Beruflich Dokumente

Kultur Dokumente

Quick Install Manual Xaar382

Hochgeladen von

leandrorochaaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quick Install Manual Xaar382

Hochgeladen von

leandrorochaaCopyright:

Verfügbare Formate

quick install manual

Quick install manual Xaar382

quick install manual

Notice:

z All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of TEC CORPORATION. The contents of this manual are subject to change without notice. All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, TEC would greatly appreciate being informed of them. The above not withstanding TEC CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

z z

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

quick install manual

1. Product list

MotherBoard

CarriageBoard

quick install manual

Connector plugs 3Pin x14 unitsMotherBoard x 5CarriageBoard x 9

Stepper Motor Driver connector plug 5Pin x1 unit

Linear Encoder connector plug. 4Pin x 1 unit

D type Servo Motor Driver connector plug x1 unit

MotherBoard power connector plug. 4pin x1 unit

CarriagerBoard power connector plug. 4pin x1 unit

quick install manual

Pump power connector plug. 7Pin x1 unit

Data cable : Connect MotherBoard and CarriageBoard

Head connect cable x8 unit

Connector Plugs needle

If above lists any item of fitting has the damage perhaps the short situation, please as soon as possible contact us.

quick install manual

2. PowerSupply

V1:5V/5A V2:24V/5A V1:24V/5A -V1 +V1 -V2 +V2 -V1 +V1

MotherBoard

CarriageBoard

CarriageBoard 24V and MainBoard 5V powersupply s GND connect

quick install manual

3. Hardware Installation

description Printer Control System include three parts: MotherBoard; CarriageBoard and Control software. Use USB2.0 port connects to PC.

3.1 System each parts guise and connector plugs

3.1.1MotherBoard

3.1.2 MotherBoard connector plugs and connect define

CN16:To Servo Motor Control

quick install manual

MotherBoard Servo Motor Dirver 1(A+)21(OA+) 3(B-)49(OB-) 4(Servo PULS+)3(PULS1) 5(Servo SIGN+)5(SIGN1) 7(24V)7(COM+) 8(Servo On)29(SRV-ON) 9(A-)22(OA-) 10(B+)48(OB+) 11(GND)13GND 12(Servo PULS)4(PULS2) 13(Servo SIGN)6(SIGN2) 15(24V-GND)41(COM-) Coherers shellSTP Detailed infosee figure

CN16 8 15 7 14 6 13 5 12 4 11 3 10 2 9 1

Servo On 24V-GND 24V

Servo Servo Servo Servo GND BB+ GND AA+

SIGNSIGN+ PULSPULS+

D Connector 15

Servo Motor Drivers parameter setting

Pr02=0 Pr03=1 Pr04=1 Pr41=0 Pr42=3 Pr4A=0 Pr4B=432 Pr5E=100 Pr70=100

Pr44=432

Pr45=0

Pr46=0 Pr48=0

quick install manual

CN17/18: Right&Left Limit Connect define

CN4/5: OrignPos&PurgePos Connect define

CN7: Vacuum Connect define

CN3: Power

Connect define

!!! Starting before, please first test the CN3 power supply is correctly

CN20: Pump

Connect define

CN8: Y Motor(Step)

Connect define

quick install manual

3.1.3 CarriageBoard

3.1.4 CarriageBoard connector plugs and defines

To Linear Encoder Connect define

To Ink Sensor Connect define

Power Supply

Connect define

!!! Starting before, please test the CN3 power supply connected correctly!

10

quick install manual

Connect Cable:Connect HeadBoard to Head Adapter

3.2 CarriageBoard and Head connect define

11

quick install manual

4. Printer Manager Software

About the Printer Manager Printer Manager Software provided has set the machine parameter, the calibration printer head, update the firmware and clean the printer head functions.

4.1 Software Installation

According to following step install Printer Manager software 1. Run Setup.exe 2. Install software according to the screen prompt. The software needed the system to install Dotnetfx.1.1 or above the version, In the installation process to be able to install this software automatically. Software interface

12

quick install manual

4.2 Hardware Setting

The hardware setting provided the system use flexibility; you can according to your machine set the different printer head type; the color number and the print head group number in the software, but dont need different firmware and control software. Step1Printer Hardware setting After the software installed, first step must do hardware setting, otherwise the machine cant start, enter the setting menu hardware setting function and setting the printer hardware option Run C:\Program Files\PrinterManager\FactoryWrite.exe

Select FactoryData:

Step2Select Encoder Select use linear encoder or servo encoder, choose directly in the software. Step3Select Color (Color NO Select color number6 or 4 Step4Select Group: Select printer head group number:1234

Step5Color Space

Setting color space in accordance with the head installer position, the unit is centimeter. Step6Group Space Setting Group space in accordance with the head installer position, the unit is centimeter.

13

quick install manual

Step7Width Select printer width1.8m2.5m3.2m3.3m Step 8Head Select printer head type: M is 14pl and L is 42pl. The color spacing and the group spacing can act according to the color and the group number which you choose, you also may own change. After all setting complete, click create, the parameter will store in the motherboard.

4.3 Real Setting

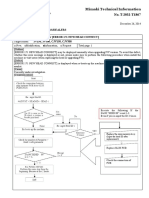

After hardware setting, user should get the real setting. See figure:

In this step, you can the set the V Trim and read the heads temperature and PWM, apply to the board. V Trim used to adjust the TC Curve offset which results in a shift to the actuator voltage in order to tune the drop velocity. Range -128 to +127. You can change it higher or lower to raise the quality of the print.

4.4 Quickly printing a high quality job

Step1Head nozzle check Click button, check the test pattern, see figure OK

NG(need clean)

14

quick install manual

Step2Cleaning the printer head Cleans the nozzle have two types: one is automatic cleaning and the other one for manual cleaning. Automatic cleaningfirst setting auto cleaning times in the setting menusee figure:

The cleaning times more, the clean time is longer, setting cleaning times according to the nozzle broken status, then perform automatic cleaning button. Manual cleaning: Perform cleaning dialog box, see figure: manual cleaning button, pop-up the manual

Click the color button and cleaning the corresponding head, and then print the pattern again to check. Step3Setting print origin Click the move buttonMove carriage to the propriety positionperform the button setting the print origin.

15

quick install manual

Step4Calibration print head Run tool menu---calibration wizard function.

Angle Check, check the printed pattern, see figure: OK

The first group head

The second group head

NG: The print head installment hasnt level, needs to do the physical position adjustment

The first group head

The second group head

16

quick install manual

Vertical check, check the printed pattern, see figure: OK:

NG: The print head installment hasnt verticality, need to do the physical position adjustment

M of the first group and M of the second group appear overlap, vertical direction adjustment head.

Click next:

17

quick install manual

Choice speed: High speed; Medium speed or low speed The horizontal left calibration, perform the print, check the printed pattern, take M as an Example, see figure:

This position M and K completely to uneven The choice pattern to the uneven position, and input correspondence numeral, the method is adds together in the original foundation. Duplication this step, is most uneven until 0 position arrangement. Click next, the horizontal right calibration, perform print, check the pattern, take M asan example, see figure:

This position M and K completely to uneven The choice pattern to the uneven position, and input correspondence numeral, the method is adds together in the original foundation. Duplication this step, is most uneven until 0 position arrangement. Click next, the Bidirection calibration, perform print, check the pattern, see figure:

This position K completely to uneven The choice pattern to the uneven position, and input correspondence numeral, the method is adds together in the original foundation. Duplication this step, is most uneven until 0 position arrangement. Click next, step calibration, choice the pass first, perform print ,check pattern, see figure:

18

quick install manual

The choice pattern to the uneven position, and input correspondence numeral, the methodis adds together in the original foundation. Duplication this step, is most uneven until 0 position arrangement. Click next, complete the calibration Step5Printing already RIP job Click add job, the support format is .prn and .prt. Click printing is start.

19

quick install manual

5. Error code information and solution

04020008 Time-limit password input mistake, contains the forbidden character. The password is ignored, please input again. 04020009 0402000A Illegal time-limit password. The password is ignored, please input again. Time-limit input again. 0402000B 0402000C Time-limit password and board ID mismatch. The password is ignored, please input again. First warning: 100 hours left against current time-limit password, 0402000D please request a new password from the producer. Second warning: 50 hours left against current time-limit password, 0402000E please request a new password from the producer. Last warning: After 1 hour, any printing will be stopped! Request a new password from the producer immediately! 40020011 40020012 40020013 40020014 40020016 EEPROM read failed. EEPROM write failed. Not initialized by factory. Head board is reset. Head board mismatch with factory data set. Please reset factory data or change a new head board. 40020017 40020018 Board manufactory ID mismatch with FW. Please update FW. Serious Error: Exceeds the time against the time-limit password. 4002000E 20020002 20020003 20020005 20020006 LVDS error. CoreBoard_Err_UART1_TXTIMEOUT CoreBoard_Err_UART2_TXTIMEOUT CoreBoard_Err_FPGA_LESSDATA CoreBoard_Err_FPGA_ULTRADATA Check the datacable and powersupply Motion COM timeout.re-update Head board COM timeout.check the datacable and powersupply Check the encoder and encoder reader positon Print data is more than fire number.

20

Re-input correct password

Re-input correct password Re-input correct password

password

and

manufacturer

ID

mismatch. The password is ignored,

please Re-input correct password please request a new password from the producer. please request a new password from the producer. Request a new password from the producer immediately! Re-update the FW.if the problem is still,replacement the mainboard Re-update the FW.if the problem is still,replacement the mainboard Re-setting the factorywrite Check the carriageboard powersupply and the data cable Re-setting the factorywrite

Re-update or replacement the mainboard Time password expiration

password,

please

input

new

quick install manual

21

Das könnte Ihnen auch gefallen

- Operation Manual: TAIMES GH2220 ECO PrinterDokument37 SeitenOperation Manual: TAIMES GH2220 ECO PrinterSoro Fohona100% (2)

- Home Brewing Log Sheet PDFDokument2 SeitenHome Brewing Log Sheet PDFStefanita0% (1)

- Dgi ps-3206 SMDokument229 SeitenDgi ps-3206 SMHoffman Elizalde100% (1)

- TAIMES T7 Printermanager Software Manual PDFDokument17 SeitenTAIMES T7 Printermanager Software Manual PDFSyamsul Arifin Ipin50% (2)

- Juan Martin Garcia System Dynamics ExercisesDokument294 SeitenJuan Martin Garcia System Dynamics ExercisesxumucleNoch keine Bewertungen

- Setting Km512c Q8otDokument35 SeitenSetting Km512c Q8otFOTOPLES Digital PrintingNoch keine Bewertungen

- MtColor Zero TrainingDokument35 SeitenMtColor Zero TrainingSalai Kyaw Thura TunNoch keine Bewertungen

- Tosun Digital (HS) Product Manual-USBDokument45 SeitenTosun Digital (HS) Product Manual-USBFerdinand CaluyaNoch keine Bewertungen

- Epson I-3200 Print Head EnglishDokument2 SeitenEpson I-3200 Print Head EnglishNischit Kunwar ChhetriNoch keine Bewertungen

- Lista de Repuestos EASY PRINTDokument90 SeitenLista de Repuestos EASY PRINTjcojedar2009Noch keine Bewertungen

- Refertonic Manual PDFDokument67 SeitenRefertonic Manual PDFsunethpfNoch keine Bewertungen

- TAIMES T208 ManualDokument29 SeitenTAIMES T208 ManualSoro Fohona100% (1)

- Versaworks Mac Setup en r3Dokument16 SeitenVersaworks Mac Setup en r3Jaime Anibal Lara VillegasNoch keine Bewertungen

- Operation Manual MyJet Xaar 128 PrintheadsDokument84 SeitenOperation Manual MyJet Xaar 128 PrintheadsRudic Ramirez80% (5)

- Uf dx5 X 2 Printheads 20140319Dokument23 SeitenUf dx5 X 2 Printheads 20140319Andres CastañoNoch keine Bewertungen

- Nikola Tesla Was Murdered by Otto Skorzeny.Dokument12 SeitenNikola Tesla Was Murdered by Otto Skorzeny.Jason Lamb50% (2)

- 20110520101701Dokument27 Seiten20110520101701Arie Teckno100% (2)

- 3000-X5 ManualDokument31 Seiten3000-X5 ManualFamDArcangeliHolmesNoch keine Bewertungen

- Ngaranaing Saha Atuh UdinDokument1 SeiteNgaranaing Saha Atuh Udinadian herawanNoch keine Bewertungen

- En-6090 Detailed InstructionsDokument36 SeitenEn-6090 Detailed InstructionsmarcuNoch keine Bewertungen

- PZR KV 1 - Operation ManualDokument65 SeitenPZR KV 1 - Operation ManualRenato CarneiroNoch keine Bewertungen

- 1600g Xp600 Tsautop EnglishDokument33 Seiten1600g Xp600 Tsautop EnglishFasjh n,ashj,sanNoch keine Bewertungen

- VISTA-KM512-PCI-DC-English Manual V.0711 PDFDokument75 SeitenVISTA-KM512-PCI-DC-English Manual V.0711 PDFJulios Santos100% (1)

- Color Profiler SAiDokument6 SeitenColor Profiler SAiRobby Deltu TNoch keine Bewertungen

- HononsoftDokument55 SeitenHononsoftMAURICIO TORRESNoch keine Bewertungen

- CY-1800 Printer ManualDokument45 SeitenCY-1800 Printer ManualFofaSista0% (1)

- Operation Manual: TAIMES KM512i Solvent PrinterDokument29 SeitenOperation Manual: TAIMES KM512i Solvent Printermelsamhe0% (1)

- SAi Production Suite 12 Readme PDFDokument22 SeitenSAi Production Suite 12 Readme PDFsherub wangdiNoch keine Bewertungen

- T7 User ManualDokument35 SeitenT7 User ManualMaxmax DesainNoch keine Bewertungen

- Printer Maintenance GuideDokument19 SeitenPrinter Maintenance GuideEDU0914100% (1)

- ETINK UV DTF Printer User's ManualDokument59 SeitenETINK UV DTF Printer User's ManualVMLP OrMdo SecGenNoch keine Bewertungen

- 5113-S System ManualDokument7 Seiten5113-S System Manualallwin.c4512iNoch keine Bewertungen

- TEXUMA Operation-ManualDokument79 SeitenTEXUMA Operation-Manualko koNoch keine Bewertungen

- PrintExp Control Software InstructionDokument21 SeitenPrintExp Control Software InstructionEduardo RiveraNoch keine Bewertungen

- Toshiba Tec Recovery Quick Guide S PDFDokument2 SeitenToshiba Tec Recovery Quick Guide S PDFAhmedNoch keine Bewertungen

- Brochure-SinoColor SJ-1260E Eco Solvent PrinteDokument2 SeitenBrochure-SinoColor SJ-1260E Eco Solvent PrinteClaudio OliveroNoch keine Bewertungen

- Mimaki Technical Information on Countermeasure for ERROR 171 NEW HEAD CONNECTDokument2 SeitenMimaki Technical Information on Countermeasure for ERROR 171 NEW HEAD CONNECTMNoch keine Bewertungen

- PrinterManager User Manual Translation VersionDokument16 SeitenPrinterManager User Manual Translation VersionهشامالبريهيNoch keine Bewertungen

- NC-DX0406-2018 User ManualDokument46 SeitenNC-DX0406-2018 User Manualसदानंद देशपांडेNoch keine Bewertungen

- Colorcalibrationtutorial 2008 v4 enDokument21 SeitenColorcalibrationtutorial 2008 v4 enpicolorjNoch keine Bewertungen

- MyJet Operation ManualDokument74 SeitenMyJet Operation ManualMostafa Mohamed Hussien50% (4)

- Konica ManualDokument69 SeitenKonica ManualCésarMarinNoch keine Bewertungen

- EPSON Error List ENDokument41 SeitenEPSON Error List ENsheel kumar sharmaNoch keine Bewertungen

- 0609 User ManualDokument45 Seiten0609 User Manualmihaiparjolea100% (1)

- Mimaki JV3-160 SP PDFDokument136 SeitenMimaki JV3-160 SP PDFAlisson BrighentiNoch keine Bewertungen

- Custody Wash - MimakiDokument12 SeitenCustody Wash - MimakimehoNoch keine Bewertungen

- TAIMES B System Install GuideDokument2 SeitenTAIMES B System Install GuideSoro FohonaNoch keine Bewertungen

- MPC6515 ManualDokument37 SeitenMPC6515 ManualJerome CeleraNoch keine Bewertungen

- TAIMES A System Install GuideDokument2 SeitenTAIMES A System Install GuideSoro FohonaNoch keine Bewertungen

- Signage Science and Technology Printer FeaturesDokument2 SeitenSignage Science and Technology Printer FeaturesPanji ArihtaNoch keine Bewertungen

- CoPeck User Manual Printer Report SoftwareDokument3 SeitenCoPeck User Manual Printer Report SoftwareShree ManjuNoch keine Bewertungen

- Allwin Calibration GuideDokument8 SeitenAllwin Calibration Guidepraneeth7Noch keine Bewertungen

- Field Repair Guide - 9-27-10 PDFDokument376 SeitenField Repair Guide - 9-27-10 PDFtdoyle10Noch keine Bewertungen

- Epson Manual Installation GuideDokument68 SeitenEpson Manual Installation GuideLuis RangelNoch keine Bewertungen

- Epson DX5 X 2 PrintheadsDokument25 SeitenEpson DX5 X 2 PrintheadsDarwin Elvis Giron HurtadoNoch keine Bewertungen

- UltraPrint User Guide. by Alto Imaging TechnologiesDokument94 SeitenUltraPrint User Guide. by Alto Imaging TechnologiesLeopoldo MedinaNoch keine Bewertungen

- 2513G UV Flatbed PrinterDokument14 Seiten2513G UV Flatbed PrinterGuillermo RussoNoch keine Bewertungen

- Instructions For Updating The Printer Firmware in Chipless, Method 13Dokument5 SeitenInstructions For Updating The Printer Firmware in Chipless, Method 13Kevin Dispo MontajesNoch keine Bewertungen

- Inkjet Printing GuideDokument26 SeitenInkjet Printing Guidelydiem09100% (1)

- Set PC Tool Quickstart GuideDokument22 SeitenSet PC Tool Quickstart GuideminhchiNoch keine Bewertungen

- CNC How To UseDokument5 SeitenCNC How To UseAgus SufianNoch keine Bewertungen

- SM300 ManualDokument32 SeitenSM300 ManualdeivisroseroNoch keine Bewertungen

- Math 202: Di Fferential Equations: Course DescriptionDokument2 SeitenMath 202: Di Fferential Equations: Course DescriptionNyannue FlomoNoch keine Bewertungen

- Clean Milk ProductionDokument19 SeitenClean Milk ProductionMohammad Ashraf Paul100% (3)

- Activities and Assessments:: ASSIGNMENT (SUBMIT Your Answers at EDMODO Assignment Section)Dokument5 SeitenActivities and Assessments:: ASSIGNMENT (SUBMIT Your Answers at EDMODO Assignment Section)Quen CuestaNoch keine Bewertungen

- Laser Surface Treatment ProcessesDokument63 SeitenLaser Surface Treatment ProcessesDIPAK VINAYAK SHIRBHATENoch keine Bewertungen

- Air Arms S400 EXPDokument3 SeitenAir Arms S400 EXPapi-3695814Noch keine Bewertungen

- Caterpillar Ep15krtDokument37 SeitenCaterpillar Ep15krtIvan MajikNoch keine Bewertungen

- LSUBL6432ADokument4 SeitenLSUBL6432ATotoxaHCNoch keine Bewertungen

- WK 43 - Half-Past-TwoDokument2 SeitenWK 43 - Half-Past-TwoKulin RanaweeraNoch keine Bewertungen

- CP 343-1Dokument23 SeitenCP 343-1Yahya AdamNoch keine Bewertungen

- Effect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanDokument7 SeitenEffect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanJuniper PublishersNoch keine Bewertungen

- 2018-04-12 List Mold TVSDokument5 Seiten2018-04-12 List Mold TVSFerlyn ValentineNoch keine Bewertungen

- 3D Area Clearance Strategies for Roughing ComponentsDokument6 Seiten3D Area Clearance Strategies for Roughing ComponentsMohamedHassanNoch keine Bewertungen

- Apollo TyresDokument78 SeitenApollo TyresADITYA33% (3)

- Answer Key p2 p1Dokument95 SeitenAnswer Key p2 p1Nafisa AliNoch keine Bewertungen

- 2 Scour VentDokument8 Seiten2 Scour VentPrachi TaoriNoch keine Bewertungen

- Drugs Pharmacy BooksList2011 UBPStDokument10 SeitenDrugs Pharmacy BooksList2011 UBPStdepardieu1973Noch keine Bewertungen

- Diia Specification: Dali Part 252 - Energy ReportingDokument15 SeitenDiia Specification: Dali Part 252 - Energy Reportingtufta tuftaNoch keine Bewertungen

- KoyoDokument4 SeitenKoyovichitNoch keine Bewertungen

- Sradham ChecklistDokument9 SeitenSradham ChecklistpswaminathanNoch keine Bewertungen

- Telco XPOL MIMO Industrial Class Solid Dish AntennaDokument4 SeitenTelco XPOL MIMO Industrial Class Solid Dish AntennaOmar PerezNoch keine Bewertungen

- European GMP Annex 1 - 2008 Edition - 'Pmeasuring'Dokument3 SeitenEuropean GMP Annex 1 - 2008 Edition - 'Pmeasuring'Khairul AnwarNoch keine Bewertungen

- ROMUS 2012 Flooring CatalogueDokument20 SeitenROMUS 2012 Flooring CatalogueDan George IIINoch keine Bewertungen

- Crew Served WeaponsDokument11 SeitenCrew Served WeaponsKyle Fagin100% (1)

- Fraktur Dentoalevolar (Yayun)Dokument22 SeitenFraktur Dentoalevolar (Yayun)Gea RahmatNoch keine Bewertungen

- CAE The Most Comprehensive and Easy-To-Use Ultrasound SimulatorDokument2 SeitenCAE The Most Comprehensive and Easy-To-Use Ultrasound Simulatorjfrías_2Noch keine Bewertungen

- DK Children Nature S Deadliest Creatures Visual Encyclopedia PDFDokument210 SeitenDK Children Nature S Deadliest Creatures Visual Encyclopedia PDFThu Hà100% (6)

- Mechanical Specifications For Fiberbond ProductDokument8 SeitenMechanical Specifications For Fiberbond ProducthasnizaNoch keine Bewertungen