Beruflich Dokumente

Kultur Dokumente

Moment Connection - Flush End Plate-19.01.06

Hochgeladen von

kalpanaadhiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Moment Connection - Flush End Plate-19.01.06

Hochgeladen von

kalpanaadhiCopyright:

Verfügbare Formate

Nov 09, 2005

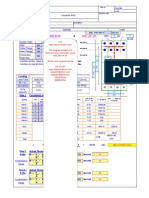

BEAM TO COLUMN FLANGE - MOMENT CONNECTION USING FLUSH END PLATE Connection Identification INPUT DATA : Supporting member D = B = tw = 310.0 mm 280.0 mm r

D' A n

MC 01

= = = = =

10.0 mm mm cm2 mm 12.7 mm 200.3 mm 136.0 cm2 0.0 mm 10.0 KN 185.00 KN 185.0 KN End plate

Ix = Iy = rx = ry =

cm4 cm4 mm mm

Zx = Zy = Sx = Sy =

cm3 cm3 cm3 cm3

16.0 mm 20.0 mm tf = Supported member UC - 254 x 254 x 107 266.7 mm D = B = tw = tf = 258.8 mm 12.8 mm 20.5 mm

4 Ix = 17510.0 cm

3 Zx = 1313.0 cm

D' = A = n = Fz = T = T =

Iy = rx = ry = Fy = V = V =

5928.0 cm

Zy = Sy = My = MZ = MZ = Web

3 458.0 cm

113.0 mm 66.0 mm 104.00 KN 104.5 KN 104.5 KN

3 Sx = 1484.0 cm 3 697.0 cm

Member end actions Unfactored C = Factored C =

( 1.0 )

0.0 KN 0.0 KN

25.0 KN.m 50.0 KN.m 50.0 KN.m

Connection

Grade of bolt (F10T/HSFG/8.8) Yield strength of bolt Ult. Tensile strength of bolt Shear strength of bolt Bearing strength of bolt Tensile strength of bolt Strength of weld Grade of material Rolled Section Ultimate strength Rolled Section Yield strength Rolled Section Bearing strength Rolled Section Diameter of bolt Diameter of bolt hole Nr of bolt columns Nr of bolt rows Spacing of bolt columns (gauge) Spacing of bolt rows (pitch) Edge distance End distance in plate at top End distance in plate at bottom End distance in member Set back Thickness of plate ( t = 15 ) Thickness of reinforcement Nr of shear planes Sum of square of 'r' for the bolt group Minimum proof stress for HSFG bolts Minimum shank tension for HSFG bolts For clearance holes Slip factor for untreated surfaces Size of weld Flange = = = = = = = = Us = py = pbs = Yf Uf ps pbb pt fw db dbh nc nr g p e' e''pt e''pb e''' Sb tp tfrp Ns e r2 po Po Ks m sw = = = = = = = = = = = = = = = = = = = =

HSFG 550 715 342 911 586 215 S 355 490 355 1065 24 26 2 3 180 70 50 85 85 50 0 20 0 1 N.A. 586 207 1 0.45 10

= M Pa M Pa M Pa M Pa M Pa M Pa 50 B M Pa M Pa M Pa mm mm

F10T

Plate Plate Plate Plate

= Us = py = pbs =

355 490 355 1065

M Pa M Pa M Pa

mm mm mm mm mm mm mm mm mm mm2 M Pa KN

Center of first row of bolts above TOS a = -63.35 mm Pitch p1-2 = 70.0 mm Pitch p2-3 = 70.0 mm Pitch p3-4 = 0.0 mm Pitch p4-5 = 0.0 mm Pitch p5-6 = 0.0 mm Pitch p6-7 = 0.0 mm Pitch p7-8 = 0.0 mm

mm

Web

10 mm

Nov 09, 2005

BEAM TO COLUMN FLANGE - MOMENT CONNECTION USING FLUSH END PLATE

Connection Identification - MC 01

87.4 KN 102.4 KN 186.1 KN

0.88

Tension in bolt due to moment Capacity of one bolt Tensile capacity of bolt Maximum tensile force in bolt Shear in bolt due to V Combined shear and tension Bearing capacity of the plate over bolt group Shear capacity of the plate Block shear capacity of the end plate Moment capacity of plate Minimum prying force Size of flange weld required Capacity of flange weld Size of web weld required Capacity of web weld Provide a supplementary web plate of 0

TbM Pb Pt Tb Vb

= = = = = = = = = = = = = = =

87.36 KN 102.4 KN 186.1 KN 164.5 KN 17.4 KN 0.88 2130 2174.304 1807.859 4.322 Pt > Tb. Safe. < Pb. ( 102.4 ) < 1.0. Safe. > V. ( 104.5 ) > V. ( 104.5 ) > V. ( 104.5 ) > Mw. ( -13 ) < Q. < swf. < sww. ( ( ( 21.6 ) 10.0 ) 10.0 )

Pt > Tb. Safe. < Pb. Safe. 0.17 < 1.0. Safe. > V. Safe. > V. Safe. < V. Safe. > Mw. Safe. < Q. Safe. 0.88 0.05 0.05 0.06 -3.04 -5.49 0.240 0.178

Vp MP Qmin

KN KN KN KN.m

-118.7 KN 2.4 728.7 1.8 199.7 x 0 mm KN mm KN

< swf. Safe. < sww.Safe.

x bp dp tp

0 = = =

mm thick. 280.0 mm 310.0 mm 20.0 mm

280.0 310.0 20.0

Width of plate Depth of plate Thickness of plate

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS DESIGN OF MOMENT CONNECTION MC 02 Supporting Member : (supporting on plate connecting between the flanges and stiffener at centre) D = 290.0 mm D - Depth of column or plate Bp = 300.0 mm Bp - Width of column flange or plate tc tf rc = 16.0 mm = 25.0 mm = 10.0 mm

tc - Web thickness of column or stiffener tf - Flange thickness of column or plate rc - Root radius of column or weld to plate and stiffener D - Depth of beam B - Width of beam flange tc - Web thickness of beam tf - Flange thickness ofbeam rc - Root radius of beam

Reference

300

63.35

70 70 63.35

Supported Member : D = 266.7 mm B = 258.8 mm tb = 12.8 mm tf1 = 20.5 mm rb = 12.7 mm

180 Thickness of End Plate tp = 25 mm

Member End Actions (Factored) Fx = 580 kN Compression Tension Shear Force Shear Force Bending moment Fx = Fy = Fz = Mz = 580 kN 50 6 20 kN kN kN-m

My = 11 kN-m Bending moment Connection Details Assumed bolt configuration Grade of Bolts (8.8 / HSFG) = HSFG Part - 2 Bolts nr = No. of rows 3 nc = No. of columns 2 Total nos of bolts n = 6 db = 24 mm Dia of bolt Spacing between rows p = 70 mm (pitch) Spacing between cols g = 180 mm (gauge) 26 mm dh = Dia of bolt hole Abg = 452.4 mm2 Gross area of one bolt Effective area of one bolt Abn = 352.9 mm2 60 mm Edge distance e' = 75 mm Edge distance in plate top e"pt = 75 mm Edge distance in plate bot. e"pb= 0.5 Slip factor for untreated m = 1 Ks = For clearance holes Least thick of plate t = 25.0 mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Forces in Bolts Tension per bolt due to Moment Mz For Row 1 T1 = T1 = For Row 2 Mz*a1/(nc(a12+a22+a32)) 34.94 kN a1= 193.1

Reference

T1

T2 = Mz*a2/(nc(a12+a22+a32)) T2 = 22.28 kN

T2

For Row 3

T3 = Mz*a3/(nc(a12+a22+a32)) T3 = 9.609 kN

a2= 123.1 a3= 53.1

T3

Force Distribution to bolts due to moment Mz Tension per bolt due to Moment My For Column 1 T1 = My / (nr b) T1 = 20.37 kN b = 180.0 T1

Force Distribution to bolts due to moment My Tension per bolt due to Axial tension Fx Fx / n 96.7 kN Maximum forces Transfer to Each Bolt 152 kN Maximum Tension in bolt row 1 = 139 kN Maximum Tension in bolt row 2 = 127 kN Maximum Tension in bolt row 3 = Check for Bolts Yf = Yield strength of bolt Ult. Tensile strength of bolt Uf = ps = Shear stress of bolt Tension stress of bolt Bearing stress of bolt Minimum proof stress of bolt Minimum shank tension in HSFG bolts pt = pbb = p0 = P0 = 882 981 400 700 N/mm2 2 N/mm N/mm2 N/mm2 =

1300 N/mm2 776 N/mm2

232.7 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Capacity of one bolt Shear capacity of bolt Bearing capacity of bolt Tension capacity of bolt

Ps = Pb = Pt' =

141.1 kN 780 kN 209.5 kN

Slip resistance of one bolt PSL = 0.9 * Ks *m*P0 = 104.7 kN py = 345 N/mm2 Design strength of steel Bearing strength of steel pb = 825 N/mm2 pw = 220 N/mm2 Design strength of weld Connection Geometry Column Side m = g/2 - tc/2 - 0.8rc = 74 mm e = B/2 - g/2 = 60 mm For n smallest of n e for the column flange e for the end plate 1.25 m for column flange Beam Side m = g/2 - tb/2 - 0.8Sww = 75.6 mm = B/2 - g/2 = 60 mm For n smallest of n e for the column flange e for the end plate 1.25 m for end plate e

= = = =

60 60 60 92.5 where,

mm mm mm mm

Leg length of fillet weld to beam web, Sww =

10 mm

= = = =

60 60 60 94.5

mm mm mm mm

Potential Resistance of Bolts in Tension Zone Pr1 Bolt Row 1 & 3 Bolt Row 1 & 3 alone Column Flange Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = Min of [ Max{ii,iii}, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m Pr2 Pr3

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS = 465 mm = 4 m + 1.25 e = 371 mm = a m1 = 444 mm l1 = m1 / (m1+e) l2 = m2 / (m1+e) l1 = l2 = a = Leff 0.552 0.26 6 (ref. Fig 2.16) m1 m2 = =

Reference

Leff for ii Leff for iii

where a from Fig 2.16

74

mm

34.9 mm

= Min of [ Max{ii,iii}, i ] = 444 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 23.93 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1294 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 544.8 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 418.9 kN Potential resistance for column flange bending Column Web Tension As row 1 & 3 is near the flange, web tension can be discounted End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = Min of [ Max{ii,iii}, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 475 mm Leff for ii = 4 m + 1.25 e = 377 mm Leff for iii = a m1 = 454 mm where a from Fig 2.16 l1 = m1 / (m1+e) l2 = m2 / (m1+e) l1 = 0.558 m1 m2 = = 75.6 mm 34.9 mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS l2 = a = Leff

Reference

0.257 6 (ref. Fig 2.16 of moment connection by BCSA)

= Min of [ Max{ii,iii}, i ] = 454 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 24.45 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1294 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n 546 kN = Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 418.9 kN Potential resistance for end plate bending Beam Web Tension As row 1 & 3 is near the flange, web tension can be discounted Bolt Row 2 Row 2 alone Column Flange Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = Min of [ ii, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 465 mm Leff for ii = 4 m + 1.25 e = 371 mm Leff = Min of [ ii, i ] = 371 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the 20 kN-m equivalent T-stub = Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1081 kN P Mode 2 Bolt failure with flange r = 2 Mp + n(S Pt') yielding m+n

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS = 486.1 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 418.9 kN Potential resistance for column flange bending

Reference

Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = Min of [ ii, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 475 mm Leff for ii = 4 m + 1.25 e = 377 mm Leff = Min of [ ii, i ] = 377 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 20.34 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1076 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 485.4 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 418.9 kN Potential resistance for end plate bending Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Row 2 & 1 as group and Row 3 & 2 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 514 mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 27.71 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1498 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n 788.7 = kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Pr = 788.7 kN Potential resistance for column flange bending Column Web Tension

Reference

Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 = 524 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 28.23 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1493 kN P Mode 2 Bolt failure with flange r = 2 Mp + n(S Pt') yielding m+n = 787.1 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Pr = 787.1 kN Potential resistance for end plate bending Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Bolt Row 3 Row 3, 2 and 1 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Leff

= { Max of [ ii/2,(iii-ii/2)] } x 2 + 2p 657 = mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 35.42 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1914 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 1091 kN Pr = S Pt' Mode 3 Bolt failure = 1257 kN Pr = 1091 kN Potential resistance for column flange bending Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] } x 2 + 2p = 670 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 36.11 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1910 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 1089 kN Pr = S Pt' Mode 3 Bolt failure = 1257 kN Pr = 1089 kN Potential resistance for column flange bending Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange.

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Potential Resistance of Bolts in Tension Zone

Reference

Step 1 Row 1

WORK SHEET: TENSION ZONE Column Side Beam Side Flange Bending Web Tension Flange Bending Web Tension Resistance of Row 1 418.9 N.A 418.9 N.A Resistance of Row 2 only 418.9 N.A 418.9 N.A Resistance of Row 2+1 as group 788.7 N.A 787.1 N.A 369.8 N.A 368.1 N.A Resistance of Row 3 only 418.9 N.A 418.9 N.A Resistance of Row 3+2 as group 788.7 N.A 787.1 N.A 420.6 N.A 418.9 N.A Resistance of Row 3+2+1 as group 1091.4 N.A 1088.7 N.A 304.3 N.A 301.6 N.A

Potential Resistance (kN) 418.9

368.1

301.6

Note: Pr1 Pr2 Pr3 = = = Capacity of row 1 alone Min. of { Capacity of row 2 alone, ( Capacity of row 2+1 ) - Pr1 } Min. of { Capacity of row 3 alone, ( Capacity of row 3+2 ) - Pr2 , ( Capacity of row 3+2+1 ) - Pr2 - Pr1}

Compression Check - Supporting member Resistance of the compression zone Column web crushing (Bearing)

Pc = (b1+n2) x tc x py + tf1 x Bp x py Stiff bearing length based b1 = 35.0 mm on a 45deg dispersion through the end plate from the edge of the welds Length obtained by a 1:2.5 dispersion

End Plate

n2 =

87.5 mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS through the column flange and root radius Column web Buckling Pc = (b1+n1) x tc x pc + tf1 x Bp x pc b1 = n1 = Pc = Resistance of the compression zone, (min of due to buckling & crushing) Compression Check - Beam Beam Flange Crushing (Bearing) Pc = 1.4 x pyb x Tb x Bb Pc = 2563 kN Resistance of Column Web panel in Shear Pv = 0.6 x pyc x tc x Dc + 0.6 x pyc x tc x Bp Pc = 2723 kN 35.0 mm 74.0 mm 2723 kN

Reference

Pc =

2798 kN

Due to crushing

Stiff bearing length based on 45deg dispersion to the center of web Length obtained by a 45deg dispersion through half the depth of the column

Due to Buckling

Pv = 1652 kN Force Distribution Equilibrium Pr1 Equilibrium is satisfied by S Fri where Axial load of column N = -580 kN Fr1 Fc is the smallest of the below S Pri or + N Pc = 508.7 kN = Fc = 2563 kN 508.7 kN Fr2 Fr3 Fr4 Fc h1 193 + N = Fc Pr2 Pr3 Pr4 Pc This force is translated into

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Equilibrium is satisfied by Fr1 + Fr2 + Fr3 + N = Fc 418.9 + 368.1 508.7 + 301.6 -- 580.0 = Fc = Fc 0.0 kN Equillibrium Satisfied

kN Load to reduce to satisfy equilibrium Fr1 = 418.9 kN Fr2 Fr3 = 368.1 kN = 301.6 kN

Capacity of Each Bolt considering all modes of failure Ratio For row 1 For row 2 = Fr1 / 2 = Fr2 / 2 = = = = 209.5 kN 184.1 kN 150.8 kN 0.84 > Tension in Bolt row 1,SAFE ( 0.73 ) > Tension in Bolt row 2,SAFE ( 0.76 ) > Tension in Bolt row 3,SAFE ( 0.84 ) < 1.0, Safe ( 152.0 kN) ( 139.3 kN) ( 126.6 kN)

For row 3 = Fr3 / 2 Maximum stress ratio

Check for Combined Shear and Tension Fs Ftot + < 1 PSL 0.9 P0 where Applied Shear Slip resistance Total Applied Tension in the bolt including prying force Specified Minimum preload Combined shear and tension Design for Vertical shear Force V = ns Pss + nt Pts where Design shear force No. of bolts not in tension zone No. of bolts in tension zone Shear capacity of single bolt Bolt shear Bolt bearing on the end plate Pss Fs = PSL = Ftot = P0 = = 8.4 kN kN kN < 1, SAFE

104.7 kN 152.0 232.7 0.806

V = ns = nt =

50.4 kN 0 6

(Resultant shear)

is the least of = 104.7 kN dtppb = 495 kN dtcpb = 495 kN

Bolt bearing on the column flange

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Shear capacity of single bolt Bolt shear Bolt bearing on the end plate Pts

Reference

in tension zone is the least of 0.4 ps As dtppb = = 41.89 kN 495 kN

dtcpb 495 kN Bolt bearing on the column flange = Shear capacity of the connection = 251.4 kN > V,Safe ( 50.4 kN ) Check for weld Weld between the member and the end plate Throat thickness of weld Moment of Inertia about ZZ Moment of Inertia about YY Moment capacity of weld about ZZ Moment capacity of weld about YY Shear capacity of weld Length of weld Shear capacity of weld a = Izz = Iyy = Mzw = = Myw = = = lw = Pw = Fr = Check for Interaction Mz My Fr + + Mzw Myw Pw Conclusion Width of end plate Depth of end plate Thickness of end plate Diameter of Bolts Number of Bolts Type of Bolt Size of weld 7.07 mm 1.31E+08 mm4 z 51416366 mm4

119.5 119.5

End Plate y

140 lww= 225.7 z

Izz pw / Ymax 206 kN-m Iyy pw / Xmax 83 kN-m a * lw * pw 1529 mm 2378 kN sqrt(Fx2+Fy2+Fz2) 582 kN < Pw, Safe ( 2378 kN) < 1, Safe > Mz, Safe ( 20 kN-m) > My, Safe ( 11 kN-m) lwf= 258.8 136 y

Resultant shear due to Fx, Fy & Fz =

0.47

300 mm = 290 mm = 25 mm = = M 24 = 3x 2 = HSFG 10 mm =

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS DESIGN OF MOMENT CONNECTION MC 02 Supporting Member : (supporting on plate connecting between the flanges and stiffener at centre) D = 350.0 mm D - Depth of column or plate Bp = 360.0 mm Bp - Width of column flange or plate tc tf rc = 16.0 mm = 20.0 mm = 10.0 mm

tc - Web thickness of column or stiffener tf - Flange thickness of column or plate rc - Root radius of column or weld to plate and stiffener D - Depth of beam B - Width of beam flange tc - Web thickness of beam tf - Flange thickness ofbeam rc - Root radius of beam

Reference

360

70.25 60 60 60 70.25

Supported Member : D = 320.5 mm B = 309.2 mm tb = 13.8 mm tf1 = 21.7 mm rb = 15.2 mm Member End Actions Compression Tension Shear Force Shear Force Bending moment

200

Thickness of End Plate

tp = 20 mm

(Factored) 450 kN 95 40 20 kN kN kN-m kN-m

Fx = Fx = Fy = Fz = Mz =

123 kN

My = 63 Bending moment Connection Details Assumed bolt configuration Grade of Bolts (8.8 / HSFG) = nr = No. of rows nc = No. of columns Total nos of bolts n = db = Dia of bolt Spacing between rows p = (pitch) Spacing between cols g = (gauge) dh = Dia of bolt hole Abg = Gross area of one bolt Effective area of one bolt Abn = Edge distance e' = Edge distance in plate top e"pt = Edge distance in plate bot. e"pb= Slip factor for untreated m = Ks = For clearance holes Lease thick of plt t =

HSFG 4 2 8 24 mm 60 mm

Part - 2 Bolts

200 mm 26 452 353 80 85 85 0.5 1 20.0 mm mm2 mm2 mm mm mm

mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Forces in Bolts Tension per bolt due to Moment Mz For Row 1 T1 = T1 = For Row 2 T2 = T2 = For Row 3 Mz*a1/(nc(a12+a22+a32+a42)) 22.3 kN

2 2 2 2 Mz*a2/(nc(a1 +a2 +a3 +a4 ))

Reference

T1

a1= 239.4 T2

16.7 kN a2= 179.4 a3= 119.4 a4= 59.4 T3

T3 = Mz*a3/(nc(a12+a22+a32+a42)) T3 = 11.1 kN Mz*a4/(nc(a12+a22+a32+a42)) 5.54 kN

For Row 4

T4 = T4 =

Force Distribution to bolts due to moment Mz Tension per bolt due to Moment My For Column 1 T1 = My / (nr b) T1 = 78.8 kN b = 200.0 T1

Force Distribution to bolts due to moment My Tension per bolt due to Axial tension Fx = Fx / n 11.9 kN Maximum forces Transfer to Each Bolt Maximum Tension in bolt row 1 = 113 kN Maximum Tension in bolt row 2 = 107 kN Maximum Tension in bolt row 3 = 102 kN Maximum Tension in bolt row 4 = 96.2 kN Check for Bolts Yf = Yield strength of bolt Ult. Tensile strength of bolt Uf = ps = Shear stress of bolt Tension stress of bolt Bearing stress of bolt Minimum proof stress pt = pbb = p0 = 882 N/mm2 981 N/mm2 400 N/mm2 700 N/mm2 1300 N/mm2 776 N/mm2

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS of bolt Minimum shank tension in HSFG bolts Capacity of one bolt Shear capacity of bolt Bearing capacity of bolt

Reference

P0 =

233 kN

Ps = Pb =

141 kN 624 kN

Pt' = 209 kN Tension capacity of bolt Slip resistance of one bolt PSL = 0.9 * Ks *m*P0 = 105 kN py = 345 N/mm2 Design strength of steel Bearing strength of steel pb = 825 N/mm2 pw = 220 N/mm2 Design strength of weld Connection Geometry Column Side m = g/2 - tc/2 - 0.8rc = 84 mm e = B/2 - g/2 = 80 mm For n smallest of n e for the column flange e for the end plate 1.25 m for column flange Beam Side m = g/2 - tb/2 - 0.8Sww = 85.1 mm = B/2 - g/2 = 80 mm For n smallest of n e for the column flange e for the end plate 1.25 m for end plate e

= = = =

80 80 80 105 where,

mm mm mm mm

Leg length of fillet weld to beam web, Sww = 10 mm

= = = =

80 80 80 106

mm mm mm mm

Potential Resistance of Bolts in Tension Zone Pr1 Bolt Row 1 & 4 Bolt Row 1 & 4 alone Column Flange Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = Min of [ Max{ii,iii}, i ] Ref. Table 2.4 of moment connection by BCSA Pr2 Pr3 Pr4

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Leff for i Leff for ii Leff for iii = 2 pi() m = 528 mm = 4 m + 1.25 e = 436 mm 504 mm = a m1 = l1 = m1 / (m1+e) l2 = m2 / (m1+e) l1 = l2 = a = Leff 0.51 m1 m2 = =

Reference

where a from Fig 2.16

84

mm

40.6 mm

0.25 6 (ref. Fig 2.16 of moment connection by BCSA)

= Min of [ Max{ii,iii}, i ] = 504 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 17.39 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m 828 kN = Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 416.4 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Potential resistance for column flange bending Pr = 416 kN Column Web Tension As row 1& 4 is near the flange, web tension can be discounted End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = Min of [ Max{ii,iii}, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 535 mm Leff for ii = 4 m + 1.25 e = 440 mm Leff for iii = a m1 = 510.6 mm where a from Fig 2.16 l1 = m1 / (m1+e) m1 = 85.1 mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS l2 = m2 / (m1+e) l1 = l2 = a = Leff 0.52 m2 =

Reference

40.6 mm

0.25 6 (ref. Fig 2.16 of moment connection by BCSA)

= Min of [ Max{ii,iii}, i ] = 511 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 17.62 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m 828 kN = Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 416.4 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 416 kN Potential resistance for end plate bending Beam Web Tension As row 1& 4 is near the flange, web tension can be discounted Bolt Row 2 Row 2 alone and Row 3 alone Column Flange Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = Min of [ ii, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 528 mm Leff for ii = 4 m + 1.25 e = 436 mm Leff = Min of [ ii, i ] 436 = mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 15.04 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 716.3 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Pr = 2 Mp + n(S Pt') m+n = 387.8 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Potential resistance for column flange bending Pr = 388 kN Mode 2 Bolt failure with flange yielding Column Web Tension

Reference

Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = Min of [ ii, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 535 mm Leff for ii = 4 m + 1.25 e = 440 mm Leff = Min of [ ii, i ] = 440 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 15.19 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 714.2 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n 387.1 = kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 387 kN Potential resistance for end plate bending Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Row 2 & 1 as group and Row 4 & 3 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 = 564 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 19.46 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 926.6 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n 646 = kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Potential resistance for column flange bending Pr = 646 kN Column Web Tension

Reference

Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 = 571 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 19.69 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 925.3 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 644.5 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Pr = 644 kN Potential resistance for end plate bending Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Bolt Row 3 Row 3 and 2 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Leff

= ( ii/2 + p/2 ) * 2 496 = mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 17.11 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 814.9 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 617.4 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Potential resistance for column flange bending Pr = 617 kN Column Web Tension Potential resistance for column web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for column web Tension Pt = Lt tc py

Lt =

406

mm

Pt =

2241 kN

End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = ( ii/2 + p/2 ) * 2 = 500 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 17.26 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 811.5 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 615.1 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Pr = 615 kN Potential resistance for end plate bending

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Beam Web Tension Potential resistance for beam web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for beam web Tension

Reference

Pt = Lt tb py

Lt =

406

mm

Pt =

1933 kN

Row 3, 2 & 1 as group and Row 4,3&1 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 + p = 624 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 21.53 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1025 kN P Mode 2 Bolt failure with flange r = 2 Mp + n(S Pt') yielding m+n = 875.6 kN Pr = S Pt' Mode 3 Bolt failure = 1257 kN Potential resistance for column flange bending Pr = 876 kN Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 + p = 631 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 21.76 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1023 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS = 872.6 kN Pr = S Pt' Mode 3 Bolt failure = 1257 kN Potential resistance for column flange bending Pr = 873 kN

Reference

Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Bolt Row 4 Row 4, 3, 2 and 1 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] } x 2 + 3p = 752 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 25.94 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1235 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 1134 kN Pr = S Pt' Mode 3 Bolt failure = 1676 kN Potential resistance for column flange bending Pr = 1134 kN Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI

Leff

= { Max of [ ii/2,(iii-ii/2)] } x 2 + 3p = 761 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 26.25 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1234 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Pr = 2 Mp + n(S Pt') m+n = 1130 kN Pr = S Pt' Mode 3 Bolt failure = 1676 kN Potential resistance for column flange bending Pr = 1130 kN Mode 2 Bolt failure with flange yielding Beam Web Tension

Reference

Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Potential Resistance of Bolts in Tension Zone WORK SHEET: TENSION ZONE Column Side Beam Side Flange Bending Web Tension Flange Bending Web Tension Resistance of Row 1 416.4 N.A 416.4 N.A Resistance of Row 2 only 387.8 N.A 387.1 N.A Resistance of Row 2+1 as group 646.0 N.A 644.5 N.A 229.6 N.A 228.1 N.A Resistance of Row 3 only 387.8 N.A 387.1 N.A Resistance of Row 3+2 as group 617.4 2241.12 615.1 1932.97 389.3 2013.0 387.1 1704.89 Resistance of Row 3+2+1 as group 875.6 N.A 872.6 N.A 231.2 N.A 228.1 N.A Resistance of Row 4 only 416.4 N.A 416.4 N.A Resistance of Row 4+3 as group 646.0 N.A 644.5 N.A 417.9 N.A 416.4 N.A Resistance of Row 4+3+2 as group 875.6 N.A 872.6 N.A 419.5 N.A 416.4 N.A Resistance of Row 4+3+2+1 as group 1133.8 N.A 1130.0 N.A 261.3 N.A 257.4 N.A

Step 1 Row 1

Potential Resistance (kN) 416.4

228.1

228.1

257.4

Note: Pr1

Capacity of row 1 alone

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Pr2 Pr3 = = Min. of { Capacity of row 2 alone, ( Capacity of row 2+1 ) - Pr1 } Min. of { Capacity of row 3 alone, ( Capacity of row 3+2 ) - Pr2 , ( Capacity of row 3+2+1 ) - Pr2 - Pr2} Min. of { Capacity of row 4 alone, ( Capacity of row 4+3 ) - Pr3 , ( Capacity of row 4+3+2 ) - Pr3 - Pr2 ( Capacity of row 4+3+2+1 ) - Pr3 - Pr2 - Pr1}

Reference

Pr4

Compression Check - Supporting member Resistance of the compression zone

Column web crushing (Bearing) Pc = (b1+n2) x tc x py + tf1 x Bp x py Stiff bearing length based b1 = 30.0 mm on a 45deg dispersion through the end plate from the edge of the welds Length obtained by a n2 = 75 mm 1:2.5 dispersion through the column flange and root Pc = radius Column web Buckling Pc = (b1+n1) x tc x pc + tf1 x Bp x pc Stiff bearing length based on 45deg dispersion to the center of web Length obtained by a 45deg dispersion through half the depth of the column Resistance of the compression zone, (min of due to buckling & crushing) Compression Check - Beam Beam Flange Crushing (Bearing) Pc = 1.4 x pyb x Tb x Bb Pc = 3241 kN Resistance of Column Web panel in Shear Pv = 0.6 x pyc x tc x Dc + 0.6 x pyc x tc x Bp Pv = 2052 kN Pc = End Plate

3275 kN

Due to crushing

b1 = n1 = Pc = 3275 kN

30.0 mm 83.9 mm 3324 kN Due to Buckling

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Force Distribution Equilibrium

Reference

Pr1 Equilibrium is satisfied by S Fri where Axial load of column N = -95 kN Fr1 Fc is the smallest of the below S Pri or + N Pc = 1035 kN = Fc = 3241 kN 1035 kN Fr2 Fr3 Fr4 Fc h1 239 + N = Fc Pr2 Pr3 Pr4 Pc This force is translated into

Equilibrium is satisfied by Fr1 + Fr2 + Fr3 + Fr4 + N = Fc 416.4 + 228.1 + 228.1 + 257.4 -95.0 = Fc kN Equillibrium Satisfied

1035 kN = Fc 0.0 Load to reduce to satisfy equilibrium Fr1 Fr2 Fr3 Fr4 = 416.4 kN = 228.1 kN = 228.1 kN

= 257.4 kN Capacity of Each Bolt considering all modes of failure For row 1 For row 2 For row 3 = Fr1 / 2 = Fr2 / 2 = Fr3 / 2 = = = = = 208.2 kN > Tension in Bolt row 1, 114.0 kN > Tension in Bolt row 2, 114.0 kN > Tension in Bolt row 3, 128.7 kN > Tension in Bolt row 4, 0.94 < 1.0, Safe Ratio SAFE ( 0.54 ) SAFE ( 0.94 ) SAFE ( 0.89 ) SAFE ( 0.75 ) ( 112.9 kN) ( 107.3 kN) ( 101.8 kN) ( 96.2 kN)

For row 4 = Fr4 / 2 Maximum stress ratio

Check for Combined Shear and Tension Fs Ftot + < 1 PSL 0.9 P0

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS where Applied Shear Slip resistance Total Applied Tension in the bolt including prying force Specified Minimum preload Combined shear and tension Design for Vertical shear Force V = ns Pss + nt Pts where Design shear force No. of bolts not in tension zone No. of bolts in tension zone Shear capacity of single bolt Pss Bolt shear Bolt bearing on the end plate Bolt baring on the column flange Shear capacity of single bolt Bolt shear Bolt bearing on the end plate Bolt baring on the column flange Shear capacity of the connection = Pts Fs = PSL = Ftot = P0 = = 16.2 kN 104.7 kN 112.9 232.7 0.69 kN kN

Reference

< 1, SAFE

V = ns = nt =

129.3 kN 0 8

(Resultant shear)

is the least of = 105 kN dtppb = 396 kN dtcpb 0.4 ps As dtppb dtcpb = = = = 396 kN 41.9 kN 396 kN 396 kN > V,Safe ( 129.3 kN ) End Plate y in tension zone is the least of

335.2 kN

Check for weld Weld between the member and the end plate Throat thickness of weld Moment of Inertia about ZZ Moment of Inertia about YY Moment capacity of weld about ZZ Moment capacity of weld about YY a = Izz = Iyy = 7.07 mm 2.3E+08 mm4 z 1.77E+08 mm4 167

lww= 277.1 z

144.2 144.2

Mzw = Izz pw / Ymax = 303 kN-m > Mz, Safe ( 20 kN-m) > My, Safe ( 63 kN-m) lwf= 309.2 162 y

Myw = Iyy pw / Xmax = 241 kN-m

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Shear capacity of weld Length of weld Shear capacity of weld = a * lw * pw lw = Pw = Fr = Check for Interaction Fr Pw Mz Mzw My Myw = 0.39 < 1, Safe 1749 mm 2721 kN 160 kN < Pw, Safe ( 2721 kN)

Reference

Resultant shear due to Fx, Fy & Fz = sqrt(Fx2+Fy2+Fz2)

Conclusion Width of end plate Depth of end plate Thickness of end plate Diameter of Bolts Number of Bolts Type of Bolt Size of weld = 360 mm = 350 mm 20 mm = = M 24 = 4x 2 = HSFG 10 mm =

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS DESIGN OF MOMENT CONNECTION MC 02 Supporting Member : (supporting on plate connecting between the flanges and stiffener at centre) D = 484.0 mm D - Depth of column or plate Bp = 220.0 mm Bp - Width of column flange or plate tc = 10.0 mm tf = 16.0 mm rc = 8.0 mm Supported Member : D = 457.0 mm B = 190.4 mm tb = 9.0 mm tf1 = 14.5 mm rb = 10.2 mm

tc - Web thickness of column or stiffener tf - Flange thickness of column or plate rc - Root radius of column or weld to plate and stiffener D - Depth of beam B - Width of beam flange Thickness of end plate tc - Web thickness of beam tf - Flange thickness ofbeam rc - Root radius of beam

Reference

220

88.5 70 70 70 70 88.5

120

Thickness of End Plate Member End Actions (Factored) Fx = 285 kN Compression Tension Shear Force Shear Force Bending moment Bending moment Fx = Fy = Fz = Mz = My = 300 kN 8 0 0 0 kN kN kN-m kN-m

tp = 16 mm

Connection Details Assumed bolt configuration Grade of Bolts (8.8 / HSFG) = nr = No. of rows nc = No. of columns Total nos of bolts n = db = Dia of bolt Spacing between rows p = (pitch) Spacing between cols g = (gauge) dh = Dia of bolt hole Abg = Gross area of one bolt Effective area of one bolt Abn = Edge distance e' = Edge distance in plate top e"pt = Edge distance in plate bot. e"pb= Slip factor for untreated m = Ks = For clearance holes Lease thick of plt t =

HSFG 5 2 10 24 mm 70 mm

Part - 2 Bolts

120 mm 26 452 353 60 102 102 0.5 1 16.0 mm mm2 mm2 mm mm mm

mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Forces in Bolts Tension per bolt due to Moment Mz For Row 1 T1 = T1 = For Row 2 T2 = T2 = For Row 3

Mz*a1/(nc(a12+a22+a32+a42+a52))

Reference

T1

kN

a1= 361.3 T2

Mz*a2/(nc(a12+a22+a32+a42+a52))

kN a2= 291.3 a3= 221.3 a4= 151.3 a5= 81.3 T3

T3 = Mz*a3/(nc(a12+a22+a32+a42+a52)) T3 = 0 kN

For Row 4

T4 = T4 =

Mz*a4/(nc(a12+a22+a32+a42+a52))

kN

For Row 5

T5 = Mz*a5/(nc(a12+a22+a32+a42+a52)) Force Distribution to bolts due to moment Mz T5 = 0 kN

Tension per bolt due to Moment My For Column 1 T1 = My / (nr b) T1 = 0 kN b = 120.0 T1

Force Distribution to bolts due to moment My

Tension per bolt due to Axial tension Fx

= Fx / n 30 kN Maximum forces Transfer to Each Bolt 30 kN Maximum Tension in bolt row 1 = 30 kN Maximum Tension in bolt row 2 = 30 kN Maximum Tension in bolt row 3 = 30 kN Maximum Tension in bolt row 4 = 30 kN Maximum Tension in bolt row 5 =

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Check for Bolts Yf = Yield strength of bolt Ult. Tensile strength of bolt Uf = ps = Shear stress of bolt Tension stress of bolt Bearing stress of bolt Minimum proof stress of bolt Minimum shank tension in HSFG bolts Capacity of one bolt Shear capacity of bolt Bearing capacity of bolt Tension capacity of bolt pt = pbb = p0 = P0 = 882 N/mm2 981 N/mm2 400 N/mm2 700 N/mm2 1300 N/mm2 776 N/mm2 233 kN

Reference

Ps = Pb = Pt' =

141 kN 499 kN 209.5 kN

Slip resistance of one bolt PSL = 0.9 * Ks *m*P0 = 105 kN py = 355 N/mm2 Design strength of steel Bearing strength of steel pb = 825 N/mm2 pw = 220 N/mm2 Design strength of weld Connection Geometry Column Side m = g/2 - tc/2 - 0.8rc = 48.6 mm e = B/2 - g/2 = 50 mm For n smallest of n e for the column flange e for the end plate 1.25 m for column flange Beam Side m = g/2 - tb/2 - 0.8Sww = 49.1 mm e = B/2 - g/2 = 50 mm For n smallest of n e for the column flange e for the end plate 1.25 m for end plate

= = = =

50 50 50 60.8 where,

mm mm mm mm

Leg length of fillet weld to beam web, Sww =

8 mm

= = = =

50 50 50 61.4

mm mm mm mm

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Potential Resistance of Bolts in Tension Zone Pr1 Bolt Row 1 & 5 Bolt Row 1 & 5 alone Column Flange Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = Min of [ Max{ii,iii}, i ] Ref. Table 2.4 of moment connection by BCSA Leff for i = 2 pi() m = 305 mm Leff for ii = 4 m + 1.25 e = 257 mm Leff for iii = a m1 = 267.3 mm where a from Fig 2.16 l1 = m1 / (m1+e) l2 = m2 / (m1+e) l1 = l2 = a = Leff 0.49 0.69 5.5 (ref. Fig 2.16 of moment connection by BCSA) m1 m2 = = 48.6 mm 67.6 mm Pr2 Pr3 Pr4 Pr5

= Min of [ Max{ii,iii}, i ] = 267 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 6.073 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 499.8 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 335.6 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Potential resistance for column flange bending Pr = 336 kN Column Web Tension As row 1&5 is near the flange, web tension can be discounted

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = Min of [ Max{ii,iii}, i ] Ref. Table 2.4 Leff for i = 2 pi() m = 309 mm Leff for ii = 4 m + 1.25 e = 259 mm Leff for iii = a m1 = 270.1 mm where a from Fig 2.16 l1 = m1 / (m1+e) l2 = m2 / (m1+e) l1 = l2 = a = Leff 0.5 m1 m2 = =

Reference

49.1 mm 67.6 mm

0.68 5.5 (ref. Fig 2.16 of moment connection by BCSA)

= Min of [ Max{ii,iii}, i ] = 270 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 6.136 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 499.8 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 335.2 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 335 kN Potential resistance for end plate bending Beam Web Tension As row 1& 5 is near the flange, web tension can be discounted Bolt Row 2 Row 2 alone, Row 3 alone & Row 4 alone Column Flange Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = Min of [ ii, i ] Ref. Table 2.4 of moment connection by BCSA

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Leff for i = 2 pi() m = 305 mm Leff for ii = 4 m + 1.25 e = 257 mm Leff = Min of [ ii, i ] = 257 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 5.837 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 480.4 kN P Mode 2 Bolt failure with flange r = 2 Mp + n(S Pt') yielding m+n = 330.8 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Potential resistance for column flange bending Pr = 331 kN Column Web Tension Potential resistance for column web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for column web Tension End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = Min of [ ii, i ] Ref. Table 2.4 Leff for i = 2 pi() m = 309 mm Leff for ii = 4 m + 1.25 e = 259 mm Leff = Min of [ ii, i ] = 259 mm Plastic moment capacity of the equivalent T-stub Pt = Lt tw py

Reference

Lt =

207.6 mm

Pt =

737

kN

Mp = Leff x tp2 x py / 4 = 5.882 kN-m

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 479.2 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 330.1 kN Pr = S Pt' Mode 3 Bolt failure = 418.9 kN Pr = 330 kN Potential resistance for end plate bending Beam Web Tension Potential resistance for column web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for beam web Tension Pt = Lt tw py

Reference

Lt =

207.6 mm

Pt =

663.3 kN

Row 2&1 as group and Row 5&4 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 = 337 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 7.663 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 630.7 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 580.3 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Potential resistance for column flange bending Pr = 580 kN Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange.

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 = 340 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 7.726 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 629.4 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 578.7 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Pr = 579 kN Potential resistance for end plate bending Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Bolt Row 3 Row 3&2 as group and Row 4&3 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = ( ii/2 + p/2 ) * 2 = 327 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 7.427 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 611.3 kN P Mode 2 Bolt failure with flange r = 2 Mp + n(S Pt') yielding m+n = 575.5 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Potential resistance for column flange bending Pr = 576 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Column Web Tension Potential resistance for column web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for column web Tension Pt = Lt tc py

Reference

Lt =

277.6 mm

Pt =

985.5 kN

End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI Leff = ( ii/2 + p/2 ) * 2 = 329 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 7.473 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 608.8 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 573.6 kN Pr = S Pt' Mode 3 Bolt failure = 837.9 kN Pr = 574 kN Potential resistance for end plate bending

Beam Web Tension Potential resistance for beam web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for beam web Tension Pt = Lt tb py

Lt =

277.6 mm

Pt =

886.9 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Row 3,2&1 as group and Row 5,4&3 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 + p = 407 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 9.254 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 761.6 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n 825 kN = Pr = S Pt' Mode 3 Bolt failure = 1257 kN Potential resistance for column flange bending Pr = 762 kN

Reference

Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 + p = 410 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 9.316 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m 759 kN = Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 822.1 kN Pr = S Pt' Mode 3 Bolt failure = 1257 kN Potential resistance for column flange bending Pr = 759 kN Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange.

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Bolt Row 4 Row 4, 3 and 2 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = ( ii/2 + p/2 ) * 2 + p = 397 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 9.018 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 742.2 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 820.3 kN Pr = S Pt' Mode 3 Bolt failure = 1257 kN Potential resistance for column flange bending Pr = 742 kN Column Web Tension Potential resistance for column web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for column web Tension Pt = Lt tw py

Reference

Lt =

347.6 mm

Pt =

1234 kN

End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = ( ii/2 + p/2 ) * 2 + p = 399 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 9.063 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 738.3 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS Pr = 2 Mp + n(S Pt') m+n 817 kN = Pr = S Pt' Mode 3 Bolt failure = 1257 kN Potential resistance for column flange bending Pr = 738 kN Mode 2 Bolt failure with flange yielding Beam Web Tension Potential resistance for column web Tension Effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web Potential resistance for beam web Tension Pt = Lt tw py

Reference

Lt =

347.6 mm

Pt =

1111 kN

Row 4, 3, 2 and 1 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 + 2p = 477 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 10.84 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 892.5 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n 1070 = kN Pr = S Pt' Mode 3 Bolt failure = 1676 kN Potential resistance for column flange bending Pr = 893 kN Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange.

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI For bolt row below the flange of a flush end plate Leff = { Max of [ ii/2,(iii-ii/2)] + p/2 } + ii/2 + p/2 + 2p = 480 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 10.91 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 872.5 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 1066 kN Pr = S Pt' Mode 3 Bolt failure = 1676 kN Potential resistance for column flange bending Pr = 873 kN

Reference

Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Bolt Row 5 Row 5, 4, 3, 2 and 1 as group Column Flange Bending Calculate effective length of T-stub as per Table2.6 of SCI

Leff

= { Max of [ ii/2,(iii-ii/2)] } x 2 + 4p = 558 mm Mp = Leff x tf2 x py / 4 Plastic moment capacity of the equivalent T-stub = 12.67 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1043 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 1319 kN Pr = S Pt' Mode 3 Bolt failure = 2095 kN Potential resistance for column flange bending Pr = 1043 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Column Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. End Plate Bending Calculate effective length of T-stub as per Table2.5 of SCI

Leff

= { Max of [ ii/2,(iii-ii/2)] } x 2 + 4p = 561 mm Mp = Leff x tp2 x py / 4 Plastic moment capacity of the equivalent T-stub = 12.75 kN-m Potential resistance is the minimum of the following Mode 1 Complete flange yielding Pr = 4 Mp / m = 1039 kN Pr = 2 Mp + n(S Pt') Mode 2 Bolt failure with flange yielding m+n = 1314 kN Pr = S Pt' Mode 3 Bolt failure = 2095 kN Potential resistance for column flange bending Pr = 1039 kN Beam Web Tension Web tension can be discounted due to effective tensile length of web assuming a max. spread at 60deg from bolts to the centre of web is crossing the flange. Note: Pr1 Pr2 Pr3 = = = Capacity of row 1 alone Min. of { Capacity of row 2 alone, ( Capacity of row 2+1 ) - Pr1 } Min. of { Capacity of row 3 alone, ( Capacity of row 3+2 ) - Pr2 , ( Capacity of row 3+2+1 ) - Pr2 - Pr2} Min. of { Capacity of row 4 alone, ( Capacity of row 4+3 ) - Pr3 , ( Capacity of row 4+3+2 ) - Pr3 - Pr2 ( Capacity of row 4+3+2+1 ) - Pr3 - Pr2 - Pr1} Min. of { Capacity of row 5 alone, ( Capacity of row 5+4 ) - Pr4 , ( Capacity of row 5+4+3 ) - Pr4 - Pr3 ( Capacity of row 5+4+3+2 ) - Pr4 - Pr3 - Pr2} ( Capacity of row 5+4+3+2+1 ) -Pr4 - Pr3 - Pr2 - Pr1}

Pr4

Pr5

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Potential Resistance of Bolts in Tension Zone WORK SHEET: TENSION ZONE Column Side Beam Side Flange Bending Web Tension Flange Bending Web Tension Resistance of Row 1 335.6 N.A 335.2 N.A Resistance of Row 2 only 330.8 736.98 330.1 663.282 Resistance of Row 2+1 as group 580.3 N.A 578.7 N.A 245.1 N.A 243.5 N.A Resistance of Row 3 only 330.8 736.98 330.1 663.282 Resistance of Row 3+2 as group 575.5 985.48 573.6 886.932 332.1 742.0 330.1 643.5 Resistance of Row 3+2+1 as group 761.6 N.A 759.0 N.A 183.0 N.A 180.3 N.A Resistance of Row 4 only 330.8 736.98 330.1 663.282 Resistance of Row 4+3 as group 575.5 985.48 573.6 886.932 395.3 805.2 393.3 706.6 Resistance of Row 4+3+2 as group 742.2 1233.98 738.3 1110.582 318.4 810.2 314.6 686.8 Resistance of Row 4+3+2+1 as group 892.5 N.A 872.5 N.A 133.6 N.A 113.6 N.A Resistance of Row 5 only 335.6 N.A 335.2 N.A Resistance of Row 5+4 as group 580.3 N.A 578.7 N.A 466.8 N.A 465.1 N.A Resistance of Row 5+4+3 as group 761.6 N.A 759.0 N.A 467.8 N.A 465.1 N.A Resistance of Row 5+4+3+2 as group 892.5 N.A 872.5 N.A 355.2 N.A 335.2 N.A Resistance of Row 5+4+3+2+1 as group 1042.9 N.A 1038.7 N.A 170.3 N.A 166.2 N.A

Step 1 Row 1

Potential Resistance (kN) 335.2

243.5

180.3

113.6

166.2

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Compression Check - Supporting member Resistance of the compression zone

Column web crushing (Bearing)

Pc = (b1+n2) x tc x py + tf1 x Bp x py Stiff bearing length based b1 = 24.0 mm on a 45deg dispersion through the end plate from the edge of the welds Length obtained by a 1:2.5 dispersion through the column flange and root radius Column web Buckling Pc = (b1+n1) x tc x pc

End Plate

n2 =

60

mm

Pc =

1431 kN

Due to crushing

+ tf1 x Bp x pc b1 = n1 = Pc = 24.0 mm 53.4 mm 1407 kN Due to Buckling

Stiff bearing length based on 45deg dispersion to the center of web Length obtained by a 45deg dispersion through half the depth of the column

Resistance of the compression zone, (min of due to buckling & crushing) Compression Check - Beam Beam Flange Crushing (Bearing) Pc = 1.4 x pyb x Tb x Bb Pc = 1372 kN

Pc =

1407 kN

Resistance of Column Web panel in Shear Pv = 0.6 x pyc x tc x Dc Pv = 827 kN + 0.6 x pyc x tc x Bp

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Force Distribution Equilibrium Pr1 Equilibrium is satisfied by S Fri where Axial load of column N = -300 kN Fr1 Fc is the smallest of the below S Pri or + N Pc = 738.7 kN = Fc = Equilibrium is satisfied by Fr1 + Fr2 + Fr3 + Fr4 + Fr5 1372 kN 739 kN Fr2 Fr3 Fr4 Fr5 Fc h1 361 + N = Fc Pc This force is translated into Pr2 Pr3 Pr4

+ N = Fc 166.2 -- 300.0 = Fc kN Equillibrium Satisfied

335.2 + 243.5 + 180.3 + 113.6 +

738.7 kN = Fc 0.0 Load to reduce to satisfy equilibrium Fr1 Fr2 Fr3 Fr4 Fr5 = 335.2 kN = 243.5 kN = 180.3 kN = 113.6 kN = 166.2 kN

Capacity of Each Bolt considering all modes of failure Ratio For row 1 For row 2 For row 3 For row 4 For row 5 = Fr1 / 2 = Fr2 / 2 = Fr3 / 2 = Fr4 / 2 = Fr5 / 2 = = = = = = 167.6 kN > Tension in Bolt row 1, 121.7 kN > Tension in Bolt row 2, 90.1 kN > Tension in Bolt row 3, 56.8 kN > Tension in Bolt row 4, 83.1 kN > Tension in Bolt row 5, 0.53 < 1.0, Safe SAFE ( 0.18 ) SAFE ( 0.25 ) SAFE ( 0.33 ) SAFE ( 0.53 ) SAFE ( 0.36 ) ( 30.0 kN) ( 30.0 kN) ( 30.0 kN) ( 30.0 kN) ( 30.0 kN)

Maximum stress ratio

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Check for Combined Shear and Tension Fs Ftot + < 1 PSL 0.9 P0 where Applied Shear Slip resistance Total Applied Tension in the bolt including prying force Specified Minimum preload Design for Vertical shear Force Combined shear and tension V = ns Pss + nt Pts where Design shear force No. of bolts not in tension zone No. of bolts in tension zone Shear capacity of single bolt Pss Bolt shear Bolt bearing on the end plate Bolt baring on the column flange Shear capacity of single bolt Bolt shear Bolt bearing on the end plate Bolt baring on the column flange Shear capacity of the connection = Pts Fs = PSL = Ftot = P0 = 0.8 kN 104.7 kN 30.0 232.7 kN kN

0.15

< 1, SAFE

V = ns = nt =

8.0 kN 0 10

(Resultant shear)

is the least of = 105 kN dtppb = 317 kN dtcpb 0.4 ps As dtppb dtcpb = = = = 317 kN 41.9 kN 317 kN 317 kN > V,Safe ( 8 kN ) in tension zone is the least of

418.9 kN

SENDAI

EVERSENDAI ENGINEERING L.L.C

Job No Date

Sheet

of

PROJECT DUBAI MALL GRAND ATRIUM DOME

SUBJECT

Designed by

KMK

Checked by

BNRao

DESIGN OF STEEL WORK CONNECTIONS

Reference

Check for weld Weld between the member and the end plate Throat thickness of weld Moment of Inertia about ZZ Moment of Inertia about YY Moment capacity of weld about ZZ Moment capacity of weld about YY Shear capacity of weld Length of weld Shear capacity of weld a = Izz = Iyy = 5.66 mm 2.94E+08 mm4 z 61505160 mm4 234

End Plate y

lww= 428 z

87.87 87.87

Mzw = Izz pw / Ymax = 276 kN-m > Mz, Safe ( 0 kN-m) > My, Safe ( 0 kN-m) lwf= 190.4 101 y

Myw = Iyy pw / Xmax = 134 kN-m = a * lw * pw lw = Pw = Fr = 1588 mm 1976 kN 300 kN

Resultant shear due to Fx, Fy & Fz = sqrt(Fx2+Fy2+Fz2) < Pw, Safe ( 1976 kN)

Check for Interaction Fr Pw Mz Mzw My Myw = 0.15 < 1, Safe

Conclusion Width of end plate Depth of end plate Thickness of end plate Diameter of Bolts Number of Bolts Type of Bolt Size of weld = 220 mm = 484 mm 16 mm = = M 24 = 5x 2 = HSFG 8 mm =

Das könnte Ihnen auch gefallen

- End Plate-Splice ConnectionDokument76 SeitenEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Base Plate Design - BS CodeDokument3 SeitenBase Plate Design - BS Codemicheleling669667% (3)

- Moment Connection Beam Column IS & BS SECTION FOR IS800Dokument29 SeitenMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Fellow Craft Booklet FinalDokument15 SeitenFellow Craft Booklet Finalchevalier_ramsay_N492% (12)

- End Plate DesignDokument4 SeitenEnd Plate DesignAgnon Fung100% (4)

- Bolted Moment ConnectionDokument3 SeitenBolted Moment Connectionprabhu81100% (3)

- FIN PLATE - Beam To BeamDokument71 SeitenFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Base Plate DesignDokument118 SeitenBase Plate Designsanjay singhNoch keine Bewertungen

- Base Plate Design Is 800-2007Dokument6 SeitenBase Plate Design Is 800-2007Suneesh P91% (11)

- Helical Strakes DevelopmentDokument4 SeitenHelical Strakes Developmentkalpanaadhi100% (1)

- Moody's ChartDokument100 SeitenMoody's Chartbsk109100% (3)

- IS 1893 (PART 1) - 2016 Amedment No.2Dokument6 SeitenIS 1893 (PART 1) - 2016 Amedment No.2kalpanaadhi0% (1)

- LP-II Lab ManualDokument11 SeitenLP-II Lab Manualpradyumna lokhandeNoch keine Bewertungen

- Bracing Gusset Connection - LRFDDokument4 SeitenBracing Gusset Connection - LRFDkalpanaadhi75% (4)

- Combined Gusset Plate DesignDokument3 SeitenCombined Gusset Plate Designkalpanaadhi100% (3)

- Moment ConnectionDokument15 SeitenMoment Connectionnitin400Noch keine Bewertungen

- End Plate ConnectionDokument10 SeitenEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Base Plate DesignDokument32 SeitenBase Plate DesignGautam Sharma50% (2)

- Base PlateDokument32 SeitenBase PlateSunil SinghNoch keine Bewertungen

- End Plate-Beam To Column Moment ConnectionDokument81 SeitenEnd Plate-Beam To Column Moment ConnectionHemant Ramesh Narkar50% (6)

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDokument25 SeitenRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Connection Design SheetDokument47 SeitenConnection Design SheetStephen James100% (1)

- Typ-Base PlateDokument11 SeitenTyp-Base PlateManoj Jaiswal100% (2)

- Rafter Splice DesignDokument2 SeitenRafter Splice DesignkalpanaadhiNoch keine Bewertungen

- Beam To Beam Web - Shear ConnectionDokument2 SeitenBeam To Beam Web - Shear ConnectionGautam SharmaNoch keine Bewertungen

- Att-5 - End-Plate Shear ConnectionDokument7 SeitenAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- Moment Connection Portal FrameDokument18 SeitenMoment Connection Portal Frametmssorin100% (1)

- Shear Connection - Beam - Steel Column - Fin PlateDokument30 SeitenShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- End Plate DesignDokument26 SeitenEnd Plate DesignNitesh SinghNoch keine Bewertungen

- Bolted ConnectionDokument86 SeitenBolted ConnectionPooja MistryNoch keine Bewertungen

- 11 Steel Connection Design As Per AISC 23052014Dokument2 Seiten11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri67% (3)

- Base PlateDokument7 SeitenBase Plateabdul karee100% (6)

- Base PlateDokument45 SeitenBase PlateMuhammed Ali60% (5)

- Base Plate Design Fixed RevisedDokument8 SeitenBase Plate Design Fixed RevisedEngDbt80% (5)

- Moment ConnectionDokument39 SeitenMoment ConnectionRitwick MishraNoch keine Bewertungen

- Connection Design MomentDokument4 SeitenConnection Design MomentAkshit Dhawan100% (1)

- 321 Chapter 5 Splice DesignDokument91 Seiten321 Chapter 5 Splice DesignHemant Ramesh NarkarNoch keine Bewertungen

- Design of Base PlateDokument166 SeitenDesign of Base PlateAnonymous ciKyr0t86% (7)

- Hollow Section Bracing Connetion - LRFDDokument5 SeitenHollow Section Bracing Connetion - LRFDkalpanaadhiNoch keine Bewertungen

- Design of Headed Concrete AnchorDokument121 SeitenDesign of Headed Concrete AnchorkalpanaadhiNoch keine Bewertungen

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDokument1 SeiteCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- 4-Base Plate - Pin ConnectionDokument3 Seiten4-Base Plate - Pin ConnectionMUTHUKKUMARAMNoch keine Bewertungen

- Design of MonorailDokument9 SeitenDesign of MonorailAnonymous Q8XIGqHyCNoch keine Bewertungen

- Moment Connection Design-BS CODEDokument5 SeitenMoment Connection Design-BS CODEMuthukumaran SivalingamNoch keine Bewertungen

- Design of Anchor BoltDokument3 SeitenDesign of Anchor Boltdsananda100% (2)

- End-Plate-Design BS CodeDokument15 SeitenEnd-Plate-Design BS CodeRaymond SabadoNoch keine Bewertungen

- Base PlateDokument12 SeitenBase PlateD SRINIVAS100% (1)

- Base Plate CalculationDokument6 SeitenBase Plate CalculationbuildconNoch keine Bewertungen

- Base Plate DesignDokument3 SeitenBase Plate DesignrajarshiboseNoch keine Bewertungen

- Combined Footing Design For Compressive LoadDokument8 SeitenCombined Footing Design For Compressive LoadSunil JoshiNoch keine Bewertungen

- Base Plate - FixedDokument4 SeitenBase Plate - Fixedbhaskardharani80% (5)

- Column Base Plate (Fixed Type)Dokument11 SeitenColumn Base Plate (Fixed Type)Ernest Navarro100% (2)

- Base Plate Design (Fixed Base)Dokument3 SeitenBase Plate Design (Fixed Base)Saravana NNoch keine Bewertungen

- Ba Culvertf TestDokument16 SeitenBa Culvertf TestsanjuktaacharyyaNoch keine Bewertungen

- End Plate ConnectionDokument12 SeitenEnd Plate ConnectioncklconNoch keine Bewertungen

- Purlin Cleat 220908Dokument24 SeitenPurlin Cleat 220908kalpanaadhi100% (2)

- Structure of RCC Beam Design Task 01Dokument29 SeitenStructure of RCC Beam Design Task 01George GeorgianNoch keine Bewertungen

- RCC Beam Design Task-01Dokument29 SeitenRCC Beam Design Task-01Mohamed SaheelNoch keine Bewertungen

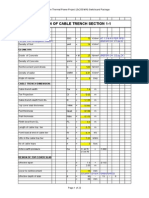

- Design of Cable Trench Section 1-1: Soil ParametersDokument23 SeitenDesign of Cable Trench Section 1-1: Soil Parametersg4goharNoch keine Bewertungen

- Composite Steel GirderDokument10 SeitenComposite Steel GirdersorowareNoch keine Bewertungen

- 16 BDokument4 Seiten16 BmaheshbandhamNoch keine Bewertungen

- DG Consulting Engineers: Job NoDokument52 SeitenDG Consulting Engineers: Job NosthakshyNoch keine Bewertungen

- AL Jazeera Design Calculation PDFDokument9 SeitenAL Jazeera Design Calculation PDFwaquarshaiNoch keine Bewertungen

- Ub 254 Fin Plate To Column Web - LRFDDokument10 SeitenUb 254 Fin Plate To Column Web - LRFDihpeterNoch keine Bewertungen

- UB254 To UB457Dokument7 SeitenUB254 To UB457ihpeterNoch keine Bewertungen

- M. L. Gambhir - Fundamentals of Solid Mechanics-PHI Learning Private Limited (2009)Dokument934 SeitenM. L. Gambhir - Fundamentals of Solid Mechanics-PHI Learning Private Limited (2009)shireenkatre100% (1)

- Structural Connections - KrishnarajuDokument11 SeitenStructural Connections - KrishnarajukalpanaadhiNoch keine Bewertungen

- Design Manual For Is 800 - 2007 - Compression MembersDokument6 SeitenDesign Manual For Is 800 - 2007 - Compression MemberskalpanaadhiNoch keine Bewertungen

- SP6 - 1 Gauge Distance in Legs of AnglesDokument1 SeiteSP6 - 1 Gauge Distance in Legs of AngleskalpanaadhiNoch keine Bewertungen

- Bolt Capacity CalculationsDokument4 SeitenBolt Capacity CalculationskalpanaadhiNoch keine Bewertungen

- Basics of Engineering DrawingDokument103 SeitenBasics of Engineering DrawingkalpanaadhiNoch keine Bewertungen

- IS 13920: 2016 Amedment No.2Dokument3 SeitenIS 13920: 2016 Amedment No.2kalpanaadhiNoch keine Bewertungen

- Is 875 (Part 3) - 2015 Annex A As Per AmendmentDokument1 SeiteIs 875 (Part 3) - 2015 Annex A As Per AmendmentkalpanaadhiNoch keine Bewertungen

- ACE Civil Interview Questions - DSSDokument8 SeitenACE Civil Interview Questions - DSSkalpanaadhiNoch keine Bewertungen

- Industrial Structures ListDokument2 SeitenIndustrial Structures ListkalpanaadhiNoch keine Bewertungen

- Engg. MathsDokument46 SeitenEngg. MathskalpanaadhiNoch keine Bewertungen

- Green SkyscrapersDokument160 SeitenGreen SkyscrapersMiti Agarwal100% (2)

- Concrete Structures (GATE)Dokument12 SeitenConcrete Structures (GATE)kalpanaadhiNoch keine Bewertungen

- Soil Basic TerminologyDokument1 SeiteSoil Basic TerminologykalpanaadhiNoch keine Bewertungen

- Assignment BeamDokument1 SeiteAssignment BeamkalpanaadhiNoch keine Bewertungen

- Soil Basic Terminology PDFDokument1 SeiteSoil Basic Terminology PDFkalpanaadhiNoch keine Bewertungen

- Hosts UmbrellaDokument1 SeiteHosts UmbrellaFabsor SoralNoch keine Bewertungen

- Is Drinking Milk EssentialDokument4 SeitenIs Drinking Milk EssentialkalpanaadhiNoch keine Bewertungen

- Irregular PeriodsDokument2 SeitenIrregular PeriodskalpanaadhiNoch keine Bewertungen