Beruflich Dokumente

Kultur Dokumente

Superduplex Welding Procedure Specification (WPS

Hochgeladen von

Claudia MmsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Superduplex Welding Procedure Specification (WPS

Hochgeladen von

Claudia MmsCopyright:

Verfügbare Formate

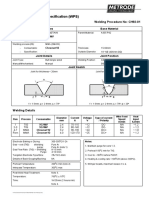

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex TIG/GTAW

Consumables

Welding process (root): Consumable: Specification: Consumable: Specification: TIG / GTAW Parent Material:

Base Material

Superduplex. (UNS S32750 & S32760). ASME IX: P or S number (QW422) = 10H group 1. Thickness: Outside Diameter: 18.26mm (Schedule 160) 6 inch NB

Zeron 100X

BS EN 12072: W 25 9 4 N L TIG / GTAW

Welding process (fill): -

Zeron 100X

BS EN 12072: W 25 9 4 N L

Joint Details

Joint Type: Manual/Mechanised: Single side butt Manual Welding Position:

Joint Position

ASME 6G

Joint Sketch

6 NB Schedule 160

Welding Sequences

655

Split layers (2 beads per layer) from runs 4/5 onwards.

18.26mm

0.5-1.5mm

.

2-4mm

Welding Details

Run Process Consumable Diameter mm Current A Voltage V Travel speed mm/min Type of current / Polarity Heat Input kJ/mm

1 2 Fill

TIG TIG TIG

Zeron 100X Zeron 100X Zeron 100X

2.4 2.4 3.2

80-100 90-130 200-225

~12 ~12 ~12

~50 ~125 100-175

DCDCDC-

~1.2 ~0.8 ~1.5

Electrode Baking or Drying: Gas root (TIG) shielding: backing: Gas - fill/cap (TIG) Shielding: Purge: Tungsten Electrode Type/Size: Details of Back Gouging/Backing: Preheat Temperature: Interpass Temperature: Post-Weld Heat Treatment and/or Ageing: Temperature: Time:

NA Ar + 2% N2 Ar Ar Ar 2%Th/2.4mm NA 20C 150C max None

Notes: 1. Tack joint securely to prevent root closure using four bridging tacks. 2. Weld pipe in four 90 segments to prevent excessive overheating. 3. Purge to maintain 0.5% oxygen max. 4. Ar + 2%N2 shielding gas is recommended for the root run to ensure G48A properties. 5. Purging 20-30l/min (reduced to ~10l/min for tie-in). Maintain purge for first two runs. 6. Shielding gas flow rate 8-12l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex MMA/SMAW

Consumables

Welding process (root): Consumable: Specification: Consumable: Specification: TIG / GTAW Parent Material:

Base Material

Superduplex. (UNS S32750 & S32760). ASME IX: P or S number (QW422) = 10H group 1. Thickness: Outside Diameter: 18.26mm (Schedule 160) 6 inch NB

Zeron 100X

BS EN 12072: W 25 9 4 N L MMA / SMAW

Welding process (fill): -

Zeron 100XKS / 2507XKS

BS EN 1600: E 25 9 4 N L B 4 2

Joint Details

Joint Type: Manual/Mechanised: Single side butt Manual Welding Position:

Joint Position

ASME 6G

Joint Sketch

6 NB Schedule 160

Welding Sequences

705

18.26mm

0.5-1.5mm

.

2-4mm

Welding Details

Run Process Consumable Diameter mm Current A Voltage V Travel speed mm/min Type of current / Polarity Heat Input kJ/mm

1 2 Fill

TIG TIG MMA

Zeron 100X Zeron 100X Zeron 100XKS / 2507XKS

2.4 2.4 3.2

80-100 90-130 75-95

~12 ~12 ~25

~50 ~125 75-125

DCDCDC+

~1.2 ~0.8 ~1.2

Electrode Baking or Drying: Gas root (TIG) shielding: backing: Gas - fill/cap: Tungsten Electrode Type/Size: Details of Back Gouging/Backing: Preheat Temperature: Interpass Temperature: Post-Weld Heat Treatment and/or Ageing: Temperature: Time:

200C/2 hours Ar + 2% N2 Ar Not applicable 2%Th/2.4mm NA 20C 150C max None

Notes: 1. Tack joint securely to prevent root closure using four bridging tacks. 2. Weld pipe in four 90 segments to prevent excessive overheating. 3. Purge to maintain 0.5% oxygen max. 4. Ar + 2%N2 shielding gas is recommended for the root run to ensure G48A properties. 5. Purging 20-30l/min (reduced to ~10l/min for tie-in). Maintain purge for first two runs. 6. Shielding gas flow rate 8-12l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex FCAW

Consumables

Welding process (root): Consumable: Specification: Consumable: Specification: TIG / GTAW Parent Material:

Base Material

Superduplex. (UNS S32750 & S32760). ASME IX: P or S number (QW422) = 10H group 1. Thickness: Outside Diameter: 23mm (Schedule 160) 8 inch NB

Zeron 100X

BS EN 12072: W 25 9 4 N L FCAW

Welding process (fill): -

Supercore Z100XP / 2507P

--

Joint Details

Joint Type: Manual/Mechanised: Single side butt Manual Welding Position:

Joint Position

ASME 6G

Joint Sketch

8 NB Schedule 160

Welding Sequences

705

23mm

0.5-1.5mm

.

2-4mm

Welding Details

Run Process Consumable Diameter mm Current A Voltage V Travel speed mm/min Type of current / Polarity Heat Input kJ/mm

1 2 3-4 Fill

TIG TIG TIG FCAW

Zeron 100X Zeron 100X Zeron 100X Supercore Z100XP/2507P

2.4 2.4 2.4 1.2

80-100 90-130 140-160 140-180

Notes:

~12 ~12 ~12 ~26

~50 ~125 ~75 100-175

DCDCDCDC+

~1.2 ~0.8 ~1.5 ~1.5

Electrode Baking or Drying: Gas root (TIG) shielding: backing: Gas - fill/cap (FCAW) Shielding: Tungsten Electrode Type/Size: Details of Back Gouging/Backing: Preheat Temperature: Interpass Temperature: Post-Weld Heat Treatment and/or Ageing: Temperature: Time:

NA Ar + 2% N2 Ar Ar-20% CO2 2%Th/2.4mm NA 20C 150C max None

1. Tack joint securely to prevent root closure using four bridging tacks. 2. Weld pipe in four 90 segments to prevent excessive overheating. 3. Purge to maintain 0.5% oxygen max. 4. Ar + 2%N2 shielding gas is recommended for the root run to ensure G48A properties. 5. Purging 20-30l/min (reduced to ~10l/min for tie-in). 6. Shielding gas flow rate: TIG = 8-12l/min, FCAW = 20-25 l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex SAW

Consumables

Welding process (root): Consumable: Specification: Consumable: Specification: TIG / GTAW Parent Material:

Base Material

Superduplex. (UNS S32750 & S32760). ASME IX: P or S number (QW422) = 10H group 1. Thickness: Outside Diameter: ~25mm Not applicable

Zeron 100X

BS EN 12072: W 25 9 4 N L SAW

Welding process (fill): -

Zeron 100X

BS EN 12072: W 25 9 4 N L

Joint Details

Joint Type: Manual/Mechanised: Single side butt Mechanised Welding Position:

Joint Position

ASME 1G

Joint Sketch

Welding Sequences

655

Split layers (2 beads per layer) from runs 4/5 onwards.

25mm

0.5-1.5mm

.

2-4mm

Welding Details

Run Process Consumable Diameter mm Current A Voltage V Travel speed mm/min Type of current / Polarity Heat Input kJ/mm

1 2 3-4 Fill

TIG TIG TIG SAW

Zeron 100X Zeron 100X Zeron 100X Zeron 100X

2.4 2.4 2.4 2.4

NA Ar + 2% N2 Ar LA491

80-100 90-130 140-160 300-400

~12 ~12 ~12 ~30

Notes:

~50 ~125 ~75 300-500

DCDCDCDC+

~1.2 ~0.8 ~1.5 ~1.5

Electrode Baking or Drying: Gas root (TIG) shielding: backing: Flux - fill/cap (SAW) Tungsten Electrode Type/Size: Details of Back Gouging/Backing: Preheat Temperature: Interpass Temperature: Post-Weld Heat Treatment and/or Ageing: Temperature: Time:

1. Tack joint securely to prevent root closure using four bridging tacks. 2. Purge to maintain 0.5% oxygen max. 3. Ar + 2%N2 shielding gas is recommended for the root run to ensure G48A properties. 4. Purging 20-30l/min (reduced to ~10l/min for tie-in). Maintain purge for first two runs. 5. Shielding gas flow rate 8-12l/min.

2%Th/2.4mm NA 20C 150C max None

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Das könnte Ihnen auch gefallen

- WPS P91Dokument6 SeitenWPS P91JoseAlbertoNeyraNoch keine Bewertungen

- WPS 316 LDokument4 SeitenWPS 316 Llaz_k100% (2)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokument3 SeitenWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNoch keine Bewertungen

- Welding Procedure Specification For 24'' PipeDokument2 SeitenWelding Procedure Specification For 24'' Pipeenels77100% (2)

- P 91 - Welding WPSDokument2 SeitenP 91 - Welding WPSSuhailshah123475% (4)

- KSL Wps PQR 012 DuplexDokument33 SeitenKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- Super Duplex Stainless SteelDokument1 SeiteSuper Duplex Stainless SteelUma Shankar100% (1)

- WPS-PQR (Er309l Mo)Dokument4 SeitenWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS Format For ASME IX - PQR-AllDokument3 SeitenWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- PQRDokument2 SeitenPQRalokbdasNoch keine Bewertungen

- AWS D1.1 - Example PQR & WPS DocumentsDokument4 SeitenAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- WPS, PQR & WPQ - Duplex 2205Dokument20 SeitenWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDokument4 SeitenWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNoch keine Bewertungen

- WPS PQR A36.20Dokument5 SeitenWPS PQR A36.20gchaves504100% (2)

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDokument9 SeitenASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- Smaw Wps FinalDokument3 SeitenSmaw Wps FinalsheikmoinNoch keine Bewertungen

- P91 Profile WpsDokument6 SeitenP91 Profile WpsZead Ali Adal100% (2)

- Proposed WPSDokument2 SeitenProposed WPSChisom Ikengwu100% (2)

- WPS PQR WPQ PeiplDokument16 SeitenWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Welder Qualification CertificateDokument2 SeitenWelder Qualification CertificateLuttpi100% (1)

- PT Kuwera Karya Me: PanduDokument2 SeitenPT Kuwera Karya Me: PanduGalang Pratama PutraNoch keine Bewertungen

- WPS For A333 ADokument1 SeiteWPS For A333 ARamzi BEN AHMED100% (1)

- WPS, PQR, WPQ (Si007)Dokument5 SeitenWPS, PQR, WPQ (Si007)Suresh RathodNoch keine Bewertungen

- WPS E6013+e7018Dokument2 SeitenWPS E6013+e7018Anvesh Vaddi100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Dokument6 SeitenMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNoch keine Bewertungen

- Acceptance Criteria for WeldsDokument7 SeitenAcceptance Criteria for WeldsAnilNoch keine Bewertungen

- Page No: 01: SA 240 GR 304 SA 240 GR 304Dokument5 SeitenPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNoch keine Bewertungen

- Loading Unloading Temperature Welding ProgressionDokument5 SeitenLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- 6GR WPS PQRDokument15 Seiten6GR WPS PQRKiukStaks100% (6)

- Manual Standard WeldingDokument192 SeitenManual Standard WeldingGEORGE IVAN0% (1)

- WPS For Structure Mild Steel Fillet WeldDokument2 SeitenWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- PQR Template (Asme)Dokument2 SeitenPQR Template (Asme)jok1974Noch keine Bewertungen

- WPS & PQRDokument46 SeitenWPS & PQRJohn Candidate CIns88% (8)

- WPS PQRDokument23 SeitenWPS PQRHashim Khan88% (8)

- Metrode - P92 WPS PDFDokument3 SeitenMetrode - P92 WPS PDFXing ChenNoch keine Bewertungen

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium Weldingvishal bailur50% (2)

- WPS PQR 12Dokument9 SeitenWPS PQR 12Ranjan KumarNoch keine Bewertungen

- WELDING PROCEDURE SPECIFICATION DETAILSDokument2 SeitenWELDING PROCEDURE SPECIFICATION DETAILStuatk60% (5)

- Manual Overlay WeldingDokument8 SeitenManual Overlay Weldingcarlmac6183% (6)

- WPQ Sample PrintoutDokument1 SeiteWPQ Sample PrintoutKannan VelNoch keine Bewertungen

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Dokument12 SeitenPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNoch keine Bewertungen

- WPS PQR FormatDokument1 SeiteWPS PQR FormatJatin Kamdar100% (2)

- Fit-Up Inspection Report PDFDokument1 SeiteFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDokument2 SeitenWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNoch keine Bewertungen

- Multi Process Welding Procedures QW200.4 (ASME IX)Dokument1 SeiteMulti Process Welding Procedures QW200.4 (ASME IX)HoangNoch keine Bewertungen

- WPS for 316L Pipe WeldingDokument3 SeitenWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- Welder Performance Qualification-Interactive Form QW-484ADokument1 SeiteWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS 304L &316LDokument2 SeitenWPS 304L &316LShakeel Memon100% (1)

- WPS 2014-002 002 - 1G & 2G S 275 JRDokument2 SeitenWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- All Position Stainless Steel Welding ProcedureDokument6 SeitenAll Position Stainless Steel Welding ProcedureJaime PatrónNoch keine Bewertungen

- PWHT ProcedureDokument10 SeitenPWHT ProcedureMohammed Kamal100% (11)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDokument2 SeitenElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- P91 Welding Procedure SpecificationDokument6 SeitenP91 Welding Procedure SpecificationPepe SagitarioNoch keine Bewertungen

- P91 Profile WpsDokument6 SeitenP91 Profile WpsManzar KhanNoch keine Bewertungen

- PQR-WPS-WPQR XXX Rev 0Dokument6 SeitenPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS GTAW Stainless SteelDokument4 SeitenWPS GTAW Stainless SteelAnand NarayananNoch keine Bewertungen

- WPS 856110.016 Rev 3Dokument1 SeiteWPS 856110.016 Rev 3laz_kNoch keine Bewertungen

- WPS - D1.1Dokument1 SeiteWPS - D1.1Nam_HitechNoch keine Bewertungen

- WPS FormatDokument1 SeiteWPS FormatAbdullah AnsariNoch keine Bewertungen

- WPS - Welding Instruction - FUCHSDokument23 SeitenWPS - Welding Instruction - FUCHSShanoor ASNoch keine Bewertungen

- A Brief History of Holocaust Denial - Jewish Virtual LibraryDokument3 SeitenA Brief History of Holocaust Denial - Jewish Virtual LibraryClaudia MmsNoch keine Bewertungen

- An Introduction To Cathodic Protection PDFDokument5 SeitenAn Introduction To Cathodic Protection PDFGERMAN1979Noch keine Bewertungen

- ANL Preliminary Matls Selection For Next Gen Nuclear Plant Reactor PVDokument109 SeitenANL Preliminary Matls Selection For Next Gen Nuclear Plant Reactor PVClaudia MmsNoch keine Bewertungen

- Alc-10030c Alcotec Alloy Selection BrochureDokument2 SeitenAlc-10030c Alcotec Alloy Selection BrochurefogdartNoch keine Bewertungen

- Proc. 1999 US DOE Hydrogen Program Review Applications Analysis PDFDokument4 SeitenProc. 1999 US DOE Hydrogen Program Review Applications Analysis PDFClaudia MmsNoch keine Bewertungen

- What Is Bellows Pressure Thrust PDFDokument2 SeitenWhat Is Bellows Pressure Thrust PDFClaudia MmsNoch keine Bewertungen

- Magnatech Welding The Maui A B Pipeline Orbital Welding Systems PDFDokument5 SeitenMagnatech Welding The Maui A B Pipeline Orbital Welding Systems PDFClaudia MmsNoch keine Bewertungen

- Ways To Avoid Boiler Tube CorrosionDokument8 SeitenWays To Avoid Boiler Tube CorrosionTiu TonNoch keine Bewertungen

- Advantages and Limitations of Martensitic Steels For FusionDokument4 SeitenAdvantages and Limitations of Martensitic Steels For FusionClaudia MmsNoch keine Bewertungen

- Hydrostatic Pressure Test Safety ChecklistDokument3 SeitenHydrostatic Pressure Test Safety ChecklistKyaw Kyaw AungNoch keine Bewertungen

- Factors Aggravating Chloride SCCracking in Austenitic SSs PDFDokument4 SeitenFactors Aggravating Chloride SCCracking in Austenitic SSs PDFClaudia MmsNoch keine Bewertungen

- Pourbaix Diagram Fe-C-H2O System at 25°C PDFDokument1 SeitePourbaix Diagram Fe-C-H2O System at 25°C PDFClaudia MmsNoch keine Bewertungen

- Titanium Spec - Chart PDFDokument1 SeiteTitanium Spec - Chart PDFClaudia MmsNoch keine Bewertungen

- How To Become Certified by ASME 2010Dokument2 SeitenHow To Become Certified by ASME 2010quiron2010Noch keine Bewertungen

- High Performance Stainless Steels Parr Instrument PDFDokument1 SeiteHigh Performance Stainless Steels Parr Instrument PDFClaudia MmsNoch keine Bewertungen

- Det N V Technical Report Bsee PDFDokument1 SeiteDet N V Technical Report Bsee PDFClaudia MmsNoch keine Bewertungen

- Expansion of The Sourcebook For Hydrogen Applications 03-10-2006Dokument1 SeiteExpansion of The Sourcebook For Hydrogen Applications 03-10-2006Claudia MmsNoch keine Bewertungen

- Heat Exchangers ComparisionDokument2 SeitenHeat Exchangers Comparisionramms_73Noch keine Bewertungen

- Remaining Life Evaluation of Coke DrumsDokument15 SeitenRemaining Life Evaluation of Coke DrumsRohit KaleNoch keine Bewertungen

- CV of The YearDokument1 SeiteCV of The YearRKKhatriNoch keine Bewertungen

- Section Viii Div 1 Div 2 Div ComparisonDokument2 SeitenSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- Hydrostatic Pressure Test Safety ChecklistDokument3 SeitenHydrostatic Pressure Test Safety ChecklistKyaw Kyaw AungNoch keine Bewertungen

- Chemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Dokument2 SeitenChemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Claudia MmsNoch keine Bewertungen

- DPVC 09 PetrobrasDokument47 SeitenDPVC 09 PetrobrasClaudia MmsNoch keine Bewertungen

- Condition of The Firetube Right After Removal From ServiceDokument1 SeiteCondition of The Firetube Right After Removal From ServiceClaudia MmsNoch keine Bewertungen

- Owen Barfield BibliographyDokument50 SeitenOwen Barfield BibliographyClaudia MmsNoch keine Bewertungen

- Pipeline Corrosion Assessment MethodsDokument31 SeitenPipeline Corrosion Assessment MethodsRicardo Andres Santamaria Torres100% (2)

- Ways To Avoid Boiler Tube CorrosionDokument8 SeitenWays To Avoid Boiler Tube CorrosionTiu TonNoch keine Bewertungen

- Fastener Failures Due To Stress Corrosion CrackingDokument3 SeitenFastener Failures Due To Stress Corrosion CrackingClaudia MmsNoch keine Bewertungen

- Inspection and Welding Repairs of Pressure VesselsDokument9 SeitenInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- DiGas 4000 Light E 08.02Dokument2 SeitenDiGas 4000 Light E 08.02manit1963Noch keine Bewertungen

- HVCB Timing ApplicationDokument52 SeitenHVCB Timing Applicationbhuban mohanNoch keine Bewertungen

- EI Manifold Pressure ManualDokument12 SeitenEI Manifold Pressure Manualjkloepping_634367970Noch keine Bewertungen

- Solution 2 AntennaDokument7 SeitenSolution 2 Antennaabdulwahab12100% (1)

- Oral and Practical Tests: MechanicDokument19 SeitenOral and Practical Tests: MechanicHugo AlmeidaNoch keine Bewertungen

- Desizing of CottonDokument16 SeitenDesizing of CottonDeepali RastogiNoch keine Bewertungen

- T REC K.Sup16 201905 I!!PDF E PDFDokument24 SeitenT REC K.Sup16 201905 I!!PDF E PDFMark LionNoch keine Bewertungen

- Gas Sensors: Jiturvi Chokshi ENPM-808BDokument27 SeitenGas Sensors: Jiturvi Chokshi ENPM-808Banon_44955929Noch keine Bewertungen

- Nuclear Radioactivity WorksheetDokument3 SeitenNuclear Radioactivity Worksheet14569874Noch keine Bewertungen

- Lab Report Experiment 5Dokument4 SeitenLab Report Experiment 5Czarina mantuano100% (2)

- PalindromeDokument7 SeitenPalindromeZy AdrianneNoch keine Bewertungen

- P1125P1/P1250E1: Output RatingsDokument6 SeitenP1125P1/P1250E1: Output Ratingsmohsen_cumminsNoch keine Bewertungen

- Safety ValvesDokument11 SeitenSafety Valvesravindra_jivaniNoch keine Bewertungen

- Transmission ErrorDokument7 SeitenTransmission ErrorTapas JenaNoch keine Bewertungen

- BDOs SheetsDokument25 SeitenBDOs Sheets3J Solutions BDNoch keine Bewertungen

- Bridge Operational ClassificationDokument1 SeiteBridge Operational ClassificationFrancis DomingoNoch keine Bewertungen

- Theory of Metal Cutting-Module 1Dokument116 SeitenTheory of Metal Cutting-Module 1rejeesh_rajendranNoch keine Bewertungen

- HW03 5ad S19 PDFDokument2 SeitenHW03 5ad S19 PDFbobNoch keine Bewertungen

- Wabco Air Suspension Compressor RepairDokument3 SeitenWabco Air Suspension Compressor RepairgarcolNoch keine Bewertungen

- Peanut Brittle LabDokument2 SeitenPeanut Brittle LabMary Bacon HillebrandNoch keine Bewertungen

- International Tubulars MSDS RegisterDokument4 SeitenInternational Tubulars MSDS RegisterMuhammad SuhaibNoch keine Bewertungen

- Twice As Sharp Operators ManualDokument34 SeitenTwice As Sharp Operators ManualLeonardo CHTZNoch keine Bewertungen

- TI Oxydur PTB 206 - en PDFDokument5 SeitenTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- Iso Dis 20283-4 2011Dokument27 SeitenIso Dis 20283-4 2011Ricardo RamirezNoch keine Bewertungen

- Ricoh 2090Dokument832 SeitenRicoh 2090cosmin176100% (1)

- Tractor 2017 Catalogue WebDokument36 SeitenTractor 2017 Catalogue WebAnonymous 1XBCMXNoch keine Bewertungen

- Ultrasonic TestingDokument55 SeitenUltrasonic Testingdhasdj100% (1)

- Explorador Ww90j6410cwec Version 02Dokument13 SeitenExplorador Ww90j6410cwec Version 02Cristi PopescuNoch keine Bewertungen

- Vista 128BPT Program ManualDokument72 SeitenVista 128BPT Program ManualyalmanzaNoch keine Bewertungen

- Physicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892Dokument389 SeitenPhysicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892AbdelhamidHarratNoch keine Bewertungen