Beruflich Dokumente

Kultur Dokumente

Metrode Nickel G04

Hochgeladen von

Claudia MmsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Metrode Nickel G04

Hochgeladen von

Claudia MmsCopyright:

Verfügbare Formate

General Guidance on Welding Nickel Alloys

The majority of problems encountered when welding nickel alloys arise as a result of the different characteristics of nickel alloys compared to CMn or stainless steels. The following comments apply to most of the commonly used nickel alloys. The fluidity of nickel alloys is low, causing a sluggish weld pool which does not wet out easily. To overcome this the weld pool needs to be manipulated or weaved; to enable this to be carried out easily the joint preparation may need to be wider than for CMn or stainless steel welds (~80 in a single V). The weave should not be excessive (no more than three times core wire diameter) and there should be a pause at each side of the weave to prevent undercut. The penetration achieved with nickel base alloys is also significantly lower than with CMn steel. The penetration cannot be altered by increasing the current; this will only result in electrode overheating and eventually porosity. To ensure proper fusion the joint has to be designed appropriately ie. correct joint angle and thinner land or root face. Hot cracking is not a common problem in practice but it is generally recognised that nickel alloy welds are, to some extent, naturally susceptible. The extent of the susceptibility to hot cracking will depend on the situation (such as weld restraint, weld bead profile, alloy type and level of impurities). Solidification cracking is a visibly significant form of hot cracking, typically occurring along the weld centreline or in the weld pool crater. When such cracking occurs it is usually associated with a flat/concave weld profile and can normally be prevented by producing a larger weld bead with a more convex profile. It is also beneficial to ensure that craters are well-filled, and some authorities insist that weld craters are removed by grinding. Base metal cleaning is very important on nickel base alloys for two reasons firstly to ensure heavy oxides are removed, secondly to remove potential contaminants eg. S, P, Pb, Zn, Sn. The oxide needs to be removed because it will not melt during welding owing to its very high melting point and can result in radiographic indications; removal is carried out by grinding, abrasive blasting or pickling. The second form of contaminant, which can be present in the form of machining lubricant, marking crayons, temperature indicating crayons, oil, grease, paint etc, can be removed with appropriate solvents. More resistant paints etc. may require proprietary cleaners. Care should be taken to ensure that contaminants are not introduced from grinding wheels, wire brushes or other tools. Preheating of nickel alloys is not necessary, unless the material is below the workshop air temperature, in which case preheating to air temperature will prevent the formation of condensation and potential porosity problems. The majority of standard nickel base alloys do not require post weld heat treatment (PWHT) for normal service conditions. Some specialized age-hardenable alloys will require PWHT and some alloys eg. UNS N02200, may require PWHT for optimum stress corrosion resistance in certain environments. Heat input and interpass temperatures are not as critical as for some alloys but to ensure optimum aswelded corrosion resistance those alloys (usually with high Cr + Mo) likely to see corrosive service should be welded with a maximum interpass temperature of 150C and maximum heat input of 1.5kJ/mm. For data on specific alloys contact Metrode Products Ltd. Metrode Products Ltd Hanworth Lane Chertsey Surrey KT16 9LL UK Tel: +44 (0)1932 566721 Fax: +44 (0)1932 565168 Email: info@metrode.com Website: www.metrode.com

Electrode Wire Nimrod 182KS

20.70.Nb

Data sheet D-10

Matching base material None (3)

Other nickel base alloys UNS N06600 UNS N06075 UNS N06600 UNS N06075 BS NA17 UNS K93600 UNS N06004

Other materials (1)

Dissimilar (2) Ni alloys to CMn, low alloy and stainless steels Ni alloys to CMn, low alloy and stainless steels Similar to above preferably not duplex Ni alloys to duplex

3-5% Ni steels

Nimrod AKS

20.70.Nb

D-11

None (3)

UNS N08800 3-9% Ni steels

Nimrod 625KS

62-50

D-20

UNS N06625

UNS N08800 UNS N08810 UNS N08825

Nimrod C276KS

HAS C276

D-30

UNS N10276 UNS S31254 UNS N08367 UNS N08925 UNS S32654 UNS S34565 UNS S31254 UNS N08367 UNS N08925 UNS S32654 UNS S34565

Nimrod 59KS

HAS 59

D-31

UNS N06059

UNS N06022 UNS N10276

Ni alloys to duplex

Nimrod C22KS

HAS C22

D-32

UNS N06022

UNS N06059 UNS N10276

Ni alloys to duplex

Nimrod 190

65NiCu

D-60

UNS N04400

N04400 to CuNi Useful as a buffer layer for some cladding applications UNS N06601 UNS N10675 UNS N10629 UNS N08811 ASTM HP40Nb Ni alloys to CMn, low alloy and stainless steels N10665 to CMn and other alloys

Nimrod 200Ti

Nickel 2Ti

D-50

UNS N02200 UNS N02201

Nimrod 617KS

61-70

D-40

UNS N06617 UNS N10001 UNS N10665

Nimax B2L

HAS B2

D-80

The above electrodes are for joining and surfacing in all-positions; also available are Nimrod 182, Nimrod AB, Nimrod 625 and Nimrod C276 electrodes which are used predominantly for surfacing in the flat. (1) Some of the materials listed in this column could also be welded with lower alloyed, near matching composition electrodes eg. UNS N08800/N08810/N08811 = Thermet 800Nb; UNS N08825 = E825L-15; HP40Nb = Thermet HP40Nb (2) This only provides a selection of uses, most nickel alloys can be used for other dissimilar applications including cladding. (3) These are weld metal compositions and have no directly equivalent base materials.

Das könnte Ihnen auch gefallen

- ANL Preliminary Matls Selection For Next Gen Nuclear Plant Reactor PVDokument109 SeitenANL Preliminary Matls Selection For Next Gen Nuclear Plant Reactor PVClaudia MmsNoch keine Bewertungen

- Alc-10030c Alcotec Alloy Selection BrochureDokument2 SeitenAlc-10030c Alcotec Alloy Selection BrochurefogdartNoch keine Bewertungen

- Factors Aggravating Chloride SCCracking in Austenitic SSs PDFDokument4 SeitenFactors Aggravating Chloride SCCracking in Austenitic SSs PDFClaudia MmsNoch keine Bewertungen

- Hydrostatic Pressure Test Safety ChecklistDokument3 SeitenHydrostatic Pressure Test Safety ChecklistKyaw Kyaw AungNoch keine Bewertungen

- Advantages and Limitations of Martensitic Steels For FusionDokument4 SeitenAdvantages and Limitations of Martensitic Steels For FusionClaudia MmsNoch keine Bewertungen

- Heat Exchangers ComparisionDokument2 SeitenHeat Exchangers Comparisionramms_73Noch keine Bewertungen

- Titanium Spec - Chart PDFDokument1 SeiteTitanium Spec - Chart PDFClaudia MmsNoch keine Bewertungen

- A Brief History of Holocaust Denial - Jewish Virtual LibraryDokument3 SeitenA Brief History of Holocaust Denial - Jewish Virtual LibraryClaudia MmsNoch keine Bewertungen

- Ways To Avoid Boiler Tube CorrosionDokument8 SeitenWays To Avoid Boiler Tube CorrosionTiu TonNoch keine Bewertungen

- Magnatech Welding The Maui A B Pipeline Orbital Welding Systems PDFDokument5 SeitenMagnatech Welding The Maui A B Pipeline Orbital Welding Systems PDFClaudia MmsNoch keine Bewertungen

- What Is Bellows Pressure Thrust PDFDokument2 SeitenWhat Is Bellows Pressure Thrust PDFClaudia MmsNoch keine Bewertungen

- How To Become Certified by ASME 2010Dokument2 SeitenHow To Become Certified by ASME 2010quiron2010Noch keine Bewertungen

- Det N V Technical Report Bsee PDFDokument1 SeiteDet N V Technical Report Bsee PDFClaudia MmsNoch keine Bewertungen

- High Performance Stainless Steels Parr Instrument PDFDokument1 SeiteHigh Performance Stainless Steels Parr Instrument PDFClaudia MmsNoch keine Bewertungen

- Pourbaix Diagram Fe-C-H2O System at 25°C PDFDokument1 SeitePourbaix Diagram Fe-C-H2O System at 25°C PDFClaudia MmsNoch keine Bewertungen

- Proc. 1999 US DOE Hydrogen Program Review Applications Analysis PDFDokument4 SeitenProc. 1999 US DOE Hydrogen Program Review Applications Analysis PDFClaudia MmsNoch keine Bewertungen

- Hydrostatic Pressure Test Safety ChecklistDokument3 SeitenHydrostatic Pressure Test Safety ChecklistKyaw Kyaw AungNoch keine Bewertungen

- An Introduction To Cathodic Protection PDFDokument5 SeitenAn Introduction To Cathodic Protection PDFGERMAN1979Noch keine Bewertungen

- Section Viii Div 1 Div 2 Div ComparisonDokument2 SeitenSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- Chemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Dokument2 SeitenChemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Claudia MmsNoch keine Bewertungen

- DPVC 09 PetrobrasDokument47 SeitenDPVC 09 PetrobrasClaudia MmsNoch keine Bewertungen

- Expansion of The Sourcebook For Hydrogen Applications 03-10-2006Dokument1 SeiteExpansion of The Sourcebook For Hydrogen Applications 03-10-2006Claudia MmsNoch keine Bewertungen

- Pipeline Corrosion Assessment MethodsDokument31 SeitenPipeline Corrosion Assessment MethodsRicardo Andres Santamaria Torres100% (2)

- CV of The YearDokument1 SeiteCV of The YearRKKhatriNoch keine Bewertungen

- Owen Barfield BibliographyDokument50 SeitenOwen Barfield BibliographyClaudia MmsNoch keine Bewertungen

- Inspection and Welding Repairs of Pressure VesselsDokument9 SeitenInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- Remaining Life Evaluation of Coke DrumsDokument15 SeitenRemaining Life Evaluation of Coke DrumsRohit KaleNoch keine Bewertungen

- Condition of The Firetube Right After Removal From ServiceDokument1 SeiteCondition of The Firetube Right After Removal From ServiceClaudia MmsNoch keine Bewertungen

- Fastener Failures Due To Stress Corrosion CrackingDokument3 SeitenFastener Failures Due To Stress Corrosion CrackingClaudia MmsNoch keine Bewertungen

- Ways To Avoid Boiler Tube CorrosionDokument8 SeitenWays To Avoid Boiler Tube CorrosionTiu TonNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- AISI Steel GradesDokument1 SeiteAISI Steel GradessanoopvkNoch keine Bewertungen

- MagneticMaterials1Dokument603 SeitenMagneticMaterials1Adinda Van Den BergNoch keine Bewertungen

- Powder Standerd & CodeDokument9 SeitenPowder Standerd & CodeAbhijeet AnkushNoch keine Bewertungen

- Soil & Tillage Research: Alicja Kici Nska, Justyna WikarDokument11 SeitenSoil & Tillage Research: Alicja Kici Nska, Justyna WikarYoselin GomezNoch keine Bewertungen

- AlloyDokument12 SeitenAlloyMani MaranNoch keine Bewertungen

- BP Toledo Inert EntryDokument32 SeitenBP Toledo Inert EntrySam Mebarek100% (1)

- F899 10.1374633 2010Dokument7 SeitenF899 10.1374633 2010Rouse ToxquiNoch keine Bewertungen

- Corrosion & Degradation of MaterialsDokument20 SeitenCorrosion & Degradation of Materialsleodavid87Noch keine Bewertungen

- Aço China - Cross Reference SteelDokument12 SeitenAço China - Cross Reference SteelPaulo BaltorNoch keine Bewertungen

- Ammonia: Concept and ApplicationDokument40 SeitenAmmonia: Concept and ApplicationSapna AndyaniNoch keine Bewertungen

- Ni DMGDokument7 SeitenNi DMGNatarajan PalaniNoch keine Bewertungen

- Carlisle Wire Cable Guide 2011 PDFDokument24 SeitenCarlisle Wire Cable Guide 2011 PDFnizarfebNoch keine Bewertungen

- Chapter-3 Metals and Non-Metals MCQsDokument13 SeitenChapter-3 Metals and Non-Metals MCQsfagstdjdNoch keine Bewertungen

- F3055 14aDokument8 SeitenF3055 14asenthilNoch keine Bewertungen

- CONDUX Classifier Mill CSM Ceramic eDokument2 SeitenCONDUX Classifier Mill CSM Ceramic emapalptsNoch keine Bewertungen

- Engineering Chemistry Lab Manual - Winter 2020 - Dr.r.saravanakumar - PDFDokument50 SeitenEngineering Chemistry Lab Manual - Winter 2020 - Dr.r.saravanakumar - PDFRonitNoch keine Bewertungen

- Adobe Scan 27-Nov-2023Dokument1 SeiteAdobe Scan 27-Nov-2023Partha Sarathy PandaNoch keine Bewertungen

- 5 Denture Base Materials and Processsing TechsDokument78 Seiten5 Denture Base Materials and Processsing TechsDRNIRBANMITRANoch keine Bewertungen

- Flyer The Adixen 2000 Series Vacuum GaugesDokument2 SeitenFlyer The Adixen 2000 Series Vacuum GaugespradungNoch keine Bewertungen

- Mineral Commodity Report 10 - Nickel: by Tony Christie and Bob BrathwaiteDokument7 SeitenMineral Commodity Report 10 - Nickel: by Tony Christie and Bob Brathwaiteewin basokeNoch keine Bewertungen

- DSM-0283.1 NiAl HoneycombDokument3 SeitenDSM-0283.1 NiAl HoneycombApichitNoch keine Bewertungen

- Materials for Solar Energy Conversion ReviewDokument29 SeitenMaterials for Solar Energy Conversion ReviewW BogaertsNoch keine Bewertungen

- Tta 7Dokument8 SeitenTta 7Saravanan ManiNoch keine Bewertungen

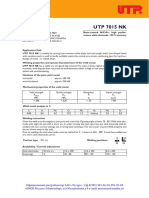

- Utp 7015 NKDokument1 SeiteUtp 7015 NKsergey.pu4kaNoch keine Bewertungen

- Development of Hydrogen Electrodes For Alkaline Water ElectrolysisDokument190 SeitenDevelopment of Hydrogen Electrodes For Alkaline Water ElectrolysisNikolas FerreiraNoch keine Bewertungen

- Production of Renewable Hydrogen by Aqueous-Phase Reforming of Glycerol OverDokument7 SeitenProduction of Renewable Hydrogen by Aqueous-Phase Reforming of Glycerol OverMahdy HajienayatiNoch keine Bewertungen

- Alternate Source ICP Standards For Use With Popular Analytical InstrumentationDokument14 SeitenAlternate Source ICP Standards For Use With Popular Analytical InstrumentationAlexSNoch keine Bewertungen

- What FCC Catalyst Tests ShowDokument5 SeitenWhat FCC Catalyst Tests ShowPraveen KumarNoch keine Bewertungen

- (Elias, 2002) Nickel Laterite Deposits - Geological Overview, Resources and ExploitationDokument24 Seiten(Elias, 2002) Nickel Laterite Deposits - Geological Overview, Resources and ExploitationRika yustika100% (1)

- Technical. Cross Reference Steel Material To ASTM: Material Forgings Castings Wrought FittingsDokument1 SeiteTechnical. Cross Reference Steel Material To ASTM: Material Forgings Castings Wrought FittingsAndis DianNoch keine Bewertungen