Beruflich Dokumente

Kultur Dokumente

Nitriding Ces-196 A

Hochgeladen von

MATHANKUMAR.SCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nitriding Ces-196 A

Hochgeladen von

MATHANKUMAR.SCopyright:

Verfügbare Formate

CORPORATE ENGINEERING SPECIFICATION CES 196 NITRIDING TREATMENT

1. SCOPE This procedure covers the technical requirements for nitriding of valve parts.

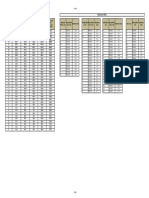

2. MATERIALS Materials covered by this specification are as follows : Material grades ASTM A 487 Gr CA 6 NM class B ASTM A 479 Ty 316 ASTM M 351 Gr CF 8M Masoneilan material code number 193 163 163

3. MANUFACTURE Martensitic stainless steel type CA 6 NM : This material shall be stress relieving, prior to the nitriding treatment, after any of the following operations : Hard deposit Total on local quenching Welding. This stress relieving may be omitted depending on parts weight, geometry and required dimension tolerance values. The stress relieving treatment conditions must be : Temperature :565C to 620C Time : 3 hours Austenitic stainless steel : A specific heat treatment of austenitic stainless steel is not mandatory prior to the nitriding treatment.

Copyright 1996 as an unpublished trade secret. This document and all information herein is the property of Valve & Controls Division of Dresser Industries, Inc. It is confidential and must not be made public or copied and is subject to return upon demand.

Cond sur Noireau, FRANCE

Rev.

Revisions Description

Date

Prepared By: F. COTTRAIT. Date: Feb, 1999 Approved By: G.ROUSSEAU .Date: CES 196 REV. A SHEET 1 OF 3

CES196.doc

4. PART CLEANING The parts will be free from scale, oxide, dirt, grease etc...

5. NITRIDED AREAS Unless otherwise specified on the part drawing, the surfaces are fully nitrided (see appendix No 1 for non nitrided permissible areas).

6. NITRIDING TREATMENT REQUIREMENTS 6.1. White layer thickness : The thickness of the white layer shall not exceed 0.013 mm. 6.2. Case depth and hardness : The hardness and the case depth must be in such a way that the surface hardness is not less than 1000 HV 0.1. 6.3. Temperature limitations : Maximum nitriding temperature must be at 15C below the minimum temperature of the final tempering treatment which is 565C for CA 6 NM material.

7. DISTORTION - REMACHINING All parts shall be properly supported in the nitriding furnace to minimize distortion, see examples in appendix No 1. Turning, grinding, polishing or any other remachining are not acceptable after nitriding treatment. The nitrited part dimensions must be in accordance with the drawing requirements.

8. TESTS Metallographic test may be performed, on coupons which are representative of the parts, to determine the white layer thickness. The HV 0.1 hardness measurement can be performed on representative samples or on polished areas of the parts which must be prepared prior to nitriding.

Copyright 1996 as an unpublished trade secret. This document and all information herein is the property of Valve & Controls Division of Dresser Industries, Inc. It is confidential and must not be made public or copied and is subject to return upon demand.

CES - 196 - REV. A SHEET 2 OF 3

Appendix No 1

Permissible supporting areas are identified in black All other surfaces must be nitrided.

Copyright 1996 as an unpublished trade secret. This document and all information herein is the property of Valve & Controls Division of Dresser Industries, Inc. It is confidential and must not be made public or copied and is subject to return upon demand.

CES - 196 - REV. A SHEET 3 OF 3

Das könnte Ihnen auch gefallen

- PWHT TableDokument1 SeitePWHT TableSumner TingNoch keine Bewertungen

- PWHT Requirement (Rev.3)Dokument6 SeitenPWHT Requirement (Rev.3)Oliver SanvictoresNoch keine Bewertungen

- FAQ To NORSOK M650 Rev4Dokument19 SeitenFAQ To NORSOK M650 Rev4punitdubeyNoch keine Bewertungen

- WM PWHTDokument18 SeitenWM PWHTFaiz IshakNoch keine Bewertungen

- NDT Method Magnetic Particle InspectionDokument23 SeitenNDT Method Magnetic Particle Inspectionabhaymehta67Noch keine Bewertungen

- 034-Saferad ProcedureDokument34 Seiten034-Saferad ProcedureasikurNoch keine Bewertungen

- PMI Testing - Limitations With XRFDokument3 SeitenPMI Testing - Limitations With XRFArun Kumar Kar100% (2)

- B473Dokument7 SeitenB473djlucho123456Noch keine Bewertungen

- Safety Training Brochure MetaboDokument4 SeitenSafety Training Brochure MetaboJonathan DouglasNoch keine Bewertungen

- Reduction Ratio Chart in Steel Rolling MillDokument1 SeiteReduction Ratio Chart in Steel Rolling MillSoumyo Broto DasNoch keine Bewertungen

- Total Preventive Maintenance ForgerDokument4 SeitenTotal Preventive Maintenance Forgermr. kNoch keine Bewertungen

- Shell Rolling Report 1Dokument6 SeitenShell Rolling Report 1Hanuman RaoNoch keine Bewertungen

- Ni-Fe-Cr-Mo-Cu-N Low-Carbon Alloys (UNS N08925, UNS N08031, UNS N08354, and UNS N08926), and Cr-Ni-Fe-N Low-Carbon Alloy (UNS R20033) Bar and Wire, and Ni-Cr-Fe-Mo-N Alloy (UNS N08936) WireDokument7 SeitenNi-Fe-Cr-Mo-Cu-N Low-Carbon Alloys (UNS N08925, UNS N08031, UNS N08354, and UNS N08926), and Cr-Ni-Fe-N Low-Carbon Alloy (UNS R20033) Bar and Wire, and Ni-Cr-Fe-Mo-N Alloy (UNS N08936) WireSrinivasan KrishnamoorthyNoch keine Bewertungen

- Instruction Manual Coating Thickness GaugeDokument16 SeitenInstruction Manual Coating Thickness GaugeRaheel ZiaNoch keine Bewertungen

- Shaft Tolerance Table (ISO 286)Dokument2 SeitenShaft Tolerance Table (ISO 286)garyianderson100% (4)

- Installation, Operation AND Maintanance Manual: Always A Step Ahead in TechnologyDokument26 SeitenInstallation, Operation AND Maintanance Manual: Always A Step Ahead in TechnologyBharat TailorNoch keine Bewertungen

- Bar Bending MachineDokument8 SeitenBar Bending MachineVirendra ChavdaNoch keine Bewertungen

- Bakelite PropertiesDokument6 SeitenBakelite PropertiesAlexander PrasetyaNoch keine Bewertungen

- Astm A 388 PDFDokument9 SeitenAstm A 388 PDFVarun DevNoch keine Bewertungen

- Manual Apollo AnalysisDokument114 SeitenManual Apollo AnalysisvrapciudorianNoch keine Bewertungen

- D1 3scopeDokument4 SeitenD1 3scopeayub82Noch keine Bewertungen

- Carbon Black Feedstock SpecificationsDokument1 SeiteCarbon Black Feedstock Specificationssushant0% (1)

- GPT - Honeywell Pressure SensorDokument10 SeitenGPT - Honeywell Pressure SensorKaran Bir SinghNoch keine Bewertungen

- Innerspec Manual ZzzzzzzzzzzzzzzzzzzzzSensors Accessories T SA A18Dokument273 SeitenInnerspec Manual ZzzzzzzzzzzzzzzzzzzzzSensors Accessories T SA A18Jack PadiNoch keine Bewertungen

- Interlloy 440C MartensiticDokument4 SeitenInterlloy 440C MartensiticGuillaume BoyerNoch keine Bewertungen

- 70 XMET8000 Series User Guide EN PDFDokument134 Seiten70 XMET8000 Series User Guide EN PDFSantosh KumarNoch keine Bewertungen

- Alphagage + Manual - v5Dokument80 SeitenAlphagage + Manual - v5JC Schwartz100% (2)

- Table 1 Limiting Thickness For Which Postweld Heat Treatment Is Not Required For CDokument4 SeitenTable 1 Limiting Thickness For Which Postweld Heat Treatment Is Not Required For CMohd AmaniNoch keine Bewertungen

- WPS-PQR Review Checklist 2007Dokument2 SeitenWPS-PQR Review Checklist 2007sajeed76740Noch keine Bewertungen

- TDS PDF Intertherm - 751CSADokument4 SeitenTDS PDF Intertherm - 751CSAwilliam sukyonoNoch keine Bewertungen

- Sa 395Dokument12 SeitenSa 395Widya widyaNoch keine Bewertungen

- STD-02-0860 Rev 5.0 Part Cleanliness StandardDokument8 SeitenSTD-02-0860 Rev 5.0 Part Cleanliness StandardCARLOS A.N. LANZILLOTTONoch keine Bewertungen

- ASTM A370 - 97a PDFDokument53 SeitenASTM A370 - 97a PDFbaolengocNoch keine Bewertungen

- Hypress Compressor For VSP (Vertical Seismic Profile) JobDokument103 SeitenHypress Compressor For VSP (Vertical Seismic Profile) JobIAN.SEMUTNoch keine Bewertungen

- Hot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaDokument4 SeitenHot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaraajmrkNoch keine Bewertungen

- Close Proximity RadiographyDokument3 SeitenClose Proximity RadiographySantanu SahaNoch keine Bewertungen

- Sa-240 Asme Sec.2Dokument1 SeiteSa-240 Asme Sec.2arianaseriNoch keine Bewertungen

- ASTM Welding Procedures A36 To A930Dokument22 SeitenASTM Welding Procedures A36 To A930Israel Mojica MNoch keine Bewertungen

- Tensile TesterDokument12 SeitenTensile Testerlhanx2Noch keine Bewertungen

- API Source Inspector Fixed Equipment Exam Publications Effectivity SheetDokument2 SeitenAPI Source Inspector Fixed Equipment Exam Publications Effectivity Sheetzachari.alamsyahNoch keine Bewertungen

- How To Passivate Stainless Steel PartsDokument11 SeitenHow To Passivate Stainless Steel Partsnqh2009Noch keine Bewertungen

- 733Dokument17 Seiten733Subhajit DasNoch keine Bewertungen

- ASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsDokument31 SeitenASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsSamsudin AhmadNoch keine Bewertungen

- Jis S2147-1998Dokument35 SeitenJis S2147-1998Xuan KhaiNoch keine Bewertungen

- DIN 51502 SpecsDokument8 SeitenDIN 51502 SpecskhaledNoch keine Bewertungen

- C 561Dokument2 SeitenC 561Asep TheaNoch keine Bewertungen

- Color Code Chart Qfm-qc-03 Rev. 17Dokument1 SeiteColor Code Chart Qfm-qc-03 Rev. 17Balram Ji100% (1)

- INS P 035, Circularity Check - Cyl.sectionsDokument10 SeitenINS P 035, Circularity Check - Cyl.sectionsDeepakNoch keine Bewertungen

- AWS ClassificationDokument4 SeitenAWS ClassificationBarita JonBos SilalahiNoch keine Bewertungen

- STTDokument11 SeitenSTTamr kouranyNoch keine Bewertungen

- Astm A 986 - 2016 PDFDokument3 SeitenAstm A 986 - 2016 PDFEmmanuel BoquetNoch keine Bewertungen

- Hi - Temp 900Dokument5 SeitenHi - Temp 900bhavesh solankiNoch keine Bewertungen

- M47-16781-EN RevF - Impact TestingDokument48 SeitenM47-16781-EN RevF - Impact TestingIvy LiNoch keine Bewertungen

- WPS Casing Sea Water PumpDokument10 SeitenWPS Casing Sea Water PumpdethamrnNoch keine Bewertungen

- Welding Procedure Casing Pump PDFDokument4 SeitenWelding Procedure Casing Pump PDFdethamrnNoch keine Bewertungen

- AESW016Dokument10 SeitenAESW016aslam.ambNoch keine Bewertungen

- Engineering StandardDokument10 SeitenEngineering StandardAnonymous 6eDqP1HUNoch keine Bewertungen

- Standard Specification For Hot Dip GalvanizingDokument4 SeitenStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- 80080-TCH-0000-SP-006 - SIGNED-Additional Material RequirementDokument24 Seiten80080-TCH-0000-SP-006 - SIGNED-Additional Material RequirementPaul NieNoch keine Bewertungen

- Hy 19580Dokument6 SeitenHy 19580kompany_dNoch keine Bewertungen

- Biomedical Engineering Project: A Biosensor Based On Silver Enhanced Self Assembled Rfid Antenna.Dokument4 SeitenBiomedical Engineering Project: A Biosensor Based On Silver Enhanced Self Assembled Rfid Antenna.MATHANKUMAR.SNoch keine Bewertungen

- Matlab Basic Questions Without AnswersDokument1 SeiteMatlab Basic Questions Without AnswersMATHANKUMAR.SNoch keine Bewertungen

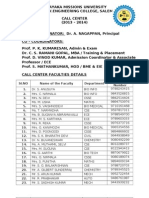

- Biomedical Engineering Alumi Details (Vmkvec)Dokument3 SeitenBiomedical Engineering Alumi Details (Vmkvec)MATHANKUMAR.SNoch keine Bewertungen

- Adaptive Control Question Bank Without Answer KeyDokument5 SeitenAdaptive Control Question Bank Without Answer KeyMATHANKUMAR.S100% (1)

- Electrical Engineering QUESTION BANKDokument7 SeitenElectrical Engineering QUESTION BANKMATHANKUMAR.S100% (1)

- Telemedicine-Introduction: Telemedicine Is The Remote Communication of Information To Facilitate Clinical CareDokument8 SeitenTelemedicine-Introduction: Telemedicine Is The Remote Communication of Information To Facilitate Clinical Caresuhail_ahmed018Noch keine Bewertungen

- Module 1 Lecture 1 What Is InformaticsDokument28 SeitenModule 1 Lecture 1 What Is InformaticsMATHANKUMAR.SNoch keine Bewertungen

- Call Center Faculty DetailsDokument6 SeitenCall Center Faculty DetailsMATHANKUMAR.SNoch keine Bewertungen

- Top Three Rankers in BMEDokument1 SeiteTop Three Rankers in BMEMATHANKUMAR.SNoch keine Bewertungen

- Top Three Rankers in EIEDokument1 SeiteTop Three Rankers in EIEMATHANKUMAR.SNoch keine Bewertungen

- Demodulation of AM & Demodulation of Comparison of Amplitude Modulation SystemsDokument4 SeitenDemodulation of AM & Demodulation of Comparison of Amplitude Modulation SystemsMATHANKUMAR.SNoch keine Bewertungen

- Biomaterials PPT - IITDokument12 SeitenBiomaterials PPT - IITMATHANKUMAR.SNoch keine Bewertungen

- Breast Cancer (Research Paper)Dokument12 SeitenBreast Cancer (Research Paper)Katrina Arnaiz100% (3)

- Sym CertificateDokument2 SeitenSym CertificateMATHANKUMAR.SNoch keine Bewertungen

- Sponsor Project List EEEDokument3 SeitenSponsor Project List EEEMATHANKUMAR.SNoch keine Bewertungen

- Embedded System Lession PlanDokument4 SeitenEmbedded System Lession PlanMATHANKUMAR.SNoch keine Bewertungen

- V. M. K. V. Engineering College, Salem: Vinayaka Missions UniversityDokument1 SeiteV. M. K. V. Engineering College, Salem: Vinayaka Missions UniversityMATHANKUMAR.SNoch keine Bewertungen

- V. M. K. V. Engineering College, Salem: Vinayaka Missions UniversityDokument1 SeiteV. M. K. V. Engineering College, Salem: Vinayaka Missions UniversityMATHANKUMAR.SNoch keine Bewertungen

- Ed LPDokument2 SeitenEd LPMATHANKUMAR.SNoch keine Bewertungen

- Seminar-I Assignment-IDokument2 SeitenSeminar-I Assignment-IMATHANKUMAR.SNoch keine Bewertungen

- Cold Rolled Steel Sheet: Cat - No.B1E-002-03Dokument27 SeitenCold Rolled Steel Sheet: Cat - No.B1E-002-03Frankie Ting100% (1)

- A Face Adorada (304 HC)Dokument39 SeitenA Face Adorada (304 HC)MizaNascimentoNoch keine Bewertungen

- ME364 Forming SheetDokument11 SeitenME364 Forming SheetVed Prakash ChoudharyNoch keine Bewertungen

- COMP EYF Test Questions CH 01-The History of EngineerringDokument4 SeitenCOMP EYF Test Questions CH 01-The History of EngineerringManuel Sanchez NoaNoch keine Bewertungen

- En 47Dokument3 SeitenEn 47Ankit SinghNoch keine Bewertungen

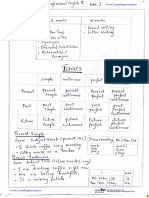

- HS3151 Professional-English-I 01 - by WWW - LearnEngineering.inDokument34 SeitenHS3151 Professional-English-I 01 - by WWW - LearnEngineering.inabera alemayehuNoch keine Bewertungen

- Liebherr LR 11350Dokument52 SeitenLiebherr LR 11350Kompanija VRKtravelNoch keine Bewertungen

- Additive Manufacturing Seminar PresentationDokument19 SeitenAdditive Manufacturing Seminar PresentationMohammed Tanveer55% (11)

- 01.05.2018 To 12.05.2018Dokument22 Seiten01.05.2018 To 12.05.2018SunilNoch keine Bewertungen

- Level 1A - Tracing Alphabet (A-Z)Dokument26 SeitenLevel 1A - Tracing Alphabet (A-Z)Francis TranNoch keine Bewertungen

- Lab 1 Metallography Specimen Preparation - RepairDokument6 SeitenLab 1 Metallography Specimen Preparation - RepairMifzal IzzaniNoch keine Bewertungen

- CMOS QuestionsDokument12 SeitenCMOS QuestionsShiva CharanNoch keine Bewertungen

- Inventors Study GuideDokument9 SeitenInventors Study GuideNatasha AbaevaNoch keine Bewertungen

- Chapter 1 Introduction To The Semiconductor Industry 2005 VLSI TECH.1Dokument28 SeitenChapter 1 Introduction To The Semiconductor Industry 2005 VLSI TECH.1samactrangNoch keine Bewertungen

- Report Engineering MaterialsDokument3 SeitenReport Engineering MaterialsRomari Estrella MirandaNoch keine Bewertungen

- Aws StandartsDokument12 SeitenAws StandartsWagnerTarossiNoch keine Bewertungen

- Business Directory - BSR Road, GhaziabadDokument17 SeitenBusiness Directory - BSR Road, Ghaziabadmittalrajat60% (5)

- Advanced Machining ProcessDokument22 SeitenAdvanced Machining ProcessNauman KhanNoch keine Bewertungen

- FETDokument49 SeitenFETPalak Agrawal100% (2)

- Weld Joint PreparationDokument2 SeitenWeld Joint PreparationMurali Krishna DNoch keine Bewertungen

- VANDERVOORT - Materials Manufacturing ProblemsDokument79 SeitenVANDERVOORT - Materials Manufacturing ProblemsFabio AlvesNoch keine Bewertungen

- AM58330 Fastrans PET Matte Chrome Permanent S2045P BG40Dokument1 SeiteAM58330 Fastrans PET Matte Chrome Permanent S2045P BG40Yashvanth ShettyNoch keine Bewertungen

- CHURUMBELERIAS (Paso Doble PDFDokument16 SeitenCHURUMBELERIAS (Paso Doble PDFRodriigo AllendeNoch keine Bewertungen

- Гирокомпас 1 SPERRY REPEATERS - RUSDokument20 SeitenГирокомпас 1 SPERRY REPEATERS - RUSVadim KiselevNoch keine Bewertungen

- Welding QuizDokument5 SeitenWelding QuizHamza NoumanNoch keine Bewertungen

- Bullseye Annealing Thick Slabs PDFDokument1 SeiteBullseye Annealing Thick Slabs PDFAnonymous X0SrEQR0mXNoch keine Bewertungen

- CircuitsDokument474 SeitenCircuitsSriramNoch keine Bewertungen

- Asahi India GlassDokument12 SeitenAsahi India GlassAman ChandelNoch keine Bewertungen

- Heat Treatment of SteelDokument3 SeitenHeat Treatment of SteelKristine ReyesNoch keine Bewertungen

- Motherboard The Common MOSFET (FET) Substitution TableDokument3 SeitenMotherboard The Common MOSFET (FET) Substitution TableDhruv Gonawala100% (3)