Beruflich Dokumente

Kultur Dokumente

SAIC-L-2074 Rev 0

Hochgeladen von

philipyapOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAIC-L-2074 Rev 0

Hochgeladen von

philipyapCopyright:

Verfügbare Formate

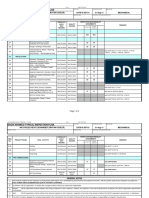

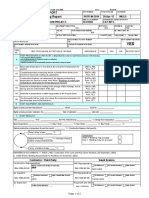

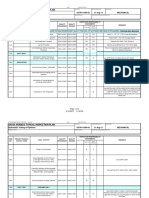

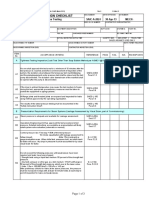

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

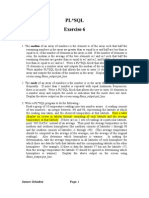

SAUDI ARAMCO INSPECTION CHECKLIST

Storage, Handling and Preservation of Cement Lined Pipe/Fittings and Joint Filler Materials

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-L-2074

WBS / BI / JO NUMBER

25-May-05

PIPE-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A1 A2

ACCEPTANCE CRITERIA Internally coated or lined pipe is handled at all times in a manner that prevents damage. Internally coated or lined pipes are handled from the outside diameter (OD) only. Lined pipes and fittings are lifted with wide fabric or rubber-covered slings and padding is used to prevent damage to lining, in accordance with SAES-H-200. Filler material is stored in well-ventilated buildings at storage temperatures as recommended in the Manufacturer's data sheet Filler material used at construction sites is covered with appropriate canvas, tarpaulins, or equivalent for a temporary storage period not to exceed 14 days. Fittings are stored in shipping crates or on racks. Plastic end caps are securely fastened to ends of completed pipe for protection of the cement-mortar lining. End caps are maintained in place until time of installation. The maximum number of rows in a stack of pipe is limited by the maximum allowable static load stress in the wall of the most heavily loaded pipe in the bottom row of the stack. For stacks in the pipe yard: 0.6 times the SMYS of the pipe material. Handling, Loading & Stacking, Plastic End Cap requirements as per Final Inspection & Testing Requirements, is observed.

REFERENCE SAES-H-200 Para. 5.1.1 01-SAMSS-024 Para. 5.1.6 SAES-L-350 Para. 8.2 SAES-H-100 Para. 6.1 SAES-H-100 Para. 6.2 SAES-L-350 Para. 7.3 AWWA C205 Sec. 6.2

PASS

FAIL

N/A

RE-INSP DATE

A3

A4

A5

A6

A7

A8

01-SAMSS-024 Para. 7.1 SA Form 175012500

A9

REMARKS:

REFERENCE DOCUMENTS: 1. SAES-H-200, Storage, Handling and Installation of Externally Coated Pipe, 31 July, 2004 2. 01-SAMSS-024, Pipe Handling and Nesting, 29 October, 2003 3. SAES-L-350, Construction of Plant Piping, 30 September, 2003 4. SAES-H-100, Coating Materials & Application Requirements for Industrial Facilities, 31 July, 2004 5. AWWA C205, Cement-Mortar Lining..., 11 June 2000 6. Saudi Aramco Form 175-012500, Concrete-Mortar Lining, March 1998

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 1 of 1

Das könnte Ihnen auch gefallen

- SAIC-L-2136 Rev 0Dokument3 SeitenSAIC-L-2136 Rev 0philipyapNoch keine Bewertungen

- Satip F 001 04Dokument4 SeitenSatip F 001 04Anonymous 4e7GNjzGWNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- Satip D 001 01Dokument11 SeitenSatip D 001 01Rijwan Mohammad0% (1)

- Satip e 007 01Dokument2 SeitenSatip e 007 01Anonymous 4e7GNjzGWNoch keine Bewertungen

- Iii. Applicable Codes & Standards For Aramco ProjectsDokument5 SeitenIii. Applicable Codes & Standards For Aramco ProjectsZain Ali KidwaiNoch keine Bewertungen

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDokument5 SeitenSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNoch keine Bewertungen

- SAIC-S-4056 Rev 7Dokument3 SeitenSAIC-S-4056 Rev 7Eswari AnandNoch keine Bewertungen

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Dokument3 SeitenSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Dokument8 SeitenSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNoch keine Bewertungen

- 175 325100Dokument2 Seiten175 325100sridhar100% (1)

- @StandardSharing-EEMUA 237-2018Dokument40 Seiten@StandardSharing-EEMUA 237-2018Morteza ShakerienNoch keine Bewertungen

- CBT QuestionsDokument17 SeitenCBT QuestionsNaseer Ahmed SokhalNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDokument2 SeitenSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNoch keine Bewertungen

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDokument2 SeitenSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNoch keine Bewertungen

- 00 Saip 12Dokument8 Seiten00 Saip 12aamirtec301Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWNoch keine Bewertungen

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Dokument2 SeitenSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 MechDokument23 SeitenSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 Mechkarthi51289Noch keine Bewertungen

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDokument2 SeitenSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- Saes A 005 PDFDokument32 SeitenSaes A 005 PDFAdnanAtifNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDokument3 SeitenSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNoch keine Bewertungen

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDokument5 SeitenTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNoch keine Bewertungen

- SATIP B 019 01 (Revision 4)Dokument2 SeitenSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNoch keine Bewertungen

- Satip A 004 03Dokument3 SeitenSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Ir 175-010000Dokument2 SeitenIr 175-010000Abu Anas M.SalaheldinNoch keine Bewertungen

- 175-Ir171300, (850146), 11.30.2015Dokument2 Seiten175-Ir171300, (850146), 11.30.2015Rami ELLOUMINoch keine Bewertungen

- Saep 119Dokument11 SeitenSaep 119Demac SaudNoch keine Bewertungen

- 32 Samss 017Dokument11 Seiten32 Samss 017naruto256Noch keine Bewertungen

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Dokument2 SeitenSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNoch keine Bewertungen

- SAIC L 2031 (Comments)Dokument2 SeitenSAIC L 2031 (Comments)Anton Thomas PunzalanNoch keine Bewertungen

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokument2 SeitenInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNoch keine Bewertungen

- SATIP-N-001-02 Rev. 4Dokument2 SeitenSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Saep 306Dokument15 SeitenSaep 306nadeem shaikh100% (1)

- Schedule B - Attachment IVDokument29 SeitenSchedule B - Attachment IVAbdul Ahad LoneNoch keine Bewertungen

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Dokument2 SeitenSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Dokument7 SeitenVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNoch keine Bewertungen

- Inspection ProcedureDokument13 SeitenInspection ProcedureSantosh Kumar100% (1)

- 175 091300Dokument2 Seiten175 091300Abu Anas M.SalaheldinNoch keine Bewertungen

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDokument8 SeitenSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289Noch keine Bewertungen

- SAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersDokument28 SeitenSAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersSergey KichenkoNoch keine Bewertungen

- 01 Samss 031Dokument3 Seiten01 Samss 031Awais CheemaNoch keine Bewertungen

- SATIP H 002 08 Rev 4.unlockedDokument2 SeitenSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveNoch keine Bewertungen

- Satr-W-2010Dokument1 SeiteSatr-W-2010Joni Carino SuniNoch keine Bewertungen

- Saudi Aramco Typical Inspection PlanDokument3 SeitenSaudi Aramco Typical Inspection PlanOmer aliNoch keine Bewertungen

- Satip - S-050-01Dokument4 SeitenSatip - S-050-01LIJINNoch keine Bewertungen

- Materials System SpecificationDokument3 SeitenMaterials System SpecificationMoustafa BayoumiNoch keine Bewertungen

- SAIC-A-2024 Rev 6 Leakness Tightness TestDokument3 SeitenSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalNoch keine Bewertungen

- SATIP S 070 02 Irrigation PipingDokument2 SeitenSATIP S 070 02 Irrigation PipingMuhammad Farukh ManzoorNoch keine Bewertungen

- Saep 1105 PDFDokument7 SeitenSaep 1105 PDFbalajiNoch keine Bewertungen

- Saep 351Dokument24 SeitenSaep 351Raj KumarNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDokument2 SeitenSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDokument3 SeitenSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNoch keine Bewertungen

- 01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)Dokument3 Seiten01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)PelifullHDNoch keine Bewertungen

- Saep 324Dokument13 SeitenSaep 324Up WeldNoch keine Bewertungen

- Risk Based Inspection A Complete Guide - 2020 EditionVon EverandRisk Based Inspection A Complete Guide - 2020 EditionNoch keine Bewertungen

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- Asset Integrity Management A Complete Guide - 2020 EditionVon EverandAsset Integrity Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Resilent FlooringDokument7 SeitenResilent FlooringphilipyapNoch keine Bewertungen

- Fire Protection SysytemDokument5 SeitenFire Protection SysytemphilipyapNoch keine Bewertungen

- Bazaar Tent StructureDokument5 SeitenBazaar Tent StructurephilipyapNoch keine Bewertungen

- Piping and Ducting SupportDokument7 SeitenPiping and Ducting SupportphilipyapNoch keine Bewertungen

- DuctworksDokument7 SeitenDuctworksphilipyapNoch keine Bewertungen

- Saudi Aramco Oil Company: SECTION 16110 RacewaysDokument10 SeitenSaudi Aramco Oil Company: SECTION 16110 RacewaysphilipyapNoch keine Bewertungen

- Sealant and CaulkingDokument8 SeitenSealant and CaulkingphilipyapNoch keine Bewertungen

- Control SystemDokument21 SeitenControl SystemphilipyapNoch keine Bewertungen

- Wire, Cable and Low VotageDokument9 SeitenWire, Cable and Low VotagephilipyapNoch keine Bewertungen

- Finish CarpentryDokument17 SeitenFinish CarpentryphilipyapNoch keine Bewertungen

- Chilled Water PumpDokument6 SeitenChilled Water PumpphilipyapNoch keine Bewertungen

- Exterior LightingDokument8 SeitenExterior LightingphilipyapNoch keine Bewertungen

- Duct Works & AccessoriesDokument5 SeitenDuct Works & AccessoriesphilipyapNoch keine Bewertungen

- Metal FramesDokument4 SeitenMetal FramesphilipyapNoch keine Bewertungen

- SignageDokument4 SeitenSignagephilipyapNoch keine Bewertungen

- Roof and Deck InsulationDokument3 SeitenRoof and Deck InsulationphilipyapNoch keine Bewertungen

- Sheet Membrance Water ProofingDokument6 SeitenSheet Membrance Water ProofingphilipyapNoch keine Bewertungen

- Floor MatsDokument3 SeitenFloor MatsphilipyapNoch keine Bewertungen

- Handrail RailingDokument11 SeitenHandrail RailingphilipyapNoch keine Bewertungen

- Plumbing SpecialitiesDokument4 SeitenPlumbing SpecialitiesphilipyapNoch keine Bewertungen

- Example 2 - Two Equal Spans: AbutmentDokument94 SeitenExample 2 - Two Equal Spans: AbutmentphilipyapNoch keine Bewertungen

- Bridge Superstructure DesignDokument108 SeitenBridge Superstructure Designstefanotomasi123550% (2)

- GeotectilesDokument2 SeitenGeotectilesphilipyapNoch keine Bewertungen

- Swimming PoolDokument4 SeitenSwimming PoolphilipyapNoch keine Bewertungen

- Glass and GlazingDokument8 SeitenGlass and GlazingphilipyapNoch keine Bewertungen

- Sap2000 Analysis Refer ManualDokument467 SeitenSap2000 Analysis Refer ManualphilipyapNoch keine Bewertungen

- Example 2 - Option 2: Bent Columns On Capped Piles: AbutmentDokument178 SeitenExample 2 - Option 2: Bent Columns On Capped Piles: AbutmentphilipyapNoch keine Bewertungen

- 5) Manual SAP200 - Bridge Seismic Design (Pu)Dokument71 Seiten5) Manual SAP200 - Bridge Seismic Design (Pu)Alejandro AntezanaNoch keine Bewertungen

- Concrete Curb, EdgingDokument3 SeitenConcrete Curb, EdgingphilipyapNoch keine Bewertungen

- ECU MS 4 Sport ManualpdfDokument26 SeitenECU MS 4 Sport ManualpdfLucas DuarteNoch keine Bewertungen

- Model-Checking: A Tutorial Introduction: January 1999Dokument26 SeitenModel-Checking: A Tutorial Introduction: January 1999Quý Trương QuangNoch keine Bewertungen

- Islami Bank Bangladesh Limited: Ibbl Ibanking ServiceDokument2 SeitenIslami Bank Bangladesh Limited: Ibbl Ibanking ServiceShaikat AlamNoch keine Bewertungen

- Krunker SettingsDokument2 SeitenKrunker SettingsArsyad DanishNoch keine Bewertungen

- Board of DirectorsDokument2 SeitenBoard of DirectorsjonahsalvadorNoch keine Bewertungen

- Comprehension: The Boy Is Playing With A Fire TruckDokument79 SeitenComprehension: The Boy Is Playing With A Fire Truckbhupendra singh sengarNoch keine Bewertungen

- Confirmation 2Dokument11 SeitenConfirmation 2حمزة دراغمةNoch keine Bewertungen

- 2 Issues in Language LearningDokument30 Seiten2 Issues in Language LearningEva JakupcevicNoch keine Bewertungen

- Shock Cat 2009Dokument191 SeitenShock Cat 2009gersonplovasNoch keine Bewertungen

- Harmonica IntroDokument5 SeitenHarmonica Introapi-26593142100% (1)

- Monster Energy v. Jing - Counterfeit OpinionDokument9 SeitenMonster Energy v. Jing - Counterfeit OpinionMark JaffeNoch keine Bewertungen

- Effect of Spent Engine Oil On The Internal Structure of Corchorus OlitoriusDokument55 SeitenEffect of Spent Engine Oil On The Internal Structure of Corchorus Olitoriusanon_568621284Noch keine Bewertungen

- Flexure Hinge Mechanisms Modeled by Nonlinear Euler-Bernoulli-BeamsDokument2 SeitenFlexure Hinge Mechanisms Modeled by Nonlinear Euler-Bernoulli-BeamsMobile SunNoch keine Bewertungen

- Robotech Hannibal Digital 114dpi V1.0Dokument119 SeitenRobotech Hannibal Digital 114dpi V1.0nonfarb14thNoch keine Bewertungen

- Oleg Losev NegativeDokument2 SeitenOleg Losev NegativeRyan LizardoNoch keine Bewertungen

- RK3066 Mid PDFDokument17 SeitenRK3066 Mid PDFSharon MurphyNoch keine Bewertungen

- PESTEL AnalysisDokument2 SeitenPESTEL AnalysisSayantan NandyNoch keine Bewertungen

- Focus: Optimised Efficiency For The Paper IndustryDokument24 SeitenFocus: Optimised Efficiency For The Paper IndustryZoran BadurinaNoch keine Bewertungen

- Action Research Intervention in English 9Dokument6 SeitenAction Research Intervention in English 9Rey Kris Joy ApatanNoch keine Bewertungen

- BE 503 - Week 1 - Analysis 7.18.11Dokument6 SeitenBE 503 - Week 1 - Analysis 7.18.11dwoodburyNoch keine Bewertungen

- FeCl3 Msds - VISCOSITYDokument9 SeitenFeCl3 Msds - VISCOSITYramkesh rathaurNoch keine Bewertungen

- Va797h 15 Q 0019 A00001003Dokument35 SeitenVa797h 15 Q 0019 A00001003Hugo GranadosNoch keine Bewertungen

- Eimco Elecon Initiating Coverage 04072016Dokument19 SeitenEimco Elecon Initiating Coverage 04072016greyistariNoch keine Bewertungen

- Harvester Main MenuDokument3 SeitenHarvester Main MenuWonderboy DickinsonNoch keine Bewertungen

- Review Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFDokument3 SeitenReview Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFBilal SalaamNoch keine Bewertungen

- Mastering The Art of Self Hypnosis: by Dr. Kenneth GrossmanDokument46 SeitenMastering The Art of Self Hypnosis: by Dr. Kenneth GrossmanguilhermeosirisNoch keine Bewertungen

- PL SQL Exercise6Dokument2 SeitenPL SQL Exercise6Nishant AndhaleNoch keine Bewertungen

- 4612 4621 Vitamin D Supplementation For Osteoporosis in Older AdultsDokument10 Seiten4612 4621 Vitamin D Supplementation For Osteoporosis in Older AdultsMohammedNoch keine Bewertungen

- 5CT PDVSA em - 18!00!05 EnglishDokument27 Seiten5CT PDVSA em - 18!00!05 EnglishJuan Gutierrez100% (1)

- Assembling Your Antenna SystemDokument27 SeitenAssembling Your Antenna SystemKam MusNoch keine Bewertungen