Beruflich Dokumente

Kultur Dokumente

Mechanical Properties of Solids and Acoustics

Hochgeladen von

Mayank AgarwalCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechanical Properties of Solids and Acoustics

Hochgeladen von

Mayank AgarwalCopyright:

Verfügbare Formate

1

MECHANICAL PROPERTIES OF

SOLIDS AND ACOUSTICS

1.1 Elasticity and Plasticity

When the shape or size of a body has been altered by the application of a force or a system

of forces, there is usually some tendency for the body to recover its original shape or size on the

removal of the force. This property of the body by virtue of which it tends to regain its original

shape or size on the removal of deforming force is called elasticity.

The property of the body by virtue of which it tends to retain the altered size and shape on

removal of deforming forces is called plasticity.

1.2 Stress and Strain

Stress is a quantity that characterizes the strength of the forces causing the deformation, on

a force per unit area basis. The deforming force per unite area of the body is called stress. The

SI unit of stress is the Pascal (abbreviated Pa, and named for the 17

th

century French scientist and

philosopher Blaise Pascal). One Pascal equals one Newton per square meter.1 Pascal = 1Pa =

1N/m

2

. Strain is a quantity which describes the resulting deformation. Strain is the fractional

deformation produced in a body when it is subjected to a set of deforming forces. Strain being

ratio has no units.

There are following three types of stress and strain

(i) Tensile and compressive stress and strain

(ii) Bulk stress and strain

(iii) Shear stress and strain

1.3 Hookes Law

This law was proposed by Robert Hooke, the founder of Royal society, in 1676. Hookes

law states that within the elastic limit, the stress developed is directly proportional to the strain.

The constant of proportionality is the elastic modulus (or modulus of elasticity).

Stress

Strain

= elastic modulus (Hookes law)

Physics for Technologists 1.2

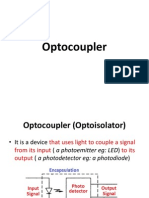

Fig. 1.1 Stress - Strain diagram

If we plot a graph between stress and strain we get a curve as shown in Fig. 1.1 and it is

called stress - strain diagram. It is clear from this graph that Hookes law holds good only for the

straight line portion of the curve.

1.4 Elastic Moduli

The coefficient of elasticity or modulus of elasticity indicates how a specimen behaves

when subjected to given stress. This has the same units as stress that is Nm

-2

or Pa. There are three

kinds of elastic moduli as given in Table 1.1.

Table 1.1 Three kinds of elastic moduli

Elastic Modulus Definition Nature of strain

Youngs modulus (Y)

Tensile stress

Tensile strain

Change of shape and size

Bulk modulus (B)

Bulk stress

Bulk strain

Change of size but not shape

Shear modulus or

Rigidity modulus (S)

Shear stress

Shear strain

Change of shape but not size

Worked Example 1.1: A steel rod 2.0m long has a cross sectional area of 0.30cm

2

. The rod is

now hung by one end from a support structure and a 550kg milling

machine is hung from the rods lower end. The Youngs modulus of

steel is 20 10

10

Pa. Determine the stress, the strain and the elongation

of the rod.

2

8

5 2

(550 ) (9.8 / )

1.8 10

3.0 10

F kg m s

Stress Pa

A m

= = =

8

4

10

1.8 10

9.0 10

20 10

o

Stress Pa

Strain

Y Pa

A

= = = =

Elongation = A = (strain)

o

= (9.010

-4

) (2.0)

= 0.0018m = 1.8mm.

Strain

Plastic range

0

S

t

r

e

s

s

Elastic limit

Elastic range

Permanent set

Mechanical Properties of Solids and Acoustics 1.3

Disc

Torsionally flexible elastic wire

Fixed End

1.5 Torsion Pendulum

Definition

A torsion pendulum is an oscillator for which the restoring force is torsion.

Description

The device as shown in Fig.1.2 consisting of a disc or other body of large moment of

inertia mounted on one end of a torsionally flexible elastic rod wire whose other end is held fixed;

if the disc is twisted and released, it will undergo simple harmonic motion, provided the torque in

the rod is proportional to the angle of twist.

Theory

When the disc is rotated in a horizontal plane so as to twist the wire, the various elements

of the wire undergo shearing strains. Restoring couples, which tend to restore the unstrained

conditions, are called into action. Now when the disc is released, it starts executing torsional

vibrations.

If the angle of twist at the lower end of the wire is , then the restoring couple is C ,

where C is the torsional rigidity of the wire, this couple acting on the disc produces in it an angular

acceleration given by

Fig. 1.2 Torsion Pendulum

C =

2

2

d

I

dt

u

(1)

where I is the moment of inertia of the disc about the axis of the wire. The minus sign

indicates that the couple C tends to decrease the twist. Equation (1) can be rewritten as

2

2

d C

dt I

u

= u (2)

The above relation shows that the angular acceleration is proportional to the angular

displacement and is always directed towards the mean position. Hence the motion of the disc is

simple harmonic motion and the time period of the vibration will be given by

Physics for Technologists 1.4

T = 2

Displacement

Acceleration

2

C

I

u

t

u

=

| |

|

\ .

or T = 2 C / I

Uses of Torsion Pendulum

(1) For determining the moment of inertia of an irregular body

For determining the moment of inertia of an irregular body the torsion pendulum is found

to be very useful. First, the time period of pendulum is determined when it is empty and then the

time period of the pendulum is determined after placing a regular body on the disc and after this

the time period is determined by replacing the regular body by the irregular body whose moment

of inertia is to be determined. It is ensured that the body is placed on the disc such that the axes of

the wire pass through the centre of gravity of the body placed on the disc.

If I, I

1

and I

2

are the moments of inertia of the disc, regular body and irregular body and T,

T

1

and T

2

are the time periods in the three cases respectively, then

T = 2

I

C

(3)

T

1

= 2

1

I I

C

+

(4)

T

2

=

2

2 I I

C

+

(5)

From relations (3) and (4), we have

T

1

2

T

2

=

2

1

4 I

C

t

(6)

and from relations (3) and (5), we have

T

2

2

T

2

=

2

2

4 I

C

t

(7)

2 2 2

1 1 1

2 2 2

2 2 2

4 /

4 /

T T I C I

T T I C I

t

= =

t

(8)

or

2 2

2

2 1 2 2

1

T T

I I

T T

(9)

The moment of inertia of the regular body I

1

is determined with the help of the dimensions

of the body, thus the moment of inertia of the irregular body is calculated.

Mechanical Properties of Solids and Acoustics 1.5

(2) Determination of Torsional Rigidity

For determining the modulus of rigidity N the time period of the pendulum is found (i)

when the disc is empty, and (ii) when a regular body is placed on the disc with axis of wire

passing through the centre of gravity of the body. If T is the time period of the pendulum in first

case and T

1

in the second case, then we have

T = 2

I

C

(10)

and T

1

= 2

C

I

I I +

(11)

where I is the moment of inertia of the disc and I

1

the moment of inertia of the regular body placed

on the disc. From relations (10) and (11), we have

T

1

2

T

2

=

C

I

1

2

4t

(12)

or

2

2

1

1

2

4

T T

I

C

=

t

(13)

For a wire of modulus of rigidity N, length l and radius r, we have

l

Nr

C

2

4

t

= (14)

Equating (13) and (14), we have

l

Nr

T T

I

2

4

4

2

2

1

1

2

t

t

=

(15)

or

4 2

2

1

1

) (

8

r T T

lI

N

=

t

(16)

Thus, the value of N can be determined.

Worked Example 1.2: A torsion pendulum is made using a steel wire of diameter 0.5mm and

sphere of diameter 3cm. The rigidity modulus of steel is 80 GPa and

density of the material of the sphere is 11300 kg/m

3

. I f the period of

oscillation is 2 second, find the length of the wire.

4 2

8

r T

I

N

t

=

For sphere, I = 2/5 MR

2

M = volume density

M = 4/3 (3/2 10

-2

)

3

11300 = 0.1598 kg

Physics for Technologists 1.6

I = 2/5 0.1598 (3/2 10

-2

)

2

= 0.14382 10

-4

kgm

2

4

0.5

9 2 3

80 10 2 10

2 4

NT r

2

4

8 I

8 0.14382 10

= = =

t

t

| |

|

\ .

5.531m l .

1.6 Bending of Beams

A beam is a rod or bar of uniform cross-section (circular or rectangular) whose length is

very much greater than its thickness as shown in Fig. 1.3.

The beam is considered to be made up of a large number of thin plane layers called

surfaces placed one above the other. Consider a beam to be bent into an arc of a circle by the

application of an external couple as shown Fig. 1.4. Taking the longitudinal section ABCD of the

bent beam the layers in the upper half are elongated while those in the lower half are compressed.

Fig. 1.3 A beam

In the middle there is a layer (MN) which is not elongated or compressed due to bending

of the beam. This layer is called the neutral surface and the line (MN) at which the neutral layer

intersects the plane of bending is called the neutral axis.

Fig.1.4 Bending of a beam

It is obvious that the length of the filament increases or decreases in proportion to its

distance away from the neutral axis MN.

The layers below MN are compressed and those above MN are elongated and there will be

such pairs of layers one above MN and one below MN experiencing same forces of elongation and

compression due to bending and each pair forms a couple.

Mechanical Properties of Solids and Acoustics 1.7

The resultant of the moments of all these internal couples are called the internal bending

moment and in the equilibrium condition, this is equal to the external bending moment.

1.6.1 Bending Moment of a Beam

Consider the section PBCP' (Fig. 1.5), the extended filaments lying above the neutral axis

MN are in state of tension and exert an inward pull on the filament adjacent to them towards the

fixed end of the beam. In the same way the shortened filaments lying below the neutral axis MN

are in a state of compression and exert an outward push on the filaments adjacent to them towards

the loaded end of the beam. As a result tensile and compressive stresses develop in the upper and

lower halves of the beam respectively and form a couple which opposes to bending of the beam.

The moment of this couple is called the moment of the resistance. When the beam is in

equilibrium position the bending moment and restoring moment or moment of resistance should be

equal.

To find an expression for the moment of the restoring couple consider a fiber A'B' at a

distance r from the neutral axis MN as shown in Fig.1.6. Let the radius of curvature be R of the

part PB and be the angle subtended by it at the centre of curvature. In unstrained position of the

beam, the length of the fiber A'B' = MN = R. In the strained position the length of the fibre

A'B'

= (R + r) .

Fig. 1.5 Calculation of bending moment of a beam

Fig.1.6 Strained position

Strain in the fiber A

1

B

1

, =

length Original

length the in Change

M

N

C

B

P'

D

A

P

Load

r

N

A' B'

R

M

Physics for Technologists 1.8

or

R

r

R

R r R

Strain =

+

=

|

| | ) (

(1)

i.e., strain is proportional to the distance from the neutral axis.

Let the area of the fiber be a and its neutral axis be at a distance r from neutral axis of the

beam and the strain produced be r/R. We have

Stress = Y Strain = Y r / R (2)

where Y is the Youngs modulus of the material

Hence, force on the area a

F = Y(r/R) a (3)

Therefore the moment of this force about MN

= Y(r/R) a r = Y a r

2

/ R (4)

As the moment of the forces acting on both the upper and lower halves of the section are

in the same direction, the total moment of the forces acting on the filaments due to straining

g

I

R

Y

ar

R

Y

R

r a

Y = E = E =

2

2

(5)

where I

g

is the geometrical moment of inertia and is equal to AK

2

, A being the total area of the

section and K being the radius of gyration of the beam

:. moment of the forces

g

I

R

Y

= (6)

In equilibrium bending moment of the beam is equal and opposite to the moment of

bending couple due to the load on one end.

:. Bending moment of the beam =

g

I

R

Y

(7)

The quantity YI

g

(=Y A K

2

) is called the flexural rigidity of the beam. Flexural rigidity is

defined as the bending moment required to produce a unit radius of curvature.

1.6.2 Uniform Bending

The beam is loaded uniformly on its both ends, the bent beam forms an arc of a circle.

The elevation in the beam is produced. This bending is called uniform bending.

Consider a beam (or bar) AB arranged horizontally on two knife edges C and D

symmetrically so that AC = BD = a as shown in Fig. 1.7

Fig. 1.7 Uniform Bending

The beam is loaded with equal weights W and W at the ends A and B.

Mechanical Properties of Solids and Acoustics 1.9

D

F

C

o

E

y

R

l/2

F

The reactions on the knife edges at C and D are equal to W and W acting vertical upwards.

The external bending moment on the part AF of the beam is

= W AF W CF = W (AF CF)

= W AC = W a (1)

Internal bending moment =

R

YI

g

(2)

where

Y - Youngs modulus of the material of the bar

I

g

- Geometrical moment of inertia of the cross-section of beam

R - Radius of curvature of the bar at F

In the equilibrium position,

external bending moment = internal bending moment

R

YI

Wa

g

= (3)

Since for a given value of W, the values of a, Y and I

g

are constants, R is constant so that

the beam is bent uniformly into an arc of a circle of radius R.

CD = l and y is the elevation of the midpoint E of the beam so that y = EF

Then from the property of the circle as shown in Fig. 1.8

Fig. 1.8 Circle Property

EF (2R EF) = (CE)

2

(4)

y (2R y) =

2

2

| |

|

\ .

l

(5)

y 2R =

2

4

l

(since y

2

is negligible) (6)

Physics for Technologists 1.10

y =

2

8R

l

(7)

or

2

8

R

1

l

y

=

(8)

From (3) and (8), Wa =

8

YI

g

2

y

l

or

y I

a l W

Y

g

8

2

=

(9)

If the beam is of rectangular cross-section,

12

3

bd

I

g

=

, where b is the breath and d is the

thickness of beam.

If M is the mass, the corresponding weight W = Mg

Hence

y bd

a Mgl

Y

3

2

2

3

=

(10)

from which Y the Youngs modulus of the material of the bar is determined.

Worked Example 1.3: Uniform rectangular bar 1 m long 2 cm broad and 0.5 cm thick is

supported on its flat face symmetrically on two knife edges 70 cm apart.

I f loads of 200 g are hung from the two ends, find the elevation at the

center of the bar. Youngs modulus of the material of the bar is 18

10

10

Pa.

The distance between the nearer knife edge and the point of suspension

a=1510

-2

m

Elevation at the centre,

3

2

2

3

d Yb

l a g M

y =

3 2 2 10

2 2 3

) 10 5 . 0 ( 10 2 10 18 2

7 . 0 10 15 8 . 9 10 200 3

=

= 4.802 10

-4

m

1.6.3 Non-Uniform Bending

If the beam is loaded at its mid-point, the depression i produced will not form an arc of a

circle. This type of bending is called non-uniform bending.

Consider a uniform beam (or rod or bar) AB of length l arranged horizontally on two knife

edges K

1

and K

2

near the ends A and B as shown in Fig. 1.9.

Mechanical Properties of Solids and Acoustics 1.11

Fig. 1.9 Non-uniform bending

A weight W is applied at the midpoint E of the beam. The reaction at each knife edge is

equal to W/2 in the upward direction and y is the depression at the midpoint E.

The bent beam is considered to be equivalent to two single inverted cantilevers, fixed at E

each of length

|

.

|

\

|

2

l

and each loaded at K

1

and K

2

with a weight

2

W

In the case of a cantilever of length l and load W,

the depression =

Y I

l W

g

3

3

Hence, for cantilever of length

2

| |

|

\ .

l

and load

|

.

|

\

|

2

W

, the depression is

y =

Y I

l W

g

3

2 2

3

|

.

|

\

|

|

.

|

\

|

(1)

or

Y I

l W

y

g

48

3

=

(2)

If M is the mass, the corresponding weight W is

W = Mg (3)

If the beam is a rectangular, I

g

=

12

3

bd

, where b is the breadth and d is the thickness of the

beam.

Hence

3

3

48

12

Mg l

y

bd

Y

=

(4)

Y bd

gl M

y

3

3

48

12

=

(5)

or

y bd

gl M

Y

3

3

4

=

Nm

-2

(6)

The value of youngs modulus, Y can be determined by the above equation.

E

K2 K1

B A

W/2 W/2

W

Physics for Technologists 1.12

1.7 Stress-Strain Relation for Different Engineering Materials

The stress and strain relation can be studied by drawing a graph or curve by taking strain

along the x axis and the corresponding stress along the y axis. This curve is called stress- strain

curve. The stress-strain relations for different engineering materials are discussed below.

For ferrous metal

Fig.1.10 shows the stress-strain diagram for different types of steel and wrought iron. The

strength of the ferrous metals depends up on carbon content, but at the cost of its ductility, as it is

clearly understood from the figure. The proportion of carbon does not have an appreciable effect

on youngs modulus of elasticity during any hardening process.

Fig. 1.10. Stress- Strain curve for ferrous metals

For non-ferrous metal

For hard steels and non-ferrous metals stress is specified corresponding to a definite

amount of permanent elongation. This stress is known as proof stress. For aircraft materials the

stress corresponding to 0.1% of strain is the proof stress. The proof stress is applied for 15 seconds

and when removed, the specimen should not lengthen permanently beyond 0.1%.

Fig.1.11. Stress Strain curve for non - ferrous metals

Alloy steel or tool steel

Mild steel (Ductile)

High carbon steel

Medium carbon steel

Wrought iron (Most ductile)

Cast iron (Brittle iron)

Strain

S

t

r

e

s

s

Aluminium bronze

Magnesium

oxide

Brass 70:30

Annealed copper

Strain

S

t

r

e

s

s

Mechanical Properties of Solids and Acoustics 1.13

Fig.1.11 shows stress-strain curves for non-ferrous materials. The elastic properties of

non-ferrous metals vary to a considerable extent, depending upon the method of working and their

compositions in the case of alloys. From the figure it is clear that the early portion of the stress-

strain diagram for most of the metals is never quite straight line, but the yield point is well define.

Brittle materials show little or no permanent deformation prior to fracture. Brittle behavior

is exhibited by some metals and ceramics like magnesium oxide .The small elongation prior to

fracture means that the materials gives no indication of impending fracture and brittle fracture

usually occurs rapidly. It is often accompanied by loud noise.

Saline Features of stress-strain relation

- The properties of ductile metals can be explained with the help of stress-strain curves.

- Higher yield point will represents greater hardness of the metals.

- A higher value of maximum stress point will represent a stronger metal.

- The distance from the ordinates of the load point (or) breaking stress will indicate the

toughness and brittleness of the metal. The shorter the distance then the metal is more

brittle.

1.8 Ductile and Brittle Materials

1.8.1 Ductile materials

A body is said to have yielded or to have undergone plastic deformation if it does not

regains its original shape when a load is removed. The resulting deformation is called permanent

set. If permanent set is obtainable, the material is said to exhibit ductility. Ductility measures the

degree of plastic deformation sustained it fracture. One way of specify a material is by the

percentage of elongation (%EL).

Percentage of elongation = 100

L

L - L

o

o f

Where L

f

is the length of the specimen at fracture

L

o

is the length of the specimen without load.

A ductile material is one with a large Percentage of elongation before failure. The original

length of the specimen L

o

is an important value because a significant portion of the plastic

deformation at fracture is confined to the neck region. Thus, the magnitude of percentage of

elongation will depend on the specimen length.

Table 1.2 Percentage of elongation for ductile materials

Material Percentage of Elongation

Low-Carbon 37%

Medium-Carbon 30%

High-Carbon 25%

The percentage of elongation of different ductile materials is tabulated above. For ductile

material, the ultimate tensile and compressive strength have approximately the same absolute

value. The steel is ductile material because it far exceeds the 5% elongation. High strength alloys,

Physics for Technologists 1.14

such as spring steel, can have 2% of elongation but even this is enough to ensure that the material

yields before it fractures. Hence it is behaved like a ductile material. Gold is relatively ductile at

room temperature. Most of the material becomes ductile by increasing the temperature.

Properties of ductile materials:

- Easily drawn into wire or hammered thin.

- Easily molded or shaped.

- Capable of being readily persuaded or influenced tractable.

- Easily stretched without breaking in material strength.

Stress strain behavior of ductile materials

In the case of ductile materials at the beginning of the tensile test, the material extends

elastically. The strain at first increase proportionally to the stress and the specimen returns to its

original length on removal of the stress. The limit of proportionality is the stage up to which the

material obeys Hookes law perfectly.

Beyond the elastic limit the applied stress produces plastic deformation so that a

permanent extension remains even after the removal of the applied load. In this stage the resultant

strain begins to increase more quickly than the corresponding stress and continues to increase till

the yield point is reached. At the yield point the material suddenly stretches.

The rate of applied load to original cross-sectional area is termed the nominal stress. This

continues to increase with elongation, due to strain hardening or work hardening, until the tensile

stress is maximum. This is the value of stress at maximum load and can be calculated by dividing

the maximum load by the original cross-sectional area. This stress is called ultimate tensile stress.

Fig 1.12 Stress- strain curve for a ductile material.

Fig.1.12 is a stress-strain diagram for ductile material (mild steel) showing the limit of

proportionality, elastic limit, yield point, ultimate tensile stress and fracture.

Upper yield point

Strain

Ultimate stress

Lower yield point

Limit of proportionality

Elastic limit

Fracture

S

t

r

e

s

s

Mechanical Properties of Solids and Acoustics 1.15

From Fig.1.12 it is clearly show that at a certain value of load the strain continues at slow

rate without any further stress. This phenomenon of slow extension increasing with time, at

constant stress is termed creep. At this point a neck begins to develop along the length of the

specimen and further plastic deformation is localized within the neck. After necking the nominal

stress decreases until the material fractures at the point of minimum cross-sectional area.

1.8.2 Brittle Materials

Brittle material is one which is having very low percentage of elongation. Brittle materials

break suddenly under stress at a point just beyond its elastic limit. A Brittle material exhibits little

or no yielding before failure. Brittle material will have a much lower elongation and area reduction

than ductile ones. The tensile strength of Brittle material is usually much less than the compressive

strength. The brittle material can be deformed in a ductile only under the conditions of high

pressure.

Ceramic glass and cast iron are having very good brittle nature. Grey cast iron is a best

example for brittle material whose percentage of elongation is so small. Brittle materials are used

in design of hard ceramic armor, exclusive excavation of rocks, space craft windows, impact of

condensed particle on turbine blades etc.

Determination of Brittle materials

- If the percentage of elongation is at or below 5%, assume brittle behavior.

- If the ultimate compressive strength is greater than the ultimate tensile strength

assume brittle behavior

- If no yield strength is occurred suspect brittle behavior

Stress strain behavior of brittle materials

Fig. 1.13 Stress strain curve for a brittle material

Figure 1.13 shows a poorly defined yield point in brittle materials. For the determination

of yield strength in such materials, one has to draw a straight line parallel to the elastic portion of

the stress strain curve at a predetermined strain ordinate value (say 0.1%). The point at which this

line intersects the stress-strain curve is called the yield strength.

Strain

Yield point at off-set

S

t

r

e

s

s

Parallel

Proof stress

Physics for Technologists 1.16

1.9 Some Fundamental Mechanical Properties

The following are the some of the fundamental mechanical properties of metals:

(i) Tensile strength (ii) Hardness (iii) Impact strength (iv) fatigue and (v) Creep

1.9.1 Tensile Strength

This is the maximum conventional stress that can be sustained by the material. It is the

ultimate strength in tension and corresponds to the maximum load in a tension test. It is measured

by the highest point on the conventional stress-strain curve. In engineering tension tests this

strength provides the basic design information on the materials.

The tensile strength of a material is the maximum amount of tensile stress that it can be

subjected to before failure. There are three typical definitions of tensile strength.

Yield strength

The stress at which material strain changes from elastic deformation to plastic

deformation, causing it to deform permanently is known as yield strength.

Ultimate strength

The maximum stress a material can withstand is known as ultimate strength.

Breaking strength

The strength co-ordinate on the stress-strain curve at the point of rupture is known as

breaking strength.

In ductile materials the load drops after the ultimate load because of necking. This

indicates the beginning of plastic instability. In brittle materials, the ultimate tensile strength is a

logical basis for working stresses. Like yield strength, it is used with a factor of safety.

Table 1.3 Typical tensile strengths of engineering materials

Material Tensile Strength kg/mm

2

Alloy steel 60 -70

Mild Steel 42

Grey CI 19

White CI 47

Aluminum alloy 47

1.9.2 Hardness

Hardness is the resistance of material to permanent deformation of the surface. However,

the term may also refer to stiffness, temper resistance to scratching and cutting. It is the property of

a metal, which gives it the ability to resist being permanently deformed (bent, broken or shape

change), when a load is applied.

The hardness of a surface of the material is, of course, a direct result of inter atomic

forces acting on the surface of the material. We must note that hardness is not a fundamental

property of a material, but a combined effect of compressive, elastic and plastic properties relative

to the mode of penetration, shape of penetration etc. The main usefulness of hardness is, it has a

constant relationship to the tensile strength of a given material and so can be used as a practical

Mechanical Properties of Solids and Acoustics 1.17

non-destructive test for an approximate idea of the value of that property and the state of the metal

near the surface.

Hardness Measurement

Hardness measurement can be in Macro, Micro & nano scale according to the forces

applied and displacements obtained.

Measurement of the Macro-hardness of materials is a quick and simple method of

obtaining mechanical property data for the bulk materials from a small sample. It is also widely

used for the quality control of a surface treatments process. The Macro-hardness measurement will

be highly variable and will not identify individual surface features. It is here that micro-hardness

measurements are appropriate.

Micro hardness is the hardness of a material as determined by forcing an indenter into the

surface of the material under load, usually the indentations are so small that they must be measured

with a microscope. Micro hardness measurements are capable of determines the hardness of

different micro constituent with in a structure.

Nano hardness tests measure hardness by using indenter, on the order of nano scale. These

tests are based one new technology that allows precise measurement and control of the indenting

forces and precise measurement of the indentation depth.

Hardness Measurement Methods

There are several methods of hardness testing, depending either on the direct thrust of

some form of penetrator into the metal surface, or on the ploughing of the surface as a styles is

drawn across it under a controlled load, or on the measurement of elastic rebound of an impacting

hammer which possessing known energy. Measurements of hardness are the easiest to make and

are widely used for industrial design and in research. As compared to other mechanical tests,

where the bulk of the material is involved in testing, all hardness tests are made on the surface or

close to it.

The following are the most common hardness test methods used in todays technology.

1. Rockwell hardness test

2. Brinell hardness

3. Vickers

4. Knoop hardness

5. Shore

Brinell, Rockwell and Vickers hardness tests are used to determine hardness of metallic

materials to check quality level of products, for uniformity of sample of metals, for uniformity of

results of heat treatment. The relative micro hardness of a material is determined by the knoop

indentation test. The shore scleroscope measures hardness in terms of the elasticity of the material.

Brinell hardness number is the hardness index calculated by pressing a hardened steel ball

(indenter) into test specimen under standard load. The rock well hardness is another index which

widely used by engineers. This index number is measured by the depth of penetration by a small

indenter. By selecting different loads and shapes of indenter, different Rockwell scales have been

developed. The value of Brinell hardness number is related to tensile strength, which is as shown

in Fig.1.14.

Physics for Technologists 1.18

Fig.1.14 Tensile strength verses Brinell hardness curves

The mechanism of indentation in all indentation tests is that when the indenter is pressed

into the surface under a static load, a large amount of plastic deformation takes place. The

materials thus deformed flows out in all directions. As a result of plastic flow, sometimes the

material in contact with the indenter produces a ridge around the impression. Large amount of

plastic deformation are accompanied by large amount of transient creep which vary with the

material and time of testing. Transient creep takes place rapidly at first and more slowly as it

approaches its maximum. For harder materials, the time required for reaching maximum

deformation is short (few seconds) and for soft materials the time required to produce the derived

indentation is unreasonably long up to a few minutes.

Hardness of materials is of importance for dies and punches, limit gauges, cutting tools

bearing surfaces etc. Softness of a material is opposite extreme of hardness. On heating all

materials become soft.

1.9.3 Impact Strength

Impact strength is the resistance of a material to fracture under dynamic load. Thus, it is a

complex characteristic which takes into account both the toughness and strength of a material. In

S.I. units the impact strength is expressed in Mega Newton per m

2

(MN/m

2

). It is defined as the

specific work required to fracture a test specimen with a stress concentrator in the mid when

broken by a single blow of striker in pendulum type impact testing machine.

Impact strength is the ability of the material to absorb energy during plastic deformation.

Obviously brittleness of a material is an inverse function of its impact strength. Course grain

structures and precipitation of brittle layers at the grain boundaries do not appreciably change the

mechanical properties in static tension, but substantially reduce the impact strength.

Impact strength is affected by the rate of loading, temperature and presence of stress

raisers in the materials. It is also affected by variation in heat treatment, alloy content, sulphur and

phosphorus content of the material.

Impact strength is determined by using the notch-bar impact tests on a pendulum type

impact testing machine. This further helps to study the effect of stress concentration and high

velocity load application.

Mechanical Properties of Solids and Acoustics 1.19

Factors affecting Impact strength

- If the dimensions of the specimen are increased, the impact strength also increases.

- When the sharpness of the notch increase, the impact strength required causing failure

decreases.

- The temperature of the specimen under test gives an indication about the type of

fractures like ductile, brittle or ductile to brittle transition.

- The angle of the notch also improves impact-strength after certain values.

- The velocity of impact also affects impact strength to some extent.

1.9.4 Fatigue

Fatigue is caused by repeated application of stress to the metal. It is the failure of a

material by fracture when subjected to a cyclic stress. Fatigue is distinguished by three main

features.

i) Loss of strength

ii) Loss of ductility

iii) Increased uncertainty in strength and service life

Fatigue is an important form of behaviour in all materials including metals, plastics,

rubber and concrete. All rotating machine parts are subjected to alternating stresses; aircraft wings

are subjected to repeated loads, oil and gas pipes are often subjected to static loads but the dynamic

effect of temperature variation will cause fatigue. There are many other situations where fatigue

failure will be very harmful. Because of the difficulty of recognizing fatigue conditions, fatigue

failure comprises a large percentage of the failures occurring in engineering. To avoid stress

concentrations, rough surfaces and tensile residual stresses, fatigue specimens must be carefully

prepared.

The S-N Curve

A very useful way to visual the failure for a specific material is with the S-N curve. The

S-N means stress verse cycles to failure, which when plotted using the stress amplitude on the

vertical axis and the number of cycle to failure on the horizontal axis. An important characteristic

to this plot as seen in Fig.1.15 is the fatigue limit.

Physics for Technologists 1.20

10

4

10

5

10

6

10

7

10

8

10

9

Cycles

Fig.1.15 S-N curve for a metal

The point at which the curve flatters out is termed as fatigue limit and is well below the

normal yield stress. The significance of the fatigue limit is that if the material is loaded below this

stress, then it will not fail, regardless of the number of times it is loaded. Materials such as

aluminium, copper and magnesium do not show a fatigue limit; therefore they will fail at any

stress and number of cycles. Other important terms are fatigue strength and fatigue life. The

fatigue strength can be defined as the stress that produces failure in a given number of cycles

usually 10

7

. The fatigue life can be defined as the number of cycles required for a material to fail

at a certain stress.

1.9.5 Creep

The creep is defined as the property of a material by virtue of which it deforms

continuously under a steady load. Creep is the slow plastic deformation of materials under the

application of a constant load even for stressed below the yield strength of the material. Usually

creep occurs at high temperatures. Creep is an important property for designing I.C. engines, jet

engines, boilers and turbines. Iron, nickel, copper and their alloys exhibited this property at

elevated temperature. But zin, tin, lead and their alloys shows creep at room temperature. In

metals creep is a plastic deformation caused by slip occurring along crystallographic directions in

the individual crystals together with some deformation of the grain boundary materials.

Fig.1.16 Creep curve at constant temperature and stress

6

10

14

16

22

18

26

30

34

38

Fatigue strength

S

t

r

e

s

s

Mechanical Properties of Solids and Acoustics 1.21

Fig.1.16 shows a typical creep curve. The creep curve usually consists of three points

corresponding to particular stages of creep.

(i) Primary Stage: In this stage the creep rate decreases with time, the effect of work

hardening is more than that of recovery processes. The primary stage is of great

interest to the designer since it forms an early part of the total extension reached in a

given time and may affect clearness provided between components of a machine.

(ii) Secondary Stage: In this stage, the creep rate is a minimum and is constant with

time. The work hardening and recovery processes are exactly balanced. It is the

important property of the curve which is used to estimate the service life of the

alloy.

(iii) Tertiary Stage: In this stage, the creep rate increases with time until fracture

occurs. Tertiary creep can occur due to necking of the specimen and other processes

that ultimately result in failure.

The temperature and time dependence of creep deformation indicates that it is a thermally

activated process. Several atomic processes are known to be responsible for creep in crystalline

materials.

The yield strength which is determined in short term tests cannot be the criterion of high

temperature strength. Hence it does not consider the behaviour of a material in long-term loading.

The actual criteria of high temperature strength are the creep limit and long term strength. The

Creep Limit is the stress at which a material can be formed by a definite magnitude during a

given time at a given temperature. The calculation of creep limit includes the temperature, the

deformation and the time in which this deformation appears.

Types of Creep

The creep are classified into three different categories based on the temperature

(i) Logarithmic Creep

(ii) Recovery Creep

(iii) Diffusion Creep

At low temperature the creep rate decreases with time and the logarithmic creep curve is

obtained. At high temperature, the influence of work hardening is weakened and there is a

possibility of mechanical recovery. As a result, the creep rate does not decrease and the recovery

creep curve is obtained. At very high temperature, the creep is primarily influenced by diffusion

and load applied has little effect. This creep is termed as diffusion creep or plastic creep.

1.10 Fracture

Fracture is the separation of a specimen into two or more parts by an applied stress.

Fracture is caused by physical and chemical forces and takes place in two stages: (i) initial

formation of crack and (ii) spreading of crack. Depend upon the type of materials, the applied load,

state of stress and temperature metals have different types of fracture.

There are four Main types of fracture

i) Brittle Fracture

ii) Ductile Fracture

Physics for Technologists 1.22

iii) Fatigue Fracture

iv) Creep Fracture

Fracture is usually undesirable in engineering applications. We may note that flaws such

as surface cracks lower the stress for brittle fracture where as line defects are responsible for

initiating ductile fractures. Different types of fracture are shown in Fig.1.17.

Fig. 1.17 Different types of fractures

1.10.1 Brittle Fracture

Brittle fracture is the failure of a material with minimum of plastic deformation. If the

broken pieces of a brittle fracture are fitted together, the original shape & dimensions of the

specimen are restored.

Brittle fracture is defined as fracture which occurs at or below the elastic limit of a

material. The brittle fracture increases with

(i) Increasing strain rate

(ii) Decreasing temperature

(iii) Stress concentration conditions produced by a notch.

Salient Features of Brittle Fracture

(1) Brittle fracture occurs when a small crackle in materials grows. Growth continues

until fracture occurs.

(2) The atoms at the surfaces do not have as many neighbors as those in the interior of a

solid and therefore they form fever bonds. That implies, surface atoms are at a

higher energy than a plane of interior atom. As a result of Brittle fracture destroying

the inter atomic bonds by normal stresses.

(3) In metals brittle fracture is characterized by rate of crack propagation with minimum

energy of absorption.

Mechanical Properties of Solids and Acoustics 1.23

(4) In brittle fracture, adjacent parts of the metal are separated by stresses normal to the

fracture surface.

(5) Brittle fracture occurs along characteristics crystallographic planes called as

cleavage planes. The fracture is termed as cleavage fracture.

(6) Brittle fracture does not produce plastic deformation, so that it requires less energy

than a ductile failure.

Mechanism of Brittle Fracture

The mechanism of Brittle fracture is explained by Griffith theory. Griffith postulated that

in a brittle material there are always presence of micro cracks which act to concentrated the stress

at their tips. The crack could come from a number of source, e.g. as a collection of dislocations, as

flow occurred during solidification or a surface scratch.

In order to explain the mechanism of ideal brittle fracture, let us consider the stress

distribution in a specimen under constant velocity in the vicinity of crack. When a longitudinal

tensile stress is applied, the crack tends to increase its length causes an increase in surface area of a

crack. As a result, the surface energy of the specimen is also increased. Moreover, there is also

compensation release of energy. This means, an increase in crack length causes the release of

elastic energy Griffith state that when the elastic energy released by extending a crack equal to

the surface energy required for crack extension then the crack will grow.

o =

e

E 2

t

(1)

where, e is half of the crack length, is the true surface energy and E is the Young's modulus.

Equation (1) gives the stress necessary to cause the brittle fracture and the stress is

inversely proportional to the square root of the crack length. Hence the tensile strength of a

completely brittle material is determined by the length of the largest crack existing before loading.

The relation (1) is known as the Griffiths equation.

For ductile materials there is always some plastic deformation before fracture. This

involves an additional energy term

p

. Therefore the fracture strength is given by

o =

1

2

p

2E

e

(

(

t

(

(2)

Generally

p

>> for metals.

From the above formula, one can get the size of largest flaw or crack.

1.10.2 Ductile Fracture

Ductile fracture is defined as the fracture which takes place by a slow propagation of crack

with considerable amount of plastic deformation.

There are three successive events involved in a ductile fracture.

- The specimen begins necking and minute cavities form in the necked region. This is

the region in which the plastic deformation is concentrated. It indicates that the

formation of cavities is closely linked to plastic deformation.

Physics for Technologists 1.24

- It has been observed that during the formation of neck small micro cracks are

formed at the centre of the specimen due to the combination of dislocations.

- Finally these cracks grow out ward to the surface of the specimen in a direction 45

to the tensile axis resulting in a cup-end-cone-type fracture.

-

Fig.1.18 Various stages in ductile fracture

Fig.1.18 shows the various stages in ductile fracture. Ductile fracture has been studied

much less extensively than brittle fracture, as it is considered to be a much less serious problem.

An important characteristic of ductile fracture is that it occurs through a slow tearing of the metal

with the expenditure of considerable energy.

The fracture of ductile materials can also explained in terms of work-hardening coupled

with crack-nucleation and growth. The initial cavities are often observed to form at foreign

inclusions where gliding dislocations can pile up and produce sufficient stress to form a void or

micro-crack. Consider a specimen subjected to slow increasing tensile load. When the elastic limit

is exceeded, the material beings to work harden. Increasing the load, increasing the permanent

elongation and simultaneously decrease the cross sectional area. The decrease in area leads to the

formation of a neck in the specimen, as illustrated earlier. The neck region has a high dislocation

density and the material is subjected to a complex stress. The dislocations are separated from each

other because of the repulsive inter atomic forces. As the resolved shear stress on the slip plane

increase, the dislocation comes closed together. The crack forms due to high shear stress and the

presence of low angle grain boundaries. Once a crack is formed, it can grow or elongated by

means of dislocations which slip. Crack propagation is along the slip plane for this mechanism.

Once crack grows at the expense of others and finally cracks growth results in failure.

Mechanical Properties of Solids and Acoustics 1.25

Table 1.4 Comparison between Brittle and Ductile fracture

Ductile fracture Brittle fracture

- Material fractures after plastic

deformation and slow propagation

of crack

- Material fractures with very little or no

plastic deformation.

- Surface obtained at the fracture is

dull or fibrous in appearance

- Surface obtained at the fracture is

shining and crystalling appearance

- It occurs when the material is in

plastic condition.

- It occurs when the material is in elastic

condition.

- It is characterized by the formation

of cup and cone

- It is characterized by separation of

normal to tensile stress.

- The tendency of ductile fracture is

increased by dislocations and other

defects in metals.

- The tendency brittle fracture is

increased by decreasing temperature,

and increasing strain rate.

- There is reduction in cross

sectional area of the specimen

- There is no change in the cross

sectional area.

1.10.3 Fatigue Fracture

Fatigue fracture is defined as the fracture which takes place under repeatedly applied

stresses. It will occur at stresses well before the tensile strength of the materials. The tendency of

fatigue fracture increases with the increase in temperature and higher rate of straining.

The fatigue fracture takes place due to the micro cracks at the surface of the materials. It

results in, to and fro motion of dislocations near the surface. The micro cracks act as the points of

stress concentration. For every cycle of stress application the excessive stress helps to propagate

the crack. In ductile materials, the crack grows slowly and the fracture takes place rapidly. But in

brittle materials, the crack grows to a critical size and propagates rapidly through the material.

1.10.4 Creep Fracture

Creep fracture is defined as the fracture which takes place due to creeping of materials

under steady loading. It occurs in metals like iron, copper & nickel at high temperatures. The

tendency of creep fracture increases with the increase in temperature and higher rate of straining.

The creep fracture takes place due to shearing of grain boundary at moderate stresses and

temperatures and movement of dislocation from one slip to another at higher stresses and

temperatures. The movement of whole grains relation of each other causes cracks along the grain

boundaries, which act as point of high stress concentration. When one crack becomes larger it

spreads slowly across the member until fracture takes place. This type of fracture usually occurs

when small stresses are applied for a longer period. The creep fracture is affected by grain size,

strain hardening, heat treatment and alloying.

Physics for Technologists 1.26

Worked Example 1.4: A Youngs modulus of a certain material is 180 10

3

mega Newton/ m

2

and its true surface energy is 1.8 J/m

2

. The crack length is 5 m.

Calculate the fracture strength.

The fracture strength is

o =

e

E 2

t

o =

9

6

2 1 8 180 10

3 14 5 2 10

.

. /

o = 278 10

6

Newton /m

2

1.11 Acoustics of Buildings

Introduction

Acoustics is the science of sound. Building acoustics or architectural acoustics deals with

sound in the built environment. From the theaters of ancient Greece to those of the twenty first

century, architectural acoustics has been a key consideration in building design.

1.11.1 Intensity

Intensity I of sound wave at a point is defined as the amount of sound energy Q flowing

per unit area in unit time when the surface is held normal to the direction of the propagation of

sound wave.

i.e.,

Q

I

At

=

If A = 1m

2

and t = 1 sec, then I = Q, where Q is sound energy.

The intensity is a physical quantity which depend upon the factors like amplitude a,

frequency f and velocity v of sound together with the density of the medium .

The intensity I in a medium is given by

I = 2tf

2

a

2

v

The unit of intensity is Wm

-2

.

The minimum sound intensity which a human ear can sense is called the threshold

intensity. Its value is 10

12

watt/m

2

. If the intensity is less than this value then our ear cannot hear

the sound.

This minimum intensity is also known as zero or standard intensity. The intensity of a

sound is measured with reference to the standard intensity.

Mechanical Properties of Solids and Acoustics 1.27

1.11.2 Intensity level (relative intensity) I

L

The intensity level or relative intensity of a sound is defined as the logarithmic ratio of

intensity of I of a sound to the standard intensity I

o

.

i.e.,

10

log

L

o

I

I K

I

| |

=

|

\ .

Let I and I

0

represent intensities of two sounds of a particular frequency, and L

t

and L

o

be

their corresponding measures of loudness. Then, according to Weber-Fechner law,

L

1

= K log

10

I

(1)

L

0

= K log

10

I

0

(2)

Therefore, the intensity level or relative intensity is

I

L

= L

1

L

0

= K log

10

I K log

10

I

0

= K (log

10

I log

10

I

0

)

10

log

L

o

I

I K

I

| |

=

|

\ .

(1)

If K = 1, then I

L

is expressed in a unit called bel.

From the relation (1), it is seen that, 10 ties increase in intensity i.e., I = 10I

0

corresponds

to 1 bel. Therefore, bel is the intensity level of a sound whose intensity is 10 times the standard

intensity.

Similarly, 100 times increase in intensity, i.e., I = 100I

0

corresponds to 2 bel and 1000

times increase in intensity, i.e. I = 1000 I

0

corresponds to 3 bel and so on.

In practice, bel is a large unit. Hence, another unit known as decibel dB is more often

used.

1

1

10

dB bel =

i.e. one decibel is

1

10

th of a bel.

Thus,

10

0

log

L

I

I K dB

I

| |

=

|

\ .

The threshold of audibility is 0 dB and the maximum intensity level is 120 dB. The sound of

intensity level 120 dB produces a feeling of pain in the ear and is therefore called as the threshold

of feeling.

Physics for Technologists 1.28

1.11.3 Loudness

Loudness is characteristic which is common to all sounds whether classified as musical

sound or noise.

Loudness is a degree of sensation produced on ear. Thus, loudness varies from one

listener to another. The loudness depend upon intensity and also upon the sensitiveness of the ear.

Loudness and intensity are related to each other by the relation

I L

10

log

or

10

log L K I = where K is a constant.

From this relation it is seen that, loudness is directly proportional to the logarithm of

intensity, and is known as Weber-Fechner law.

From the above equation,

dL

dI I

K

=

where,

dL

dI

is called as sensitiveness of ear. Therefore, sensitiveness decrease with increase of

intensity. Loudness is a physiological quantity.

Worked Example 1.5: If the intensity of a source of sound is increased 20 times its value, by how

many decibel does the intensity level increase.

10

10 log

L

o

I

I

I

| |

=

|

\ .

= 10 log

10

10

20

10 log 20 10 1.3012

o

o

I

I

| |

= =

|

\ .

I

L

= 13.01 dB.

Thus, the sound intensity level is increased by 13 dB when the intensity is

doubled.

Worked Example 1.6: The amplitude of a sound wave is doubled; by how many dB will the

intensity level increase?

We know I a

2

, therefore when amplitude is doubled, intensity increases

four times.

I = 4I

0

Mechanical Properties of Solids and Acoustics 1.29

Hence,

10

4

10 log

o

L

o

I

I

I

| |

=

|

\ .

I

L

= 10 log

10

4 = 10 0.6020

I

L

= 6.020 dB.

Thus, the intensity level increase by 6 dB.

Worked Example 1.7: What is the resultant sound level when a 70 dB sound is added to a 80 dB

sound?

1

10

10 log

L

o

I

L

I

| |

=

|

\ .

70 =

1

10

log

o

I

I

| |

|

\ .

7 =

1

10

log

o

I

I

| |

|

\ .

7 1

10

o

I

I

=

or I

1

= 10

7

I

o

Similarly, 80 = 10 log

10

2

o

I

I

| |

|

\ .

8 2

10

o

I

I

=

1.12 Sound Absorption

When sound is incident on the surface of any medium, it splits into three parts. One part is

reflected from the surface; another part gets absorbed in the medium, while the remaining part is

transmitted through the medium and emerges on the other side. The property of a surface by which

sound energy is converted into other form of energy is known as absorption. In the process of

absorption sound energy is converted into heat due to frictional resistance inside the pores of the

material. The fibrous and porous materials absorb sound energy more, than other solid materials.

1.12.1 Sound Absorption Coefficient

Different surfaces absorb sound to different extents. The effectiveness of a surface in

absorbing sound energy is expressed with the help of absorption coefficient. The coefficient of

absorption `o of a materials is defined as the ratio of sound energy absorbed by its surface to that

of the total sound energy incident on the surface. Thus,

Physics for Technologists 1.30

o =

surface the on incident energy sound Total

surface the by absorbed energy Sound

In order to compare the relative efficiency of different absorbing surfaces, it is essential to

select a standard in terms of which all surfaces can be described. A unit area of open window is

selected as the standard. All the sound incident on an open window is fully transmitted and none is

reflected. Therefore, it is considered as an ideal absorber of sound. Thus the unit of absorption is

the open window unit (O.W.U.), which is named a sabin after the scientist who established the

unit. A 1m

2

sabin is the amount of sound absorbed by one square metre area of fully open window.

Table 1.5 lists the absorption coefficients of various materials.

Table 1.5 Absorption coefficients of some materials

Material Absorption coefficient per m

2

at 500 Hz

Open window

Ventilators

Stage curtain

Curtains with heavy folds

Carpet

Audience (One adult in upholstered seat)

Fibrous plaster, Straw board

Perforated compressed fibre board

Concrete

Marble

1.00

0.10 to 0.50

0.20

0.40 to 0.75

0.40

0.46

0.30

0.55

0.17

0.01

The value of `o depends on the nature of the material as well as the frequency of sound.

The greater the frequency the larger is the value of `o for the same material. Therefore, the values

of `o for a material are determined for a wide range of frequencies. It is a common practice to use

the value of `o at 500 Hz in acoustic designs.

If a material has the value of o as 0.5, it means that 50% of the incident sound energy

will be absorbed per unit area. If the material has a surface area of S sq.m., then the absorption

provided by that material is

a = o. S

If there are different materials in a hall, then the total sound absorption by the different

materials is given by

A = a

1

+ a

2

+ a

3

+

A = o

1

S

1

+ o

2

S

2

+ o

3

S

3

+

or A =

n

n n

S

1

o

where o

1

, o

2

, o

3

. are absorption coefficients of materials with areas S

1

, S

2

, S

3

, .

Mechanical Properties of Solids and Acoustics 1.31

1.12.2 Reverberation

Sound produced in an enclosure does not die out immediately after the source has ceased

to produce it. A sound produced in a hall undergoes multiple reflections from the walls, floor and

ceiling before it becomes inaudible. A person in the hall continues to receive successive reflections

of progressively diminishing intensity. This prolongation of sound before it decays to a negligible

intensity is called reverberation.

Some reverberation is often desirable, especially in a hall used for musical performance. A

small amount of reverberation improves the original sound. However, too much reverberation

causes boom sound quality in a musical performance, Speeches given in such a hall would be

unintelligible. Reverberation is a familiar phenomenon experienced in halls without furniture.

Note that the reverberation of sound pertains to enclosed spaces only. In open air the

sound spreads out in all directions without repeated reflections.

1.12.3 Reverberation Time

The time taken by the sound in a room to fall from its average intensity to inaudibility

level is called the reverberation time of the room. Reverberation time is defined as the time during

which the sound energy density falls from its steady state value to its one-millionth (10

-6

) value

after the source is shut off. We can also express reverberation time in terms of sound energy level

in dB as follows. If initial sound level is L

i

and the final level is L

f

and reference intensity value is

I ,then we can write

L

i

= 10 log

I

I

i

and L

f

= 10 log

I

I

f

L

i

L

f

= 10 log

f

i

I

I

As

i

f

I

I

= 10

-6

. L

i

L

f

= 10 log 10

6

= 60 dB

Thus, the reverberation time is the period of time in seconds, which is required for

sound energy to diminish by 60 dB after the sound source is stopped.

1.12.4 Sabines Formula for Reverberation Time

Prof.Wallace C.Sabine (1868-1919) determined the reverberation times of empty halls and

furnished halls of different sizes and arrived at the following conclusions.

i) The reverberation time depends on the reflecting properties of the walls, floor and ceiling

of the hall. If they are good reflectors of sound, then sound would take longer time to die

away and the reverberation time of the hall would be long.

ii) The reverberation time depends directly upon the physical volume V of the hall.

iii) The reverberation time depends on the absorption coefficient of various surfaces such as

carpets, cushions, curtains etc present in the hall.

Physics for Technologists 1.32

iv) The reverberation time depends on the frequency of the sound wave because absorption

coefficient of most of the materials increases with frequency. Hence high frequency would

have shorter reverberation time.

Prof. Sabine summarized his results in the form of the following equation.

Reverberation Time, T

Volumeof the Hall V

Absorption A

or T =

A

V

K

(1)

where K is a proportionality constant. It is found to have a value of 0.161 when the dimensions are

measured in metric units. Thus,

T =

A

V 161 . 0

(2)

Equation (2) is known as Sabines formula for reverberation time. It may be rewritten as

T =

N

n n

S

V

1

161 . 0

o

(3)

or T =

n n

S S S S

V

o o o o + + + + .......

161 . 0

3 3 2 2 1 1

(4)

1.12.5 Optimum Reverberation Time

Sabine determined the time of reverberation for halls of various sizes and is given in Table

1.6. In these measurements, he used an organ pipe as the source, which was blown at a definite

frequency and under a constant pressure. The instant of cutting off of the sound and the instant at

which the observer ceased to hear the sound were recorded. And from the results, he deduced the

reverberation time that is likely to be most satisfactory for the purpose for which a hall is built.

Such satisfactory value is known as the optimum reverberation time.

Table 1.6 Optimum Reverberation Time for Halls

Activity in Hall Optimum Reverberation Time (s)

Conference halls

Cinema theatre

Assembly halls

Public lecture halls

Music concert halls

Churches

Large halls

1 to 1.5

1.3

1 to 1.5

1.5 to 2

1.5 to 2

1.8 to 3

2 to 3

1.13 Factors Affecting Acoustics of Buildings

There are several factors that affect the acoustical quality of a hall. We discuss here seven

common acoustical defects and their remedies.

Mechanical Properties of Solids and Acoustics 1.33

(1) Reverberation Time

If a hall is to be acoustically satisfactory, it is essential that it should have the right

reverberation time. The reverberation time should be neither too long nor too short. A very short

reverberation time makes a room `dead. On the other hand, a long reverberation time renders

speech unintelligible. The optimum value for reverberation time depends on the purpose for which

a hall is designed. A reverberation time of 0.6 s is acceptable for speeches and lectures, while a

reverberation time of 1 to 2 s is satisfactory for concerts. In case of theatres the optimum value

varies with the volume. For small theatres 1.1 to 1.5 s is suitable whereas for large theatres, may

go up to 2.3 s.

Remedies

The reverberation time can be controlled by the suitable choice of building materials and

furnishing materials. If the reverberation time of a hall is too long, it can be cut down by increasing

the absorption or reducing volume and if it is too short, it can be increased by changing high

absorption materials to materials of low absorption or increasing volume.

Since open windows allow the sound energy to flow out of the hall, there should be a

limited number of windows. They may be opened or closed to obtain optimum reverberation time.

Carboard sheets, perforated sheets, felt, heavy curtains, thick carpets etc are used to

increase wall and floor surface absorption. Therefore, the walls are to be provided with absorptive

materials to the required extent and at suitable places. Heavy fold curtains may be used to increase

the absorption. Covering the floor with carpet also increase the absorption.

Audience also contribute to absorption of sound. The absorption coefficient of an

individual is about 0.45 sabins. In order to compensate for an increase in the reverberation time

due to an unexpected decrease in audience strength, upholstered seats are to be provided in the

hall. Absorption due to an upholstered chair is equivalent to that of an individual. In the absence of

audience the upholstered chair absorbs the sound energy and it does not contribute to absorption

when it is occupied.

(2) Loudness

Sufficient loudness at every point in the hall is an important factor for satisfactory hearing.

Excessive absorption in the hall or lack of reflecting surfaces near the sound source may lead to

decrease in the loudness of the sound.

Remedies

A hard reflecting surface positioned near the sound source improve the loudness. Polished

wooden reflecting boards kept behind the speaker and sometimes above the speaker will be

helpful.

Low ceilings are also of help in reflecting the sound energy towards the audience.

Adjusting the absorptive material in the hall will improve the situation.

When the hall is large and audience more, loud speakers are to be installed to obtain the

desired level of loudness.

Physics for Technologists 1.34

(3) Focussing

Reflection concave surfaces cause concentration of reflected sound, creating a sound of

larger intensity at the focal point. These spots are known as sound foci. Such concentrations of

sound intensity at some points lead to deficiency of reflected sound at other points. The spots of

sound deficiency are known as dead spots. The sound intensity will be low at dead spots and

inadequate hearing. Further, if there highly reflecting parallel surfaces in the hall, the reflected and

direct sound waves may form standing waves which leads to uneven distribution of sound in the

hall.

Remedies

The sound foci and dead spots may be eliminated if curvilinear interiors are avoided. If

such surfaces are present, they should be covered highly absorptive materials.

Suitable sound diffusers are to be installed in the hall to cause even distribution of sound

in the hall. A paraboloidal reflecting surface arranged with the speaker at its focus is helpful in

directing a uniform reflected beam of sound in the hall.

(4) Echoes

When the walls of the hall are parallel, hard and separated by about 34m distance, echoes

are formed. Curved smooth surfaces of walls also produce echoes.

Remedies

This defect is avoided by selecting proper shape for the auditorium. Use of splayed side

walls instead of parallel walls greatly reduces the problem and enhance the acoustical quality of

the hall.

Echoes may be avoided by covering the opposite walls and high ceiling with absorptive

material.

(5) Echelon effect

If a hall has a flight of steps, with equal width, the sound waves reflected from them will

consist of echoes with regular phase difference. These echoes combine to produce a musical note

which will be heard along with the direct sound. This is called echelon effect. It makes the original

sound unintelligible or confusing.

Remedies

It may be remedied by having steps of unequal width.

The steps may be covered with proper sound absorbing materials, for example with a

carpet.

(6) Resonance

Sound waves are capable of setting physical vibration in surrounding objects, such as

window panes, walls, enclosed air etc. The vibrating objects in turn produce sound waves. The

Mechanical Properties of Solids and Acoustics 1.35

frequency of the forced vibration may match some frequency of the sound produced and hence

result in resonance phenomenon. Due to the resonance, certain tones of the original music may

get reinforced any may result in distortion of the original sound.

In a hall the whole air mass vibrates if sound is continuously produced from a source. The

vibration of air in turn adds to the resonant frequencies of the hall depending on its dimensions. If

lower modes of resonant frequencies are excited by the source, the sound distribution in the hall

will be erratic.

Remedies

The vibrating bodies may be suitably damped to eliminate resonance due to them.

In larger halls, the resonant frequencies are quite low. Hence by selecting larger halls

resonance defect can be eliminated.

(7) Noise

Noise is unwanted sound which masks the satisfactory hearing of speech and music. There

are mainly three types of noises that are to be minimized. They are (i) air-borne noise, (ii)

structure-borne noise and (iii) internal noise.

(i) The noise that comes into building through air from distant sources is called air-borne

noise. A part of it directly enters the hall through the open windows, doors or other

openings while another part enters by transmission through walls and floors.

Remedies

The building may be located on quite sites away from heavy traffic, market places, railway

stations, airports etc. They may be shaded from noise by interposing a buffer zone of trees, gardens

etc.

(ii) The noise which comes from impact sources on the structural extents of the building is

known- as the structure-borne noise. It is directly transmitted to the building by vibrations

in the structure. The common sources of this type of noise are foot-steps, moving of

furniture, operating machinery etc.

Remedies

The problem due to machinery and domestic appliances can be overcome by placing

vibration isolators between machines and their supports.

Cavity walls, compound walls may be used to increase the noise transmission loss and

keep the noise in the building at desired level.

(iii) I nternal noise is the noise produced in the hall or office etc. They are produced by air

conditioners, movement of people etc.

Physics for Technologists 1.36

Remedies

The walls, floors and ceilings may be provided with enough sound absorbing materials.

The gadgets or machinery should be placed on sound absorbent material.

Split-type air conditioners etc are to be used.

Worked Example 1.8: A classroom has dimensions 20 15 5 m

3

. The reverberation time is

3.5 sec. Calculate the total absorption of its surfaces and the average

absorption coefficient.

=

S

V

T

o

161 . 0

69

5 . 3

) 5 15 20 ( 161 . 0

3

=

=

s

m

S o

average

69 69

2(20 15 15 5 20 5) 950

o = = =