Beruflich Dokumente

Kultur Dokumente

SAIC-W-2006 Rev 0

Hochgeladen von

philipyapOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAIC-W-2006 Rev 0

Hochgeladen von

philipyapCopyright:

Verfügbare Formate

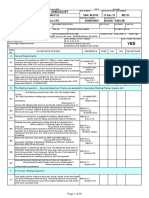

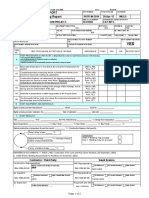

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Welding Inspection

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2006

WBS / BI / JO NUMBER

25-May-05

WELD-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A A1

ACCEPTANCE CRITERIA Joint preparation & cleanliness: Weld number and Welder symbol are marked adjacent to the weld joint. (NOTE: Markings shall be made with a suitable weather-proof marking material.) Weld joint identification markings conformed with the requirements of the approved Weld Joint Identification System per SAIC-W-2008. (NOTE: Project QA/QC and PID may attach the weld numbering system as Attachment 1 to this checklist. ) An approved Welding Procedure (WPS) is available at the weld site. (NOTE: Page A1 of the Welding Procedure Approval Request requires signature by the Saudi Aramco Inspection Agency. ) Welder(s) have been issued Job Clearance Card, and that range of qualification shown matches the application of WPS being used. Oil, moisture, scale, rust, paint (except an approved weldable primer), metallic coatings (e.g. zinc) or other foreign matter, has been removed from the weld surface and at least 25mm of the adjacent base metal surface. Coated and clad or overlaid surfaces are protected from the welding arc, associated weld spatter, and damage from ground clamps or other associated equipment. Stainless steel and nonferrous material is cleaned with grinding wheels or stainless steel brushes, not previously used on other materials. Welding Environment: Wind shields or tents are installed when the wind is strong enough to affect arc stability or shielding gas coverage. The wind velocity in the weld area for GTAW, GMAW, or gas shielded FCAW shall not exceed 8 kph (2.2 m/s). Welding is not done during inclement weather e.g., wind blown sand, rain etc. For field welding, remote Current controls shall be used if the welding is more than 30 m from the welding power source or when the welders are working in "remote" locations (e.g., on an elevated piperack). Welding power supplies for use in welding where impact toughness test is required by the code or standard are verified to have been validated within 1 year in accordance with BS 7570. Welding Consumables Filler metal size, type and classification conform with the WPS. (NOTE: A change in filler metal or deposit chemistry from A-number 1 (based on ASME SEC IX) to A-number 2 and vice-versa is not permitted without approval .)

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

SAES-W-011, Para. 16.1 SAES-W-011, Para. 16.2

A2

A2

SAES-W-011, Para. 7.1.8 SAEP-324, Sec. 5 SAES-W-011, Para. 11.3.1

A3

A4

A5

SAES-W-011, Para. 11.11 SAES-W-011, Para. 11.4.3

A6 B B1 B2 B3

SAES-W-011, Para. 11.2.1 & 11 2 3 SAES-W-011, Para. 11.2.1 SAES-W-011, Para. 11.2.2 SAES-W-011, Para. 19.1

B4

B5

SAES-W-011, Para. 19.2

C1

SAES-W-011, Para. 7.4.5

Page 1 of 4

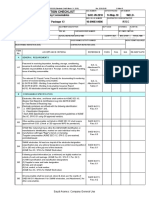

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Welding Inspection

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2006

WBS / BI / JO NUMBER

25-May-05

WELD-

CONTRACTOR / SUBCONTRACTOR

ITEM No. C2

ACCEPTANCE CRITERIA Filler Metal and other weld consumables at weld site are maintained as per SAIC-W-2032. Welding consumables shall be of the same brand, type and maximum size as indicated on the WPS for the following welding processes: a. GMAW electrode to be used for procedures with impact toughness requirements b. SAW flux c. FCAW electrode d. WPS/PQR using any consumable with a "G" designation (ASME SEC IIC) per SAES-W-011, Para. 7.4.8. Preheat Wet or damp weld joints are surface dried by heating to a distance of 100mm from the toe, and are hand warm before welding. The actual preheat temperature was selected and used by the fabricator that is sufficient to prevent cracking and to achieve the required hardness,or, shall not be less than the greater of the following: a) 10C. b) The required or recommended preheat listed in ASME B31.3. c) Pre-heat temperatures from Std. Drg. W-AE-036451for all ASME P-No. 1 materials, including API grades up to and including X60. d) The preheat listed in Tables 3A and 3B for the SMAW process. e) Temperature determined by CSD for steels with specified minimum yield strengths above 60 ksi, (including API grades X65 or greater) or for materials not listed as an ASME P-number. f) Temperaturee as specified in the approved welding procedure. The preheat temperature shall be established over a minimum distance of 75 mm on each side of the weld. Temperature-indicating crayons, thermocouples, or contact pyrometers shall be used to measure preheat and interpass temperatures. Temperature indicating crayons have not been used for any weld joint that is to be coated, or that will have a heat-shrink sleeve installed on it. On wall thickness exceeding 25mm, preheat is done from the same side as the welding and heat source removed fro 1 minute prior to measuring the temperature. Back Purging & Shielding Gas Inert gas is used for GTAW or GMAW root passes on single-sided groove welds, on ASME P-No. 5 materials and higher. For P-No. 5 materials and higher, back purging is maintained until at least 10mm of the weld deposit thickness is completed. Nitrogen as a backing gas for austenitic stainless steel, is not used. Shielding gases conformed to the following requirements: a. Carbon dioxide (CO2): Federal Specification BC-C-101, Type B or Compressed Gas Association CGA G-6.2, Type F. b. Argon (Ar): Compressed Gas Association CGA G-11.1, Grade A. c. Other gases and gas mixtures with approval from CSD. Back purge for carbon and low alloy steel has reduced the oxygen level to below 1%. (NOTE: Verification is made by the use of oxygen analyzer. )

REFERENCE Project Quality Plan

PASS

FAIL

N/A

RE-INSP DATE

C3

SAES-W-011, Para. 7.4.4

D D1

SAES-W-011, Para. 12. 3

D2

SAES-W-011, Para. 12.1

D3

SAES-W-011, Para. 12.5 SAES-W-011, Para. 12.4 SAES-W-011, Para. 12. 4 SAES-W-011, Para. 12. 6

D4

D5

D6 E E1 E2 E3

SAES-W-011, Para. 11.14.1 SAES-W-011, Para. 11.14.2 SAES-W-011, Para. 11.14.3

E4

SAES-W-011, Para. 6.7

E5

SAES-W-011, Para. 11.14.4

Page 2 of 4

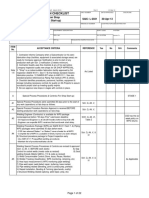

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Welding Inspection

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2006

WBS / BI / JO NUMBER

25-May-05

WELD-

CONTRACTOR / SUBCONTRACTOR

ITEM No. E6 F F1

ACCEPTANCE CRITERIA Back purge for stainless steel and nickel alloys has reduced the oxygen level to below 0.05%. Root Pass The direction of welding conforms with the WPS. (NOTE: If the WPS is not qualified in the vertical position, then the direction of welding shall be vertical-up. ) Each weld pass is thoroughly cleaned and all slag or other foreign matter removed before the next pass is deposited. NOTE: See WPS remarks for cleaning method, e.g. mechanical brush. Root pass is deposited without backing for WPS qualified for singlesided groove welds without backing. The GTAW process shall be used for the root pass of butt welds without backing in piping and nozzles of 50.8mm nominal diameter or less. (NOTE: Exempted are vent and drain piping open to the atmosphere or Category D piping. ) Hot Pass & Weld-Out The direction of welding conforms with the WPS. (NOTE: If the WPS is not qualified in the vertical position, then the direction of welding shall be vertical-up. ) Each weld pass is thoroughly cleaned and all slag or other foreign matter removed before the next pass is deposited. NOTE: See WPS remarks on cleaning method, e.g. mechanical brush. SAW Flux fused during welding shall not be reused (i.e., fluxes that use recrushed slag are not acceptable). The maximum allowable SMAW electrode sizes that can be used are given below. a) Low hydrogen electrodes - 5 mm for the 1G/1F position; 4 mm for all other positions. b) Non-low hydrogen electrodes - 5 mm for all positions. Remote Current controls are used if the welding is more than 30 m from the welding power source or when the welders are working in "remote" locations (e.g., on an elevated pipe rack). The heat input (HI) of each production weld is calculated (using the formula below) if notch-toughness tests are specified, and then confirmed not to exceed the heat input limits listed in the WPS's. HI (kj/cm) = Voltage X Amperage X 60/Travel Speed (cm/min) Adjacent weld beads shall be staggered and not started from the same location. All full penetration joints requiring double sided welding shall be ground or gouged to sound metal and inspected by penetrant testing (PT) or magnetic particle testing (MT) prior to welding the reverse side, unless exempted by SAES-W-011, Para. 7.4.11as follows: a) For automatic or mechanized processes if additional PQR testing is conducted. b) For other special processes, approved by CSD, on butt joints where the production weld will be radiographed. Unless specified otherwise, the maximum interpass temperature are: a. 177C for P-No. 8 and P-No. 4x materials and b. 315C for P-1 steels. Unless specified in the WPS, back welding is done using the same process, consumables and preheat as the fill passes.

REFERENCE SAES-W-011, Para. 11.14.5

PASS

FAIL

N/A

RE-INSP DATE

SAES-W-011, Para. 7.4.7.1 SAES-W-011, Para. 11.4.1 SAES-W-011, Para. 7.4.10 SAES-W-011, Para. 5.2.3

F2

F3

F4

G G1

SAES-W-011, Para. 7.4.7.1 SAES-W-011, Para. 11.4.1 SAES-W-011, Para. 6.5.2 SAES-W-011, Para. 11.1

G2

G3

G4

G5

SAES-W-011, Para. 19.1

G6

SAES-W-011, Para. 19.4 SAES-W-011, Para. 11.13

G7

G8

SAES-W-011, Para. 11.3.4

G9

SAES-W-011, Para. 12.7 SAES-W-011, Para. 11.17

G10

Page 3 of 4

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Welding Inspection

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-W-2006

WBS / BI / JO NUMBER

25-May-05

WELD-

CONTRACTOR / SUBCONTRACTOR

ITEM No. G11 G12

ACCEPTANCE CRITERIA Forced or accelerated cooling of welds is prohibited without the specific approval of CSD. All slag, flux, weld spatters, and undercuts are removed from the completed weld and surrounding areas.

REFERENCE SAES-W-011, Para. 11.18 SAES-W-011, Para. 11.4.2

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

ATTACHMENTS: 1. Attachment 1 - Weld Joint Identification/Markings (NOTE: This will be attached by the Project QA/QC & PID ) REFERENCE DOCUMENTS: 1. 2. 3. 4. 5. 6. SAES-W-011, Welding Requirements for On-Plot Piping, (30 October, 2002) SAEP-324, Certification Review and Registration of Project Welders and Brazers, (30 June, 2003) Std. Dwg. W-AE-036451, Pre-Heat Levels for Welding Carbon Steel, Rev 2 ASME B31.3, Process Piping, (2002) ASME SEC II Part C Specifications for Welding Rods, Electrodes, and Filler Metals, (1 July, 2001) ASME SEC IX - Qual. Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators, (7/12001)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 4 of 4

Das könnte Ihnen auch gefallen

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- SAIC M 2012 (Structural Welding)Dokument30 SeitenSAIC M 2012 (Structural Welding)rubda11100% (1)

- Satr-W-2008 Atyb TRDokument6 SeitenSatr-W-2008 Atyb TRDeo MNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDokument1 SeiteSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387Noch keine Bewertungen

- Saudi Aramco Test ReportDokument4 SeitenSaudi Aramco Test Reportkarthi51289Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection ChecklistManoj KumarNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDokument23 SeitenSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNoch keine Bewertungen

- Materials System SpecificationDokument7 SeitenMaterials System Specificationaanouar77Noch keine Bewertungen

- Saep 321Dokument25 SeitenSaep 321AbdullahNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDokument3 SeitenSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNoch keine Bewertungen

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionDokument5 SeitenSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنNoch keine Bewertungen

- Satr-W-2010Dokument1 SeiteSatr-W-2010Joni Carino SuniNoch keine Bewertungen

- SAIC-L-2035 Rev 6Dokument2 SeitenSAIC-L-2035 Rev 6biplabpal2009Noch keine Bewertungen

- Saudi Aramco Typical Inspection PlanDokument10 SeitenSaudi Aramco Typical Inspection Plankarthi51289Noch keine Bewertungen

- Aramco Pwht-QandA PDFDokument2 SeitenAramco Pwht-QandA PDFAnasNoch keine Bewertungen

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDokument3 SeitenSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument15 SeitenSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDokument2 SeitenWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDokument2 SeitenSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Aramco-Guide Testing QC Candidates (Piping-Hydro-Welding - Part 2 PDFDokument8 SeitenAramco-Guide Testing QC Candidates (Piping-Hydro-Welding - Part 2 PDFanon_585140390100% (1)

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDokument19 SeitenSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNoch keine Bewertungen

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Dokument2 SeitenSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNoch keine Bewertungen

- Weld Repair - PR - 0XXDokument10 SeitenWeld Repair - PR - 0XXRAMAKRISHNANoch keine Bewertungen

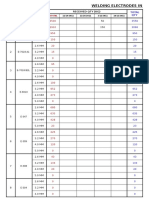

- Received Qty (KG) : SL# Electrode SizeDokument34 SeitenReceived Qty (KG) : SL# Electrode Sizepadinharethil50% (2)

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistJoni Carino SuniNoch keine Bewertungen

- GRE-RTR QC Responsibilities.Dokument1 SeiteGRE-RTR QC Responsibilities.ansar100% (1)

- Control of Welding Rejection Rate and NDT Backlog in MEGA ProjectDokument10 SeitenControl of Welding Rejection Rate and NDT Backlog in MEGA ProjectMubeenNoch keine Bewertungen

- SAIC-A-2008 Rev 0Dokument3 SeitenSAIC-A-2008 Rev 0Kristine Caye DatarioNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDokument5 SeitenSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNoch keine Bewertungen

- Saic L 2008 PDFDokument4 SeitenSaic L 2008 PDFHesham HelalNoch keine Bewertungen

- Interview Ques & Ans - KNPCDokument8 SeitenInterview Ques & Ans - KNPCStephen RajNoch keine Bewertungen

- Welder and Procedure QualificationDokument26 SeitenWelder and Procedure Qualification'Izzad AfifNoch keine Bewertungen

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDokument6 SeitenOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNoch keine Bewertungen

- SAEP-379 Quality Issues NotificationDokument4 SeitenSAEP-379 Quality Issues NotificationMusic And FunNoch keine Bewertungen

- L 1 Asad Ahmad Qaqc Piping Welding Ins PDFDokument9 SeitenL 1 Asad Ahmad Qaqc Piping Welding Ins PDFyasiriftikharNoch keine Bewertungen

- Satip A 004 03Dokument3 SeitenSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- 1 SATIP-L-108-01 Valve Installation-Rev 2Dokument15 Seiten1 SATIP-L-108-01 Valve Installation-Rev 2Md ShariqueNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument22 SeitenSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Saic L 2003Dokument9 SeitenSaic L 2003MAZHARULNoch keine Bewertungen

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Dokument2 Seiten1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- Satip W 014 01Dokument12 SeitenSatip W 014 01spravin231Noch keine Bewertungen

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Dokument4 Seiten1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764Noch keine Bewertungen

- 6GR RequirementsDokument1 Seite6GR Requirementswalitedison100% (1)

- Pipeline Weld Joint & Ragiograph Film Numbering SystemDokument9 SeitenPipeline Weld Joint & Ragiograph Film Numbering Systemgst ajah100% (2)

- Qualification of Procedure and Welder (19 February 2014)Dokument20 SeitenQualification of Procedure and Welder (19 February 2014)Zanuardi YahyaNoch keine Bewertungen

- SAIC-W-2006 Rev 0 PDFDokument4 SeitenSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNoch keine Bewertungen

- SAES-W-012 - Google Search3Dokument1 SeiteSAES-W-012 - Google Search3fayceal0% (1)

- Saep 351Dokument24 SeitenSaep 351Raj KumarNoch keine Bewertungen

- 2019 - Saep-1160Dokument24 Seiten2019 - Saep-1160smdriyazbashaNoch keine Bewertungen

- Materials System SpecificationDokument11 SeitenMaterials System Specificationimranb_001100% (1)

- Saep 1146Dokument8 SeitenSaep 1146Ronanki RaviNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saep 324Dokument13 SeitenSaep 324Up WeldNoch keine Bewertungen

- API 1104 SummaryDokument7 SeitenAPI 1104 Summarymohamedqc100% (1)

- Application Form For CSWIP 5 Year Renewal (Overseas)Dokument7 SeitenApplication Form For CSWIP 5 Year Renewal (Overseas)prabuNoch keine Bewertungen

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDokument2 SeitenSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- General Mechanical-2 PDFDokument6 SeitenGeneral Mechanical-2 PDFAhmed Shaban KotbNoch keine Bewertungen

- Saic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionDokument4 SeitenSaic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionAnsuman Kalidas100% (1)

- Split TeeDokument80 SeitenSplit TeeJohn Peter100% (1)

- SAIC-D-2022 Rev 2Dokument5 SeitenSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Fire Protection SysytemDokument5 SeitenFire Protection SysytemphilipyapNoch keine Bewertungen

- Piping and Ducting SupportDokument7 SeitenPiping and Ducting SupportphilipyapNoch keine Bewertungen

- Resilent FlooringDokument7 SeitenResilent FlooringphilipyapNoch keine Bewertungen

- Panel BoardDokument7 SeitenPanel BoardphilipyapNoch keine Bewertungen

- DuctworksDokument7 SeitenDuctworksphilipyapNoch keine Bewertungen

- Bazaar Tent StructureDokument5 SeitenBazaar Tent StructurephilipyapNoch keine Bewertungen

- Exterior LightingDokument8 SeitenExterior LightingphilipyapNoch keine Bewertungen

- Saudi Aramco Oil Company: SECTION 16110 RacewaysDokument10 SeitenSaudi Aramco Oil Company: SECTION 16110 RacewaysphilipyapNoch keine Bewertungen

- Wire, Cable and Low VotageDokument9 SeitenWire, Cable and Low VotagephilipyapNoch keine Bewertungen

- Finish CarpentryDokument17 SeitenFinish CarpentryphilipyapNoch keine Bewertungen

- Bazaar Tent StructureDokument5 SeitenBazaar Tent StructurephilipyapNoch keine Bewertungen

- Roof and Deck InsulationDokument3 SeitenRoof and Deck InsulationphilipyapNoch keine Bewertungen

- Sealant and CaulkingDokument8 SeitenSealant and CaulkingphilipyapNoch keine Bewertungen

- Chilled Water PumpDokument6 SeitenChilled Water PumpphilipyapNoch keine Bewertungen

- Sheet Membrance Water ProofingDokument6 SeitenSheet Membrance Water ProofingphilipyapNoch keine Bewertungen

- FanDokument7 SeitenFanphilipyap100% (1)

- Duct Works & AccessoriesDokument5 SeitenDuct Works & AccessoriesphilipyapNoch keine Bewertungen

- DuctworksDokument7 SeitenDuctworksphilipyapNoch keine Bewertungen

- SignageDokument4 SeitenSignagephilipyapNoch keine Bewertungen

- Variable Air UnitDokument4 SeitenVariable Air UnitphilipyapNoch keine Bewertungen

- Control SystemDokument21 SeitenControl SystemphilipyapNoch keine Bewertungen

- G.furniture & FixturesDokument2 SeitenG.furniture & FixturesphilipyapNoch keine Bewertungen

- Metal FramesDokument4 SeitenMetal FramesphilipyapNoch keine Bewertungen

- Fan Coil UnitsDokument3 SeitenFan Coil UnitsphilipyapNoch keine Bewertungen

- Metal FramesDokument4 SeitenMetal FramesphilipyapNoch keine Bewertungen

- Plumbing SpecialitiesDokument4 SeitenPlumbing SpecialitiesphilipyapNoch keine Bewertungen

- 03210-Epoxy Coated Conc ReoDokument7 Seiten03210-Epoxy Coated Conc ReophilipyapNoch keine Bewertungen

- Glass and GlazingDokument8 SeitenGlass and GlazingphilipyapNoch keine Bewertungen

- Floor MatsDokument3 SeitenFloor MatsphilipyapNoch keine Bewertungen

- Swimming PoolDokument4 SeitenSwimming PoolphilipyapNoch keine Bewertungen

- Surgical Sutures & BandagesDokument49 SeitenSurgical Sutures & BandagesAnni Sholihah100% (1)

- This PDF Is The Sample PDF Taken From Our Comprehensive Study Material For NEET & AiimsDokument13 SeitenThis PDF Is The Sample PDF Taken From Our Comprehensive Study Material For NEET & AiimsVikash Rao khatodiyaNoch keine Bewertungen

- (T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterDokument214 Seiten(T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterANTENOR JOSE ESCUDERO GÓMEZNoch keine Bewertungen

- Oxidation NumberDokument21 SeitenOxidation NumberChristian LopezNoch keine Bewertungen

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDokument20 SeitenFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenNoch keine Bewertungen

- Experiment A Test For Lipid Result: Result When Added To WaterDokument5 SeitenExperiment A Test For Lipid Result: Result When Added To WaterSuu Wan0% (2)

- The Municiplaity of Busia Solid Waste Management PlanDokument15 SeitenThe Municiplaity of Busia Solid Waste Management PlanToi JanetNoch keine Bewertungen

- The 7 TH International Conference On Unsaturated Soils (UNSAT2018)Dokument7 SeitenThe 7 TH International Conference On Unsaturated Soils (UNSAT2018)pooNoch keine Bewertungen

- REPORTDokument31 SeitenREPORTUnique Boss50% (2)

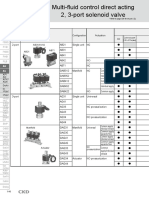

- General Purpose ValvesDokument46 SeitenGeneral Purpose ValvesbataNoch keine Bewertungen

- J.ultsonch.2014.08.022 InglesDokument48 SeitenJ.ultsonch.2014.08.022 InglesBrayan LuisNoch keine Bewertungen

- TWM 3178 PDSDokument2 SeitenTWM 3178 PDSsunnyooiNoch keine Bewertungen

- Oleic Acid TechnologiesDokument11 SeitenOleic Acid Technologiessoham kawaleNoch keine Bewertungen

- UO-II Chapter 4 (Adsorption)Dokument27 SeitenUO-II Chapter 4 (Adsorption)Ghaydah Hamed Rashid Al-AbriNoch keine Bewertungen

- Carbon and Its Compounds - Shobhit NirwanDokument17 SeitenCarbon and Its Compounds - Shobhit NirwanBhaskar 8287Noch keine Bewertungen

- WPS - PQR (Sa516 GR.70)Dokument4 SeitenWPS - PQR (Sa516 GR.70)miltonangulomorrisNoch keine Bewertungen

- Calculations in Furnace TechnologyDokument277 SeitenCalculations in Furnace Technologysakthivel100% (2)

- Gravimetric Analysis Laboratory ReportDokument9 SeitenGravimetric Analysis Laboratory ReportShawn RizalNoch keine Bewertungen

- Types of Chemical ReactionsDokument7 SeitenTypes of Chemical ReactionsAirene PalerNoch keine Bewertungen

- Dissolution TestDokument5 SeitenDissolution TestAlecza Mae SavellaNoch keine Bewertungen

- Table 1: Patient's Response On The Effectiveness of The Aratiles Leaves TeaDokument11 SeitenTable 1: Patient's Response On The Effectiveness of The Aratiles Leaves TeaAlice Del Rosario CabanaNoch keine Bewertungen

- tmpA3C2 TMPDokument11 SeitentmpA3C2 TMPFrontiersNoch keine Bewertungen

- Culligan MedallistDokument58 SeitenCulligan MedallistskballNoch keine Bewertungen

- HEPA Cleanroom Filter Testing PDFDokument4 SeitenHEPA Cleanroom Filter Testing PDFprovaoralNoch keine Bewertungen

- Wear Debris AnalysisDokument2 SeitenWear Debris Analysisthoma111sNoch keine Bewertungen

- CentrifugationDokument43 SeitenCentrifugationSudeeksha RavikotiNoch keine Bewertungen

- Interconection Pipe RackDokument16 SeitenInterconection Pipe RackPhucChuVanNoch keine Bewertungen

- Qw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationDokument7 SeitenQw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationHgagselim SelimNoch keine Bewertungen

- S.No. Type Medicine NameDokument6 SeitenS.No. Type Medicine Namered petalsNoch keine Bewertungen

- Exercises: Not One of The Possible Answers ListedDokument12 SeitenExercises: Not One of The Possible Answers ListedSarah ChoiNoch keine Bewertungen