Beruflich Dokumente

Kultur Dokumente

Pdms Commands

Hochgeladen von

Karthik P MuraliCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

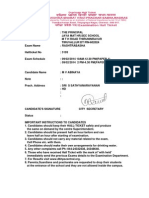

Pdms Commands

Hochgeladen von

Karthik P MuraliCopyright:

Verfügbare Formate

PDMS COMMANDS PIPING COMMANDS 1. ADD ALL PIP 2. REM ALL PIP 3. MOVE U THROU IDP@ 4.

MOVE E THROU IDP@ 5. MOVE W THROU IDP@ 6. MOVE N THROU IDP@ 7. MOVE S THROU IDP@ 8. Q DTXR (To See Name Of Component) 9. Q STEXT 10. STEXT NOTE (Naming For Attachment) 11. Q ATT (To see the attributes) 12. REPR INSU ON/OFF UPDATE 13. Q ISPEC (To see the insulation) 14. ISPEC NULREF (To Remove the Insulation) 15. CONN NEXT (Connection to next element) 16. FCONN (For force connection) 17. DIST 500 18. AXES AT PH (To see Axes of Pipe Head) 19. AXES AT PT (To see Axes of Pipe Tail) 20. AXES OFF

21. BY U 500 22. BY D 500 23. BY E 500 24. BY W 500 25. BY S 500 26. BY N 500 27. Q NAME 28. ROTATE BY 45 (Rotated command) 29. ROT BY 90 ABOUT Z THRO ID@ (Rotated) 30. Q PARA (To check nozzle size) 31. Q CATREF (To See nozzle Rating) 32. Q POS IN WORLD 33. CH CE (check current element) 34. Q SPREF (check piping Spec) 35. Q ORI (To see the orientation) 36. DIR D (Direction Down) U E W N S (For elbow, tee, valve) 37. Q P1/P2/P3 (To see pipe Bore Direction Connection type and Position) 38. Q HBORE 39. Q TBORE 40. Q LBORE 41. NEW BRA COPY PREV BY E/W/S/N/U/D 100 42. Q U (To see the elevation)

43. Q ANGLE (For change the angle) 44. THRO NEXT (To connect element to next component) 45. Q LTLE (To cheek pipe length) 46. Q MEM 47. Q RTEX OF DETREF (To see element type and detail) 48. CONN IDP@ TO IDP Q CE 49. Q PL (For Direction and position) 50. BRA CONN PH TO FIST MEM 51. BRA CONN PT TO NOZZ ID@ 52. BRA CONN PT TO LAST 53. RAD 500 (Control Valve Radius) 54. HEI 500 (Control Valve Height) 55. BACK (Backward) 56. FORW (Forward) 57. For Drain pipe a. ADD ATT (For isometric note) b. Q ATT c. TCONN OPEN d. Q STEXT e. STEXT DRAIN POINT 58. For Slope Line /Rotated Elbow a. FORWARDS (Select in piping components)

b. DIR TOW NEXT c. BACKWARDS (Select in piping components) d. DIR TOW NEXT 59. MTOC DOTD (Do not want in bill of material) You can see the Doted DOTD 60. MTOC ON (Want in bill of material) 61. MTOC OFF (Don t Want in bill of material) 62. Q PA BOP/TOP (To see the pipe BOP/TOP) 63. Q LSTUBE (To Change the spec Brake) 64. Q PSPEC (To see the pipe spec) 65. CONN PH TO P3 OF ID@ ( AND SELECT THE PIPE P3) 66. CONN PT TO LAS MEM STRUCTURE COMMANDS 1. AXES AT POSE/S (end or start) 2. Q POSE WRT/* 3. EXTE END BY D 500 WRT/* 4. EXTE START BY U 500 WRT/* 5. EXTE END/START THRO ID@ 6. EXTE END/START THRO IDPL@ (PL-Pline) 7. Q CUTL (To see length of section) 8. Q POS PPLINE BOS IN/* (BOS TOS NA) 9. ADD ALL STR

10. REM ALL STR 11. Q ATT 12. BY U//D/E/W/N/S 500 13. Q DRNS DRNE 14. DRNSTART S 45 E (Direction and angle) 15. DRNEND S 45 W (Direction and angle) EQUIPMENT COMMANDS 1. ADD ALL EQUI 2. REM ALL EQUI 3. MOVE U THROU IDP@ 4. MOVE E THROU IDP@ 5. MOVE W THROU IDP@ 6. MOVE N THROU IDP@ 7. MOVE S THROU IDP@ 8. REPR HOLES ON/OFF UPDATE 9. REPR OBST ON/OFF UPDATE 10. To Copy New Equipment a. VAR1 NAME b. NEW EQU COPY $V1 (To Include Equipment in another zone) 11. BY U//D/E/W/N/S 500 12. NEW BOX COPY PRE 13. NEW BOX XLEN 400 YLEN 250 ZLN 150

14. NEW CYL COPY PRE 15. NEW PYRE COPY PRE 16. NEW NOZZ COPY PRE 17. NEW BOX COPY PRE ROT BY 90 ABOUT Z THRO IDP@ OTHERS COMMANDS 1. For copy equip/sub equipment from one project to another project. a. FILE /FILE NAME.TXT b. OUTPUT CE c. TERM 2. For pest equipment / sub equipment from one project to another project. a. $M FILE NAME.TXT 3. For Undo Command a. MDB NOUPDATE b. EXIT 4. Mdb Update a. MDB UPDATE b. USER PROMQAMQA/MQA c. /SUFN d. EXIT 5. UNCLAIM CE 6. UNCLAIM ALL

7. ALPHA REQ CLEAR (To clear the command screen) 8. CREATE NEW ZONE/SITE/EQUI 9. ADD ALL WITHIN VOL CE 100 10. Q ORI (To see the orientation) 11. ALPHA LOG /C:/ANANT.TXT (To make command line file) ALFA LOG END 12. SAVEWORK 13. Q US (User name) 14. Q MDB (Multiple data base) 15. Q REF 16. RECREATE DISPLAY /ABC.TXT (For save Display) 17. $M ABC.TXT (For restore Display) 18. Q UNITS 19. Q DISPLAY 20. Q BANNER (To Check the version number) 21. Q BANNER FULL 22. Q TEAM (PDMS user name) 23. Q USER (Logging name) 24. Q DBNAME (To check DB name) 25. Q DBTYPE 26. Q DBFNUMBER 27. Q DBFILE 28. Q LASTMOD

29. Q SESSMOD 30. Q SESSMODI 31. Q USERMODI 32. Q LASTMODI HIER 33. Q DRAW 34. Q DRAW COUNT 35. Q DRAW FULL 36. STATUS 37. SYSTAT (Gives you information about the current active Status of the project) 38. recre disp /gggg over (U can save as a display or u can do like this) $m gggg 39. FILE /C:/AAA OVER OUTPUT NEW CEV TERM ENTER $M /C:/AAA PDMS Syntax Examples Position>Move>Distance Moves the element s origin by a given distance in a given direction. Ex. MOVE N DIST 10 MOVE S WRT /* DIST 5' MOVE E IN SITE DIST 5' Position>Move>Through Moves the origin of the element in a given direction through a Reference Plane perpendicular to the line of travel that is passing

through a picked element, p-point, or coordinate. Ex. MOVE N THRO ID@ MOVE N THRO IDP@ MOVE N THRO N46 Position>Move>Clearance Moves the element s origin, p-point, or obstruction in a given direction with a clearance from another items origin, p-point, or obstruction. Ex. MOVE E DIST 10 FROM /P-101 MOVE E CLEARANCE 10 FROM /P-101 The options INFRONT, BEHIND, ONTO, and UNDER refer to a picked or named items physical obstruction, while the TO and FROM options refer to the items origin. INFRONT and TO refer to the near side while BEHIND and FROM refer to the far side of an item. Position>Plane Move>Through Moves the origin of the element in a given direction through a Reference Plane specified by the user that is passing through a picked element, p-point, or coordinate. Ex. MOVE ALONG E PLANE N45W THRO ID@

AT E3 N30 U10 -- Position the current element at a specific coordinate (must specify all three coordinates) BY E66 -- Move the current element a relative distance in a given direction TO U126 -- Move a piping component to one specified zone coordinate along constrained centerline Q ATT -- Query all attributes of current element Q NAME -- Query name (or any specific attribute may be used) of the current element Q REFNO -- Query the reference number of the current element

Q POS -- Query position wrt owner of the current element Q POS WRT ZONE -- Query position wrt zone of current element Q CE - Query the name attribute (or reference name) of current element Q MEM -- Query members of current element Q OWN -- Query the name of the owner of the current element NEXT -- Go to next element in list PRE -- Go to previous element in list SAME -- Go to the previous current element $Q -- Lists all valid commands MOVE $Q -- Lists all options for the MOVE command NAME /ANYNAME -- Set the name attribute of the current element DESC ANY TEXT STRING -- Set the Description attribute of the current element to a text string. $S QA=Q ATT -- Create synonym to query attributes Q POS PPLINE TOS START WRT WORL -- Query TOS of current element (SCTN) Q EVAR PDMSUSER -- Query the operating system location of user file directory (%PDMSUSER%) NEW STRU -- Create new structure element (Note: CE must be a owner level (ZONE) or below NEW SUBS /MAIN-DECK -- Create new substructure element and set the name attribute POS E20 N10 U5 -- Position CE at specified owner coordinates

10

POS E20 N10 U5 WRT /* -- Position CE at specified world coordinates CONN IDP@ TO IDP@ -- Connect a picked Ppoint on the current primitive to a picked Ppoint of another. CONN P1 TO IDP@ -- Connect P1 of the current primitive to a picked Ppoint of another primitive. Setting PDMS attributes

In principle, any attribute can be set by specifying the attribute name and value you want it to take. The following are examples: XLEN 200 DESC 'PLATE GIRDER' HEIGHT 300 TEMP 120 NAME /FRED PURP EQUI ORI Y IS N ORI Y IS N AND Z IS U Navigation Commands for moving around the PDMS database.

/NAME - Move to an element by name =23/506 - Move to an element by its reference number END - Move up the database hierarchy by 1 level 6 - Move to the sixth element in the list of the current element

11

NEXT - Move to the next element in the list at the same level NEXT 2 - Move to the second element after the current element NEXT ELBO - Move to the next elbo in the current list by passing any other elements PREV - Move to the previous element in the list PREV 4 - Move four elements back from ce SAME - Go to the previous current element

NOTE: NEXT and PREV commands work on the list according to the modes Forwards or Backwards. In backwards mode, the list is considered to be reversed so these commands have the effect of working from the opposite end of the list. Query Commands

Q ATT - Query all the attributes of the current element Q POS - Query the position of the current element Q POS IN SITE (or Q POS WRT SITE) - Query the position of the current element relative to the site position

NOTE: Normally, the Q POS command gives the position relative to the element's owner.

Q NAME - Query the name of the current element. This may either begin with '/' character. '/PIPING' or may be by a list position name (full name) such as: ELBO 2 OF /P1/B1

Q REF - Query the database unique reference number i.e. = 234/702. This is the best way of ensuring that you get to the element you want. Names can change but reference numbers are fixed so you always get the same element.

12

Positioning Commands (General) At E300 N400 U500 At E3333 N6000 U50 WRT SITE At N500W30U600 WRT WORLD AT N400 U500 E300 IN ZONE At N40 WRT /FRED

---->>> Position an element explicitly at the coordinates given relative to the element's owner. To position relative to some other element, wrt can be added, as shown above.

BY N500 -->> Move the element north from it's current position by 500mm (This is relative movement.) CONN P1 TO P2 OF PREV --->>> Positions P1 at the specified point and orientates the element such that P1 is pointing in the opposite direction to the specified ppoint. CONN IDP@ TO IDP@ --->>> Connect a picked Ppoint on the current primitive to a picked Ppoint of another CONN P1 TO IDP@ --->>> Connect P1 of the current primitive to a picked Point of another primitive

Positioning Commands (Piping) NOTE: All the above commands can be used with piping components for exact positioning. The following commands are specific to piping because they use the implied direction of the previous component to determine the position. This implied direction is some times referred to as the constrained centreline and is simply a line drawn in the direction of the previous component. All of the following commands will move components along this line.

13

DIST 300 --->>>> Position the current element 300mm away from the previous component. The direction is taken as the leave direction of the previous component. CLEAR 400 --->>>> Position the current element with a clearance of 400m between it and the previous element. For most types of component, this command gives a tube spool length equal to the clearance value. For some components such as level operated valves the clearance is likely to take the lever length as the obstruction length of the valve, so in this case the clearance might be more unpredictable. THRO N500 TO N500 --->>>> Position the origin of the CE along constrained centerline through N500 in ZONE coordinates. THRO PT --->>>> Position the origin of the CE along constrained centerline at the point where it intersects a perpendicular plane positioned at the branch tail. CONNect --->>>> Position the arrive point at the leave point of the previous component and orientate the component to suit. Orientation Commands (General)

ORI Y IS N AND Z IS U --->>>> This is the default orientation (wrt owner) for all elements that have an orientation attribute. ORI Y IS E45N --->>>> Specify that the Y axis is pointing E45N. When only one axis is specified, the other tries to get to it's default, so in this case, Z will default to UP. ORI P1 IS N --->>>> Rather than specifying an axis, this command specifies that a particular ppoint is to be orientated in the direction specified. Orientation Commands (Piping)

ORI --->>>> This command orientates the arrive of the element in the opposite direction to the leave of the previous element. It does not change the position.

14

CONNECT --->>>> Perform an ORI, then position the arrive at the leave of previous. DIR S --->>>> This is a special command which is allowed to change the angle of a component. It first performs an ori, then adjusts the angle to ensure that the leave direction is in the direction specified. ORI AND P3 IS U --->>>> Used for valves, tees, etc., this command performs an ori and then points the ppoint in the required direction. It does not change the angle. DIR AND P3 IS U --->>>> This is another special command which is only used on tees with variable angles. (Usually for sloping lines.) In this case, the tee is orientated and the angle adjusted to allow p3 to point in the direction specified. Creating Elements

NEW BOX --->>>> To create anything in PDMS, you need to be at the right level in the hierarchy and use the command NEW followed by the TYPE of element you want to create. NEW EQUI /T-1101 --->>>> Create EQUI element and set the name attribute NEW ELBO CHOOSE --->>>> For piping components, you need to create the element and then link it to the catalogue via the spref attribute. The CHOOSE command allows you to select components from the specification by picking them from a displayed menu. CHOOSE ALL ---->>>> Allows you to see more detail about the component than CHOOSE on it's own. Deleting Elements DELETE ELBO --->>>> To delete an element, the syntax is DELETE followed by the TYPE of element you are deleting.

15

DELETE BRAN MEM --->>>> This deletes the members of an element (i.e. BRAN in this example) without deleting the element itself.

PSEUDO ATTRIBUTES In order to get specific information directly from the database, a number of keyword or pseudo attributes have been introduced. Pseudo attributes are not attributes as such, but they have the ability to extract data when queried. For Example

ELBO 1 --->>>> Go to elbo 1 of the branch Q PARAM --->>>> Query the parameters of the catref of the spref Q DTXR --->>>> Query the rtext of the detref of the spref_ can also use dtxs or dtxt Q MTXX --->>>> Query the xtext of the matref of the spref _ can also use mtxy or mtxz Q PSATTS --->>>> Query the list of pseudo attributes available for the CE.

A few useful pseudo attributes appear below: General Queries Q LIST --->>>> Query what you can create below the current element Q OLIST --->>>>Query the type of elements which can own CE Q ORDER --->>>>Query the list position

16

Q PROP DESC --->>>> Query the data element with the dkey equal to DESC in the component's dataset (Steelwork and Piping elements) Q PRLS --->>>> Query the list of properties in the component's dataset Q PURP XXX --->>>> Query the purpose attribute of the property XXX Piping Attributes

Q CHOICE --->>>> Query the answers of the selectors of the spref Q CHOICE STYP --->>>> Query the styp used to select the component Q PL BOP --->>>> Query the bottom of pipe elevation of the leave point Q PA INSU --->>>> Query the insulation thickness at the arrive point Q PGRAD 1 --->>>> Query the slope at ppoint 1 Q ITLE --->>>> Query the length of implied tube (must navigate first by using 'IL TUBE' at a component) Q LBOR --->>>> Query the leave bore Q ABOR --->>>> Query the arrive bore Q APOS --->>>> Query the arrive position Q LPOS --->>>> Query the leave position At Branch Level

Q TULEN --->>>> Query the length of tube in a branch

17

Q CLLEN --->>>> Query the centerline length through all components Steelwork

Q ODESP --->>>> Query the design params of the joint owner Q ADESP --->>>> Query the design params of the joint attached beam Q DRPS --->>>> Query the derived position of the beam start Q NWEI -->>>> Query the net weight (considering joint cut outs) Q GWEI --->>>> Query the gross weight (beam before cutting) Q NCOF --->>>> Query the net centre of gravity for the beam Q NSRF --->>>> Query the net surface area Q MIDP --->>>> Query the mid point Q POS PPLINE TOS START WRT /* --->>>> Query TOS of current element (SCTN) Q PPLINE TOS DIR --->>>> Query the direction of the TOS pline on a SCTN

The Construct Syntax The construct syntax is described more fully in the Design reference manual and it is worth looking at it in more detail. CONST allows distances and angles to be calculated from the design data and is invaluable when you are writing applications. For example

Q CONST ANGLE N AND W --->>>> gives 90 CONST A PIN1 TO PIN2 TO PIN3

18

Q CONST DIST FROM P1 to P2 TO P2 OF/BOX1 --->>>> gives a distance CONST DIST FROM PA TO PL OF PREV $S QA=Q ATT --->>>> Create a synonym to query attributes Q EVAR PDMSUSER --->>>> Query the operating system location of user file directory PDMSUSER REPORTING SYNTAX

You can create an array which includes a number of elements which all satisfy specific selection criteria, as defined by yourself. The syntax is: VAR !Array COLLECT selection criteria !Array is the name of the array that will be created to contain the elements selected. The following general criteria can be used to define the selection:

A class of elements or element types A logical expression to be satisfied at all selected elements A physical volume in whichall selected elements must lie A point in the hierarchy below which all selected elements must lie

Eg VAR !PIPECOMPS COLLECT ALL BRANCH MEMBERS This would create the array !PIPECOMPS and set it to contain the reference numbers of every piping component in the MDB. Logical expressions use the WITH and WHERE option; a volume is defined by the WITHIN keyword; and the hierarchy criteria is defined by the FOR keyword. Eg VAR !ELBO COLL ALL ELBO WITH SPREF EQ /A300B/100

19

Evaluating Selected DB Elements Using the facilities described here you can create an expression and have it evaluated for all elements which satisfy particular selection criteria. The results of the expression are then placed in a named array. The command syntax is: VAR !Array EVALUATE (Expression) FOR Select !Array is the name of the array that will be created (expression) is the expression that will be carried out for all elements that match the select criteria Select is the selection criteria Eg VAR !BOXES EVALUATE ( XLEN * YLEN ) FOR ALL BOXES

IF ALL ELSE FAILS! As you can see, there are a lot of commands available to the PDMS user and the list above is only scratching the surface. Almost all of the command syntax is described in the reference manuals but in some cases you might find it difficult to compose the required command from these alone. In these cases, it might be necessary to build a command by using the query syntax itself, using $Q and $H syntax. The command: $Q gives a list of all possible commands at any one time. On it's own, $Q gives a complete list of top level commands in any PDMS module. When applied in the middle of a command line, it lists the options available at that point. E.G. the command:

SETUP FORM --->>>> Yields an error incomplete command line

20

SETUP FORM $Q --->>>> list_name as required SETUP FORM _FRED $Q --->>>> lists a number of options including: 'BLOCK/ING' 'RESI/ZABLE' 'AT' 'SIZE' 'COPY' and Newline

Each of the words in quotes can be used at this point. There may be further options after these words and the same technique can be used to find the way through. The characters before the '/' indicate the minimum abbreviation which may be used for each part of the command. The presence of the Newline keyword without the quotes indicates that the return key may be pressed at this point and the command is executed. Another form of syntax querying is the $H command. $H is a slightly more sophisticated form of $Q, which lists the available options numerically as the following example shows: SETUP $H 1 SETUP $H1 'FORM' SETUP FORM $H UNAME And so on.

Positioning Radial Nozzles Method 1 1. Create and then position the nozzle to the correct Up coordinate only. P1 should point in the correct direction, i.e. E 45 N. 21

2. From the application menu bar, choose: Position > Move > Distance The direction of movement is the same as P1. The distance is the PROJECTION DISTANCE. Note: If the nozzles height is set from face to centerline, you might use Position > Relatively (BY) and define the relative movement as the offset from P2 to P1. Solid line nozzle shows position after Step 1. Dashed line nozzle shows position after Step 2. Method 2 1. Create and then position the nozzle at the correct Up coordinate and position it to an orthagonal direction the PROJECTION DISTANCE away from the equipment centerline, i.e. E 29. P1 should point in the orthagonal direction, i.e. E.

22

2. From the application menu bar, choose: Orientate > Rotate The rotation axis should pass through any point on the equipment centerline, i.e. CYLI origin, DISH origin, EQUI origin, etc. Change the wrt to WORL, SITE, ZONE, or EQUI if required. <!--[if !vml]--><!--[endif]-->

23

Das könnte Ihnen auch gefallen

- PDMS CommandsDokument15 SeitenPDMS CommandsAbraham PoolNoch keine Bewertungen

- Essential PDMS Piping CommandsDokument12 SeitenEssential PDMS Piping CommandsKuchipudi Sai100% (1)

- Command Syntax ReferenceDokument15 SeitenCommand Syntax ReferenceLIto Lamonte100% (2)

- BIBLE v3Dokument155 SeitenBIBLE v3MOHAMMAD ASIFNoch keine Bewertungen

- CommandsDokument9 SeitenCommandsKamalakannan AyyaduraiNoch keine Bewertungen

- PDMS piping commands & equipment detailsDokument12 SeitenPDMS piping commands & equipment detailssumitsharma2010Noch keine Bewertungen

- Quick PDMS command line referenceDokument3 SeitenQuick PDMS command line referenceVenkatesan VijayakumarNoch keine Bewertungen

- PDMS - Command SyntaxDokument8 SeitenPDMS - Command SyntaxSiva PrakashNoch keine Bewertungen

- PDMS General CommandsDokument17 SeitenPDMS General CommandsashokNoch keine Bewertungen

- PDMS ShortcutsDokument11 SeitenPDMS ShortcutsSomnath LahaNoch keine Bewertungen

- Commands PdmsDokument5 SeitenCommands Pdmsrahul,aswin gamez sureshNoch keine Bewertungen

- PDMS CommandDokument12 SeitenPDMS CommandPrashant KumarNoch keine Bewertungen

- PDMS Piping CommandsDokument5 SeitenPDMS Piping CommandsSomnath Laha100% (1)

- E3D Command ListDokument2 SeitenE3D Command ListHARISH_IJTNoch keine Bewertungen

- PDMS commands for general, piping and equipmentDokument7 SeitenPDMS commands for general, piping and equipmentSankar GaneshNoch keine Bewertungen

- Command Line Entries for PDMS and DraftDokument13 SeitenCommand Line Entries for PDMS and DraftSasha KatichNoch keine Bewertungen

- PDMS Design SyntaxDokument8 SeitenPDMS Design SyntaxGangatharen NackeeranNoch keine Bewertungen

- Pdms Command Line InputDokument13 SeitenPdms Command Line InputipikipikmamaNoch keine Bewertungen

- Rename TEE ELBOW to ELBOW in Pipe IsometricDokument1 SeiteRename TEE ELBOW to ELBOW in Pipe IsometricSudheepNoch keine Bewertungen

- Pdms TricksDokument1 SeitePdms TricksAaron PabloNoch keine Bewertungen

- Pdms CommndsDokument35 SeitenPdms CommndsManoj BaviskarNoch keine Bewertungen

- Pdms CommandsDokument3 SeitenPdms CommandsNithin ZsNoch keine Bewertungen

- S.No. Pdms Piping Command Expansion of CommandDokument3 SeitenS.No. Pdms Piping Command Expansion of CommandRam MurtyNoch keine Bewertungen

- PDMS Design Reference Manual Part1Dokument140 SeitenPDMS Design Reference Manual Part1limp_engNoch keine Bewertungen

- PDMS Installation GuideDokument54 SeitenPDMS Installation Guidemaverikme23Noch keine Bewertungen

- PdmsDokument150 SeitenPdmsPoonam AshwinNoch keine Bewertungen

- Pdms TrickDokument10 SeitenPdms Trickarifin rizalNoch keine Bewertungen

- New User Defined ATTA in The MDS CatalogueDokument5 SeitenNew User Defined ATTA in The MDS CatalogueerlifieNoch keine Bewertungen

- PDMS COMMANDS: QUICK REFERENCE FOR STRUCTURAL COMMANDSDokument3 SeitenPDMS COMMANDS: QUICK REFERENCE FOR STRUCTURAL COMMANDSMOHAMMAD ASIFNoch keine Bewertungen

- AVEVA E3D Has In-Canvas CommandsDokument4 SeitenAVEVA E3D Has In-Canvas CommandsrolwinNoch keine Bewertungen

- 100's Design Simple Single Line Commands PDFDokument16 Seiten100's Design Simple Single Line Commands PDFhaschere100% (1)

- Chapter 4Dokument15 SeitenChapter 4arnandaNoch keine Bewertungen

- BP - E3D CommandDokument7 SeitenBP - E3D CommandPrashant Dubal0% (1)

- E3D Admin Data Sheet-NewDokument2 SeitenE3D Admin Data Sheet-NewASTAR GAMINGNoch keine Bewertungen

- Senior Piping Design Engineer and PDMS & E3D AdministratorDokument5 SeitenSenior Piping Design Engineer and PDMS & E3D Administratorravi 340Noch keine Bewertungen

- Pdms Draft: User Guide Part 2: Drawing AnnotationDokument225 SeitenPdms Draft: User Guide Part 2: Drawing AnnotationMakoto TakanoNoch keine Bewertungen

- New Method of Managing Pipe Wall Thickness - Feb14Dokument1 SeiteNew Method of Managing Pipe Wall Thickness - Feb14monkey_vt02100% (1)

- Pdms BoltsDokument10 SeitenPdms BoltsSargunam SankaravadivelNoch keine Bewertungen

- Postavljanje trajnog bojanja elemenata u PDMS-uDokument4 SeitenPostavljanje trajnog bojanja elemenata u PDMS-uSargunam SankaravadivelNoch keine Bewertungen

- Level and Obstruction For PDMS PrimitivesLevelDokument2 SeitenLevel and Obstruction For PDMS PrimitivesLevelShirishJadhavNoch keine Bewertungen

- Command List PDMSDokument5 SeitenCommand List PDMSAhmed Khan100% (1)

- AVEVA PDMS PML Basic Guide Forms Menus Romeldhagz Gmail Com PDFDokument96 SeitenAVEVA PDMS PML Basic Guide Forms Menus Romeldhagz Gmail Com PDFPolarogramaNoch keine Bewertungen

- AVEVA Bocad Training Modules and Guides SummaryDokument14 SeitenAVEVA Bocad Training Modules and Guides SummaryRahulNikam50% (2)

- AVEVA Plant 12.x Training Course ListDokument2 SeitenAVEVA Plant 12.x Training Course ListNatchimuthu Durai Balan67% (3)

- A Guide to Generating PDMS Electronic SpecificationsDokument26 SeitenA Guide to Generating PDMS Electronic SpecificationsAou UgohNoch keine Bewertungen

- Show !!syntaxhelp: Want Help On Your Syntax (PDMS Commands) Then TypeDokument35 SeitenShow !!syntaxhelp: Want Help On Your Syntax (PDMS Commands) Then TypeKrunalpanchalNoch keine Bewertungen

- Positioning Radial Nozzles for Optimal DirectionDokument15 SeitenPositioning Radial Nozzles for Optimal DirectionTrungSon NguyenNoch keine Bewertungen

- PDMS CommandsDokument25 SeitenPDMS Commandsreach_arindomNoch keine Bewertungen

- PDMS CommDokument4 SeitenPDMS CommShrikant PillayNoch keine Bewertungen

- Commandes PDMS4Dokument23 SeitenCommandes PDMS4Anonymous TRthlKkWWNoch keine Bewertungen

- Pdms CommandsDokument10 SeitenPdms CommandsEliomar RivasNoch keine Bewertungen

- PDMS piping, structure, equipment commandsDokument13 SeitenPDMS piping, structure, equipment commandsselvakumar sNoch keine Bewertungen

- Pdms CommandsDokument6 SeitenPdms CommandsMOHAMMAD ASIFNoch keine Bewertungen

- Pdms Piping CommandsDokument9 SeitenPdms Piping CommandsSomnath LahaNoch keine Bewertungen

- Pdms Command Line Syntax AdvancedDokument6 SeitenPdms Command Line Syntax AdvancedSomeshNoch keine Bewertungen

- CommandsDokument8 SeitenCommandsganguly139Noch keine Bewertungen

- PDMS CommandDokument51 SeitenPDMS CommandAris PurniawanNoch keine Bewertungen

- Query CommandsDokument7 SeitenQuery Commandssteepa22Noch keine Bewertungen

- Setting PDMS Attributes: 8 Want Help On Your Syntax (PDMS Commands) Then Type Show !!syntaxhelpDokument8 SeitenSetting PDMS Attributes: 8 Want Help On Your Syntax (PDMS Commands) Then Type Show !!syntaxhelpsteepa22Noch keine Bewertungen

- PDMS Command Line Syntax AdvancedDokument6 SeitenPDMS Command Line Syntax AdvanceddwhowardNoch keine Bewertungen

- AA4Dokument19 SeitenAA4Karthik P MuraliNoch keine Bewertungen

- Carboguard 190HB: Selection & Specification DataDokument2 SeitenCarboguard 190HB: Selection & Specification DataAchraf BoudayaNoch keine Bewertungen

- Tie in & Hot TappingDokument2 SeitenTie in & Hot TappingKarthik P MuraliNoch keine Bewertungen

- GE Energy Management Visual Inspection RequirementsDokument10 SeitenGE Energy Management Visual Inspection RequirementsKarthik P MuraliNoch keine Bewertungen

- Recd - Concrete DetailsDokument2 SeitenRecd - Concrete DetailsKarthik P MuraliNoch keine Bewertungen

- DocDokument1 SeiteDocKarthik P MuraliNoch keine Bewertungen

- Game PlayDokument8 SeitenGame PlayKarthik P MuraliNoch keine Bewertungen

- Vijayakumar P's Resume SummaryDokument4 SeitenVijayakumar P's Resume SummaryKarthik P MuraliNoch keine Bewertungen

- Transforms Partial Differential EquationsDokument13 SeitenTransforms Partial Differential EquationsViji Yogi BaluNoch keine Bewertungen

- Lecture Plan-Unit IIIDokument18 SeitenLecture Plan-Unit IIIKarthik P MuraliNoch keine Bewertungen

- HMTDokument11 SeitenHMTKarthik P MuraliNoch keine Bewertungen

- Engineering Thermodynamics - Department of Mechanical EngineeringDokument5 SeitenEngineering Thermodynamics - Department of Mechanical EngineeringKarthik P MuraliNoch keine Bewertungen

- Transforms Partial Differential EquationsDokument13 SeitenTransforms Partial Differential EquationsViji Yogi BaluNoch keine Bewertungen

- Nilsen J Top 4000 Vocabulary Test For ThaiDokument9 SeitenNilsen J Top 4000 Vocabulary Test For ThaiplopNoch keine Bewertungen

- First Order Shear Deformation TheoryDokument11 SeitenFirst Order Shear Deformation TheoryShlokNoch keine Bewertungen

- Matrices PDFDokument13 SeitenMatrices PDFRJ Baluyot MontallaNoch keine Bewertungen

- Seventh Grade Language Arts Letter of Introduction Frissora WillisDokument4 SeitenSeventh Grade Language Arts Letter of Introduction Frissora Willisapi-188248147Noch keine Bewertungen

- Economic Problems of Population ChangeDokument27 SeitenEconomic Problems of Population ChangeAner Salčinović100% (1)

- Gen Ed Day 5Dokument5 SeitenGen Ed Day 5Jessica Villanueva100% (1)

- Circular Central Tech Fest For WebDokument2 SeitenCircular Central Tech Fest For WebDax ShuklaNoch keine Bewertungen

- Tutorial Sheet 2 PDFDokument4 SeitenTutorial Sheet 2 PDFWesleyNoch keine Bewertungen

- Tower Scientific CompanyDokument3 SeitenTower Scientific Companymaloy0% (1)

- ROHR2 InterfacesDokument16 SeitenROHR2 InterfacesMarcia Akutsu MainardiNoch keine Bewertungen

- Seven Steps of Wisdom - SRIADokument35 SeitenSeven Steps of Wisdom - SRIAWolfgang LochnerNoch keine Bewertungen

- HBR How To PitchDokument9 SeitenHBR How To PitchA.J.Noch keine Bewertungen

- Ushvinder Kaur - SSN PDFDokument48 SeitenUshvinder Kaur - SSN PDFShraddha ShaduNoch keine Bewertungen

- HemeDokument9 SeitenHemeCadenzaNoch keine Bewertungen

- Scope of The StudyDokument13 SeitenScope of The StudyKather ShaNoch keine Bewertungen

- Determination of CaCO3 in The EggshellDokument33 SeitenDetermination of CaCO3 in The EggshellbushlalaNoch keine Bewertungen

- Civil DisobedienceDokument1 SeiteCivil DisobedienceJeremy KeeshinNoch keine Bewertungen

- Biological TransmutationsDokument15 SeitenBiological TransmutationsBryan GraczykNoch keine Bewertungen

- Dosha NakshatrasDokument3 SeitenDosha NakshatrasNeo RagNoch keine Bewertungen

- Timer Pro Professional: A Full Featured Continuous Improvement and Process Measurement ToolDokument21 SeitenTimer Pro Professional: A Full Featured Continuous Improvement and Process Measurement ToolwararmNoch keine Bewertungen

- 5 Basic Phases of Project ManagementDokument5 Seiten5 Basic Phases of Project ManagementAditi Mahajan100% (1)

- Brigada Eskwela 2019Dokument12 SeitenBrigada Eskwela 2019Renelyn Rodrigo SugarolNoch keine Bewertungen

- Igcse Topic 1 Lesson 1 Water Cycle IgcseDokument25 SeitenIgcse Topic 1 Lesson 1 Water Cycle Igcsedanielphilip68Noch keine Bewertungen

- Syllabus FLM - 307 Fall 2016Dokument21 SeitenSyllabus FLM - 307 Fall 2016Mary SingletonNoch keine Bewertungen

- Cisco Network Services Orchestrator (NSO) Operations (NSO200) v2.0Dokument3 SeitenCisco Network Services Orchestrator (NSO) Operations (NSO200) v2.0parthieeeNoch keine Bewertungen

- Allegory of The CaveDokument2 SeitenAllegory of The CaveVanessa SantosNoch keine Bewertungen

- Curriculum Vitae App LetterDokument4 SeitenCurriculum Vitae App Letterapi-298390154Noch keine Bewertungen

- BS en 10217-6-2019Dokument42 SeitenBS en 10217-6-2019Federico De MartiniNoch keine Bewertungen

- Life Cycle of GISDokument12 SeitenLife Cycle of GISNikin JayswalNoch keine Bewertungen

- Area Traffic Control System Implementation at Pune - Case StudyDokument29 SeitenArea Traffic Control System Implementation at Pune - Case Studychandu0714Noch keine Bewertungen