Beruflich Dokumente

Kultur Dokumente

Fibrceptor FFP: Depth Microglass Coalescers With Integral Pre-Filter

Hochgeladen von

matteo2009Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fibrceptor FFP: Depth Microglass Coalescers With Integral Pre-Filter

Hochgeladen von

matteo2009Copyright:

Verfügbare Formate

FibrCeptor FFP

Depth Microglass Coalescers with Integral Pre-Filter

Remove particulate and aerosolized liquids from air and gas streams using the FibrCeptor FFP . The integral pleated pre-filter extends service life by preventing most particulate from reaching the coalescing media. The quality of these process streams impacts emissions, productivity, and product quality. As a part of a well designed gas treatment system the FibrCeptor FFP will ensure clean, dry air/gas to your process, helping to maintain optimum operational metrics.

SPECIFICATIONS

THE BOTTOM LINE Integral Pre-Filter Used in applications with a footprint that won't permit a separate stand alone pre-filter vessel, the FibrCeptor FFP provides extended element service life reducing maintenance and operating costs. The Right Choice for the Right Application An economical alternative to expensive pleated and engineered depth coalescers for applications with small aerosol concentrations or high temperature requirements. Provides superior efficiency and compatibility at a sensible price point. Structural Integrity The FibrCeptor FFP is reinforced with a steel core and outer support layers. Whether flowing in the normal flow direction, or back flowing, the structural integrity of this product will help ensure that your process equipment is not damaged by debris launched when less robust elements collapse or burst in service. Common Sizes and End Cap Styles Easy installation in existing housings without modifications. Saves costly downtime and maintenance expenses associated with housing modifications. MATERIALS COALESCING MEDIA PRE-FILTER MEDIA DRAIN LAYER CORE INNER & OUTER SUPPORT END CAPS GASKETS OPTIONS Unicast microglass pleated cellulose fiberglass steel (galvanized or tin plated) steel (galvanized or tin plated) molded silicone 1 integral to silicone end cap S.S. hardware, galvanized steel end caps, gasket materials

OPERATING DATA Max Temp. [F] 350

Max D.P .2

[psid]

100

Recommended change-out DP is 8 psid Normal flow direction is inside to outside

APPLICATIONS These applications typically have lower volumes with small concentrations of contaminants making them sensible places to use the FibrCeptor FFP. Plant Air and Instrument Gas Vent and Exhaust Systems Pre-filtered Fuel Gas and Seal Gas NOMINAL DIMENSIONS Model FFP-336 FFP-540 O.D. [in.] 4.3 6.0 I.D. [in.] 2.68 4.12 Length [in.] 36 40

CORE TECHNOLOGY

A Name You Know...Filters You Can Trust

FibrCeptor FFP

Depth Microglass Coalescers with Integral Pre-Filter

FibrCeptor FFP Flow Chart

0.65 S.G. and 60 deg. F

Dirt Holding The following data refers to the FibrCeptor FFP integral pleated pre-filter: FFP-336 - 1.66 lbs FFP-540 - 3.03 lbs The integral pre-filter is not a substitute for a separate, stand- alone pre-filter vessel that will optimize operating and maintenance economics. However, in applications where a stand-alone pre-filter is not an option the FibrCeptor FFP provides extended element service life.

Based on 2 psi Initial Pressure Drop

10000

Pressure [psig]

1000

100

336

10

540

1 100 1000 10000 100000

Flow Rate [scfm]

Integral End Cap/Gasket Maximum Incoming Aerosol Rate 3 Size 336: 25 gpd/element Size 540: 37 gpd/element PARTICLE RETENTION Coalescing Efficiency 0.3 to 0.6 Micron Particles 99.97 98.5 Maximum Oil Carry Over 4 ppm w/w 0.008 0.2 Micron Rating 0.1 0.5

Integral Pre-Filter Core Coalescing Media Inner Wrap

Grade 0.1 0.3

REPLACEMENT OPTION FOR Clark-Reliance Gardner & Clark Jonell VESSELS PECO Series 77V Other reverse flow coalescers Nowata Parker Finite Others

Inner Support

Drainage Layer

Outer Support 1. 2. 3. 4.

NOTES Do not use in H2S service > 5%. Max. D.P . may be limited by vessel manufacturers design. Installed in a PECO designed vessel. Tested per ADF-400 at 40 ppm inlet.

ORDERING INFORMATION

FFP

336

SIZE 336 540

GRADE [m] Blank = 0.3 AA = 0.1

MISC Blank = Silicone end caps B = Buna gaskets (steel hardware) SS = Stainless hardware V = Fluorocarbon gaskets (steel hardware)

Not all combinations are available. Consult customer service for verification if necessary.

Brought to you by PECOFacet a CLARCOR company

2009 PECOFacet PECOFacet has a policy of continuous product research and development and reserves the right to change design and specifications without notice.

Wolters Industrial Park / P .O. Box 640 / Mineral Wells, TX 76068

CORE TECHNOLOGY Phone 940.325.2575 / 1.800.877.PECO / Fax 940.325.4622

perryequipment.com / Email PECOElements@PECOFacet.com

EL-FC-TD-02 7/10

Das könnte Ihnen auch gefallen

- DonalsonDokument6 SeitenDonalsonrockyttpmcNoch keine Bewertungen

- Ficha Técnica 150-040Dokument8 SeitenFicha Técnica 150-040manuelaNoch keine Bewertungen

- Don GTS BrochureDokument8 SeitenDon GTS BrochuresanigzlNoch keine Bewertungen

- Bulletin 114 IOM Manual GP Steam DsfilterDokument4 SeitenBulletin 114 IOM Manual GP Steam DsfiltervextersNoch keine Bewertungen

- El FF TD 01Dokument2 SeitenEl FF TD 01Masood Alam FarooquiNoch keine Bewertungen

- Starlette Plus: The Small Range of Refrigeration DryersDokument4 SeitenStarlette Plus: The Small Range of Refrigeration DryersJas SumNoch keine Bewertungen

- Trane Split System 23-55 TonsDokument4 SeitenTrane Split System 23-55 Tonsyadi_baeNoch keine Bewertungen

- Filter ElsterDokument4 SeitenFilter ElsterkuwatiNoch keine Bewertungen

- TM CatalogDokument58 SeitenTM CataloghacenescribdNoch keine Bewertungen

- MAGTECH-Presentation - Main 2020 - CompressedDokument68 SeitenMAGTECH-Presentation - Main 2020 - CompressedMazaharul IslamNoch keine Bewertungen

- Filtro de AireDokument7 SeitenFiltro de AirejlfyNoch keine Bewertungen

- GDS134Dokument4 SeitenGDS134Saurabh VermaNoch keine Bewertungen

- LFDCDokument12 SeitenLFDCSuchitKNoch keine Bewertungen

- (P) SRFDokument6 Seiten(P) SRFYing Kei ChanNoch keine Bewertungen

- 50P Series: High Pressure FiltersDokument10 Seiten50P Series: High Pressure FiltersPartsGopher.comNoch keine Bewertungen

- Lista Filtros BOBCATDokument18 SeitenLista Filtros BOBCATmadscoutNoch keine Bewertungen

- Laminova Intercooler Core PerformanceDokument8 SeitenLaminova Intercooler Core PerformanceAnonymous dEfIaUNoch keine Bewertungen

- Flowserve Pump Gas SealsDokument37 SeitenFlowserve Pump Gas Sealsmujeebmehar50% (2)

- GT Air FilterDokument38 SeitenGT Air FilterasodiyamechNoch keine Bewertungen

- TD Pmo 6000 en 080108Dokument16 SeitenTD Pmo 6000 en 080108Ricardo DávilaNoch keine Bewertungen

- 3LPP Three Layer Polypropylene CoatingDokument3 Seiten3LPP Three Layer Polypropylene CoatingCarlos Maldonado SalazarNoch keine Bewertungen

- FD Brosur1Dokument2 SeitenFD Brosur1rahmansyah_alfarisiNoch keine Bewertungen

- Condensadora TTB TraneDokument24 SeitenCondensadora TTB TraneRoberto Reyes Lara100% (1)

- 39FX - PD Ahu DesignDokument60 Seiten39FX - PD Ahu DesignHanan SFNoch keine Bewertungen

- Carrier Ahu .-39fx - PDDokument60 SeitenCarrier Ahu .-39fx - PDAlfredo Anzures Eearn100% (4)

- MANUAL DezumidificatorDokument98 SeitenMANUAL DezumidificatorcivodulNoch keine Bewertungen

- MAHLE FilterDokument4 SeitenMAHLE FilterParinpa KetarNoch keine Bewertungen

- Optimize your refrigeration with ultra-slim unit coolers and silent condensersDokument3 SeitenOptimize your refrigeration with ultra-slim unit coolers and silent condensersdarwish1982Noch keine Bewertungen

- Automatic Filter Type 6.64 en BOLLFILTER 01Dokument7 SeitenAutomatic Filter Type 6.64 en BOLLFILTER 01Vannex MensidorNoch keine Bewertungen

- HoodedProp CatalogDokument52 SeitenHoodedProp CatalogTed K NagaraNoch keine Bewertungen

- Liquid Gas Filter Separator Material Spec SheetDokument1 SeiteLiquid Gas Filter Separator Material Spec SheetNguyen Ngoc CuongNoch keine Bewertungen

- Course Caterpillar Acert Technology Engine Systems Maintenance Components Parts Filters Sensors Combustion Fuel PDFDokument134 SeitenCourse Caterpillar Acert Technology Engine Systems Maintenance Components Parts Filters Sensors Combustion Fuel PDFImam Java100% (4)

- Filtro Especial PME AirtekDokument2 SeitenFiltro Especial PME AirtekEduardo CervantesNoch keine Bewertungen

- Fisa Sisteme FiltrareDokument7 SeitenFisa Sisteme FiltrareDragos MafteiNoch keine Bewertungen

- York EspecificacionesDokument34 SeitenYork EspecificacionesblasspascalNoch keine Bewertungen

- Capsulas Limpias para ProduccionDokument12 SeitenCapsulas Limpias para ProduccionluisrayvcNoch keine Bewertungen

- Swagelok Gas FiltersDokument4 SeitenSwagelok Gas FilterstotcsabNoch keine Bewertungen

- TF4 Mar 20 06Dokument6 SeitenTF4 Mar 20 06DANIZACHNoch keine Bewertungen

- BCSWFRP CatalogDokument24 SeitenBCSWFRP CatalogFranklin JprstNoch keine Bewertungen

- Cast Aluminum BrochureDokument2 SeitenCast Aluminum BrochureRomanCHubaNoch keine Bewertungen

- Filtros Sealkeen Emflon IIDokument2 SeitenFiltros Sealkeen Emflon IItheflamebearerNoch keine Bewertungen

- Tender Specifications-Exhaust SystemDokument6 SeitenTender Specifications-Exhaust Systemgullipalli srinivasa raoNoch keine Bewertungen

- 2008 Filter and Fluid Application Guide2Dokument16 Seiten2008 Filter and Fluid Application Guide2KAPDSCNoch keine Bewertungen

- Donaldson AccessoriesDokument74 SeitenDonaldson AccessoriesCentral HydraulicsNoch keine Bewertungen

- Dynasep Peach Depth CartridgeDokument4 SeitenDynasep Peach Depth CartridgecartarNoch keine Bewertungen

- B615 Pollution ControlDokument12 SeitenB615 Pollution ControlClarence AG YueNoch keine Bewertungen

- 38eyg 3pdDokument48 Seiten38eyg 3pdBlueSkyMasterNoch keine Bewertungen

- Braden 2010 PDFDokument16 SeitenBraden 2010 PDFTompson Steven100% (1)

- Sparger Design GuideDokument11 SeitenSparger Design GuideHarshavardhan D. GorakhNoch keine Bewertungen

- Sparger Design Guide PDFDokument11 SeitenSparger Design Guide PDFRyan SyahMemethNoch keine Bewertungen

- Donaldson FilterDokument22 SeitenDonaldson FilterParinpa KetarNoch keine Bewertungen

- ST CT Combined Series US0621Dokument4 SeitenST CT Combined Series US0621QuietRideNoch keine Bewertungen

- Coalescers ZM E25Dokument2 SeitenCoalescers ZM E25abaskmNoch keine Bewertungen

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallVon EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallBewertung: 4 von 5 Sternen4/5 (8)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Working Guide to Drilling Equipment and OperationsVon EverandWorking Guide to Drilling Equipment and OperationsBewertung: 5 von 5 Sternen5/5 (9)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Watlow Product SheetDokument4 SeitenWatlow Product Sheetmatteo2009Noch keine Bewertungen

- Brochure FATI 2018Dokument1 SeiteBrochure FATI 2018matteo2009Noch keine Bewertungen

- Flue Gas in Industry 0981 2773Dokument149 SeitenFlue Gas in Industry 0981 2773Dragos PlaesuNoch keine Bewertungen

- ReciprocatingcompressorsDokument13 SeitenReciprocatingcompressorsasbuasbuNoch keine Bewertungen

- RMG 790 en PDFDokument8 SeitenRMG 790 en PDFmatteo2009Noch keine Bewertungen

- Usm Gt400 Manual enDokument1 SeiteUsm Gt400 Manual enmatteo2009Noch keine Bewertungen

- EXHEAT Datasheet CastDokument3 SeitenEXHEAT Datasheet Castmatteo2009Noch keine Bewertungen

- Seal Gas Heater: Typical ApplicationsDokument1 SeiteSeal Gas Heater: Typical Applicationsmatteo2009Noch keine Bewertungen

- Sample PID Symbols and LegendsDokument32 SeitenSample PID Symbols and Legendstwinbrothers97% (29)

- Indirect Fired HeaterDokument3 SeitenIndirect Fired Heatermatteo2009Noch keine Bewertungen

- Calculate Gas Compressibility FactorDokument2 SeitenCalculate Gas Compressibility Factormatteo2009Noch keine Bewertungen

- Natural Gas Processing Principles and Technology - Part IDokument364 SeitenNatural Gas Processing Principles and Technology - Part IRichard Gutierrez100% (1)

- Process Calculations For DesignDokument26 SeitenProcess Calculations For DesignOmprakaash MokideNoch keine Bewertungen

- Cert CE CIB Unigas GAR 2018 PDFDokument6 SeitenCert CE CIB Unigas GAR 2018 PDFmatteo2009Noch keine Bewertungen

- Pressure Relief Devices Scott OstrowskiDokument82 SeitenPressure Relief Devices Scott OstrowskiAffify AfifyNoch keine Bewertungen

- Ejb EnclosuresDokument8 SeitenEjb Enclosuresmatteo2009Noch keine Bewertungen

- Best Practice Guide Impulse Lines For Differential-Pressure FlowmetersDokument22 SeitenBest Practice Guide Impulse Lines For Differential-Pressure FlowmetersamietkolteNoch keine Bewertungen

- Differential Level Transmitter For Low Side Dry LegDokument2 SeitenDifferential Level Transmitter For Low Side Dry Legmatteo2009Noch keine Bewertungen

- Electrical Functions Start-Up ChecklistDokument26 SeitenElectrical Functions Start-Up ChecklistAhsan KhanNoch keine Bewertungen

- AGA Purging.2001 PDFDokument157 SeitenAGA Purging.2001 PDFLeDzung100% (1)

- EX Wiring Methods and IEC Cable TestsDokument47 SeitenEX Wiring Methods and IEC Cable TestsGaurav SinghalNoch keine Bewertungen

- GER 3620K (1) - Heavy Duty Gas Turbine O&M Consideration - ZulfiqarDokument60 SeitenGER 3620K (1) - Heavy Duty Gas Turbine O&M Consideration - Zulfiqaramer_arauf100% (2)

- Typical P&ID Arrangement For Pig Launchers Pig ReceiversDokument2 SeitenTypical P&ID Arrangement For Pig Launchers Pig Receiversmatteo2009100% (2)

- 33 033Dokument287 Seiten33 033matteo2009Noch keine Bewertungen

- Belden 9841Dokument2 SeitenBelden 9841matteo2009Noch keine Bewertungen

- AGA Purging.2001 PDFDokument157 SeitenAGA Purging.2001 PDFLeDzung100% (1)

- Communication Network: ModbusDokument4 SeitenCommunication Network: Modbusmatteo2009Noch keine Bewertungen

- Coated Stud Bolts Protection GuideDokument3 SeitenCoated Stud Bolts Protection Guidematteo2009Noch keine Bewertungen

- SeparatorsDokument140 SeitenSeparatorsmatteo2009Noch keine Bewertungen

- En 54 Standard Family PartsDokument2 SeitenEn 54 Standard Family Partsmatteo2009100% (1)

- 01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Dokument4 Seiten01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Akd DeshmukhNoch keine Bewertungen

- MD Module 1 StressDokument5 SeitenMD Module 1 StressCllyan Reyes100% (1)

- Motor Hyundai D4eb-Diesel 2.2Dokument91 SeitenMotor Hyundai D4eb-Diesel 2.2Igatech Diesel82% (11)

- Terex Rh200 Maintenance Training: Hydraulic Cooling SystemDokument14 SeitenTerex Rh200 Maintenance Training: Hydraulic Cooling Systemchurypizarro2367Noch keine Bewertungen

- Ersatzteilliste SD20 Bis SD185 enDokument5 SeitenErsatzteilliste SD20 Bis SD185 enAswin AntonyNoch keine Bewertungen

- Sublimation Heat Press Quick Guide 1Dokument2 SeitenSublimation Heat Press Quick Guide 1renato jr baylasNoch keine Bewertungen

- Cutting Speeds & RPM CalculationsDokument7 SeitenCutting Speeds & RPM Calculationsyanuar_adhiNoch keine Bewertungen

- Super Asia Mds Limited Service Centre, LahoreDokument40 SeitenSuper Asia Mds Limited Service Centre, Lahoresohailakhtar5Noch keine Bewertungen

- Worthington D1022 Pump DataSheet P-701Dokument10 SeitenWorthington D1022 Pump DataSheet P-701Andrey Pulido Barrera100% (1)

- Diked & Spill Protection: Dike Protection Fixed Mount Low Level Foam MakersDokument4 SeitenDiked & Spill Protection: Dike Protection Fixed Mount Low Level Foam MakersAamerMAhmadNoch keine Bewertungen

- River Training and Protection WorksDokument8 SeitenRiver Training and Protection Worksnandi_scrNoch keine Bewertungen

- SPLM - Construction Pre-Planning PDFDokument11 SeitenSPLM - Construction Pre-Planning PDFJommarVocalTagalogNoch keine Bewertungen

- Pulverizador 4730Dokument858 SeitenPulverizador 4730Fernando Sabino100% (3)

- J. Struct. Eng. 1989.115:2276-2296Dokument21 SeitenJ. Struct. Eng. 1989.115:2276-2296afuhcivNoch keine Bewertungen

- Execution ScheduleDokument5 SeitenExecution ScheduleBagadi AvinashNoch keine Bewertungen

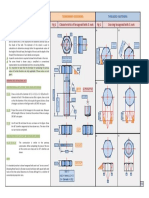

- Machine Drawing: Hexagonal Bolts & NutsDokument1 SeiteMachine Drawing: Hexagonal Bolts & Nutsyesbee100% (1)

- Woodsmith Magazine 217Dokument68 SeitenWoodsmith Magazine 217chrix100% (9)

- PBI Warranty Building Technical BidDokument39 SeitenPBI Warranty Building Technical BidDonalyn NatorillaNoch keine Bewertungen

- Interstate PVC Fence Brochure - Sunrise Custom Fence East Inc.Dokument20 SeitenInterstate PVC Fence Brochure - Sunrise Custom Fence East Inc.Sunrise Custom Fence East IncNoch keine Bewertungen

- ProjectSchedulingHandbook 1Dokument391 SeitenProjectSchedulingHandbook 1Lucio Loyloy SanchezNoch keine Bewertungen

- New COADokument15 SeitenNew COAAhadNurParagNoch keine Bewertungen

- Guide To Standards-Pools and SpasDokument15 SeitenGuide To Standards-Pools and SpasMIguel HazNoch keine Bewertungen

- Alver AaltoDokument5 SeitenAlver AaltoJayant RajNoch keine Bewertungen

- Cat 326D2 Excavator Hydraulic System PDFDokument2 SeitenCat 326D2 Excavator Hydraulic System PDFkeron trotz100% (1)

- Manufacturing Process and Type ApprovalDokument231 SeitenManufacturing Process and Type Approvalscribd_alireza2013Noch keine Bewertungen

- Madhya Pradesh - Major District Road Up-Gradation Project (MPMDRUP) Package - 09 Dhooma Gotegaon Road (MDR-37-04)Dokument3 SeitenMadhya Pradesh - Major District Road Up-Gradation Project (MPMDRUP) Package - 09 Dhooma Gotegaon Road (MDR-37-04)yogesh daharwalNoch keine Bewertungen

- A400Dokument8 SeitenA400Aleksei AvilaNoch keine Bewertungen

- UCSanDiegoBEPTemplate v1.1 CompleteSampleDokument26 SeitenUCSanDiegoBEPTemplate v1.1 CompleteSampleMarvvvNoch keine Bewertungen

- 6000 5 Inox LCDDokument17 Seiten6000 5 Inox LCDpotoculNoch keine Bewertungen

- 1397087072193-Approved Material List AMLDokument3 Seiten1397087072193-Approved Material List AMLIsmed PrajanegaraNoch keine Bewertungen