Beruflich Dokumente

Kultur Dokumente

Lab05 FatigueTest PDF

Hochgeladen von

noor590Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lab05 FatigueTest PDF

Hochgeladen von

noor590Copyright:

Verfügbare Formate

LAB

FATIGUE TEST

INTRODUCTION

Most machinery and many structures do not operate under a constant load and

stress. In fact, these loads and stresses are constantly changing. A good

example of this is a rotating shaft such as the axle on a railroad car. The bending

stresses change from tension to compression as the axle rotates. This constant

change in stress can cause fatigue failure in which the material suddenly

fractures. The process that leads to fatigue failure is the initiation and growth of

cracks in the material. Fracture occurs when the crack grows so large that the

remaining uncracked material can no longer support the applied loads. Fatigue

may be defined as a cyclic (or stochastic) time-dependent loading or straining of

a material. The change in the loading with respect to time is more common from

an engineering perspective and is generally considered to be mechanically

induced. Some examples of this are: the changing compressive and tensile

stresses due to the rotation of a train or car axle; the forces on an airplane wing;

the forces on structural components of buildings, etc.

EXPERIMENTAL PROCEDURES

Equipment

Fatigue testing machine of rotary bending fatigue method is used in order to

perform the experimental work. The machine is designed and manufactured by

the testing equipment division of SHIMAZU CORPORATION Company. The

model of the machine is H. This machine model is especially designed to

determine fatigue properties under room and high temperature. The fatigue

machine is shown schematically in Figure . Table also gives the general

specifications of the fatigue machine.

Figure Schematic drawing of the fatigue machine

Table Main specifications of Fatigue Machine

Maximum bending motor kg/m

Testing speed ~ r.p.m

Inverter

Mitsubishi inverter device,

frequency of A

Driving motor Three phases, V, W

Machine dimensions

WDH in mm

(changing of the test revolution speed is due to using of inverter)

No. Item Name No. Item Name

1 Driving motor 7 Arm lever

2 Rotary pivot of left rotary spindle 8 Right rotary spindle

3 Left rotary spindle 9 Loading rod

4

Center of loading applied on the

left spindle

10 Loading jack

5 Hanger of the left spindle 11 Rotary pivot of right rotary spindle

6 Specimen 12 Receiver plate of load system

Specimen Dimensions

The dimensions of the specimen used in the experimental work are given in

Figure . However, Figure shows the other dimensions of the testing

specimens used for testing under high temperature.

Figure Dimensions of fatigue specimens

Figure Fatigue specimen used for testing under high temperature

Experimental Procedures

The procedures of each experiment run are determined as the following:

- The specimen is inserted inside the left and right grips of the machine spindle.

- Special weight (delivered with the machine) is placed on the receiving plate of

the loading mechanism to compensate the unbalance of both left and right

rotary spindles.

- The predetermined weights to apply the required stress

- The motor of the machine is started up and the test is run after adjusting the

motor revolution per minutes during testing at 2500 r.p.m.

- During testing the number of revolution, N, is digitally recorded by using built-

in photocell attached at the end of the right rotary spindle which contains

toothed disc rotate with the spindle between the two sides of the photocell

sensor. The signal of the photocell is transmitted to a digital counter mounted

on the machine

- After fracturing the machine is stopped automatically and the number of

revolution at fracturing is displayed on the front panel of the machine.

- The test is repeated under different load until adequate numbers of points can

be plot to obtain the S-N curve

Students Work

TENSION TEST

:

.................................................................. ...................... ..........................

:

................................................

:

........

:

.................................................................. ...................... ..........................

:

................................................

:

........

:

.................................................................. ...................... ..........................

:

................................................

:

........

:

................................. ................................. ...................... ..........................

:

................................................

:

........

:

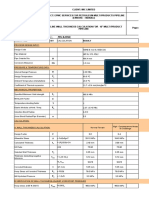

The following data are obtained from a previous test it is required to plot any

group data on simelog scale and determine the endurance limit.

The fatigue data for a brass alloy are given as follows:

Group

Stress

(MPa)

Cycles to

Failure

170 3.7 x 10

4

148 1.0 x 10

5

130 3.0 x 10

5

114 1.0 x 10

6

92 1.0 x 10

7

80 1.0 x 10

8

74 1.0 x 10

9

Group

Stress

(MPa)

Cycles to

Failure

470 1.0 x 10

4

440 3.0 x 10

4

390 3.0 x 10

5

350 3.0 x 10

5

310 1.0 x 10

6

290 3.0 x 10

6

285 1.0 x 10

7

Group

Stress

(MPa)

Cycles to

Failure

345 8.0 x 10

3

276 4.0 x 10

4

207 2.5 x 10

5

138 1.0 x 10

6

69 5.0 x 10

7

65 1.0 x 10

8

60 1.0 x 10

9

Group

Stress

(MPa)

Cycles to

Failure

965 800

825 1.4 x 10

3

690 3.0 x 10

3

550 7.0 x 10

5

400 1.0 x 10

7

380 5.0 x 10

7

370 1.0 x 10

8

Group

Stress

(MPa)

Cycles to

Failure

350 3.7 x 10

4

300 1.0 x 10

5

250 3.0 x 10

5

230 1.0 x 10

6

185 1.0 x 10

7

160 1.0 x 10

8

150 1.0 x 10

9

Group

Stress

(MPa)

Cycles to

Failure

940 1.0 x 10

4

880 3.0 x 10

4

780 3.0 x 10

5

700 3.0 x 10

5

620 1.0 x 10

6

580 3.0 x 10

6

570 1.0 x 10

7

Das könnte Ihnen auch gefallen

- Machine Design Elements and AssembliesVon EverandMachine Design Elements and AssembliesBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Mechanical Advantage of Inclined PlaneDokument4 SeitenMechanical Advantage of Inclined PlaneShuja MarwatNoch keine Bewertungen

- Fatigue Test DesignDokument5 SeitenFatigue Test Designamir_homNoch keine Bewertungen

- Lab7 Fatigue Testing MachineDokument13 SeitenLab7 Fatigue Testing MachineHosam0% (1)

- Assignment 2Dokument2 SeitenAssignment 2just0% (2)

- Som Lab ManualDokument33 SeitenSom Lab ManualRakheeb BashaNoch keine Bewertungen

- Tensile TestDokument9 SeitenTensile Testonkod1Noch keine Bewertungen

- CH 14Dokument13 SeitenCH 14mssaber77Noch keine Bewertungen

- Compression Test Lab ReportDokument11 SeitenCompression Test Lab ReportRobert K OtienoNoch keine Bewertungen

- Mechanics of Material Lab Report Angle of TwistDokument6 SeitenMechanics of Material Lab Report Angle of TwistAhsan MumtazNoch keine Bewertungen

- Clutches and BrakesDokument77 SeitenClutches and BrakesKaushikUpadyaNoch keine Bewertungen

- Tensile Testing of Ferrous and Non-Ferrous AlloyDokument7 SeitenTensile Testing of Ferrous and Non-Ferrous Alloyrama100% (1)

- 11 Heat TreatmentDokument5 Seiten11 Heat TreatmentamokhtaNoch keine Bewertungen

- Module 4 Mechanical Properties of Engineering MaterialsDokument11 SeitenModule 4 Mechanical Properties of Engineering MaterialsChristopher NazarenoNoch keine Bewertungen

- Machine Design IIDokument23 SeitenMachine Design IIBinar Arum OktaviaNoch keine Bewertungen

- Machine Design by S K Mondal PDFDokument81 SeitenMachine Design by S K Mondal PDFYuuvraj SinghNoch keine Bewertungen

- Result: 500 MM 50 MM Specimen W, LoadDokument21 SeitenResult: 500 MM 50 MM Specimen W, LoadamirulfahmieNoch keine Bewertungen

- Ejercicios 3DDokument6 SeitenEjercicios 3DDaniel Joya BeltranNoch keine Bewertungen

- PDFDokument3 SeitenPDFRajkumar ANoch keine Bewertungen

- CVE 230. Lab Report 3 (Compression Tests On Douglar Fir and Ponderosa Pine Wood) .Dokument7 SeitenCVE 230. Lab Report 3 (Compression Tests On Douglar Fir and Ponderosa Pine Wood) .Juan VillaNoch keine Bewertungen

- Tensile TestDokument9 SeitenTensile TestDhana KumaranNoch keine Bewertungen

- Fatigue Test ProcedureDokument30 SeitenFatigue Test ProcedureAsprilla Mangombe100% (1)

- Fatigue Test Lab ReportDokument1 SeiteFatigue Test Lab Reportforgamingpps0% (2)

- UtmDokument7 SeitenUtmMirza Aqeel AhmedNoch keine Bewertungen

- Metallography:: Steps To Reveal Microstructures of A SpecimenDokument7 SeitenMetallography:: Steps To Reveal Microstructures of A SpecimenJoyce Saddhu MeettooNoch keine Bewertungen

- Precipitation Hardening in 350 Grade Maraging SteelDokument14 SeitenPrecipitation Hardening in 350 Grade Maraging SteelAriel NemcoNoch keine Bewertungen

- Literature Review Spur GearDokument3 SeitenLiterature Review Spur Gearthai avvaiNoch keine Bewertungen

- HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFDokument18 SeitenHES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFrisirarocksNoch keine Bewertungen

- Creep TestDokument4 SeitenCreep TestFerry Ferdiansyah50% (2)

- Tensile TestingDokument8 SeitenTensile TestingAddrien DanielNoch keine Bewertungen

- PHY203Dokument237 SeitenPHY203MitrabhanuNoch keine Bewertungen

- Woven Fibre Glass Tensile StrengthDokument11 SeitenWoven Fibre Glass Tensile StrengthDonald MathabelaNoch keine Bewertungen

- Hardness TestDokument8 SeitenHardness TestFakhrul MuizzNoch keine Bewertungen

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Dokument8 SeitenAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNoch keine Bewertungen

- Thermo 1 & 2Dokument4 SeitenThermo 1 & 2Oloj YuNoch keine Bewertungen

- Tensile Test WorksheetDokument5 SeitenTensile Test WorksheetRaj Das100% (1)

- Fatigue Ch12Dokument87 SeitenFatigue Ch12Bolaji Suberu100% (1)

- Exp-5 Heat Balance Sheet PDFDokument5 SeitenExp-5 Heat Balance Sheet PDFNarender NarruNoch keine Bewertungen

- Mechanics of Materials Torsion TestDokument18 SeitenMechanics of Materials Torsion Testjrkling100% (1)

- 3.1 Basic Principle of Wind Energy ConversionDokument4 Seiten3.1 Basic Principle of Wind Energy ConversionnandhakumarmeNoch keine Bewertungen

- Lab ReportDokument3 SeitenLab Reportdeanellis100% (1)

- Binary CycleDokument14 SeitenBinary CycleSuheal SkNoch keine Bewertungen

- Lec. 01) TRIBOLOGY OutlinesDokument17 SeitenLec. 01) TRIBOLOGY OutlinesAhmedAhmedNoch keine Bewertungen

- Single Stage CompressorDokument5 SeitenSingle Stage CompressorHaziq HanifahNoch keine Bewertungen

- Lab 2Dokument14 SeitenLab 2Dilshad S FaisalNoch keine Bewertungen

- Experimental Elasticity 2ed - SearleDokument218 SeitenExperimental Elasticity 2ed - Searlejrfisico2011Noch keine Bewertungen

- Solve: 196.13 KG/CM 242.2 KG/CMDokument9 SeitenSolve: 196.13 KG/CM 242.2 KG/CMAhmed ShakerNoch keine Bewertungen

- WL377e - Natural Convection and Radiation - V0.1Dokument49 SeitenWL377e - Natural Convection and Radiation - V0.1Petrônio PauloNoch keine Bewertungen

- Experiment No. (2) : Determination of Liquid Viscosity by Stock'S MethodDokument5 SeitenExperiment No. (2) : Determination of Liquid Viscosity by Stock'S MethodKawar Abid100% (1)

- Mechanical Behaviour Laboratory MSE 313: Laboratory ManualDokument41 SeitenMechanical Behaviour Laboratory MSE 313: Laboratory ManualVenkteshwarlu KNoch keine Bewertungen

- Chapter 8: Designing For Heating and CoolingDokument11 SeitenChapter 8: Designing For Heating and CoolingmegaspiceNoch keine Bewertungen

- Torsion TestingDokument10 SeitenTorsion TestingSean BruegmanNoch keine Bewertungen

- Ch.3 Support Reactions of BeamsDokument5 SeitenCh.3 Support Reactions of BeamsUmesh ShindeNoch keine Bewertungen

- Take Home QuizDokument8 SeitenTake Home QuizAshley SimmonsNoch keine Bewertungen

- Expt 5 (A) - Rotating Bending Fatigue Testing PDFDokument5 SeitenExpt 5 (A) - Rotating Bending Fatigue Testing PDFjyoti swaroop repaka100% (2)

- Assignment 2Dokument28 SeitenAssignment 2ahsan aliNoch keine Bewertungen

- Design, Fabrication and Testing of Human Powered Water PurifierDokument8 SeitenDesign, Fabrication and Testing of Human Powered Water PurifierIJRASETPublicationsNoch keine Bewertungen

- Lab Report DilatometerDokument7 SeitenLab Report DilatometerTaqqi HaiderNoch keine Bewertungen

- Cam Analysis ApparatusDokument7 SeitenCam Analysis ApparatusGurmeet Mehma100% (6)

- Lab 4 Fatigue Test: EquipmentDokument4 SeitenLab 4 Fatigue Test: EquipmentBotol KosongNoch keine Bewertungen

- Design of Welded Steel StructuresDokument198 SeitenDesign of Welded Steel StructuresyogeshNoch keine Bewertungen

- Chapter 5 Principal Stresses PDFDokument61 SeitenChapter 5 Principal Stresses PDFcoded coderNoch keine Bewertungen

- Gas Line - 20 BargDokument22 SeitenGas Line - 20 Bargsaravanakkumar boominahtan100% (1)

- Coaching Design - 01 May 2022Dokument104 SeitenCoaching Design - 01 May 2022Mayya Bona100% (1)

- Elasticity 1Dokument32 SeitenElasticity 1Sesha Sai KumarNoch keine Bewertungen

- Foundation Repair and StrengtheningDokument24 SeitenFoundation Repair and Strengtheningnimmi kpNoch keine Bewertungen

- Unit 1 Compressibility of Soil (Part 2)Dokument8 SeitenUnit 1 Compressibility of Soil (Part 2)Joshua John JulioNoch keine Bewertungen

- 2006 Structural Seismic Design Manual 1Dokument220 Seiten2006 Structural Seismic Design Manual 1Charugalla Jeevan Phani Sreeram100% (1)

- Stell G+5 Design ReportDokument7 SeitenStell G+5 Design ReportVirat DesaiNoch keine Bewertungen

- Research Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDADokument4 SeitenResearch Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDAAyush GoyalNoch keine Bewertungen

- Hollow Pot Design WorksheetDokument7 SeitenHollow Pot Design Worksheetpatrick chegeNoch keine Bewertungen

- Chapter 1Dokument18 SeitenChapter 1ephNoch keine Bewertungen

- 8fc63d2f f6Dokument18 Seiten8fc63d2f f6Chandra MohanNoch keine Bewertungen

- From Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDokument5 SeitenFrom Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDipakNoch keine Bewertungen

- Astm E1820-20aDokument65 SeitenAstm E1820-20aMehdi Gouader100% (2)

- Pdam DentsDokument9 SeitenPdam DentsnankingNoch keine Bewertungen

- Fatigue Performance of Sour Deepwater Riser WeldsDokument21 SeitenFatigue Performance of Sour Deepwater Riser WeldsshervinyNoch keine Bewertungen

- Stress Strain Curve-1Dokument5 SeitenStress Strain Curve-1AsadNoch keine Bewertungen

- Appendix - F - 147645033 012 R Rev0Dokument58 SeitenAppendix - F - 147645033 012 R Rev0bufaloteNoch keine Bewertungen

- Structural Use of Bamboo: Part 4: Element Design EquationsDokument10 SeitenStructural Use of Bamboo: Part 4: Element Design EquationsNgissah NketiahNoch keine Bewertungen

- Helical SpringDokument7 SeitenHelical SpringSalam Albaradie100% (4)

- Seismic Strengthening of Reinforced Concrete Bridge Pier With FRP CompositesDokument8 SeitenSeismic Strengthening of Reinforced Concrete Bridge Pier With FRP CompositesVipin Kumar ParasharNoch keine Bewertungen

- Types of Failure Failure Theories For Ductile Materials Failure Theories For Brittle MaterialsDokument6 SeitenTypes of Failure Failure Theories For Ductile Materials Failure Theories For Brittle MaterialsArturo GonzalezNoch keine Bewertungen

- Additional Calculation For Folding DoorDokument14 SeitenAdditional Calculation For Folding DoorNoman AliNoch keine Bewertungen

- Pressuremeter Testing An IntroductionDokument17 SeitenPressuremeter Testing An IntroductionVeenoyNoch keine Bewertungen

- BOLTGRPDokument18 SeitenBOLTGRPPascal Gino BirkenborgNoch keine Bewertungen

- Understanding Loss Modulus and Tan DeltaDokument7 SeitenUnderstanding Loss Modulus and Tan DeltaJohn BenedictNoch keine Bewertungen

- Soil 6 Ap (Ril 2023Dokument2 SeitenSoil 6 Ap (Ril 2023Nica SudamaNoch keine Bewertungen

- SUB.: TAE-2 Topic:-: G. H. Raisoni College of Engineering & Management Pune (An Autonomous Institute Affiliated To SPPU)Dokument19 SeitenSUB.: TAE-2 Topic:-: G. H. Raisoni College of Engineering & Management Pune (An Autonomous Institute Affiliated To SPPU)Rishi ChoudharyNoch keine Bewertungen

- Methods of Analysis For Earthquake Resistant Structures Wendor CherekeDokument40 SeitenMethods of Analysis For Earthquake Resistant Structures Wendor CherekeTem Pouno100% (1)