD or disassembling maintenance after

manual shutdown. This decreases the production

time, increases the maintenance cost, and causes new

faults or even accidents during startup and shutdown

process of machines. The Fault Self-recovering(FSR)

technique is the effective way to improve the

reliability of equipments, maintain long period

operation and reduce the production cost.

[1]

This paper studies the essential reasons for the

typical high-pressure centrifugal compressor faults

caused by over standard of axial displacement in

domestic factories recent years; and then establishes

the fault diagnosis technique of axial displacement

which makes oil-film stiffness of bearing as the

parameter; based on these studies, establishing an

on-line monitoring, diagnosis and self-recovering

regulation system of axial displacement is highly

significant to ensure the long period running of

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1217 Issue 11, Volume 8, November 2009

machines without faults; finally, an experimental

study on the axial displacement fault self-recovering

system was conducted. The results shows that the

axial displacement fault of centrifugal compressor

can be online elimination by this system.

2 Diagnose the axial displacement fault

2.1 Summary: The axial displacement fault

Axial displacement is an important shutdown

indicator of centrifugal compressor ESD, and the

major factor of why centrifugal compressor cant be

operated for long period is because of axial

displacement fault, especially the high-pressure CO

2

compressor. This fault doesnt have any obvious

symptom before the axial displacement suddenly

increases, with the tilt pads worn-out heavily after

shutdown. There are two factors causing this fault,

one is the difficulty to decide the axial force of rotor

during design. In engineering design, The fall of

pressure caused by air flow in clearance between the

bladed disk and bladed lid was ignored when

calculating the axial force, which leads to a big

deviation between the calculated axial displace value

and the actual, even the coefficient of safety is 1.7-2

in design, it cant guarantee the axial force not

exceeding the carrying capacity of bearings. On the

other hand, the fall of pressure can be calculated with

the development of fluid mechanics computing

technology, but the fall of pressure varies with the

change of sealing leakage when compressor is

running, at the same time, the conditions of

compressor is fluctuant, and the fluctuation cant be

predicted, so the residual axial force may exceed the

carrying capacity of bearings and the bush-burning

takes place

[2]

. A thrust bearing and tilt pads with high

load perennial is presented in Fig.1. It is clearly

shown that there is a lot of carbon deposition on the

surface of the tilt pads. Because the axial

displacement is beyond standard, the reliability of

compressor is already too low, therefore even if the

fault doesnt happen, the interlock shutdown of

centrifugal compressor caused by axial displacement

will happen in most cases once the condition

changes.

Fig.1 the thrust bearing pad with coking

The CO

2

compressor of urea plant installed in a

branch of Sinopec is a high-pressure centrifugal

compressor made by Shenyang Blower Factory,

consisted of a 2MCL607 low pressure cylinder and a

2BCL306A high pressure cylinder. The maintenance

about the thrust-bearing pads of the high pressure

cylinder has never stopped from commissioning in

1984, Especially in the later half of 2002, with a

number of faults happening continually because of

the changing of operational conditions. For example,

the axial displacement of this high pressure cylinder

up to -395 m suddenly from -230 m during the

adjustment of the operating conditions at 8:00 on the

August 28, 2002, which could severely impair the

safe running of compressor. It was found that the

main thrust bearing pads was over-burnt and should

be replaced during the maintenance on September

16

[3]

. The similar faults happened on another CO

2

compressor of urea plant in a branch of China

National Petroleum Corporation. The interlock

shutdown fault caused by axial displacement

occurred many times since production

commencement in 1988, especially in J uly of 2002,

this kind of faults took place five times in one month.

2.2 The mechanical property of bearing

The axial displacement fault usually refers to the

alarming or emergency shutdown caused by the axial

displacement beyond standard level. The axial

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1218 Issue 11, Volume 8, November 2009

displacement is mostly consisted of bearing

clearance, attenuation of the oil-film thickness,

elastic deflection of bearing support, errors of

measurement system, wear of the tilt pads surface

and other factors

[4]

. The essential reasons of axial

displacement fault are various as there are many

factors bringing about the axial displacement . And

the axial displacement caused by changing of the

oil-film thickness have the most important effect on

the bearing safety Other factors such as the

temperature of lubricating oil, frequency of the rotor

and the load of bearing varying the axial

displacement also have certain impact

[5]

.

1-journal bearing, 2-base ring, 3-thrust disc, 4-thrust

bearing bush, 5-level block

Fig.2 the structure of thrust bearing

Fig.3 load-axial displacement of thrust bearing

Fig.2 presents the basic strcture of tilting pad

thrust bearing. Look, there is a clearance C between

the thrust disc (3) and the thrust bearing bush (4)

when rotor stops. The clearance C will be filled with

oil-film by the hydrodynamic slurry pressure when

rotor runs, and the action of axial force will cause

elastic deflection on the bearing. The stiffness of

thrust bearing depends on the stiffness of oil-film,

thrust bearing bush base ring and level block. The

axial displacement of rotor is showed in fig.3. The

vertical axis presents axial force and the horizontal

axis presents axial displacement.

After the rotor is installed, The bearing should

be adjusted at zero point of axial displacement,

namely, the thrust disk at the middle of thrust bearing.

And the axial force is zero too, right at the O point

of fig.3. The axial displacement arrives at A point

easily with a little axial force because of the

existence of clearance C when rotor stops. The value

of axial displacement here marked as d

2

, the axial

displacement arrives at C point along the AC line

with the increment of axial force, and marked as d

4

,

the non-linear factors of the bearing structure were

ignored here. A oil-film forms between the thrust

disc and the thrust bearing bush because of the

fluids viscidity when rotor is running. The axial

displacement arrives at G point with the affection

of a little axial force, and marked as d

1

. The axial

displacement will arrive at E point with the

increment of axial force along the GE line, axial

displacement maked as d

3

here. The slope of AC

line just lie on the stifness of bearing structure, and

the slope of GE line depends on the stifness of

oil-film and beraring structure in series. These two

lines will cross at H point with the difference of

slopes if there is no control, and marked as d

5

.

The thickness of oil-film h is the horizontal

distance of F point and B point with the axial

force f, and the distance between G and A is the

original oil-film thickness, marked as h

ori

. The

minimum oil-film thickness will be thicker than h

min

to ensure the bearing safety, and the axial load here

marked as f

max

. The alarm point and emergency

shutdown point should be set at d

3

and d

4

separately

when rotor is running.

2.3 Diagnosis of axial displacement fault

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1219 Issue 11, Volume 8, November 2009

Fig.4 diagnosis theory diagram of axial displacement

fault

According to the reasons leading to emergency

shutdown by axial displacement beyond standard, we

can divide the above into the axial force factors and

not axial force factors in engineer practice. As its

difficult to measure the axial force of compressor

rotor on line, its not easy to diagnose the reasons

leading to the axial displacement increment. For

example, the axial displacement can increment

suddenly without symptoms due to the increment

of axial force or inferior quality of lubricating oil

[6]

,

all of these will lead to emergency shutdown finally.

The diagnosis way of bearing fault by monitor the

axial stiffness of bearing is introduced and presented

in fig.4.

Given a bearing, we measure the bearing

clearance and plot line OA. The load-displacement

curve AC can be plotted by the ways of finite

element analysis or add static load by materials

universal test machine. To ensure the safety of

bearing, the minimum thickness oil-film should be

determined. If we move line AC h

min

to left and get

line FE, we will get the line of safeguard of bearing.

To the operating machine, we only measure the axial

displacement, and there may be three different axial

force corresponding with the measurement value of

axial displacement. Fig.4 shows three typical axial

force f

1

, f

2

and f

3

. If the axial force is f

1

, the thickness

of oil-film will be zero, and the bearing pad will be

damaged seriously. If the axial force is f

2

, here the

thickness of oil-film is h

min

, we should do something

to avoid the oil-film thickness being thin. And if the

axial force is f

3

, the bearing is safe.

The real-time oil-film stiffness is defined as K

i

,

and the oil-film stiffness of f

1

, f

2

and f

3

are defined as

K

FP

, K

FN

and K

FM

, It will alarm when

FN i

K K s ,

and check up the quality of lubricating oil. The

machine will interlock shutdown if

FP i

K K s .

2.4 Determine the axial stiffness of thrust

bearing

The axial stiffness of thrust bearing can be

defined as the axial force that is needed to move unit

axial displacement. Its related with the structure of

bearing, viscosity of oil-film and the speed of rotor.

The relationship can be defined as:

( )D r u f F , = (1)

u is the viscosity of oil-film and r is rotor

revolving speed. The axial stiffness f is presented

as:

( )

dD

dF

r u f = , (2)

Therefore if we measure the axial displacement,

given a little disturbance to axial force when the

compressor is running, then the axial stiffness of

thrust bearing can be calculated. On a real

compressor, we can change the pressure of balance

dick low pressure side by adjusting the control valve,

and record the change of pressure as P A , so the

change of axial force F A is:

A P F A = A (3)

Where A is the area of balance disk.

Referring to the fig.4, by Measuring the stiffness

of thrust bearing on line and combining with the

axial displacement, the health condition of

compressor bearing can be identified. Based on this,

with the ways stated in ref.[7], the axial displacement

fault can be eliminated online and axial displacement

fault self-recovering will be achieved accordingly.

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1220 Issue 11, Volume 8, November 2009

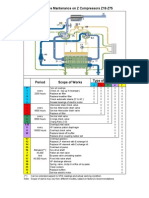

PT-Pressure transmitter, FG-Flow transmitter, T-Temperature, 1-Axial displacement sensor, 2-Key sensor,

3&4-Vibration sensor

Fig.5 axial displacement fault self-recovering system

3 design of the experimental device

3.1 Introduction of the axial displacement

fault experiment device

To verify the validity of the axial displacement

fault self-recovering system, we design a simulate

experiment device in Diagnosis and Self-recovering

Research Center of Beijing university of Chemical

Technology. The structure of experiment device is

presented in fig.5.

The motor is connected with the rotor via the

coupler, and the speed of motor can be adjusted by

VFD which is controlled by the computer. The

bearing (5) of compressor is five-pad tilting pads

journal bearing, and the bearing (6) is five-pad

tilting pads thrust journal bearing. The temperature

sensors of bearing and load sensors of tilt pads are

embedded in it. The sensors (3,4) are used to

measure the vibration of rotor, sensor (1) is used to

measure the axial displacement, and the data of

sensor (2) is used to calculate the speed of rotor. The

disk 1 and disk 2 simulate the impeller and balance

disk of turbo machine respectively, which divide the

cavity into three parts, the pressure of the three parts

are P

1

, P

2

and P

3

respectively. There is an axial force

F

2

because of the pressure difference between the

two sides of disk 2. F

2

equals to the balance force

generated by balance disk of a real compressor.

Similarly, F

1

, generated by the pressure difference

between the two sides of disk 1, equals to the thrust

force of real machine. The combination of F

1

and F

2

is the axial force of the machine, supported by the

thrust bearing.

3.2 the mechanical property of experimental

device

The area of disk 1 and disk 2 are defined S

1

and

S

2

respectively, hence, F

1

and F

2

can be calculated

as:

2 3 2 2

1 1 2 1

) (

) (

S P P F

S P P F

=

=

(4)

So the total axial force of the experimental

device can be calculated by equations of (4):

2 1

F F F = (5)

The designed diameters of disk 1, disk 2 and

the axis are 210mm, 150mm and 85mm respectively,

so

2

1

029 . 0 m S = ,

2

2

012 . 0 m S = .

The measured value of P

1

is 0.003MPa in

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1221 Issue 11, Volume 8, November 2009

experimental study, therefore:

N P P

P P P F

6

3

3 2 2

10 ) 000087 . 0 012 . 0 2 017 . 0 (

012 . 0 ) ( 029 . 0 ) 003 . 0 (

+ =

=

(6)

The axial force F is related to P

2

and P

3

seen

from equation (6). If keep the pressure of air supply,

the axial force can be controlled by changing P

3

, the

direction of axial force is correspond with F

1

which

presented in fig.5. And control the pressure of P

3

, as

well as control the axial force F, just like keep the

axial displacement not over standard.

3.3 The implementation of axial displacement

fault self-recovering system

The system structure is presented in fig.5. The

system collects, processes and analyze the real-time

data of temperature of journal bearing and tilt pads,

the axial displacement, the vibration of rotor, and the

pressure of P

2

and P

3

, and other data and transfer the

control signal via a second meter to pressure

adjusting valve. After this, the axial displacement is

solved through self-recovering adjustment.

1&2- Pneumatic membrane valve, 3&4-Pressure

transmitter, 5-Vibration sensor, 6-Axial displacement

sensor, 7-Key sensor

Fig.6(a) the system experimental device

Fig.6(a) and 6(b) presents the axial

displacement fault self-recovering system

experimental device. The air comes out from the air

supply and goes into the cavity II through a valve,

and leaks to the cavity I and III through seals. The

pressure cavity II and III can be measured by

pressure transmitter (4, 3-Rosemount 3051), and the

data are read by secondary meters. The pressure of

cavity I and III can be controlled by pneumatic

membrane valve (2,1-Arca 101-P1), and the system

can control the opening of these valves by XSTS

single return circuit PID adjusting meter. The meters

are made by Beijing Kunlun TianChen Instrument

Science Technology Company. The system is

completed in Labview7.1. It reads the pressure data

from secondary meters by serial port communication,

and reads the data of axial displacement and

vibration by NI PCI6220 data collection board, and

control signal output to the valve by secondary

meters too.

8-Secondary meters, 9-Self-recovering regulation

system

Fig.6(b) the control platform device of the system

4 Experimental study

4.1 Determine the zero point of axial

displacement

The sensitivity of used eddy current sensor is

8 m mv / , and output signal is -24V to 0V. Turn on

the valve of cavity I, then the pressure of cavity I is

close to the zero. At the same time, turn off the valve

of cavity III, so the pressure here we get will equal

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1222 Issue 11, Volume 8, November 2009

to the cavity IIs pressure. Hence, F

2

=0, F=F

1

. Then

change F=0 little by little by adjust the air supply,

and the axial displacement sensor data is -8.07V

when F=0. Then turn off the valve of cavity I, turn

on the valve of cavity III, keep F

1

=0, F=F

2

. Adjust

the air supply to make F=0 gradually, and the data of

sensor is -10.99V, so the middle point of balance

disk is V 53 . 9 07 . 8

2

07 . 8 99 . 10

=

+

, this

point is the zero point of axial displacement, the

sensor data of other measure points is defined as D

i

,

and corresponding axial displacement is defined as

d

i

:

m

D

d

i

i

1000

8

53 . 9

+

= (7)

4.2 Study the mechanical property of

experimental device journal bearing

The experimental procedure of analyzing the

mechanical property of the experimental device as

follows:

(1) Turn on the valve of cavity I, make the

pressure of this cavity close to the atmospheric

pressure. Turn off the valve of cavity III, make the

pressure of this cavity close to the pressure of cavity

II. The air supply is a screw compressor. Turn on the

valve when the pressure of air supply arrives at

1MPa, then stop the screw compressor. Record the

pressure data of cavity II and III and axial

displacement data, plot the load-displacement

curve.

(2) Star up the motor and adjust the revolving

speed of rotor to 8000r/min, and do the procedure (1)

again, plot the curve of this speed.

(3) Adjust the speed to 7000r/min, 6000r/min,

5000r/min, 4000r/min, 3000r/min and 2000r/min

respectively, and do the procedure (2) and plot the

curve of different speed.

4.3 Identify the stiffness of bearing

The procedure of identifying the stiffness of

bearing as follows:

(1) Star up the motor and adjust the revolving

speed of rotor to 8000r/min, turn on the screw

compressor and keep the pressure of cavity II stable.

Turn on the valve of cavity I, adjust the opening of

cavity IIIs valve to 20% and stay there, so the axial

displacement and axial force will be stable after a

few minutes.

(2) Record the temperature of lube oil, and

adjust the opening of cavity IIIs valve to 30% and

keep three seconds then adjust to 20% again. In the

experimental process, record the data of pressure of

cavity II, III and corresponding axial displacement.

The stiffness of bearing can be calculated by

equation (2).

(3) The temperature of lube oil will rise when

the machine is running, so the stiffness of different

temperature at 8000r/min can be achieved by repeat

the step (2).

(4) Adjust the rotor revolving speed to

7000r/min, 6000r/min, 5000r/min, 4000r/min,

3000r/min and 2000r/min respectively, repeat step

(2) and (3), and study the bearing stiffness of

different speed of rotor revolving.

4.4 Axial displacement fault self-recovering

control

The experiment aims to achieve the axial

displacement fault self-recovering, and verify the

real-time capability and stability of the fault

self-recovering system. The process as follows:

(1) Star up the motor and adjust the revolving

speed of rotor to 8000r/min, and turn on the screw

compressor at the same time. Adjust the valve

opening of cavity II to 10%.

(2) The safe set-point of axial displacement is

235 m . Run the fault self-recovering system, the

real-time data of pressure of cavity II, III, the axial

displacement and the valve opening of cavity III can

be recorded within this system. Turn on the valve of

cavity II completely within a short time manually

after the pressure of air supply goes up to 1MPa.

And the axial force will increase suddenly due to the

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1223 Issue 11, Volume 8, November 2009

120 140 160 180 200 220 240 260 280

2000

4000

6000

8000

10000

12000

14000

1-2000rpm

2-3000rpm

3-4000rpm

4-5000rpm

5-6000rpm

6-7000rpm

7-8000rpm

A

x

i

a

l

f

o

r

c

e

(

N

)

Axial displacement (um)

8-0rpm

1

2

3

4

5

6

7

8

G

A

Fig.8. the experimental devices load-axial displacement curves of different rotor revolving speed

sudden increase of the cavity IIs pressure. The axial

displacement increases suddenly, and the control

results shall be recorded.

(3) Select other controllers of the system, and

repeat (2) again.

5 The results of experiment

5.1 The load-axial displacement curve of

bearing

The load-axial displacement curve is plotted

by the procedure of 4.2 and presented in fig.8. The

conclusions as follows:

(1) The load-axial displacement curve is

similar to the curve of fig.3, the bearing clearance is

200 m according to the position of A point. The

axial displacement is increased with the increase of

load, and the axial displacement is up to 276 m

when the load is 13800N.

(2) Comparing the curves we will find that the

oil-film thickness of low speed is thinner than the

one at high speed when the load is at low lever. The

oil-film thickness will be thinner and thinner with

the increase of load and speed. The changing of

oil-film thickness made these curves has a clear

intersection point G, to the point, we can

understand that the axial displacement is mainly

controlled by stiffness of oil-film before the G

point, and after this, the axial displacement is mainly

controlled by axial stiffness of tilt pads journal

bearing. The axial stiffness of tilt pads journal

bearing will turn lower with the rotor revolving

speed getting higher. The more power will be

achieved in unit time at a higher rotor revolving

speed, so the temperature of lube oil will rise fast

and make the viscosity of lube oil smaller.

(3) The no-linear phenomenon is clear in these

curves, namely, the stiffness of thrust bearing varies

with the change of load. But after the G point, the

curves are close to linear, the stiffness changes to

stable, the slopes of these curves turn close to the

slope of load-axial displacement curve where the

rotor stopped.

(4) The near polynomial can be achieved by the

method of least squares, as listed in table 1. These

polynomials of normal operation conditions provide

reference for diagnosis the fault., and determined the

axial displacement fault is caused by exceeding

axial force or not.

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1224 Issue 11, Volume 8, November 2009

Table 1, The polynomial fit of axial force of axial displacement at different revolving speed

revolving speedr/min polynomials fit

2000

3 12825.1230 + 185.0143d - 0.73083d = F

2

3000

9 13503.8055 + 188.4900d - 0.73014d = F

2

4000

8 13188.4894 + 181.7717d - 0.70117d = F

2

5000

4 12472.1490 + 171.4285d - 0.66574d = F

2

6000

7 12687.1559 + 170.3231d - 0.65224d = F

2

7000

7 12434.8705 + 164.8987d - 0.62964d = F

2

8000

6 12598.7689 + 165.8128d - 0.62251d = F

2

32 34 36 38 40 42 44 46 48

60

80

100

120

140

A

x

i

a

l

S

t

i

f

f

n

e

s

s

(

N

/

u

m

)

Temperture (

o

C)

Fig.9(a) the varying curve of axial stiffness with the

temperature

2000 3000 4000 5000 6000 7000 8000

130

135

140

145

150

155

160

A

x

i

a

l

S

t

i

f

f

n

e

s

s

(

N

/

u

m

)

Revolving Speed (r/min)

Fig.9(b) The varying curve of axial stiffness with

revolving speed

5.2 Identify the stiffness of bearing

A axial force disturbance made with purpose is

added the running rotor in order to measure the axial

displacement, and obtain the stiffness of bearing in this

way. The reason for the fault can be determined by

comparing the current stiffness with the regular one.

Fig.9(a) is the axial stiffness of different temperatures,

plotted at the revolving speed of 8000r/min and the axial

force is 7242N by the ways of 4.3. We can see that the

axial stiffness changes little by little with the raising of

the temperature. Fig.9(b) presents the change of stiffness

with the rotors revolving speed, keeping the

temperature same. Its clear the stiffness is lower when

revolving speed gets higher.

4.3 Results of several different controllers of the

axial displacement fault self-recovering system

4.3.1 Result of Boolean controller

Determine the safe threshold of axial displacement

according to the design of compressor, the max value

means the self-recovering system should start working

when axial displacement goes over this value , and

means if the measured axial displacement is , the

conditions of machine is safe. And the Boolean

controller will output 100% opening signal to the

controlled valve if and turn off the valve if . The

controlled axial displacement curve is presented in

fig.10(a). It is clear that the axial displacement is axial

float, and this condition is a new incertitude factor to the

production plant. Hence Boolean controller isnt reliable

to this fault although its responsive.

4.3.2 The results of PID controller and fuzzy PID

controller

The PID controller is one of the most widely used

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1225 Issue 11, Volume 8, November 2009

controllers in process control of industries. The PID

curve of fig.10(b) is the result of the controller. The PID

controller will only have better result in single operation

condition. If the operation condition changes, the

controller will lose its advantage. The short response

time and trim control cant be achieved at same time.

The fuzzy controller is adopted, its curve is

presented in fig.10(b). This controller can conduct the

varying operations. When the error is big, the controller

can make the variable reach set-point in a short time and

then adjust its output to get trim control

[9][10]

. The control

result is better than PID controller and can be shown in

fig.10(b).

0 5 10 15 20 25 30

220

230

240

250

260

A

x

i

a

l

d

i

s

p

l

a

c

m

e

n

t

(

u

m

)

Time (s)

Fig.10(a) The controlled axial displacement curve

0 10 20 30 40 50 60

220

230

240

250

260

A

x

i

a

l

d

i

s

p

l

a

c

e

m

e

n

t

(

u

m

)

Time (S)

PID

Fuzzy PID

P3 PID

Fig.10(b) The axial displacement curves of different

controllers

5.3.3 Make the pressure of cavity III as control

variable

The former controllers control variable is axial

displacement, and the axial force is related with the

cavity II and IIIs pressure according to the equation (7).

The experimental result shows that its near linear

between the axial force and axial displacement when

axial force is bigger than 4000N. Take 8000r/min as an

example:

m

P P

F

d

i

404 . 120

10 ) 000087 . 0 012 . 0 017 . 0 (

404 . 120

6

3 2

+

=

=

(8)

Here 120.404 is axial stiffness of bearing, P

2

can be

measured, so the threshold value of P

3

with

corresponding P

2

can be calculated by:

MPa

P d

P

i

sp

12000

17000 87 404 . 120

2

3

+ +

= (9)

The control curve is presented in fig.10(b). Its response

time is the shortest of all these controllers. But the

premise is that the axial stiffness must be reliable. And

the controllers parameter should reset at different

revolving speeds.

Based on the overall consideration of various

factors, the fuzzy PID controller is the better choice to

this fault self-recovering system.

6 Conclusions

The below conclusions are obtained through the

experimental study on axial displacement fault

self-recovering system:

(1) The system can control the axial displacement

safely by controlling the pressure of balance disk lower

pressure side, and avoid the emergency shutdown.

(2) The axial displacement fault can be diagnosed

by the online identification of axial stiffness.

(3) The temperature of lube oil has little influence

on the stiffness of bearing, but the stiffness varies with

the revolving speed. The system adapts better for the

high revolving speed compressor.

To conclude, the axial displacement fault

self-recovering system has important significance on

extending the running period of process production in

petrochemical enterprises.

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1226 Issue 11, Volume 8, November 2009

Acknowledgements

We gratefully acknowledge support of this research

under Grant No.50575016 and 50635010 of the Chinese

National Nature Science Foundation, and the Program

No. 2006BAK01B01 of the Chinese National Key

Technology R&D Program in the 11

th

five year.

References:

[1] Gao, J .J ., Wang, W.M., and J iang, Z.N., 2005,

Research on the Axial Displacement Fault

Self-recovery and Control of a High Speed

Turbo-machine, Mechanical Science and Technology,

24(11), pp. 1261-1264.

[2] Wang, K.G., 2002, Axial Displacement Increase

Reasons Analysis of K480 Turbo-Compressor,

Chemical Equipment & Anticorrosion, 5(5), pp.

351-352.

[3] Tang, Q.M., 2007, An Eccentric Alteration Attempt

on Thrust-bush of HP cylinder of CO2 Compressor,

Large Scale Nitrogenous Fertilizer Industry, 30(5), pp.

325-327.

[4 Yang, R.F., 1997, Reason Analysis of Misalarm and

Interlock of Control System For Large Scale Machine

Set, Petro-Chemical Equipment Technology, 18(5), pp.

43-45.

[5] Glavatskikh, S. B., 2001, Steady state performance

characteristics of a tilting pad thrust bearing, J ournal of

Tribology, 123(3), pp.608-615.

[6] Chen, Z.H., Liang, X.G., and Qin, Y.L., etc. 2004,

Reason Analysis On Common Failure of Large-scale

Centrifugal Compressor Set and Its Handling,

Petro-Chemical Equipment Technology, 25(1), pp.

45-51.

[7] Wang, W.M., 2006, Rotor Axial Displacement Fault

Self-Recovering Regulation and Rotating Sealing

Improvement for Better Efficiency, Ph.D. thesis,

Beijing University of Chemical Technology, Beijing.

[8] Wang, X.J ., Wang, X.S., and Mao Yan, 2008,

Adaptive Sliding Model Control for Hysteresis System

Based on Prandtl-Ishlinskii Model, Chinese J ournal of

Mechanical Engineering, 44(4), pp. 171-178.

[9] Li S.Y., 2006, Fuzzy Control Neuro-control and

Intelligent Cybernetics, Harbin Institute of Technology

Press.

[10] Nicoletti, R., and Santos, I.F., 2008, Control

System Design for Flexible Rotors Supported by

Actively Lubricated Bearings, J ournal of Vibration and

Control, 14(3) , pp. 347-374.

WSEAS TRANSACTIONS on SYSTEMS Yan Li, Weimin Wang, Jinji Gao, Shuangxi Li

ISSN: 1109-2777 1227 Issue 11, Volume 8, November 2009

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- PT Tech HPTO12HXX-XXX Power Take OffDokument27 SeitenPT Tech HPTO12HXX-XXX Power Take OffRonald100% (5)

- Elevator Maintenance ManualDokument27 SeitenElevator Maintenance ManualBadal BiswasNoch keine Bewertungen

- Air Brake Work BookDokument47 SeitenAir Brake Work BookRudolf Oppermann50% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- WEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishDokument40 SeitenWEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishHatem AbdelrahmanNoch keine Bewertungen

- Kingsbury Leg ComponentsDokument3 SeitenKingsbury Leg ComponentsHatem Abdelrahman100% (1)

- Porsche 928 1982 Service InformationDokument55 SeitenPorsche 928 1982 Service InformationwaggcasNoch keine Bewertungen

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYDokument46 SeitenEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYDokument46 SeitenEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- Oisd Standard - 194 For Restricted Circulation Only: Government of India, Ministry of Petroleum & Natural GasDokument38 SeitenOisd Standard - 194 For Restricted Circulation Only: Government of India, Ministry of Petroleum & Natural GasmkkamarajNoch keine Bewertungen

- GP170501 Human Factors in Plant Design PDFDokument27 SeitenGP170501 Human Factors in Plant Design PDFegfernandez21100% (1)

- 19 KKKKKKKKKKKKKKKKKKDokument4 Seiten19 KKKKKKKKKKKKKKKKKKHatem Abdelrahman100% (1)

- SD 25 eDokument20 SeitenSD 25 ejbsb1100% (1)

- Cartuchos Sandvik PDFDokument16 SeitenCartuchos Sandvik PDFJefatura de Planta Invemet PeruNoch keine Bewertungen

- User Instructions: ERPN-M Centrifugal PumpsDokument37 SeitenUser Instructions: ERPN-M Centrifugal Pumpstexwan_Noch keine Bewertungen

- Manual PerforadoraDokument42 SeitenManual PerforadoraFrancisco Gajardo100% (1)

- FCC Unit TURNAROUNDDokument6 SeitenFCC Unit TURNAROUNDGroover ContrerasNoch keine Bewertungen

- Practical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetDokument2 SeitenPractical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetHatem AbdelrahmanNoch keine Bewertungen

- V106 Relative Motion Record FormDokument0 SeitenV106 Relative Motion Record FormHatem Abdelrahman100% (1)

- Understandingamp - Phaseinrotatingmachineryvibinst 07 20pgsDokument20 SeitenUnderstandingamp - Phaseinrotatingmachineryvibinst 07 20pgsHatem Abdelrahman100% (1)

- Field Balancing Large Rotating MachineryDokument26 SeitenField Balancing Large Rotating MachineryShantanu SamajdarNoch keine Bewertungen

- Article 6hy JytjuytDokument7 SeitenArticle 6hy JytjuytHatem AbdelrahmanNoch keine Bewertungen

- Article 6hy JytjuytDokument7 SeitenArticle 6hy JytjuytHatem AbdelrahmanNoch keine Bewertungen

- Dynamic Stresses Hydro Power Plant RKAggarwalDokument22 SeitenDynamic Stresses Hydro Power Plant RKAggarwalDheeraj DhimanNoch keine Bewertungen

- The Magnetic Center Finding Using Vibrating Wire TechniqueDokument6 SeitenThe Magnetic Center Finding Using Vibrating Wire TechniqueHatem AbdelrahmanNoch keine Bewertungen

- Fault Zone - : Air GapDokument0 SeitenFault Zone - : Air GapHatem AbdelrahmanNoch keine Bewertungen

- Huang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDDokument130 SeitenHuang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDHatem AbdelrahmanNoch keine Bewertungen

- Don't Get Soft: Cover Series: Installation Best PracticesDokument6 SeitenDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Gei 100351Dokument32 SeitenGei 100351Hatem Abdelrahman100% (1)

- Prec Maint March 2007Dokument9 SeitenPrec Maint March 2007Hatem AbdelrahmanNoch keine Bewertungen

- Icmtech435435 345435 43543Dokument63 SeitenIcmtech435435 345435 43543Hatem Abdelrahman100% (1)

- 1q07 Beat Freq Back To BasicsDokument3 Seiten1q07 Beat Freq Back To BasicsHatem AbdelrahmanNoch keine Bewertungen

- Preventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsDokument1 SeitePreventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsHatem AbdelrahmanNoch keine Bewertungen

- Vibrations NotesDokument43 SeitenVibrations NotesNicolas LuchmunNoch keine Bewertungen

- Customer Application Centers: Global Accessibility To Our TechnologyDokument1 SeiteCustomer Application Centers: Global Accessibility To Our TechnologyHatem AbdelrahmanNoch keine Bewertungen

- Best Practices: Asset Condition ManagementDokument2 SeitenBest Practices: Asset Condition ManagementHatem AbdelrahmanNoch keine Bewertungen

- Why Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsDokument2 SeitenWhy Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsHatem AbdelrahmanNoch keine Bewertungen

- IBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsDokument4 SeitenIBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsHatem AbdelrahmanNoch keine Bewertungen

- 1q03 3500 22mDokument4 Seiten1q03 3500 22mscribdkhatnNoch keine Bewertungen

- Helping You ... : Fourth Quarter 1999 Vol. 20 No. 4Dokument1 SeiteHelping You ... : Fourth Quarter 1999 Vol. 20 No. 4Hatem AbdelrahmanNoch keine Bewertungen

- Ontario Power Generation's Nanticoke Power PlantDokument3 SeitenOntario Power Generation's Nanticoke Power PlantHatem AbdelrahmanNoch keine Bewertungen

- 2 Q 01 HanifanDokument2 Seiten2 Q 01 HanifanHatem AbdelrahmanNoch keine Bewertungen

- Modulo de Control de Osmosis PDFDokument15 SeitenModulo de Control de Osmosis PDFrafaelNoch keine Bewertungen

- Tech Manual: 5.12", 10,000 PSI WORKING PRESSURE Es Series, 3,000 Psi Hydraulics Quad BopDokument25 SeitenTech Manual: 5.12", 10,000 PSI WORKING PRESSURE Es Series, 3,000 Psi Hydraulics Quad BopJavier RivasNoch keine Bewertungen

- 08 - Enriquecedor de Oxigeno AS-DDokument61 Seiten08 - Enriquecedor de Oxigeno AS-DCRISTIAN ALEXANDER SALDANA GARZONNoch keine Bewertungen

- BRT-100 User ManualDokument2 SeitenBRT-100 User ManualEricNoch keine Bewertungen

- Material Selection GuideDokument2 SeitenMaterial Selection GuideshervinyNoch keine Bewertungen

- OPS 1 Maintenance ManualDokument10 SeitenOPS 1 Maintenance ManualMustang33Noch keine Bewertungen

- 06 Pasteur Eng enDokument8 Seiten06 Pasteur Eng enVukasin ZivicNoch keine Bewertungen

- H 3 1 Third Generation FA5ADokument6 SeitenH 3 1 Third Generation FA5AjlmunozvNoch keine Bewertungen

- Gen Set 30 KVA HA 494Dokument20 SeitenGen Set 30 KVA HA 494Pankaj TiwariNoch keine Bewertungen

- Aeromats Aeropress Aeropress 10s Aerovac GeneralDokument2 SeitenAeromats Aeropress Aeropress 10s Aerovac Generalsaket2006Noch keine Bewertungen

- Gas Cylinders RulesDokument9 SeitenGas Cylinders Ruleshani_shaabanNoch keine Bewertungen

- Indian StandardDokument17 SeitenIndian StandardMd Tajijul IslamNoch keine Bewertungen

- m359 Rev e Ecl Plus-1Dokument78 Seitenm359 Rev e Ecl Plus-1isaias100% (1)

- NeumaticaDokument39 SeitenNeumaticaJulian DiazNoch keine Bewertungen

- 9b. 2013catalogDokument96 Seiten9b. 2013catalogEny Sri RyNoch keine Bewertungen

- Protective Covers: N N N NDokument2 SeitenProtective Covers: N N N NMNoch keine Bewertungen

- Maintenance Cylinder Booster Unit MAN PDFDokument12 SeitenMaintenance Cylinder Booster Unit MAN PDFgmegoulis_772534693Noch keine Bewertungen

- Scroll Chiller TenderDokument61 SeitenScroll Chiller Tenderjun005Noch keine Bewertungen

- MegaTherm 500 1825Dokument32 SeitenMegaTherm 500 1825jose luisNoch keine Bewertungen