Beruflich Dokumente

Kultur Dokumente

Stargrip Cat PDF

Hochgeladen von

DGWOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stargrip Cat PDF

Hochgeladen von

DGWCopyright:

Verfügbare Formate

Mechanical Joint Wedge Action Restraint for Ductile Iron Pipe Patent #5,772,252

Stargrip series 3000

Joint Restraint Products

INFORMATION The Stargrip Mechanical Joint Restraint System is a unique product with a proven design that provides an exceptional restraining system for mechanical joint fittings (AWWA C153 or C110), valves, fire hydrants and all classes of ductile iron pipe.

More Adaptable for Field Use

Stargrip series 3000 for Ductile Iron Pipe

FEATURES & ADVANTAGES Gland is made from high strength Ductile Iron per ASTM A536, Grade 65-45-12 and is compatible with all Mechanical Joints conforming to ANSI/AWWA C111/A21.11. The Wedge Assembly is designed with a Break-Off Torque Control Nut that will only break off in one direction, ensuring proper installation. The Stargrip offers a full 5 deflection through 12" size, 3 on 14"-24", 2 on 30"-36" and 1 on 42"-48". Minimum safety factor of 2:1. Stargrip sizes 3"-36" are listed with Underwriters Laboratories Inc. and sizes 3"-12" are approved by Factory Mutual Research. The Wedges are heat treated to a minimum of 370 BHN. The Wedge Assembly is designed to fit specific pipe sizes and is field repairable. No special tools are required for installation of the Stargrip. Stargrip eliminates tie rods and thrust blocks. Standard gland color is Graphite Black (RAL 9011).

SAMPLE SPECIFICATIONS

Restrainer mechanism shall be integrated into the design of the follower gland. As the mechanism is activated, multiple wedging action shall be imparted against the pipe increasing its resistance as internal pressure increases. After burial of the restraining mechanism, joint flexibility shall be maintained. The actuating bolt shall be threaded into the restraining wedge and have a 1-1/4" hex operating nut. The operating nut shall be threaded onto the actuating bolt, not swaged or riveted. The restraining twist off nut bolt system shall have a torque-limiting feature designed to break off at preset torque levels, thus insuring proper action of restraining device. Glands shall be manufactured of high strength ductile iron in accordance with ASTM A536 Grade 65-45-12 requirements. The wedge shall be manufactured of high strength ductile iron and be heat treated to a minimum hardness of 370 BHN. Applicable dimensions shall conform to ANSI/AWWA C111/A21.11 and shall be incorporated into the mechanical joint restraint so that the device facilitates use with standard mechanical joint bells. The mechanical joint restraint mechanism shall have a maximum water working pressure of 350 PSI for sizes 3"-16" and 250 PSI for sizes 18" and above. All sizes shall have a minimum safety factor of 2:1 (i.e. twice the maximum pressure rating of the restraint). The mechanical joint restraint mechanism shall be Underwriters Laboratories listed on size 3" through 36" and Factory Mutual Research Approved on size 3"-12". The restraint mechanism shall be Star Pipe Products Stargrip series 3000 or an approved equal.

REV.07 REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 3

Mechanical Joint Wedge Action Restraint for Ductile Iron Pipe Patent #5,772,252

Stargrip series 3000

Joint Restraint Products

TECHNICAL INFORMATION

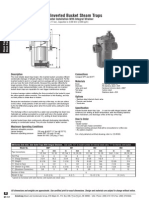

STARGRIP 3000 SPECIFICATIONS*

NOM. SIZE 3 4 6 8 10 12 14 16 18 20 24 30 36 42 48 MAX PRESSURE RATING (PSI) 350 350 350 350 350 350 350 350 250 250 250 250 250 250 250 A 4.84 5.92 8.02 10.17 12.22 14.32 16.40 18.50 20.60 22.70 26.90 33.29 39.59 45.79 52.09 B 2.40 2.40 2.40 2.51 2.51 2.51 2.91 2.91 2.91 2.67 3.50 3.49 3.49 5.15 5.15 C 4.06 4.90 7.00 9.15 11.20 13.30 15.44 17.54 19.64 21.74 25.94 32.17 38.47 44.75 51.05 D 6.19 7.50 9.50 11.75 14.00 16.25 18.75 21.00 23.25 25.50 30.00 36.88 43.75 50.62 57.50 E 3/4 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 1-1/8 1-1/8 1-3/8 1-3/8 F 9.85 11.06 13.06 15.25 17.25 19.50 21.25 23.34 26.40 28.56 33.86 40.12 46.42 54.86 61.16 F W/NUTS TWISTED OFF 8.45 9.28 11.38 13.53 15.58 12.68 19.82 21.92 24.84 27.00 32.30 38.56 44.86 53.32 59.62 G 7.69 9.15 11.15 13.40 15.92 17.90 20.25 24.83 25.25 27.50 31.54 39.12 46.00 53.12 59.42 NO. OF NO. OF APPROX WT. WEDGES T-BOLTS (LBS) 2 2 3 4 6 8 10 12 12 14 16 20 24 28 32 4 4 6 6 8 8 10 12 12 14 16 20 24 28 32 6 8 12 17 24 34 49 56 59 75 139 199 232 400 488

REV.07

*All dimensions in inches except where indicated.

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 4

Pipe Restrainers series 3000OS

Joint Restraint Products

Oversized Mechanical Joint Wedge Action Restraint for Ductile Iron Pipe Patent #5,772,252

INFORMATION The oversized Stargrip series 3000OS has the same features as the series 3000 except the bore (ID) has been increased to accomodate Class A, B, C, & D pit cast pipe. TECHNICAL INFORMATION

STARGRIP 3000OS SPECIFICATIONS*

NOM. SIZE 4 6 8 10 12 14 16

REV.07

MAX PRESSURE RATING (PSI) 250 250 250 250 250 150 150

B.C. DIAMETER 7.50 9.50 11.75 14.00 16.25 18.75 21.00

BOLT HOLES 4 x 7/8 6 x 7/8 6 x 7/8 8 x 7/8 8 x 7/8 10 x 7/8 12 x 7/8

NOMINAL GLAND I.D. 5.10 7.20 9.40 11.50 13.60 15.75 17.90

LIP THICKNESS 0.32 0.32 0.29 0.27 0.27 0.23 0.21

APPROX WT. (LBS) 8 12 16 24 34 49 56

*All dimensions in inches except where indicated.

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 5

Stargrip series 3000 & 3000OS

Joint Restraint Products

Mechanical Joint Wedge Action Restraint for Ductile Iron Pipe Patent #5,772,252

INSTALLATION INSTRUCTIONS - SIZES 3"- 48"

STEP 1

To ensure the rubber gasket will seal more effectively, clean and remove all loose materials and rust from the mating surfaces. Lubricate the gasket and plain end by brushing either soapy water or pipe lubricant. Slide the Stargrip on the plain end, followed by the MJ gasket.

STEP 2

After insertion of the pipe into the bell of the fitting, firmly press the gasket into the gasket recess. During this process the joint should be kept straight.

STEP 3

Slide the Stargrip toward the MJ bell with the gland lip against the gasket. Insert T-bolts and hand tighten nuts. IMPORTANT: Make deflection after joint is assembled but before tightening T-bolts.

STEP 4

When tightening bolts, it is essential that the gland be brought up toward the bell flange evenly, maintaining approximately the same distance between the gland and the face of the flange at all points around the socket. All T-bolts should be tightened until they are in within the torque range per ANSI/ AWWA C600 (See Table A). T-Bolts should be tightened alternately on the opposite sides (Star Pattern).

STEP 5

Tighten the torque limiting twist off nuts in a clockwise direction until all wedges are in firm contact with the pipe surface.

STEP 6

Continue tightening in an alternative manner going on the opposite sides [Star Pattern], until all of nuts have been twisted off. Never turn a single nut over 180 degrees without alternating to another nut. If removal is necessary, utilize the 5/8 hex head provided. [If reassembly is required, assemble the joint in the same manner as above and tighten the wedge bolt to 90 lbs. ft. on sizes 3"-20", 120 lbs. ft. on sizes 24"-36" & 130 lbs. ft. on sizes 42"-48"].

Note: If effective sealing is not attained at the maximum torque indicated, then the joint should be disassembled, thoroughly cleaned, and reassembled. Overstressing the bolts to compensate for poor installation practice is not acceptable. Note: Not to be used on plain end fittings or PVC, HDPE or steel pipe.

(TABLE A) T-HEAD BOLT & NUT DETAILS Pipe Size (in) 3 4-24 30-36 42-48

1

Bolt Size (in) 5/8 3/4 1 1 1/4

Range1 of Torque (ft/lbs) 45-60 75-90 100-120 120-150

These torque ranges are requirements of AWWA C600

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

REV.07

Page 6

Split Mechanical Joint Wedge Action Restraint for New or Existing Ductile Iron Pipe Patent #5,772,252

Split Stargrip series 3000S

Joint Restraint Products

INFORMATION The Split Stargrip is used for restraining new or existing ductile iron mechanical joint fittings, valves, fire hydrants and all classes of ductile iron pipe. The unique split design makes installation fast and simple.

Easy Installation

Stargrip series 3000S for Ductile Iron Pipe.

FEATURES & ADVANTAGES Split design Stargrip Series 3000S for easy installation on new or existing Ductile Iron Mechanical Joint systems. Gland is made from high strength Ductile Iron per ASTM A536, Grade 65-45-12 and is compatible with all Mechanical Joints conforming to ANSI/AWWA C111/A21.11. The Wedge Assembly is designed with a Break-Off Torque Control Nut that will only break off in one direction, ensuring proper installation. Offers a full 5 deflection through 12 size, 3 on 14-24, 2 on 30-36 and 1 on 42-48. Minimum safety factor of 2:1. The Wedges are heat treated to a minimum of 370 BHN. The Wedge Assembly is designed to fit specific pipe sizes and is field repairable. Clamping bolts per SAE J429 Grade 5 steel. Eliminates tie rods and thrust blocks. Standard gland color is Graphite Black (RAL 9011). SAMPLE SPECIFICATIONS

Restraint mechanism shall be of split design for use on new or existing mechanical joints. As the mechanism is activated, multiple wedging action shall be imparted against the pipe increasing its resistance as internal pressure increases. After burial of the restraining mechanism, joint flexibility shall be maintained. The actuating bolt shall be threaded into the restraining wedge and have a 1-1/4" hex operating nut. The operating nut shall be threaded onto the actuating bolt, not swaged or riveted. The restraining twist off nut bolt system shall have a torque-limiting feature designed to break off at preset torque levels, thus insuring proper action of restraining device. Glands shall be manufactured of high strength ductile iron in accordance with ASTM A536 Grade 65-45-12 requirements. The wedge shall be manufactured of high strength ductile iron and be heat treated to a minimum hardness of 370 BHN. Applicable dimensions shall conform to ANSI/AWWA C111/A21.11 and shall be incorporated into the mechanical joint restraint so that the device facilitates use with standard mechanical joint bells. The mechanical joint restraint mechanism shall have a maximum water working pressure of 350 PSI for sizes 3"-8", 300 PSI for sizes 10"-16", 200 PSI for sizes 18"-36" and 175 PSI for sizes 42"-48". All sizes shall have a minimum safety factor of 2:1 (i.e. twice the maximum pressure rating of the restraint). The restraint mechanism shall be Star Pipe Products Split Stargrip series 3000S or an approved equal.

REV.07

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 7

Split Mechanical Joint Wedge Action Restraint for Ductile Iron Pipe Patent #5,772,252

Split Stargrip series 3000S

Joint Restraint Products

TECHNICAL INFORMATION

CLAMPING BOLT SIZE SERIES 3000S (IN) 3-6 8-10 12 14-24 30-36 42-48 BOLT SIZE (IN) 5/8 x 3 1/2 3/4 x 3 1/2 3/4 x 4 7/8 x 3 3/4 1 x 3 1/2 1 1/4 x 4

0.75

STAR GRIP

F

A C

0.12

C

H

SPLIT STARGRIP 3000S SPECIFICATIONS*

NOM. SIZE 3 4 6 8 10 12 14 16 18 20 24 30 36 42 48 MAX PRESSURE RATING (PSI) 350 350 350 350 300 300 300 300 200 200 200 200 200 175 175 A 4.66 5.92 8.02 10.17 12.22 14.32 16.40 18.50 20.60 22.70 26.90 33.29 39.59 45.79 52.09 B 2.40 2.44 2.44 2.44 2.44 2.44 2.83 2.83 2.91 2.67 3.50 3.49 3.49 5.15 5.15 C 4.06 4.90 7.00 9.15 11.20 13.30 15.44 17.54 19.64 21.74 25.94 32.17 38.47 44.75 51.05 D 6.19 7.50 9.50 11.75 14.00 16.25 18.75 21.00 23.25 25.50 30.00 36.88 43.75 50.62 57.50 E 3/4 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 1 1/8 1 1/8 1 3/8 1 3/8 F 9.85 11.06 13.06 15.25 17.25 19.50 21.25 23.34 26.40 28.56 33.86 40.12 46.42 54.86 61.16 F W/NUTS TWISTED OFF 8.45 9.28 11.38 13.53 15.58 12.68 19.82 21.92 24.84 27.00 32.30 38.56 44.86 53.32 59.62 G 7.69 9.15 11.15 13.40 15.92 17.90 20.25 24.83 25.25 27.50 31.54 39.12 46.00 53.12 59.42 H 8.77 9.80 13.86 15.16 17.98 20.86 25.08 27.12 29.64 31.66 36.14 44.18 51.29 58.82 65.12 WEDGES (QTY) 2 2 3 4 6 8 10 12 12 14 16 20 24 28 32 T-BOLTS APPROX WT. (QTY) (LBS) 4 4 6 6 8 8 10 12 12 14 16 20 24 28 32 9 11 14 17 26 36 49 56 61 75 134 201 240 581 664

REV.07

*All dimensions in inches except where indicated.

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 8

Split Mechanical Joint Wedge Action Restraint for Ductile Iron Pipe Patent #5,772,252

Split Stargrip series 3000S

Joint Restraint Products

INSTALLATION INSTRUCTIONS - SIZES 3"- 48"

STEP 1

Existing joint must be disassembled and thoroughly cleaned. If necessary, replace the existing gasket with a field cut gasket. Brush both the gasket and the plain end with soapy water or approved pipe lubricant, which meets ANSI/AWWA C111/A21.11. Firmly insert the split gasket into the bell cavity.

STEP 2

Remove the clamping bolts from the split Stargrip. Loosely assemble the halves on the pipe, making sure that the lip extension is towards the mechanical joint bell. Then reinstall the clamping bolts.

STEP 3

Slide the loosely assembled Stargrip towards the MJ bell and insert T-Bolts and hand-tighten the nuts.

STEP 4

Tighten Clamping bolts on the Split Stargrip to 90 - 110 lbs-ft.

STEP 5

Tighten the T-bolts to normal range of bolt torque. It is necessary that the gland be brought up toward the bell flange evenly, maintaining approximately the same distance between the gland and the face of the flange at all points around the socket. T-Bolts should be tightened alternately on the opposite sides (Star Pattern). (see table A).

STEP 6

Hand tighten the torque limiting twist off nuts in a clockwise direction until all wedges are in firm contact with the pipe surface. Continue tightening in an alternative manner going on opposite sides [Star Pattern], until all of the nuts have been twisted off. Never turn a single nut over 180 degrees without alternating to another nut. If removal is necessary, utilize the 5/8 hex head provided. [If reassembly is required, assemble the joint in the same manner as above and tighten the wedge bolts to 90 lbs. ft. on sizes 3"-20", 120 lbs. ft. on sizes 24"-36" & 130 lbs. ft. on sizes 42"-48"].

Note: Not to be used on plain end fittings or PVC, HDPE or steel pipe.

(TABLE A) T-HEAD BOLT & NUT DETAILS Pipe Size (in) 3 4-24 30-36 42-48

1

Bolt Size (in) 5/8 3/4 1 1 1/4

Range1 of Torque (ft/lbs) 45-60 75-90 100-120 120-150

These torque ranges are requirements of AWWA C600

REV.07

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 9

Wedge Action Restraint for Ductile Iron Pipe Bells - New Installations Patent #5,772,252

Stargrip series 3100P

Joint Restraint Products

FEATURES & ADVANTAGES Stargrip and MJ Gland manufactured from Ductile Iron per ASTM A536, Grade 65-45-12. Includes Stargrip, Split Back-Up Ring (for sizes 3"- 30") or MJ Gland (for sizes 36"- 48") and high strength low alloy steel double ended rods and nuts which meet the requirements of ANSI/AWWA C111/A21.11 Minimum Safety Factor 2:1 For use on all classes of Ductile Iron Pipe For new pipe-to-pipe installations only Pipe OD must be gauged overall to assure restraint will fit properly. Please refer to chart for maximum bell outside diameter for rod clearance. Standard gland color is Graphite Black (RAL 9011).

Stargrip series 3100P for Ductile Iron Pipe

TECHNICAL INFORMATION SPLIT STARGRIP 3100P SPECIFICATIONS*

NOM. SIZE

3 4 6 8 10 12 14 16 18 20 24 30 36 42 48

ITEM CODE

SGDPG03 SGDPG04 SGDPG06 SGDPG08 SGDPG10 SGDPG12 SGDPG14 SGDPG16 SGDPG18 SGDPG20 SGDPG24 SGDPG30 SGDPG36 SGDPG42 SGDPG48

MAX PRESSURE RATING (PSI)

350 350 350 350 350 350 350 350 250 250 250 250 250 250 250

RODS (QTY)

4 4 6 6 8 8 8 10 10 12 14 18 24 28 32

ROD DIA X LENGTH

3/4 X 17 3/4 X 17 3/4 X 17 3/4 X 17 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 1 X 24 1 X 24 1 1/4 X 24 1 1/4 X 24

MAX. BELL OD

5.44 6.62 8.62 10.88 13.12 15.38 17.88 20.12 22.38 24.62 29.12 35.75 42.62 49.25 56.12

APPROX WT. (LBS)

19 23 35 42 60 76 121 142 165 192 276 499 495 1176 1379

*All dimensions in inches except where indicated.

SAMPLE SPECIFICATIONS

Restrainer mechanism shall be integrated into the design of the gland. As the mechanism is activated, multiple wedging action shall be imparted against the pipe increasing its resistance as internal pressure increases. After burial of the restraining mechanism, joint flexibility shall be maintained. The actuating bolt shall be threaded into the restraining wedge and have a 1-1/4" hex operating nut. The operating nut shall be threaded onto the actuating bolt, not swaged or riveted. The restraining twist off nut bolt system shall have a torque-limiting feature designed to break off at preset torque levels, thus insuring proper action of restraining device. Glands shall be manufactured of high strength ductile iron in accordance with ASTM A536 Grade 65-45-12 requirements. The wedge shall be manufactured of high strength ductile iron and be heat treated to a minimum hardness of 370 BHN. The mechanical joint restraint mechanism shall have a maximum water working pressure of 350 PSI for sizes 3"-16" and 250 PSI for sizes 18" and above. All sizes shall have a minimum safety factor of 2:1 (i.e. twice the maximum pressure rating of the restraint). The restraint mechanism shall be Star Pipe Products, Stargrip series 3100P or an approved equal.

REV.07 REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 11

Wedge Action Restraint for Ductile Iron Pipe Bells - New Installations Patent #5,772,252

Stargrip series 3100P

Joint Restraint Products

INSTALLATION INSTRUCTIONS - SIZES 3"- 30"

STEP 1

Stargrip Series 3100P is designed to restrain Push-On Ductile Iron Pipe connections (all thickness classes). It includes a Stargrip Series 3000 restraint gland for the spigot end and an Split Back-Up Ring behind the bell.

STEP 2

Install the Split Back-Up Ring, behind the pipe bell in the direction indicated on the casting. Tighten clamping bolts on the Split Back-Up Ring 90 lb-ft Assemble the Pipe Push-On joint per the pipe manufacturers installation instructions.

Place the Stargrip Series 3000 restraint gland on the spigot end of the plain pipe with the lip extension facing towards the mating bell.

STEP 3

Rotate Stargrip Series 3000 restraint gland on the spigot such that the boltholes are in alignment and adjust the position so that the distance between the glands is suitable for the double-ended rod length. Adequate length should be allowed on the double-ended rods so that nuts can be fully engaged with several threads showing. Install the remaining double-ended rods provided in each bolt hole. Place nuts on the ends of each double-ended rod. It is to be ensured that adequate length is allowed on rods to fully engage the nuts with several threads showing. Pull Stargrip Series 3000 restraint gland away from the joint until there is no slack in the rods.

STEP 4

Tighten the torque limiting twist off nuts in a clockwise direction until all the wedges are in firm contact with the pipe OD. Continue tightening in an alternative manner going on opposite sides (Star Pattern), until all of the nuts have been twisted off. Never turn a single nut over 180 degrees without alternating to another nut. The nuts on the double-ended rods must be tightened until the Split BackUp Ring is in firm contact with the back of the bell. These nuts should not be over tightened. If removal of the Stargrip Series 3000 restraint gland is necessary, utilize the 5/8" hex head provided. If reassembly is required, assemble the product in the same manner as above and tighten the wedge bolts to 90 lbs. ft. on sizes 3"-20", 120 lbs. ft. on sizes 24"-30".

Note: Not to be used on plain end fittings or PVC, HDPE and steel pipe.

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com REV.07

Page 12

Wedge Action Restraint for Ductile Iron Pipe Bells - New Installations Patent #5,772,252

Stargrip series 3100P

Joint Restraint Products

INSTALLATION INSTRUCTIONS - SIZES 36"- 48"

STEP 1

Stargrip Series 3100P is designed to restrain Push-On Ductile Iron Pipe connections (all thickness classes). It includes a Stargrip Series 3000 restraint gland for the spigot end and an MJ Gland behind the bell.

STEP 2

Install the MJ Gland, behind the pipe bell with the lip extension facing towards the bell. Assemble the Pipe Push-On joint per the pipe manufacturers installation instructions.

Place the Stargrip Series 3000 restraint gland on the spigot end of the plain pipe with the lip extension facing towards the mating bell.

STEP 3

Rotate Stargrip Series 3000 restraint gland on the spigot such that the boltholes are in alignment and adjust the position so that the distance between the glands is suitable for the double-ended rod length. Adequate length should be allowed on the double-ended rods so that nuts can be fully engaged with several threads showing. Install the remaining double-ended rods provided in each bolt hole. Place nuts on the ends of each double-ended rod. It is to be ensured that adequate length is allowed on rods to fully engage the nuts with several threads showing. Pull Stargrip Series 3000 restraint gland away from the joint until there is no slack in the rods.

STEP 4

Tighten the torque limiting twist off nuts in a clockwise direction until all the wedges are in firm contact with the pipe OD. Continue tightening in an alternative manner going on opposite sides (Star Pattern), until all of the nuts have been twisted off. Never turn a single nut over 180 degrees without alternating to another nut. The nuts on the double-ended rods must be tightened until the MJ Gland is in firm contact with the back of the bell. These nuts should not be over tightened. If removal of the Stargrip Series 3000 restraint gland is necessary, utilize the 5/8" hex head provided. If reassembly is required, assemble the product in the same manner as above and tighten the wedge bolts to 120 lbs. ft. on size 36" & 130 lbs. ft. on sizes 42"-48".

Note: Not to be used on plain end fittings or PVC, HDPE and steel pipe.

REV.07 REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 13

Split Wedge Action Restraint for Ductile Iron Pipe - New or Existing Installations Patent #5,772,252

Split Stargrip series 3100S

Joint Restraint Products

FEATURES & ADVANTAGES Split Stargrip series 3000S and Split Back-Up ring produced from Ductile Iron per ASTM A536, Grade 65-45-12. Includes Stargrip series 3000S, Split Back-Up Ring and high strength low alloy steel double ended rods and nuts which meet the requirements of ANSI/AWWA C111/A21.11 Minimum Safety Factor 2:1 For use on all classes of Ductile Iron Pipe For new and existing pipe to pipe installations Pipe OD must be gauged overall to assure restraint will fit properly. Please refer to chart for maximum bell outside diameter for rod clearance.

Split Stargrip series 3100S for Ductile Iron Pipe

Standard gland color is Graphite Black (RAL 9011).

TECHNICAL INFORMATION SPLIT STARGRIP 3100S SPECIFICATIONS*

NOM. SIZE

3 4 6 8 10 12 14 16 18 20 24 30 36 42 48

ITEM CODE

SGDPG03S SGDPG04S SGDPG06S SGDPG08S SGDPG10S SGDPG12S SGDPG14S SGDPG16S SGDPG18S SGDPG20S SGDPG24S SGDPG30S SGDPG36S SGDPG42S SGDPG48S

MAX PRESSURE RATING (PSI)

350 350 350 350 300 300 300 300 200 200 200 200 200 175 175

RODS (QTY)

4 4 6 6 8 8 8 10 10 12 14 18 22 26 30

ROD DIA X LENGTH

3/4 X 17 3/4 X 17 3/4 X 17 3/4 X 17 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 3/4 X 24 1 X 24 1 X 24 1 1/4 X 24 1 1/4 X 24

MAX. BELL OD

5.44 6.62 8.62 10.88 13.12 15.38 17.88 20.12 22.38 24.62 29.12 35.75 42.62 49.25 56.12

APPROX WT. (LBS)

22 26 36 42 64 78 122 142 154 186 288 485 600 944 1131

*All dimensions in inches except where indicated.

SAMPLE SPECIFICATIONS

Restraint for DI push on bells shall incorporate the use of a split restraint and split follower into its design. Split restrainer mechanism shall be integrated into the design of the gland. As the mechanism is activated, multiple wedging action shall be imparted against the pipe increasing its resistance as internal pressure increases. After burial of the restraining mechanism, joint flexibility shall be maintained. The actuating bolt shall be threaded into the restraining wedge and have a 1-1/4" hex operating nut. The operating nut shall be threaded onto the actuating bolt, not swaged or riveted. The restraining twist off nut bolt system shall have a torque-limiting feature designed to break off at preset torque levels, thus insuring proper action of restraining device. Split follower shall be manufactured of high strength ductile iron in accordance with ASTM A536 Grade 65-45-12 requirements. The wedge shall be manufactured of high strength ductile iron and be heat treated to a minimum hardness of 370 BHN. The split mechanical joint restraint shall have a maximum water working pressure of 350 PSI for sizes 3"-16" and 250 PSI for sizes 18" and above. All sizes shall have a minimum safety factor of 2:1 (i.e. twice the maximum pressure rating of the restraint). The restraint mechanism shall be Star Pipe Products, Split Stargrip series 3100S or an approved equal.

REV.07 REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 15

Split Wedge Action Restraint for Ductile Iron Pipe - New or Existing Installations Patent #5,772,252

Split Stargrip series 3100S

Joint Restraint Products

INSTALLATION INSTRUCTIONS - SIZES 3"- 48"

STEP 1

Split Stargrip Series 3100S is designed to restrain new and existing installations of Ductile Iron Pipe, conforming to AWWA/ANSI C151/A21.51 (all thickness classes), push-on pipe bells. It includes a Split Stargrip Series 3000S restraint gland for the spigot end and a Split Back-Up Ring behind the bell.

STEP 2

Rotate Split Stargrip Series 3000S restraint gland on the spigot such that the bolt holes are in alignment and adjust the position so that the distance between the glands is suitable for the double-ended rod length. Adequate length should be allowed on the double-ended rods so that nuts can be fully engaged with several threads showing. Install the remaining double-ended rods provided in each bolthole. Place nuts on the ends of each double-ended rod.

Assemble the Pipe Push-On joint per the pipe manufacturers installation instructions in case of new installations or make sure that Push-On Pipe joint pipe is installed correctly per manufacturers installation instructions in case of existing joints. Install the split back up ring behind the pipe bell in the direction indicated on the casting. Tighten clamping bolts on the split back-up ring to 90 lb-ft. Remove the clamping bolts from the Split Stargrip Series 3000S. Loosely assemble the halves on the spigot end of the pipe with clamping bolts, making sure that the lip extension on the halves is towards the mating pipe bell.

STEP 3

Pull Split Stargrip Series 3000S restraint gland away from the joint until there is no slack in the rods. Tighten Clamping bolts on the Split Stargrip Series 3000S to 90 - 110 lb-ft.

STEP 4

Tighten the torque limiting twist off nuts in a clockwise direction until all the wedges are in firm contact with the pipe OD. Continue tightening in an alternative manner going on the opposite sides (Star Pattern), until all of the nuts have been twisted off. Never turn a single nut over 180 degrees without alternating to another nut. The nuts on the double-ended rods for the Back-Up Ring must be tightened untill the Back-Up Ring is in firm contact with the back of the bell. These nuts should not be over tightened. If removal of the Split Stargrip Series 3000S restraint gland is necessary, utilize the 5/8" hex head provided. If reassembly is required, assemble the product in the same manner as above and tighten the wedge bolts to 90 lbs. ft. on sizes 3"-20", 120 lbs. ft. on sizes 24"-36" & 130 lbs. ft. on sizes 42"-48".

Note: Not to be used on plain end fittings or PVC, HDPE or steel pipe.

REV.07

REGISTERED TRADEMARK OF STAR PIPE PRODUCTS STAR PIPE PRODUCTS HOUSTON CORPORATE TOLL FREE 1-800-999-3009 FAX 281-558-9000 www.starpipeproducts.com

Page 16

Das könnte Ihnen auch gefallen

- Workholding MethodDokument37 SeitenWorkholding MethodAinii KunNoch keine Bewertungen

- Pipe Chart PDFDokument2 SeitenPipe Chart PDFCarlos Rivera0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- YK and YT Centrifugal Compressor Shaft Seal E-Learning CourseDokument12 SeitenYK and YT Centrifugal Compressor Shaft Seal E-Learning Coursejose2525100% (3)

- STRUCTURE 2011-02 February (Steel)Dokument60 SeitenSTRUCTURE 2011-02 February (Steel)symon ellimacNoch keine Bewertungen

- MS171 MS181 MS211 Service ManualDokument102 SeitenMS171 MS181 MS211 Service Manuallucian0757% (7)

- APV Plug Valve CatalogueDokument40 SeitenAPV Plug Valve CatalogueVeerapandianNoch keine Bewertungen

- Gaseous Hydrogen Piping SpecificationDokument5 SeitenGaseous Hydrogen Piping SpecificationAndri DoemeriNoch keine Bewertungen

- IHC S90 Hydraulic Hammer Accumulators Repair ProceduresDokument18 SeitenIHC S90 Hydraulic Hammer Accumulators Repair ProceduresNBRellos100% (2)

- Dın-Sae Flange StandartDokument9 SeitenDın-Sae Flange Standartbugrahanerdogdu100% (1)

- Simplified Steel DesignDokument22 SeitenSimplified Steel DesignBCXC LLAM100% (2)

- Terex TSR 70 Parts Manual PDFDokument38 SeitenTerex TSR 70 Parts Manual PDFoscar el carevergaNoch keine Bewertungen

- Wood Finishing Basics: Application Techniques & Product SelectionDokument13 SeitenWood Finishing Basics: Application Techniques & Product SelectionDGWNoch keine Bewertungen

- F1X1 2006Dokument0 SeitenF1X1 2006Ray Cepeda MenaNoch keine Bewertungen

- Mil-Std-1251a - Listing Screw and Bolts - An-Nas-MsDokument182 SeitenMil-Std-1251a - Listing Screw and Bolts - An-Nas-Mspradelles100% (2)

- Monolithic Insulated Joint BrochureDokument8 SeitenMonolithic Insulated Joint Brochuremarita_msNoch keine Bewertungen

- 585s. Part Manual FL 01 and 02Dokument585 Seiten585s. Part Manual FL 01 and 02Thuong HoangNoch keine Bewertungen

- Expension Joints Engineering AppliancesDokument30 SeitenExpension Joints Engineering AppliancesAcid BurnsNoch keine Bewertungen

- Hyd Inc SwivelsDokument140 SeitenHyd Inc SwivelsCentral HydraulicsNoch keine Bewertungen

- Cast Steel and Stainless Steel Y StrainersDokument13 SeitenCast Steel and Stainless Steel Y StrainersNinad SherawalaNoch keine Bewertungen

- Superbolt CatalogDokument32 SeitenSuperbolt CatalogwatcharpNoch keine Bewertungen

- Tee Split TDWDokument4 SeitenTee Split TDWmaoreales100% (1)

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDokument8 SeitenTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Noch keine Bewertungen

- MeasureMaster Dual Chamber Orifice FittingDokument6 SeitenMeasureMaster Dual Chamber Orifice FittingirfanNoch keine Bewertungen

- Ebaa 1100Dokument6 SeitenEbaa 1100sureshmaya88Noch keine Bewertungen

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDokument2 SeitenStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771Noch keine Bewertungen

- Swagelok Medium Pressure Fittings Alloy 625Dokument16 SeitenSwagelok Medium Pressure Fittings Alloy 625totcsabNoch keine Bewertungen

- Brochure 1100 PDFDokument6 SeitenBrochure 1100 PDFDavid CarvalhoNoch keine Bewertungen

- Data Sheet Flange and Torque GuideDokument4 SeitenData Sheet Flange and Torque GuidePutraSumateraNoch keine Bewertungen

- Kunkle OverviewDokument8 SeitenKunkle Overviewsamix999Noch keine Bewertungen

- Roberts Oxygen Welding Industrial Catalog 2011Dokument104 SeitenRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaNoch keine Bewertungen

- A1200 Red Thread II PipingDokument0 SeitenA1200 Red Thread II PipingjimmycabreraNoch keine Bewertungen

- Brochure - Ex TENDDokument4 SeitenBrochure - Ex TENDBilly ZununNoch keine Bewertungen

- Style 22 Vic-Ring Coupling: Product DescriptionDokument2 SeitenStyle 22 Vic-Ring Coupling: Product DescriptionDante2500Noch keine Bewertungen

- Miller Spectrum 875 XtremeDokument4 SeitenMiller Spectrum 875 XtremeomaralihasNoch keine Bewertungen

- Velan Forged Steel Gate, Globe & ChecksDokument25 SeitenVelan Forged Steel Gate, Globe & Checksmhorst1Noch keine Bewertungen

- Double Block Bleed TOSVDokument8 SeitenDouble Block Bleed TOSVplanet123Noch keine Bewertungen

- Power Stream Couplings-Specn SheetsDokument6 SeitenPower Stream Couplings-Specn SheetsAmol PatkiNoch keine Bewertungen

- CS310ADokument4 SeitenCS310Arabacet2923Noch keine Bewertungen

- 0620000008Dokument6 Seiten0620000008mahsaNoch keine Bewertungen

- Amco CR4000Dokument4 SeitenAmco CR4000Arwin TroconisNoch keine Bewertungen

- Eaton HansenKingDokument80 SeitenEaton HansenKingKING COMERCIAL LTDANoch keine Bewertungen

- TAPER GRIP-TWIST Brochure - RevB-red PDFDokument4 SeitenTAPER GRIP-TWIST Brochure - RevB-red PDFGonzalo AbarcaNoch keine Bewertungen

- Roper Serie 3600 PDFDokument2 SeitenRoper Serie 3600 PDFantonioNoch keine Bewertungen

- 2100 2800 Series PDFDokument2 Seiten2100 2800 Series PDFhendrabudimanNoch keine Bewertungen

- 6606 Ebaa 3800 Series: Restrained CouplingDokument1 Seite6606 Ebaa 3800 Series: Restrained CouplingDGWNoch keine Bewertungen

- NGV ConnectorDokument15 SeitenNGV ConnectorEddie TaiNoch keine Bewertungen

- Strainer Spec SheetDokument3 SeitenStrainer Spec Sheetswaraj4uNoch keine Bewertungen

- Lead Free Series SS009 Specification SheetDokument2 SeitenLead Free Series SS009 Specification SheetWattsNoch keine Bewertungen

- Ib 10Dokument2 SeitenIb 10dchz_62Noch keine Bewertungen

- SRDokument2 SeitenSRJong JavaNoch keine Bewertungen

- Trampas de Vapor Armstrong, Series880 PDFDokument2 SeitenTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanNoch keine Bewertungen

- Tescom Series 44-2200Dokument2 SeitenTescom Series 44-2200liamcsNoch keine Bewertungen

- Gaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)Dokument12 SeitenGaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)김윤식Noch keine Bewertungen

- Cokebuster: A Proven SolutionDokument11 SeitenCokebuster: A Proven Solutionengg_mech77Noch keine Bewertungen

- 13 - Jesse Meisterling Gaskets and Leaks PVRC Recommendations and StudiesDokument0 Seiten13 - Jesse Meisterling Gaskets and Leaks PVRC Recommendations and StudiesVicky GautamNoch keine Bewertungen

- Drawing 80H30Dokument3 SeitenDrawing 80H30kpranjal15Noch keine Bewertungen

- HeliCoil Stud-Lock ApplicationsDokument2 SeitenHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNoch keine Bewertungen

- Tru-Tension Fasteners: TDS-006A 2-1-01Dokument6 SeitenTru-Tension Fasteners: TDS-006A 2-1-01SOLRAKNoch keine Bewertungen

- Viking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsDokument12 SeitenViking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsBenicio Joaquín Ferrero BrebesNoch keine Bewertungen

- Bezrms PumpDokument2 SeitenBezrms PumpAndres BojorquezNoch keine Bewertungen

- CC Marine 2013-14 Catalogue - PumpsDokument94 SeitenCC Marine 2013-14 Catalogue - PumpsGregGGHNoch keine Bewertungen

- 3 CatalogDokument50 Seiten3 CatalogZeu AressNoch keine Bewertungen

- FT MedPress AutoclaveDokument12 SeitenFT MedPress AutoclaveAymeeenNoch keine Bewertungen

- GPT Installation Instructions - LoresDokument7 SeitenGPT Installation Instructions - LoresEWheelerFKNoch keine Bewertungen

- Eaton Hansen CatalogoDokument80 SeitenEaton Hansen Catalogorubens0001Noch keine Bewertungen

- T101 Drilling MachineDokument4 SeitenT101 Drilling MachineRemmy Torres VegaNoch keine Bewertungen

- AmeritoolBroch Aug21Dokument12 SeitenAmeritoolBroch Aug21hiscoke69Noch keine Bewertungen

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatDokument2 SeitenWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWNoch keine Bewertungen

- Overkote Asphalt Pavement Coating: DescriptionDokument1 SeiteOverkote Asphalt Pavement Coating: DescriptionDGWNoch keine Bewertungen

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Dokument2 SeitenMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWNoch keine Bewertungen

- He130 - Driveway Asphalt Coating: Physical PropertiesDokument2 SeitenHe130 - Driveway Asphalt Coating: Physical PropertiesDGWNoch keine Bewertungen

- Standard Pipe Sizes ME303-4.1.1Dokument5 SeitenStandard Pipe Sizes ME303-4.1.1manashbdNoch keine Bewertungen

- Nord-Lock Washers: The Original Wedge-Locking SolutionDokument16 SeitenNord-Lock Washers: The Original Wedge-Locking SolutionDGWNoch keine Bewertungen

- 01 04tocDokument428 Seiten01 04tocFaltooNoch keine Bewertungen

- Schedule 80 Pipe Dimensions & Pressure RatingsDokument1 SeiteSchedule 80 Pipe Dimensions & Pressure RatingsDGWNoch keine Bewertungen

- Lee Spring CatalogDokument391 SeitenLee Spring CatalogDGWNoch keine Bewertungen

- Standard Pipe Sizes ME303-4.1.1Dokument5 SeitenStandard Pipe Sizes ME303-4.1.1manashbdNoch keine Bewertungen

- Flat Washer and FastenersDokument49 SeitenFlat Washer and FastenersDGWNoch keine Bewertungen

- D-01 7041 Flange-ANSI 125,150-RevlDokument4 SeitenD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasNoch keine Bewertungen

- CAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDokument1 SeiteCAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDGWNoch keine Bewertungen

- PVC Gravity Sewer PipeDokument1 SeitePVC Gravity Sewer PipeDGWNoch keine Bewertungen

- Bolt - Astm A449Dokument2 SeitenBolt - Astm A449DGWNoch keine Bewertungen

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDokument2 SeitenTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWNoch keine Bewertungen

- Thrust Restraint For Expansion JointDokument2 SeitenThrust Restraint For Expansion JointDGWNoch keine Bewertungen

- The First Hillside Washer That Eliminated Back-Up Plates!Dokument1 SeiteThe First Hillside Washer That Eliminated Back-Up Plates!DGWNoch keine Bewertungen

- Rubber Expansion JointsDokument9 SeitenRubber Expansion JointsDGWNoch keine Bewertungen

- Tap Drill ChartDokument2 SeitenTap Drill ChartDGWNoch keine Bewertungen

- Steel Rebar SizesDokument1 SeiteSteel Rebar SizesDGWNoch keine Bewertungen

- Threaded Rod AccessoriesDokument1 SeiteThreaded Rod AccessoriesDGWNoch keine Bewertungen

- Countersinking Drill Bit ReamerDokument1 SeiteCountersinking Drill Bit ReamerDGWNoch keine Bewertungen

- Tap Drill DataDokument1 SeiteTap Drill DataDGWNoch keine Bewertungen

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDokument2 SeitenJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWNoch keine Bewertungen

- Cotter Pins and Spring PinsDokument1 SeiteCotter Pins and Spring PinsDGWNoch keine Bewertungen

- Screw Threads DesignDokument1 SeiteScrew Threads DesignDGWNoch keine Bewertungen

- Standard Pipe Schedules and Sizes ChartDokument1 SeiteStandard Pipe Schedules and Sizes ChartDGWNoch keine Bewertungen

- Steering Unit: Service ManualDokument36 SeitenSteering Unit: Service ManualPanneerChellamNoch keine Bewertungen

- 6D125-1XX-B Air Cleaner Parts BreakdownDokument2 Seiten6D125-1XX-B Air Cleaner Parts BreakdownShop ManualNoch keine Bewertungen

- Maintenance Manual: Fan Jet FalconDokument15 SeitenMaintenance Manual: Fan Jet FalconFederico KronenbergNoch keine Bewertungen

- Vehicle General Manual SectionsDokument24 SeitenVehicle General Manual SectionsAlisher AshurovNoch keine Bewertungen

- Dodge Nitro KA - 2007 - ClutchDokument29 SeitenDodge Nitro KA - 2007 - ClutcheephantomNoch keine Bewertungen

- Comment Resolution Sheet (CRS) : Document No. REV E1121-150-PS-DS-101437 - 6 1Dokument7 SeitenComment Resolution Sheet (CRS) : Document No. REV E1121-150-PS-DS-101437 - 6 1sumit kumarNoch keine Bewertungen

- Ds60 Installation ManualDokument82 SeitenDs60 Installation ManualmariannyNoch keine Bewertungen

- Easy Switch With Sulzer Adapter Brackets E10640Dokument2 SeitenEasy Switch With Sulzer Adapter Brackets E10640Marcos Chaves MagalhãesNoch keine Bewertungen

- Fishplates Fishplates: Specifications SpecificationsDokument5 SeitenFishplates Fishplates: Specifications SpecificationsMohamed ShafikNoch keine Bewertungen

- Motores Flender PFTDokument53 SeitenMotores Flender PFTantoniomelgacoNoch keine Bewertungen

- Apex Steel - Suppliers of Ferrous & Non-Ferrous MetalsDokument3 SeitenApex Steel - Suppliers of Ferrous & Non-Ferrous MetalsRamboNoch keine Bewertungen

- MT-Series Joker Parts Catalog 2013Dokument90 SeitenMT-Series Joker Parts Catalog 2013BubunGuchhaitNoch keine Bewertungen

- ASME B18.6.5M Appendix VI 1993Dokument7 SeitenASME B18.6.5M Appendix VI 1993Jesse ChenNoch keine Bewertungen

- Installation Kit Part No 1250MD-4Dokument1 SeiteInstallation Kit Part No 1250MD-4Roberto Torres ArancibiaNoch keine Bewertungen

- 08 Design For Manual Assembly PDFDokument51 Seiten08 Design For Manual Assembly PDFAnonymous VRspXsmNoch keine Bewertungen

- English)Dokument193 SeitenEnglish)vladijaraNoch keine Bewertungen

- EQPT-02-21 Pipe Strain For Rotating EquipmentDokument2 SeitenEQPT-02-21 Pipe Strain For Rotating EquipmentAmanSharmaNoch keine Bewertungen

- Catalog About ProbeDokument42 SeitenCatalog About ProbeMonica CarrollNoch keine Bewertungen

- Sf8 Duro Fr20Dokument1 SeiteSf8 Duro Fr20GoodBikes100% (1)

- Fiberizer F2Dokument108 SeitenFiberizer F2Reinaldo RamirezNoch keine Bewertungen