Beruflich Dokumente

Kultur Dokumente

Vertical 2 Phase Flow

Hochgeladen von

Lind D. QuiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Vertical 2 Phase Flow

Hochgeladen von

Lind D. QuiCopyright:

Verfügbare Formate

-- ---Fig.

P-C bi-phase friction 10ss '--"

10 f

= 66(Mlq.. I dlr3

3f'1

Pressure traverse found for 2-phase vertical flow

G.c. BORGIA G. GOITARDI University of Bologna Bologna, Italy

~

U)

.. ,g

~11O-1' e

10-2

10-3

10 Mt(qon) d1

102

-o

TIME-CONSUMING calculations for pressure traverse in vertical pipe with flowing fluids have been streamlined into two programs for fue HP 67/97 hand-held calculator. Using existing theories for such flow, fue flow equations and a calculator

Fig.2

program using assigned P-V-T and other properties are first developed. Two theories are incorporated into fue programo Then the treatment of muItiphase flow of liquid and gas as flow of a single phase with combined properties by an energy balance will be analyzed. Friction losses are accounted for differentIy in this approach. The resuIt is a second program for the HP 67/97calculator. Laws controlling two-phase flow in

Fig.3

Pressure traverses by th P-C method

Pressure traverses by the M-K method

o

qon = 60 cu m/d di = 6.2 cm

qon = 60 cu m/d di = 6.2 cm

8 .

~

E:

~

E:

~

-4

15.

Q)

15. Q)

8 1

50

50

100

150

250

........

Pressure P. bars

OGJ

OIL & GAS JOURNAL

SEPT. 15, 1980

191

Fig.4

Fig.5

Fig.6

Friction 10ss factor (Tek)

Pressure traverses

(Tek)

Pressure

traverses

-./

00:1

vertical pipe are complicated because of the variation in flowing fluids' specific volume with pressure and temperature changes. Slippage losses and the variety of flow patterns that liquid and gas may have during upward flow also complicate the picture. Results from theoretical proposals are incomplete, but in fue flow region of practical importance, equations of satisfactory accuracy have evolved. Designed for the HP 67/97 calculator, this program evaluates pressure traverses in pipe for assigned P-V-T properties of fue fluids, the oi! rafe, the GOR, and ID of the pipe. Flow equations. When the average

temperature along fue pipe is known, the pressure traverse is evaluated by integration of a differential equation f(p), where: p oi, the type dp/dh pressure; h depth; and f(p) is a function of the pressure that varies according to the different theories and to the P-V-T characteristics of fluids. By using the theory implying fue easiest mathematical formulation of the problem, the engineer can determine the pressure traverse along a vertical pipe by laborious hand calculations, or by using' gradient curve tables. TheHP 67/97 calculator was programmed to salve the flow equations (Table 1). Equation (1) is the pressure gradient obtained by Poettmann and Carpenter (P-C) in differential form, valid for an infinitesimal length of flow string.1 P-C equation (1) was obtained on

the basis oi an energy balance,wher~

fue energy los8 was calculated by th Fanning equation. The two-phase tota1'"

Nomenclature

Bg, gas umefactor, cu mI s cu m Bo, oil e factor, cu mIs cu m STO Bt, bi-phase volume factor, cu mIs -.0

Imeter ID, m

phase loss factor, dimensionless Mt, bi-phase ,mass factor, kg/cu m STO pressure, bar abs oil volumetric flow rata, cu mI sec gas volumetric flow rata, cu

m/sec

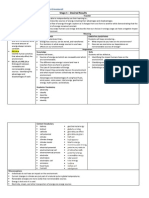

Table1

Flow equations

Rs, gas solubility, s cu mIs cu m STO Rgo, gas oil ratio, s cu mIs cu m STO g, acceleration. of gravity, bar abs (sq m/kg) oil density, kg/cu m gas density, kgl cu m average temperatura along the pipa, K. Z, gas compressibility factor, Isionless to standard n,

Tabte 2

Runge-Kutta integration

Given a differential equation of the f(x,y),the solution is: type dy/dx

= Yn+ + (ko+2k+2k2+k3)/6 Xn+ Ax xf(xn, y.) k = Axf(x.+Ax/2,y.+ko/2) k2= Axf{x.+Ax/2, y.+k/2)

k3 = AX f{Xn+AX, y.+k2)

192

OIL & GAS JOURNAL

- SEPT.15, 1980

Table3

Program

listing

J

i....'S..""".Y"'MnOG

* 4 Inilialize -51 24 _nn-_n_n_n 211 - 4 35 45 Enler data + RCL7 RCL9 x,y? TOa RTN "L"Ld 8 R 6 '1 131-Seii------35 46 nIhe melhod -- --n n -- --3 9 'ro 36 B 23 36 CO.."". ,.o. ,,"

mn nn_n_n

,."..

"""",oro

TX

T '

2214

24 21 SBb 231612 RCLO 3614 -2 x' 53 1

T1 RTN

yx ,"o RCL RCLl el STO ' + RCL0

,

* IBIe STOI

mn--n----""

.

e yx

+ RCL1 ... RCL 36

1 Poettmann 4

36 36 1 36 35 -35 -55 '36 36 1

and

and Carpenler

ST02 2 ,d ST03

35 2 The Runge2 Kutta -24 23161 inlegralion 35 melhod

ST05 CHS RCLA + P R 7

,-:-

-55 RS

35 5 -22 361 -55 16-51 36 7 -]2

formula

5

RCLl

K RCLO 1

Krylov

1 -35

36 -24 1 23 61 1

36 14 1

*LBL1 R

-- __n__--_-,

formula

+ RCL3 RCL4

-55 36 3 36

-5,

RCLE RCL6 -55 ---=3s 3615 36 -35 ...ti - 5 Bo

BI

X Pi K

53 16-24

RCLE RCL2 CL PRTX C7 T

'

-24

-55 52 -

7 EEX 5 H +

7 -23 05

-35

1 X

CB , '" 'x

".

12 -3 Muiaviev ,ro

7 Prinl - 1 resulls

o + STO RTN

+ C , RC , , +

3 6

R 3 -35 B - --DISs

FlXO

"

16-

R LB

MI "'tial"

P C

LABELS "oterd." e PO "" D START ' u"d ' 'u"d Be Me " u,.d , MK ' ,

'-'

"

o '

FLAGS

000

SETSTATUS

FLAGS

TRIG

DEGO

,

,

'e

'DO GRADO SCIO g D" B I RADO I NG20 o'

J

energy loss factor was determined by P-C by analyzing production data from Giland gas wells. Equation (4) is a good approximation (correlation factor about 0.99) for the two-phase loss factor determined by C-P (Fig. 1). The variation of the Gilvolume factor Bo and of the gas solubility factor Rs can be established at fue mean flowing temperature by diagrams based on laboratory experiments. The curves Bo Bo(p) and Rs Rs(p) can cIten be approximated by straight liDes, equations (8) and (9), with significant deviations at low pressure only. In this program fue gas compressibility factor Z Z(p) has algo been approximated by a straight line, equation (11). The two-phase mass factor Mt is expressed as a function of Gil and gas densities and of the GOR at standard conditions, equation (3). The two-phase volume factor Bt is expressed as a function of tbe Gil volume factor Bo, tbe gas volume factor Bg, the gas solubility Rs, and Rgo, the GOR, equation (10). Equation (1) is a function of pressure only, if temperature is assumed to be constant and the Gil rate, fue GOR, the ID of the pipe, and tbe P-V-T characteristics of gas and oil' are known. Tbe differential expression of pressure gradient in equation (2) by Muraviev and Krylov (M-K) was obtained by correlations of laboratory experimental data.2 Tbe first and second terms in equation (2) represent fue loss due to tbe coexistence of two flowing pbases. Tbe tbird and fourth terms account for the friction losses tbat would arise sbould gas and Gilbe flowing alone. Knowledge of pbysical and thermodynamic fluid cbaracteristics permits expression of fue rigbt-band sirle of equation (2) as a function of pressure only. Equati~ns (5) to (12) are valid for constant values of tbe Gil rate, fue GOR, tbe average temperature along tbe pipe, and fue pipe ID. The pressure traverse along fue pipe is from numerical integration of differential equations (1) and (2), using tbe four-step Runge-Kutta integration metbod (Table 2). Using the programo Table 3 is tbe program listing. The steps to be ex. ecuted from tbe instructions (Table ' 4) are: Load the program cardo Press key A to initialize registers. Enter data by pressing key B. GIL & GASJOURNAL - SEPT.15, 1980

"

194

Table 4

User instructions

I 4

Table 6

,,- K

1~~.~0 ~.~0'" 105.~~ n" 1611.~~ ..." 327.~~ n.. 1.15 "" 1.5~~"~~~1-~3 .., ".~~ .,** I.b~ *" 1.~1 H' -2.0~000000-03 ", 3.410000000-03H'

U20.00 ***

.10'00 "" 0.00 "'.' 10\.00 "" lb00.00 327.00 "" LIS'" l.500~00000-03,'" -c .00000000-03,.. 3.;10000000-03",

10.00 .., 0.80 ,.. 1.00 ".

0.>5 ..* 500.0~ *""

"20.00... 0.Y',H' 500.00 ", 0..06.",

'" ".,

6.944444444-04 9.UI000~000-05 0.lb

**' '" "H'

e.944444444-04 9."'0000000-05

"7.96 "" 100.00 .., 110.99 "', 200.00 ,..

109.35 '" 100.00 ...

114.09"" 300.00n.

113.79 ." 200.00 ... 110.32 ,.. 300.00 ".

173 .19, .. 1400.00 ... 178 . 5" '" 1000." n, ID4.0I..,

153.69'*. 14".00 ...

E7.03... 1\00.00 ,.,

lb00 00 no

Select the calculation method by en. tering cpfor P-C or 1 for M-Kmethods. Press key C. Start the program by pressing key D. At the end of each integration step, the program prints the couple of values p and h. Thereafter there is a pause of about one secando During this pause it is possible to change the length of the integration, step .:lh by executing these instructions: Press key R/S. Enter the new .:lh. STO6. Press key R/S. This program option may be used to reduce execution time of the calculation. The execution time of each integration step is about 30 seconds for the C-P method and about 50 seconds for the M-K method. 196

Input data used to calculate the pressure traverses of Figs. 2 and 3 using the C-P method and M-K method, respectively, are shown in Table 5. To test the program, the input data .. and the results obtained for two examples of ca]culation may be used (Table 6). The program uses metric units and pressure expressed in bars absolute. Single phase approach Using a third theory a second program for the HP 67/97 handheld calculator can be developed. Similar to the earlier work, fue theory of M. R. Tek treats multiphase flow of liquid and gas as the flow of a single phase with combined properties.4 Using an energy balance, the

theory leaves out of consideration the complex mechanisms caused by the coexistence of numerous flow pattems, the variation of the flowing fluids' specific volume with pressure and temperature, and the slippage losses. Friction losses are accounted for by using the concept of a "two-phase f factor," by Poettmann and Carpenter (P-C). It is in the form of an empirical correlation as a function of the "viscosity-less" Reynolds' number pvd (density)(velocity) (diameter) of the flow pipe. Tek finds a two-phase total energy loss factor by using field data from several flowing and gas-lift wells. The ' concept of the "two-phase Reynolds' number function" and of the mass ratio of gas to liquid are used. Similar to the work of P-C, the twoOIL & GAS JOURNAL - SEPT. 15, 1980

phase friction factor is a function of the liquid and Gil viscosity. The pressure traverse is evaluted

by integrating a differential equation

of the type dp/dh

= f(p,T).

Depth and

-,,"'~

Flow equations dp/dh = Mt/Bt (g + 32f qon2

pressure along the pipe (h and p) are as used earlier. The function f(p,T) is a function of pressure and temperature which varies according to the P"V-T characteristics of the flowing fIuids. Temperature is assumed to be constant in this programo Equations. The HP fJl /97 was programmed to salve the flow equations (Table 7). The expression of the pressute gradient, equation (1), is valid for an infinitesimal length of flow string. It comes from the well-known flow equation, neglecting change of kinetic energy of the fluido Equation (2) is an approximation for the two-phase loss factor proposed in a diagram by Tek (Fig. 4). Equations (4) and (5) are the

Reynolds' numbers that gas and Gil would assume flowing alone in the pipe. The gas/liquid ratio, equation (9), varies along the string according to the pressure. Linear pressure approximationsequations (12), (13), and (14)-are for the Gil volume factor Bo, the gas solubility Rs, and the gas compressibility factor Z. Two-phase mass factor Mt is a function of the Gil and gas densities and GOR at standard conditions,

equation (11).

-

The two-phase volume factor Bt is expressed as a function of the Gil volume factor Bo, the gas volume factor Bg, the gas solubility Rs, and Rgo, the gas/Gil ratio, equation (10). The assumption of constant temperature along the pipe makes the right hand sirle of equation (1) a function

Table 8

Program

listing

.""t ...,,""'" o"' "LBLA 7 2

""'.

11 7

nhhh..hmn--

..'M"M'.".

Initialize

...t...

,

""-'

4 005 006 007 008

STOl CLX RTN "LBLB PRTX SToi 1521 RT

3546 51 24 2112 -14 3545 16 26 46 24

21 13 36 13 1 35 4 16-24 24 36 15 35 3614 -24

K'V.,""""""""

+ -35 6 STo' sPC RCL' PRTX

RCL8 PRTX PSE RCL7 X> 2 GTOe RCL8 X>02 GTOD RTN 08 e

""".'N""

.tE.. ........",..,..""",. 11 RCLl

RCL7 RCL6 + RCLl RCL3

RCL2 + P;" + STO RTN 'LBL2 G58b RCLl EEX

.,"".""'

.,",.....c..."..yO"'" ,,"

l7l 172 173 174 175 176 1

178 179

05

36 35 36 06 No 36 05 62 1

33 52 31 -41 3 5 5 5 36 5

...,....t..

059

Enter data

m_mm_hnnn

061 062 063 064 065 66

35 ss , 16-11 36 0' -14

06 24

ss

3646

36 36 7 -35 6 -ss -35 36 46 36 3

-35 36 02 SS 16-51 -55 35 24 21 02 23 16 12 36 01 -23

RCLC RCL6 RCL5 1

ex 1 X yX :qy RCL5 5 + RCL5 1 X yx

Method

11 116 117 118 ll9 'w 121

122 123 124 125 126 127 128 129

Print

resulls

11 12 13 14 15 16 17 18

OLBLC RCLC STO1 4 Pi RCLE " RCLD

""

067 068 69 71 072 73 74 075 76

'

36 08 -14 1651 36 7 16-44 22 16 15 36 08 16-44 22 14 24

'""

BI

,,"

131 132

181 182 183 184 185 186 187 188

The

-2

5

022 23 024 025 026 027

028

RCL8 STD8 2 RCLO

5

3612 24 3512 02 3614 24

05

"'o 081 82 83

084

78 79

RCL8 ""5 RCL0 S X>Y? GTOD

RTN

211615 36 8 16-51 36 00 16-51 16 34 22 14

24

133 4 1'6 137 138

"

3 35 "9 3614 4 -24 33 24 31 1663 53 -35 23 3 24 6

36 36 11 14

'

189 LOG 191 192 193 194 195 196 197 198 199 21 22 23 204 205 26 Z 7 1 RCL5

9 RCLD 4

'"

141 142 143 144 145 146 147 148 149

152 153 154

" CHS ex 2 2 RCL0 XZ RCLE x

9 8

-35 1632 62 01 36 05 -35

45

Tek

formula

29

'-'"

31 032 33 34 035 036 37 38 39

41 42

yX RCLE Pi

"

" STOE "L8LD RCL9 STD GS82 RCL7

ST+8

31 3615 16-24 24 35 3515 2114 36 35 46 23 2 36 7

35-SS

85 086 087 88 "" 091 092 94 95

'-LBLd RCL' + STOl G58 RCL7 RTN 8L PS RCL5

RCLl RCL4

211614 36 09 -SS 3546 23 2 36 7 -35 24 1651 36 05

36 47 -35 36 4

eX ' yx LSrX X' EEX 3 , TD6

RCLA RCLO

4 35 22 2 -35 36 00 53 35 3615 -35

9 08

""

_mnhnn._h.

043 44 045

046 47 48

T02 2

'

GSBd ST03 2 GSBd ST04 G58d

35 2 2 -24

231614 35 3 2 -24 4

8 -35

The

'"" Runge-Kutta

96 97 98

/-Los

99

11

12 13 14 15 16 1 18

+ STOD CRS

-55 351 22

1 -SS 3 04 -23 2

RS

1SS 156

158 ,.. 161

nS RCL'

.

"

45 16-51 36 09

6 1 35

,,"

208 29

2l1 212

213 214 2

EEX 6 CHS

+ RCLA

-23 -22

-SS 36 11 1651 -35 36 08 -SS

051 52

231614 35 231614

inlegration

RCLA + 3 4 EEX CHS

RC B

36 12 -35 614 16-51

Ng

""

217 218 219

RCL8 +

54 SS 56 Bt

2 + RCL3 ReL4

2 SS 36 3 36 4

,,"

19

RCLl RCLl

III 112 REGISTERS

35 36 1 -35 36 46

6 166 6 16

ReLS S + BEntee

-35 36 8 1651 SS

l' 'od

T" 'go

l' ko

13 k1

l' k2

hm,,!"

1" '1 lB "sed

1" '2

le

l"b1

"sed

b2 1" e, o "sed E ",ed

"

l' '"

l' oh 1" e2

l' h " l'

l' p

1" Pgn "sed

'h

'Initi"iz o ;

'

d,t,e

,

pon

, ,

Bt

Stoct "sed , TEK

lABElO O

221 222 223 24

no

" CL

16-51 36 24 24

", d ' "sed 3

E , "sed

o '

RTN FlAGS

,

3

ON O" o o O , O O ' O O

3 . O

FlAGS

SETSTATUS TRIG GRAOO RAO O DEG o

DISP SOl O NG2 O FIX

'"

""'-"

OIL & GAS JOURNAL - SEPT. 15, 1980

199

Table 9

Instructions

Table

10

Test case

m m barsabs hmax 1600.00 m -Tav 327.00 K cumIs cumSTO a, 1.15 a2 1.50 (10}-3 cu m/(scumSTO x barsabs) 10.00 b, s cumIs cumSTO 0.80 b2 scum/(scumSTO x barsabs) 1.00 C, dimensionless --0.002 C2 (bars abs)-' 820.00 pon kg/scum 0.95 pgn kg/scum 500.00 scu mIs cumSTO Rgo 2.50 (10}-5 Palsec /Lg 3.00 (10)"3 Pa/sec /Lo. di 0.062 m 6.944(10)-4 qon seu m/sec 108.57 100.00 112.19 200.00 115.86 300.00 119.57 ~ 400.00 151.59 1200.00 155.92 1300.00 160.34 1400.00 164.84 1500.00 169.42 1600.00 Ah ho Po 100.00 0.00 105.00

,r

----

STEP 1 InitiaHze

INSTRuenONS

INPUT DATA/UN'TS

KEYS

OUTPUT DATA/UNITS

- 2

Enter

Llh

3

4

Enter

Enter

ho

po

n n n

[L] CJ

Llh

ho

0.00

[LI CJ C!::JCJ

IT::J CJ

Llh

ho po

po hmax

5 6 7 8 9 10 11 12 13 14 15

16

Enter Enter Enter Enter Enter Enter Enter Enter Enter Enter Enter

Enter

hmax Tav al a2 b1 b2 c c2 Pon Pgn Reo

Ug

Tav a, a2 b1 b2 c c2 Pon Pgn RgO

Ug

C!::JCJ C!::JCJ QDCJ IT:J CJ

[I] [I] [I] [I] [I]

C!::Jc=J

[LI CJ

CJ CJ CJ CJ CJ

hmax Tav al a2 b1 b2 c1 c2 Pon Pon

RgO Va

[LI CJ

[I]

17 18 19 20

Enter Enter Enter Start

Uod di qon

Uod di qon

C!::Jc=J

CJ

Uod di qon P1' h1

IT:Jc::J

CJCJ

CJCJ

u::Jc::J

CJ c::J CJCJ CJCJ CJCJ CJCJ CJCJ CJCJ

P2, h2

.......

Pn, hn

21

Return

to step

1 for a new case

(O)Steps 2, 3 and 5:

if Llh<O invert ho and hmax ; in chis case Pn<Po

CJ r=J

CJ c::J CJ c::J CJCJ c::J c::J c::J c::J c::J CJ CJCJ c::J CJ CJCJ

calculation the physically impossible condition of Rs(pRgo is met, the program will go into error. Some pressure traverses obtained from fue program are shown (Fig. 5). A comparison is shown for the presSUTetraverses calculated by the P-C, M-K (Muraviev and Krylov), and Tek methods (Fig: 6). The Tek nethod generally gives average gradients of pressure greater than the other two.6

Nomenclature is defined in the ac-

'-"

of pressure only. The form is determined by specifying the P-V-T characteristics of flowing fluids-equations (11) to (15)-the ID of the pipe, the Gil flow rate, and the GORat standard conditions. Equation (6) shows the relation between dead Gil viscosity (P,Od) and saturated Gil viscosity (P,os).5 Equations (7) and (8) are good approximations for the function of Gil solubility A(Rs) and B(Rs).5 The pressure traverse along the pipe is obtained by numerical inte gratio n of the differential equation (1). The four-step Runge-Kutta integration method allows good approximation using large steps. The programo Table 8 is the program listing. The instructions tell how to use the program (Table 9). These steps must be executed:

Load the program cardo Press key A to initialize registers. . Enter data by pressing key B. Start the program by pressing key C. At the endof each integration step, the program prints the couple of values p and h. There is a pause of about one second, during which time itis possible to change fue length of the integration step Ah by executing these instructions: Press key R/S. Enter the new integration step. STO7. Press key R/S. This program option may be used to reduce the execution time of the calculation, which is about 60 seconds for each integration step. A test case may be helpful in testing the program (Table 10). Caution must be taken in the choice of the gas/Gil ratio, Rgo. If during the

companying box. The international system of measure (SI) has been used in this programo Pressure is in bars absolute.

'-

References 1. Poettrnann, F. H., and Carpenter, P. G., "The rnulti-phase flow of gas, oil. and water through vertical fIow strings," API Drilling and Production Practice, DalIas, 1952. 2. Muraview, 1. M., and Krylov, A. P., "Ekspluatatsiya neftyanykh rnestorozhdeniy," Gostoptekhizdat, Moscow, 1949. 3. Szilas, A. P., "Production and transpOrt of oil and gas," EIsevier, Budapest, 1975. 4. Tek, M. R., "Multiphase flow of water, oil and natural gas through vertical flow strings," JPT, October 1961, pp. 1029-36. 5. Chew J. and Connally, C. A., Jr., "A viscosity correlation for gas-saturated crude ~-r-"""" oils," Trans. AIME, 1959, 216, p. 23-25. 6.0rkiszewski, J., "Predicting two-phase pressure drops in vertical pipe," JPT, June 1967, pp. 829-38.

200

OIL & GASJOURNAL - SEPT. 15,1980

Das könnte Ihnen auch gefallen

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsVon EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNoch keine Bewertungen

- An Evaluation of Critical Multiphase Flow Performance Through Wellhead ChokesDokument8 SeitenAn Evaluation of Critical Multiphase Flow Performance Through Wellhead ChokesAhmed Khalil JaberNoch keine Bewertungen

- Gas Flow Rate Calculation From Wellhead PressuresDokument1 SeiteGas Flow Rate Calculation From Wellhead Pressureschandramohan murugan100% (1)

- Example #12-Simulated Solution Gas Drive 1 (Example12.csv) : Using The Numerical ModelDokument3 SeitenExample #12-Simulated Solution Gas Drive 1 (Example12.csv) : Using The Numerical Modelwizerth apkNoch keine Bewertungen

- Aps U9 Test Review KeyDokument5 SeitenAps U9 Test Review Keydeez nutsNoch keine Bewertungen

- Kel-1 GAs Lift1Dokument12 SeitenKel-1 GAs Lift1Indra ArdiansyahNoch keine Bewertungen

- Well Test Course ExecirsesDokument4 SeitenWell Test Course ExecirsesBambang AriyantoNoch keine Bewertungen

- Compositional and Black Oil Reservoir SimulationDokument8 SeitenCompositional and Black Oil Reservoir SimulationCamiloAndresGuerreroNoch keine Bewertungen

- Assigement 1 Pete 473Dokument7 SeitenAssigement 1 Pete 473Lija BinuNoch keine Bewertungen

- RTA Example Files: Table of Contents Example Name File Type Concepts IllustratedDokument1 SeiteRTA Example Files: Table of Contents Example Name File Type Concepts Illustratedwizerth apkNoch keine Bewertungen

- Gas Lift DataDokument37 SeitenGas Lift DatavissusamuraiNoch keine Bewertungen

- Undersaturated Oil-Gas Simulation - Impes Type Solution: o Os GS So oDokument9 SeitenUndersaturated Oil-Gas Simulation - Impes Type Solution: o Os GS So onaefmubarakNoch keine Bewertungen

- Project Res - Sim - Assignment SP17 1Dokument5 SeitenProject Res - Sim - Assignment SP17 1Priozky Pratama PurbaNoch keine Bewertungen

- HW 13Dokument5 SeitenHW 13Yahya TawakalNoch keine Bewertungen

- Part 15 Slug DST MDT IpttDokument15 SeitenPart 15 Slug DST MDT IpttChai CwsNoch keine Bewertungen

- EXP 2 Compressible Gas Flow 08-15 PDFDokument16 SeitenEXP 2 Compressible Gas Flow 08-15 PDFKamran MostajiriNoch keine Bewertungen

- Theme 2: Mohr Diagram: Exercise 2 - Mathematical Demonstration of The Existence of Principal StressesDokument8 SeitenTheme 2: Mohr Diagram: Exercise 2 - Mathematical Demonstration of The Existence of Principal StressesNAFISSA BOURQUIANoch keine Bewertungen

- A Comprehensive Comparative Study On Analytical PI-IPR CorrelationsDokument19 SeitenA Comprehensive Comparative Study On Analytical PI-IPR CorrelationsAgung Doank YessNoch keine Bewertungen

- Well Logging: KfupmDokument22 SeitenWell Logging: KfupmDatabase KevinNoch keine Bewertungen

- Handout 2 PTT Measurements PCB3013Dokument12 SeitenHandout 2 PTT Measurements PCB3013Chai CwsNoch keine Bewertungen

- The Flowing Material Balance Procedure L. Mattar R. Mcneil: This Article Begins On The Next PageDokument14 SeitenThe Flowing Material Balance Procedure L. Mattar R. Mcneil: This Article Begins On The Next PageAmr HegazyNoch keine Bewertungen

- Correlations StandingDokument14 SeitenCorrelations StandingIngrid GarciaNoch keine Bewertungen

- Deconvolution of Wellbore Pressure and Flow Rate: Fikrl J. Kuchuk, Richard G. Carter, LWS AyestaranDokument7 SeitenDeconvolution of Wellbore Pressure and Flow Rate: Fikrl J. Kuchuk, Richard G. Carter, LWS AyestaranSergio FloresNoch keine Bewertungen

- 780 2147 1 SMDokument17 Seiten780 2147 1 SMhari6622100% (1)

- Horizontal/Slant/Vertical Wells: SPE 24352 Analysis of L Nflow Performance Simulation of Solution-Gas Drive ForDokument10 SeitenHorizontal/Slant/Vertical Wells: SPE 24352 Analysis of L Nflow Performance Simulation of Solution-Gas Drive FormaharabdNoch keine Bewertungen

- A Simple Productivity Equation For Horizontal Wells Based On Drainage Area PDFDokument11 SeitenA Simple Productivity Equation For Horizontal Wells Based On Drainage Area PDFWALDO DAVID SILVA SANCHEZNoch keine Bewertungen

- Gas Lift Paper ResearchDokument15 SeitenGas Lift Paper Researchmuki10Noch keine Bewertungen

- Unsolicited Rec'D: Statoil As., N-4001" Stavanger NorwayDokument23 SeitenUnsolicited Rec'D: Statoil As., N-4001" Stavanger NorwaySergio FloresNoch keine Bewertungen

- This Paper Reviews The Standard Experiments Performed in Laboratories About Constant Composition ExpansionDokument5 SeitenThis Paper Reviews The Standard Experiments Performed in Laboratories About Constant Composition Expansionyayay yayayaNoch keine Bewertungen

- Permeability Determination From Well Log DataDokument10 SeitenPermeability Determination From Well Log DataJorgeNoch keine Bewertungen

- Part 3 Global Reservoir Flow Regimes AzebDokument38 SeitenPart 3 Global Reservoir Flow Regimes AzebChai CwsNoch keine Bewertungen

- 13 - Incremental Oil PDFDokument8 Seiten13 - Incremental Oil PDFJuan Andres DuranNoch keine Bewertungen

- Correlations For Fluid Physical Property Prediction: 968 Journal of Petroleum TechnologyDokument3 SeitenCorrelations For Fluid Physical Property Prediction: 968 Journal of Petroleum TechnologyHassaanAhmedNoch keine Bewertungen

- Well Testing: (1) Productivity TestsDokument48 SeitenWell Testing: (1) Productivity TestsAhmed RaafatNoch keine Bewertungen

- 10 Type CurvesDokument18 Seiten10 Type CurvesJun Hao HengNoch keine Bewertungen

- Blasingame Decline Type CurveDokument6 SeitenBlasingame Decline Type Curvecamelion3Noch keine Bewertungen

- Exercises On Fluid Flow in HC ReservoirsDokument3 SeitenExercises On Fluid Flow in HC ReservoirsMohamed SahnounNoch keine Bewertungen

- Part 16 Horizontal Well TestingDokument16 SeitenPart 16 Horizontal Well TestingChai CwsNoch keine Bewertungen

- Productivity Index SPE-19823-MSDokument10 SeitenProductivity Index SPE-19823-MSmaharabd100% (1)

- PVT ExpressDokument28 SeitenPVT ExpressAlbertoNoch keine Bewertungen

- Relative Permeability PDFDokument12 SeitenRelative Permeability PDFsawanNoch keine Bewertungen

- Spe 101388 MS PDokument18 SeitenSpe 101388 MS PMuhammed Al-BajriNoch keine Bewertungen

- SPE 77386 Analysis of Black Oil PVT Reports Revisited: B B B at P PDokument5 SeitenSPE 77386 Analysis of Black Oil PVT Reports Revisited: B B B at P PJuan MartinezNoch keine Bewertungen

- CH 1 Gas Deliverability LectureDokument43 SeitenCH 1 Gas Deliverability LectureKesev KeshavNoch keine Bewertungen

- Review of Simple Forms of Equations of State: Ali Kh. Al-MatarDokument24 SeitenReview of Simple Forms of Equations of State: Ali Kh. Al-MatarAriel100% (1)

- Fulltext01 PDFDokument133 SeitenFulltext01 PDFAlexandru CroitoruNoch keine Bewertungen

- SPE00014265 - Sutton - Compressibility Factor PDFDokument16 SeitenSPE00014265 - Sutton - Compressibility Factor PDFsergiojgsNoch keine Bewertungen

- Spe 8206 Pa PDFDokument12 SeitenSpe 8206 Pa PDFSuci Nur HidayahNoch keine Bewertungen

- Example #11-Evaluating Spacing (Example11.csv)Dokument1 SeiteExample #11-Evaluating Spacing (Example11.csv)wizerth apkNoch keine Bewertungen

- CAP6 Whitson Phase BehaviorDokument21 SeitenCAP6 Whitson Phase BehaviorMaría José MartínezNoch keine Bewertungen

- SPE 35713 HrorizontalwellEqDokument12 SeitenSPE 35713 HrorizontalwellEqDaniel SalaNoch keine Bewertungen

- Part 13 Gas Well TestingDokument47 SeitenPart 13 Gas Well TestingChai CwsNoch keine Bewertungen

- Eclipse Tutorial2 PDFDokument15 SeitenEclipse Tutorial2 PDFAnonymous 0QHl5rz91Noch keine Bewertungen

- Well Test Analysis in Volatile Oil ReservoirsDokument18 SeitenWell Test Analysis in Volatile Oil ReservoirsDICKSON TOYO100% (1)

- Part - 5 - Semilog Analysis For Oil WellsDokument32 SeitenPart - 5 - Semilog Analysis For Oil WellsChai CwsNoch keine Bewertungen

- 5-Reservoir Fluid Property Correlations State of The ArtDokument9 Seiten5-Reservoir Fluid Property Correlations State of The ArtAnonymous Vbv8SHv0bNoch keine Bewertungen

- Gas Natural Transmision PDFDokument43 SeitenGas Natural Transmision PDFRodrigo Vasquez GonzalesNoch keine Bewertungen

- Gas Natural TransmisionDokument43 SeitenGas Natural Transmisionangel3reyesNoch keine Bewertungen

- SPE-14098-PA Raghavan Well-Test Analysis For Multiphase FlowDokument10 SeitenSPE-14098-PA Raghavan Well-Test Analysis For Multiphase FlowLorena CamposNoch keine Bewertungen

- SPE 16984 PA - PDF Performance Predictions For Gas Condensate ReservoirsDokument9 SeitenSPE 16984 PA - PDF Performance Predictions For Gas Condensate Reservoirsswaala4realNoch keine Bewertungen

- PV ManualDokument102 SeitenPV ManualLind D. QuiNoch keine Bewertungen

- High Volume Insert PCP TechnologyDokument9 SeitenHigh Volume Insert PCP TechnologyLind D. QuiNoch keine Bewertungen

- Baker 2 Phase FlowDokument2 SeitenBaker 2 Phase FlowLind D. QuiNoch keine Bewertungen

- 2K MethodDokument5 Seiten2K MethodLind D. QuiNoch keine Bewertungen

- Pressure Relief Valve Engineering HandbookDokument93 SeitenPressure Relief Valve Engineering Handbookakrouti92% (12)

- Taylor ForgeDokument204 SeitenTaylor ForgeLind D. Qui100% (3)

- Gas Processing: Equipment and Process EngineeringDokument12 SeitenGas Processing: Equipment and Process EngineeringLind D. QuiNoch keine Bewertungen

- Formation of ElementsDokument17 SeitenFormation of ElementsWinde SerranoNoch keine Bewertungen

- PhysicsDokument11 SeitenPhysicsdeondremorris56Noch keine Bewertungen

- UBD Physics Unit 2 - Energy and The EnviornmentDokument5 SeitenUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaNoch keine Bewertungen

- Ari Faba Plus - Kvs Diagram PDFDokument32 SeitenAri Faba Plus - Kvs Diagram PDFgiuseppe.timpone1100% (1)

- Black SmokerDokument25 SeitenBlack SmokergilangNoch keine Bewertungen

- How To Design and Build A Combat RobotDokument14 SeitenHow To Design and Build A Combat RobotBenjie Pasagdan MagallanoNoch keine Bewertungen

- Energy TypesDokument3 SeitenEnergy TypesSuki TsangNoch keine Bewertungen

- Product Specifications: CharacteristicsDokument5 SeitenProduct Specifications: CharacteristicsDaniel Herrera AstudilloNoch keine Bewertungen

- Astrology WebcourseDokument310 SeitenAstrology Webcoursexlearner100% (18)

- ACI 350-06 ErrataDokument7 SeitenACI 350-06 ErrataLuis Ariel B. MorilloNoch keine Bewertungen

- Science 8 ExamDokument5 SeitenScience 8 Examangge21100% (1)

- Lx400 PDFDokument3 SeitenLx400 PDFbalab2311Noch keine Bewertungen

- MFMDokument11 SeitenMFMtaboogaNoch keine Bewertungen

- RINOL Surgical Medical Industrial Flooring Application and CatalogueDokument6 SeitenRINOL Surgical Medical Industrial Flooring Application and CataloguedesignfNoch keine Bewertungen

- LG mds712Dokument71 SeitenLG mds712Usman GoodNoch keine Bewertungen

- Ation Words That Best Completes The SentenceDokument8 SeitenAtion Words That Best Completes The SentenceMG's Fhya Part II0% (1)

- Feasibility Study Part-I Thermal Hydraulic Analysis of Leu Target For 99mo Production in Tajoura ReactorDokument8 SeitenFeasibility Study Part-I Thermal Hydraulic Analysis of Leu Target For 99mo Production in Tajoura Reactorbsebsu7901Noch keine Bewertungen

- Second Grading Grade 9Dokument2 SeitenSecond Grading Grade 9VINES100% (1)

- The Knelson Concentrator: Application and Operation at RoseberyDokument9 SeitenThe Knelson Concentrator: Application and Operation at RoseberyVivek RanganathanNoch keine Bewertungen

- Solving Word Problems in ScienceDokument3 SeitenSolving Word Problems in ScienceChrisel Luat LopezNoch keine Bewertungen

- RH98Dokument2 SeitenRH98Arun Jacob CherianNoch keine Bewertungen

- 942 15Dokument1 Seite942 15Gia Trish100% (2)

- Volcanic SoilsDokument14 SeitenVolcanic SoilsVictor Hugo BarbosaNoch keine Bewertungen

- Tackifierdispersions 100106010935 Phpapp01 PDFDokument37 SeitenTackifierdispersions 100106010935 Phpapp01 PDFCarina CarvalhoNoch keine Bewertungen

- ACI 504 (R1997) Guide To Sealing Joints in Concrete StructuresDokument44 SeitenACI 504 (R1997) Guide To Sealing Joints in Concrete Structuresphilipyap100% (1)

- Soal US GanjilDokument25 SeitenSoal US GanjilRick DoNoch keine Bewertungen

- Vantablack - Wikipedia PDFDokument3 SeitenVantablack - Wikipedia PDFsamardotsinghNoch keine Bewertungen

- 3 V/5 V, 450 A 16-Bit, Sigma Delta ADC AD7715 : Ma Max at 3 V SuppliesDokument32 Seiten3 V/5 V, 450 A 16-Bit, Sigma Delta ADC AD7715 : Ma Max at 3 V SuppliesMichele BacocchiaNoch keine Bewertungen

- Ortho TRX LineDokument16 SeitenOrtho TRX LineAliOucharNoch keine Bewertungen

- Peda Office Complex: Study ByDokument12 SeitenPeda Office Complex: Study ByRiya RajNoch keine Bewertungen