Beruflich Dokumente

Kultur Dokumente

Chapter 1

Hochgeladen von

dearsaswatOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 1

Hochgeladen von

dearsaswatCopyright:

Verfügbare Formate

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Mechanics of Materials

MEM230 Mechanics of Materials

Course Web Site: http://www.mem.drexel.edu/mom

Study the behavior of SOLID bodies under the actions of various types of loading Other Commonly Used Names

Strength of Materials Mechanics of Deformable Bodies

Chapter 1 Tension, Compression, and Shear

1 / 54

Chapter 1 Tension, Compression, and Shear

2 / 54

MEM230 Mechanics of Materials

MEM

C

MEM230 Mechanics of Materials

MEM

Why Mechanics of Materials?

Example: A Two-Bar Truss

C Free-Body Diagram for Joint A 600 mm A B 800 mm P = 30 kN 600 mm

Why Mechanics of Materials?

SAC

Fx = SAB SAC cos = 0 Fy = SAC sin P = 0

P

SAC SAB A P

3

3 5 4 B 800 mm

SAB

P = 30 kN

What if AB is made of steel and AC is made of paper? Member AC may break long before load P reaches its intended value of 30 kN. The structure fails due to the low strength of member AC.

Chapter 1 Tension, Compression, and Shear

FHoriz = SAB 5 SAC = 0; FVerti = 5 SAC P = 0

S AC 5 4 = P = 50 kN (tension); S AB = S AC = 40 kN (compression) 3 5

One question we never asked in STATICS:

SNAP!

P << 30 kN

4 / 54

Will the structure survive this load?

Chapter 1 Tension, Compression, and Shear 3 / 54

MEM230 Mechanics of Materials

MEM

C

MEM230 Mechanics of Materials

MEM

Why Mechanics of Materials?

C

Why Mechanics of Materials?

SAC

600 mm A

SAC

600 mm A B 800 mm

SAB P

P = 30 kN

Fx = SAB SAC cos = 0 Fy = SAC sin P = 0

SAB P

800 mm P = 30 kN

Fx = SAB SAC cos = 0 Fy = SAC sin P = 0

What if AB is made of steel and AC is made of rubber band? The excessive deformation in member AC will prevent the structure from performing properly The structure fails due to the low stiffness of member AC.

Chapter 1 Tension, Compression, and Shear

SAC SAB

What if AB is a very slender member, i.e., AAB << AAC Member AB may buckle long before load P reaches its intended value of 30 kN. The structure fails due to the problem of instability.

5 / 54 Chapter 1 Tension, Compression, and Shear

BUCKLED!

6 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Why Mechanics of Materials?

Most of the real-world structures are statically indeterminate

C

Why Mechanics of Materials?

Real world structures are mostly statically indeterminate and are typically designed for strength, stiffness, and stability considerations Strength: The ability of the structures to carry or transmit loads. Stiffness: The ability of the structures to resist changes in shape. Stability: The ability of the structure to resist buckling under compressive loads. None of these can be accomplished with what we have learned in Statics. In MEM230, emphases will be placed on study the strength of the structures in terms of their load bearing capabilities

7 / 54 Chapter 1 Tension, Compression, and Shear 8 / 54

F.B.D. and Equilibrium Equations @ A

SAC SAB SAD

Fx = SAB SAC cos SAD cos = 0 Fy = SAC sin SAD sin P = 0

P Three unknowns, two equations

P D

A statically indeterminate structure can not be solved solely by using the equilibrium conditions. Additional conditions pertaining to the displacement of the structure and the relations between forces and displacements are usually needed.

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Real World Structures

Idealized Structures to be Studied in This Course

(Prismatic bars subjected to various types of loading)

Tension/ Compression of a bar Direct shear Torsion of a shaft Bending & shear of a beam

Buckling of a column

Chapter 1 Tension, Compression, and Shear

9 / 54

Chapter 1 Tension, Compression, and Shear

10 / 54

MEM230 Mechanics of Materials

d0 d 1a. Stress/Strain P L0 L P

MEM

d d0 d0

MEM230 Mechanics of Materials

MEM

1b. Constitutive relations (Linearly elastic)

2. Axially loaded members

3. Torsion

4. Shear force and bending moment diagrams

5 and 6. Bending and shear stresses in beams 7. Analysis of stresses; Mohrs circles

8. Applications of plane stress 9. Deflections of beams

10. Statically indeterminate beams 11. Columns

What do we study in Mechanics of Materials

( )

E (G )

E=

P A0

L L0 L0

r F2

STATICS

r F3

If the body is in a state of equilibrium, then

( )

P

G= =

G=

E 2(1 + )

MEM230 MEM330

M V VQ = Ib

F = F1 + F2 + F3 + F4 = 0

and any segment of the body must also satisfy the equilibrium.

P = = = E A L

PL = AE

T = T IP

= = G =

TL GI P

dV = q dx

dM =V dx

r F1 r F2

r F4

r (L) r f i = f i( R )

r F2 r F3 r F1

My = I

1 =

pr pr 2 = t 2t

r F1

r r FR = fi( R ) r r r r r r (L) r r r r F F = F + F + F = 0 F F = F + F + f = 0 4 1 2 L i 4 1 2 r r r r r (R ) r r r F = F3 + F4 + FR = 0 F = F3 + F4 + fi =0

Chapter 1 Tension, Compression, and Shear 12 / 54

r (L) fi

r (R ) fi

r r FL = FR r r FL = fi( L )

r F3

Chapter 1 Tension, Compression, and Shear

11 / 54

MEM230 Mechanics of Materials

MEM

r F2

MEM230 Mechanics of Materials

MEM

Mechanics of Materials: The Concept of Stress r

F2 r F3

Mechanics of Materials: The Concept of Stress

r (L) fi r F1

If the body is in a state of equilibrium, then

F = F1 + F2 + F3 + F4 = 0

and any segment of the body must also satisfy the equilibrium.

r f (t )

r f r f (n )

r F1

f: Total internal force acting on A

r F2

r F4

External forces

r F1

r (L) fi

Internal forces

r (L) r f i = f i( R ) r (R ) fi

r F3

A: An infinitesimal surface element on the internal surface External forces

r n r r f (n ) : Normalcomponentoff r r f (t ) : Tangentialcomponentoff

F = F1 + F2 + fi( L ) =0

Chapter 1 Tension, Compression, and Shear

r F4 r r r r F = F3 + F4 + fi(R ) =0

r f (n ) NormalStress : = lim A 0 A r f (t ) ShearStress : = lim A 0 A

Chapter 1 Tension, Compression, and Shear 14 / 54

13 / 54

MEM230 Mechanics of Materials

MEM

Tension

MEM230 Mechanics of Materials

MEM

How Many Different Ways Can you Break a Piece of Chalk?

Examples of Failure Mode

Compression Torsion

Impact Bending Tension Bending Twisting

Ductile Brittle

These structures failed in different modes since they are experiencing different internal stresses

Shear

Chapter 1 Tension, Compression, and Shear

15 / 54

Chapter 1 Tension, Compression, and Shear

16 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Normal Stress in a Prismatic Bar in Tension

Free-body diagram of a segment of the bar. Segment of the bar before loading. Segment of the bar after loading.

Sign Convention for Normal Stresses

When the bar is being stretched by a force, the stresses are tensile and are said to be positive.

Normal stresses in the bar

P A

dA = AdA = A A dA = P

A

Normal stress is assumed to be uniformly distributed over the cross section mn. This is a valid assumption so long as the cross section at each the stress is calculated is at a distance far away from the two ends of the bar.

17 / 54

If the force is reversed in direction, the bar will be compressed, the stresses are compressive and are said to be negative.

Chapter 1 Tension, Compression, and Shear

Chapter 1 Tension, Compression, and Shear

18 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Units for Stresses

P Stress has units of force per unit area. A Force Pounds = = psi In USCS units: Stresses = Area Square inch

Units for Stresses

Example: A bar of circular cross section with a diameter d = 2.0 in (50.8 mm) is subjected to a pair of forces P = 6,000 lb (26,688 N)

=

=

In SI units:

Stresses =

Force Newtons = = Pascals (Pa ) Area Square meter

P P = A d 2 4

P

= 1,910psi = 1.91ksi

(2.0in )2 4

6 ,000lb

Conversion between psi and Pa:

psi 6,890 Pa

Pa ( 1.45 10-4 ) Psi

(50.8 10 3 m ) 4

2

26,688N

= 13.16 10 6 Pa = 13.16MPa

The following units are often used for convenience :

1 MPa = 106 Pa 1 GPa = 109 Pa 1 ksi = 103 psi 1 Msi = 106 psi

Chapter 1 Tension, Compression, and Shear 19 / 54

Pa = 13.16 10 6 Pa = 13.16MPa psi psi = 13.16 10 6 Pa 1.45 10 4 = 1,910psi Pa = 1,910psi 6,890

Chapter 1 Tension, Compression, and Shear 20 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Limitations on the Assumption of Uniform Distribution of Normal Stresses

1. Non-centroidal force 2. Saint-Venants Effect 3. Stress Concentration

Line of Action of the Axial Forces for a Uniform Stress Distribution The line of action of the axial forces for a uniform stress distribution must pass through the centroid.

Let the line of action of force P be going through p1.

P Moments due to P: M x = Py

( )

(P ) My = Px

Moments due : M x

( )

( ) = y (dA ) M y = x (dA )

Moments due to P must be equal to moments due to

(P ) ( ) Mx = Mx (P ) ( ) Mx = Mx

Py = ydA Px = xdA

For uniformly distributed stresses, = P/A = constant

y=

Chapter 1 Tension, Compression, and Shear 21 / 54 Chapter 1 Tension, Compression, and Shear

ydA

A

x=

xdA

A

The centroid of the cross section is at p1.

22 / 54

MEM230 Mechanics of Materials

MEM

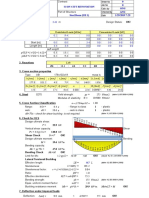

Example 1-1

MEM230 Mechanics of Materials

MEM

The Concept of Normal Strains

=

ChangeinLength (L + ) L = = OriginalLength L L

Normal Stresses and Strains

P = 54kips = 54 ,000lb d1 = 3.6in d2 = 5.0in L = 40.0in

Sign Convention

Elongation (bar in tension) is positive Shortening (bar in compression) is negative

Units

Normal strain is the ratio of two lengths, hence is a dimensionless quantity, i.e., it has no units. In practice, the original length units are often attached to the strain, e.g., mm/mm, in/in, etc. Sometimes it is also expressed as a percent. Example: If L = 2.0 m, = 1.4 mm

= 0.022in

d1=3.6 in d2=5.0 in

(d22 d12 ) = 9.456in 2 4 P 54 ,000lb = = = 5 ,710psi A 9.456in 2

A= 0.022in = = = 550 10 6 in/in L 40in

Cross section

Fig. 1-5 Example 1-1. Hollow aluminum post in compression.

=

Fig. 1-2 Prismatic bar in tension

Chapter 1 Tension, Compression, and Shear

1.4 mm = = 0.0007 m m 2.0 m L = 700 106 m m = 700 m m = 0.07%

23 / 54

How do we characterize the relationship between and ?

Chapter 1 Tension, Compression, and Shear 24 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

How Do You Break

A Piece of Chalk A Paper Clip

Mechanical Properties of Materials

The mechanical behaviors (or properties) of materials are characterized by the relationship between stress and strain. Stress

Ultimate Stress Strength

Failure

Stiffness

Toughness

Strain Brittle Materials

Chapter 1 Tension, Compression, and Shear

Ductile Materials

25 / 54 Chapter 1 Tension, Compression, and Shear

Ultimate strain

26 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Mechanical Properties of Materials

Material properties are usually characterized in terms of its stressstrain relations under loading conditions of simple tension, simple compression, simple shear, etc. The test methods and specimen dimensions must comply with American Society for Testing and Materials (ASTM), American Standards Association (ASA), or National Institute of Standards and Technology (NIST) codes.

Mechanical Properties of Materials

A Note on the Stress-Strain Relations A0

A P

L0 P

Before After

Initial cross-sectional area and length: A0, L0 Instantaneous cross-sectional area and length: A, L

TrueStress : =

P A

P A0

L TrueStrain : = ln L 0

NonimalStress : =

NonimalStrain : =

L0

Typical stress-strain diagram for a structural steel in tension.

Typical stress-strain diagram for an aluminum alloy.

Typical stress-strain diagram for a brittle material (e.g., glass).

27 / 54

In this course, the terms stresses and strains always imply nominal stresses and nominal strains, respectively, i.e., stresses and strains are determined based on the initial cross-sectional area and length.

Chapter 1 Tension, Compression, and Shear 28 / 54

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Mechanical Properties of Materials

True Stress-Strain Curve

Mechanical Properties of Materials

Definition of Yield Point

Modulus of Elasticity (Youngs Modulus)

Structural steel (with a clearly definable yield point)

Aluminum alloy (without a clearly definable yield point)

Actual scale

Fig. 1-10 Stress-strain diagram for a typical structural steel in tension (not to scale).

29 / 54

Arbitrary yield stress determined by the (0.2%) offset method.

Chapter 1 Tension, Compression, and Shear 30 / 54

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

Creep and Relaxation

MEM230 Mechanics of Materials

MEM

Mechanical Properties of Materials

Ductile vs. Brittle Elastic v.s. Elastic-Plastic

Mechanical Properties of Materials Modulus of Elasticity (Youngs Modulus)

The slope of the linearly elastic portion of the stressstrain curve is called modulus of elasticity, or Youngs Modulus, and is denoted as E.

= E

This equation relates the longitudinal stresses and strains developed in simple tension or compression of a bar, is a very limited version of the so-called Hookes law. More extensive versions of the Hookes law will be discussed later.

31 / 54 Chapter 1 Tension, Compression, and Shear 32 / 54

Reading assignment: Sections 1.3 and 1.4

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

P = 140k

L = 4.0ft d1 = 4.5in d2 = 6.0in E = 30 ,000ksi

MEM230 Mechanics of Materials

MEM

Mechanical Properties of Materials Poissons Ratio

Let L0 and d0 be the length and diameter of the bar before loading, and L and d the length and diameter of the bar after loading. The axial and lateral strains are given by, respectively, L L0 d d0 = = L0 d0 The Poissons ratio is defined as

Fig. 1-22 Axial elongation and lateral contraction of a prismatic bar in tension: (a) bar before loading, and (b) bar after loading. (The deformations of the bar are highly exaggerated.)

Chapter 1 Tension, Compression, and Shear

Example 1-3 A steel pipe in compression

Stress =

140k P = 12.37in 2 A = 11.32ksi(Compression)

Strain =

11.32 ksi = 377.3 10 6 30,000ksi

= 0.30

= L = ( 377.3 10 6 )(4.0 12 ) = 0.018in

(a) Change in length of the pipe

lateralstrain = = axialstrain NOTE: Poissons ratios are always positive as axial strains and lateral strains always have opposite signs. The values of Poissons ratio for commonly used materials range from 0.25 to 0.35.

33 / 54

= = (0.30 )( 377.3 10 6 ) = 113.2 10 6

Cross-sectional area:

(b) The lateral strain

A= =

(d

2 2

2 1

(6.02 4.52 ) 4 = 12.37in 2

d2 = d2 = (113.2 10 6 )(6.0in ) = 0.000679in d1 = d1 = (113.2 10 6 )(4.5in ) = 0.000509in

(c) The increases in outer and inner diameters

t = t = (113.2 10 6 )(0.75 ) = 0.000085in =

(d) Increase in wall thickness

d2 d1 2

34 / 54

Chapter 1 Tension, Compression, and Shear

MEM Shear Stress and Strain; Bearing Stress

MEM230 Mechanics of Materials Example Bolted connection in which the bolt is loaded in double shear. Flat Bar Bolt Clevis P P/2 P/2

MEM230 Mechanics of Materials

MEM

Bearing and Shear Stresses

P/2 P Average bearing stress: b = Fb Ab

( 2) Fb( 2 ) = P , Ab = t Bar d Bolt P ( 2) b = t Bar d Bolt

P/2

dBolt

Top View

t Bar

( 1) ( 3) Fb(1) = Fb( 3) = P 2 Ab = Ab = tClevis d Bolt P2 ( 1) ( 3) b = b = tClevis d Bolt

dBolt

Bearing Stresses Shear Forces Shear Stresses

Chapter 1 Tension, Compression, and Shear

Average shear stress: aver = V A

2 V = P 2 A = d Bolt 4

Bearing Stresses

35 / 54

A schematic of the actual bearing stress and shear stress distributions

Chapter 1 Tension, Compression, and Shear

aver =

P2

2 dBolt 4

2P

2 d Bolt

36 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Shear Stress and Strain

Shear Stress and Strain

Equality of Shear Stresses on Perpendicular Planes

2 3 4 1

1. 1 = V/A 2. There must exist a 3, equal in magnitude but opposite in direction to 1, to satisfy the equilibrium in the ydirection. 3. 1 and 3 form a couple, which must be balanced by another couple, equal in magnitude but opposite in direction, formed by shear stresses acting on the top face (2) and bottom face (4). Furthermore, 2 and 4 must be equal and opposite to each other to satisfy equilibrium in the x-direction. 4. Moment due to 1 and 3 is (1bc) a; moment due to 2 and 4 is (2ac) b. Equating these two moments results in 1 = 2 = 3 = 4.

38 / 54

2 3 4

1

3-D

Chapter 1 Tension, Compression, and Shear

2-D

37 / 54

Fig. 1-27 Small element of material subjected to shear stresses.

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Shear Stress and Strain

Equality of Shear Stresses on Perpendicular Planes Shear stresses on opposite (and parallel) faces of an element are equal in magnitude and opposite in direction. Shear stresses on adjacent (and perpendicular) faces of an element are equal in magnitude and have directions such that both stresses point toward, or both point away from, the line of intersection of the faces.

Chapter 1 Tension, Compression, and Shear 39 / 54

Shear Stress and Strain

Shear Strains Shear stresses do not elongate or shorten the element. Rather, they change the shape of the element by changing the angles between the side faces of the element. Shear strain is defined as change of angle of side faces that are originally perpendicular to each other. For example, shear strain in (b) is since the angles at points q and s are reduced by while the angles at points p and r are increased by .)

Chapter 1 Tension, Compression, and Shear 40 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Shear Stress and Strain

Sign Conventions for Shear Stresses and Strains

Positive x-face Positive y-face

Shear Stress and Strain

Sign Conventions for Shear Stresses and Strains

Positive y-face Positive x-face

Negative x-face

Negative y-face

Negative x-face

Negative y-face

A shear stress is positive if it is acting on a positive face and in the positive direction of one of the coordinate axes, or on a negative face and in the negative direction of one of the coordinate axes. A shear stress is negative if it is acting on a negative face and in the positive direction of one of the coordinate axes, or on a positive face and in the negative direction of one of the coordinate axes.

Chapter 1 Tension, Compression, and Shear 41 / 54

A shear strain in an element is positive when the angle between two positive faces (or two negative faces) is reduced, and is negative if the angle is increased.

Chapter 1 Tension, Compression, and Shear

42 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Hookes Law in Shear

Shear stress-strain diagrams are similar in shape (but different in magnitude) to the stress-strain diagrams of tension test for the same materials.

Example 1-4 A steel strut S serving as a brace for a boat hoist transmits a compressive force P to the deck of a pier

P = 54kN = 40 o dPin = 18mm dbolt = 12mm t strut = 12mm tGussets = 15mm t Base = 8mm

(a) Bearing Stress Between Strut and Pin:

G = or = G

For homogeneous and isotropic materials:

G=

E 2(1 + )

tStrut

b1 =

54kN 2 P2 = = 125MPa tStrut dPin (12mm )(18mm )

P/2

dPin

For most metals and many other engineering materials

P/2

tGussets

Pin

(b) Bearing Stress Between Pin and Gussets P2 54kN 2 b 2 = = = 100MPa tGusset dPin (15mm )(18mm ) (c) Shear Stress in Pin:

0.25 0.35G 0.37 E ~ 0.4 E

Chapter 1 Tension, Compression, and Shear 43 / 54

F.B.D. for left-half of the pin

Chapter 1 Tension, Compression, and Shear

Pin =

54kN 2 P2 = = 106MPa 2 dPin 4 (18mm )2 4

44 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Example 1-4 A steel strut S serving as a brace for a boat hoist transmits a compressive force P to the deck of a pier

P = 54kN = 40 o dPin = 18mm dbolt = 12mm t strut = 12mm tGussets = 15mm t Base = 8mm

(d) Bearing Stress Between Bolts and Base Plate: P cos 40 o 4 b3 = t Base d Bolt

o

Example 1-5. Punching a hole in a steel plate.

dPunch = 0.75in t Plate = 0.25in P = 28 ,000lb

(a) Average Shear Stress in the Plate

aver =

P P = = 47 ,500psi As d Punch t Plate

dBolt

40

P cos 40

(54kN )(cos 40o ) 4 = 108MPa (8mm )(12mm )

(b) Average Compressive Stress in Punch

c =

28 ,000lb P P = 2 = = 63 , 400psi 4 (0.75in )2 4 APunch dPunch

t Base

Bolt =

(e) Shear Stress in Anchor Bolts:

P cos 40 o 4 (54kN )(cos 40 o ) 4 = = 91.4MPa 2 d Bolt (12mm )2 4 4

45 / 54

F.B.D. of the bolt

NOTE: This analysis is highly idealized as the impact effects that occur when a punch is rammed through a plate is disregarded.

Chapter 1 Tension, Compression, and Shear 46 / 54

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Example 1-6. Bearing pad in shear.

EXAMPLE: The connection shown in the figure consists of five steel plates, each 2.5 mm thick, to be joined by a single bolt. Determine the required diameter of the bolt if the allowable bearing stress, b, is 180.0 MPa and the allowable shear stress, allow, is 45.0 MPa?

(a) Average Shear Stress in the Elastomer:

aver =

V ab

1,800 N 3,000 N 2,400 N 3,000 N 1,800 N

1,800 N 3,000 N 1,200 N 1,200 N 3,000 N 1,800 N

1,800 N 1,800 N 1,200 N 2,400 N 1,200 N 1,800 N 1,800 N

(b) Horizontal Displacement of the Plate, d::

aver

Ge

V abGe

V hV d = h tan = h tan abG h = abG e e

Chapter 1 Tension, Compression, and Shear 47 / 54 Chapter 1 Tension, Compression, and Shear

48 / 54

MEM230 Mechanics of Materials Allowable bearing stress, b, is 180.0 MPa Allowable shear stress, allow, is 45.0 MPa? Maximum Bearing Stress:

MEM

MEM230 Mechanics of Materials

MEM

Allowable Stresses and Allowable Loads

Strength: The ability of a structure to resist loads

1,800 N 3,000 N 1,200 N 1,200 N 3,000 N 1,800 N 1,800 N 1,800 N 1,200 N 2,400 N 1,200 N 1,800 N 1,800 N

Pb 3,000N b = = = 180MPa t plate d bolt (2.5 10 3 m )d bolt

Factorofsafetyn =

d bolt =

3,000N (2.5 103 m ) 180 106 N m 2 = 0.00667m = 6.67mm

Actualstrength Requiredstrength

Marginofsafety = n 1 Yieldstrength Factorofsafety Allowablestresses = Ultimatestress Factorofsafety forductilematerials forbrittlematerials

Maximum Shear Stress:

1,800N V = 2 = 45MPa Abolt d bolt 4

4 1,800N

dbolt =

allow

4 1,800N 45 10 6

dbolt = 7.14 mm

For Axial Loads and Direct Shear

Allowableload=Allowablestress Area

49 / 54 Chapter 1 Tension, Compression, and Shear 50 / 54

= 0.00714m = 7.14mm

Chapter 1 Tension, Compression, and Shear

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials

MEM

Example 1-7. Determine the allowable load P based on the following four considerations.

(a) The allowable tensile stress in the main part of the hanger is 16,000 psi.

Design for Axial Loads and Direct Shear

Analysis: Given the structure and loads, determine stresses and strains. Design: Given the loads and allowable stresses, determine the properties of the structure. Design for axial loads and direct shear entails finding the required area to carry the loads

Requiredarea = Loadtobetransmitte d (i.e.,StrengthConsiderat ion) Allowablestress

P1 = allow A = allow b1t = 12 ,000lb

(b) The allowable tensile stress in the hanger at its cross section through the bolt hole is 11,000 psi.

P2 = allow A = allow (b2 d )t = 11,000lb

(c) The allowable bearing stress between the hanger and the bolt is 26,000 psi.

P3 = b A = b dt = 13,000lb

(d) The allowable shear stress in the bolt is 6,500 psi.

Other design considerations include

Stiffness: Designing the structure to resist changes in shape. Stability: Designing the structure to resist buckling under compressive loads. Optimization: Designing the best structure to meet a particular goal.

P4 = allow A = allow (2 d 2 4 ) = 10 ,200lb

P3 > P1 > P2 > P4 Pallow = P4 = 10 ,200lb

Chapter 1 Tension, Compression, and Shear 51 / 54 Chapter 1 Tension, Compression, and Shear 52 / 54

MEM230 Mechanics of Materials

MEM

MEM230 Mechanics of Materials From F.B.D. (a) MC = 0 RAH (2.0m ) (2.7kN)(0.8m ) (2.7kN )(2.6m ) = 0

R AH = 4.590kN F = 0 horiz RCH = RAH = 4.590kN

MEM

Example 1-8. Two-bar truss ABC supporting a sign of weight W.

From F.B.D. (b) M B = 0 RCV (3.0m ) + (2.7kN)(2.2m ) + (2.7kN)(0.4m ) = 0

RCV = 2.340kN

Back to F.B.D. (a) Fvert = 0 RAV + RCV 2.7kN 2.7kN = 0

RAV = 3.060kN

RA =

(RAH )2 + (RAV )2

= 5.516kN;RC =

(RCH )2 + (RCV )2

allow

FAB =

= 5.152kN;FAB = RA = 5.156kN

Determine the required cross-sectional area of bar AB and the required diameter of the pin at support C

Required area of bar AB: Required diameter of pin at C:

AAB =

5.516 kN = 44.1 mm2 125 MPa

allow = 125Mpa; allow = 45Mpa

Chapter 1 Tension, Compression, and Shear

Free-body diagram

53 / 54

Apin =

VC RC 5.152kN = = = 57.2mm 2 ;d pin = 4 Apin = 8.54mm 2 allow 2 allow 2(45MPa )

54 / 54

Chapter 1 Tension, Compression, and Shear

Das könnte Ihnen auch gefallen

- Plastic Mechanics of Geomaterial PDFDokument258 SeitenPlastic Mechanics of Geomaterial PDFalireza سلامNoch keine Bewertungen

- Mechanics of Deformable Bodies Module 1Dokument14 SeitenMechanics of Deformable Bodies Module 1jhuascute06Noch keine Bewertungen

- Pre Stressed PDFDokument36 SeitenPre Stressed PDFmark dominicNoch keine Bewertungen

- Stress and Strain RenewDokument65 SeitenStress and Strain Renewshafarizy100% (1)

- Chapter-1, Simple StressDokument71 SeitenChapter-1, Simple Stresssherlockhisham100% (2)

- Stress and StrainDokument60 SeitenStress and StrainMuhammad Shafie100% (1)

- Mechanical Science for Technicians: Volume 1Von EverandMechanical Science for Technicians: Volume 1Bewertung: 5 von 5 Sternen5/5 (1)

- Seismic Control Device PDFDokument60 SeitenSeismic Control Device PDFRaden Budi HermawanNoch keine Bewertungen

- Module #1 – Simple StressDokument38 SeitenModule #1 – Simple StressJeffrey ManansalaNoch keine Bewertungen

- Simple Stress StrainDokument141 SeitenSimple Stress Strainjs kalyana ramaNoch keine Bewertungen

- Plate analysis, theory and application Volume 1Dokument98 SeitenPlate analysis, theory and application Volume 1Johan de Boon0% (1)

- Strength of MaterialsDokument81 SeitenStrength of MaterialsSenthil Kumar67% (3)

- Seismic Design of Concentrically Braced FramesDokument127 SeitenSeismic Design of Concentrically Braced Framesrmm99rmm9950% (2)

- Design of Major Bridge RCC Girder for Hunugund to Hospet Section of NH-13Dokument180 SeitenDesign of Major Bridge RCC Girder for Hunugund to Hospet Section of NH-13Raghums GOWDANoch keine Bewertungen

- Chapter 1 - STRESS AND STRAIN PDFDokument34 SeitenChapter 1 - STRESS AND STRAIN PDFnurul eryn100% (1)

- Section PropertiesDokument50 SeitenSection PropertiesSkyler PamatmatNoch keine Bewertungen

- Strength of MeterialsDokument142 SeitenStrength of MeterialsEricJohnDeraferaNoch keine Bewertungen

- Chapter 5Dokument62 SeitenChapter 5dearsaswatNoch keine Bewertungen

- Chapter 1 - Simple StressesDokument39 SeitenChapter 1 - Simple StressesJovy Notorio100% (2)

- Thermal StressDokument104 SeitenThermal Stressmanishtopsecrets100% (1)

- ECS 238 - Chapter 1 (Stress and Strain)Dokument131 SeitenECS 238 - Chapter 1 (Stress and Strain)dixn__Noch keine Bewertungen

- MECHANICS OF DEFORMABLE BODIESDokument106 SeitenMECHANICS OF DEFORMABLE BODIESVinayak PrabhuNoch keine Bewertungen

- Machine Design Reviewer - Complete PDFDokument104 SeitenMachine Design Reviewer - Complete PDFRae Nikka May Pablo83% (24)

- Fracture Mechanics ExercisesDokument33 SeitenFracture Mechanics Exercises2luckystar100% (1)

- Triaxial Stress State: (+ve Sense Shown)Dokument18 SeitenTriaxial Stress State: (+ve Sense Shown)Janjanam ChiranjeeviNoch keine Bewertungen

- Mechanics of Deformable Bodies1Dokument47 SeitenMechanics of Deformable Bodies1Nicole PerezNoch keine Bewertungen

- Compression TheoryDokument99 SeitenCompression TheoryBolarinwaNoch keine Bewertungen

- Simple Stress StrainDokument141 SeitenSimple Stress StrainvelavansuNoch keine Bewertungen

- Mechanicsofsolids 1lecture 1 190320182145Dokument30 SeitenMechanicsofsolids 1lecture 1 190320182145DarklotharNoch keine Bewertungen

- Tutorial 2 3Dokument0 SeitenTutorial 2 3Muhammad SaeedNoch keine Bewertungen

- 1. Simple Stress StrainDokument141 Seiten1. Simple Stress StraintccljahirdipokNoch keine Bewertungen

- Final Exam - Report About StressDokument25 SeitenFinal Exam - Report About StressMashuNoch keine Bewertungen

- Simple Stress Strain2132Dokument141 SeitenSimple Stress Strain2132ksrsunilNoch keine Bewertungen

- Axially Loaded MembersDokument13 SeitenAxially Loaded MembersUnknownNoch keine Bewertungen

- Mechanic of Materials (Normal Stress)Dokument44 SeitenMechanic of Materials (Normal Stress)moj33Noch keine Bewertungen

- MP2001 Chapter 1Dokument26 SeitenMP2001 Chapter 1Jaren FooNoch keine Bewertungen

- Chapter # 3Dokument64 SeitenChapter # 3Pharo TotNoch keine Bewertungen

- Chapter 4Dokument9 SeitenChapter 4dearsaswatNoch keine Bewertungen

- MMAN3400 Lecture 2Dokument21 SeitenMMAN3400 Lecture 2Zenik AGNoch keine Bewertungen

- Strength of Materials 2015 by S K MondalDokument471 SeitenStrength of Materials 2015 by S K MondalNaman Jain100% (1)

- Method of Consistent Deformations for Statically Indeterminate StructuresDokument45 SeitenMethod of Consistent Deformations for Statically Indeterminate Structuresfastidious_5Noch keine Bewertungen

- 2.bending and Axial Load (Tan K H - NUS)Dokument31 Seiten2.bending and Axial Load (Tan K H - NUS)trannguyenvietNoch keine Bewertungen

- Worked Exp Mechanics 2 PDFDokument144 SeitenWorked Exp Mechanics 2 PDFamit1234Noch keine Bewertungen

- A NoteDokument106 SeitenA NoteKenneth SantiagoNoch keine Bewertungen

- Mechanics of Deformable Bodies: Mechanical Engineering DepartmentDokument11 SeitenMechanics of Deformable Bodies: Mechanical Engineering DepartmentAngelo BendalNoch keine Bewertungen

- Chapter 2Dokument9 SeitenChapter 2Fadhiran YahyaNoch keine Bewertungen

- Chapter 1Dokument50 SeitenChapter 1AdzmierHassanNoch keine Bewertungen

- Mechanical Property of MetalDokument55 SeitenMechanical Property of MetalAbhishek SinghNoch keine Bewertungen

- Forces and Pin-Jointed Frames - LectureDokument9 SeitenForces and Pin-Jointed Frames - Lecturepilas_nikolaNoch keine Bewertungen

- Mechanics of Deformable Bodies Module 1Dokument15 SeitenMechanics of Deformable Bodies Module 1Christian Angelo ButacNoch keine Bewertungen

- 1-Concept of Stress and Strain PDFDokument29 Seiten1-Concept of Stress and Strain PDFMohamad Zaid83% (6)

- Steel Design LRFD GuideDokument5 SeitenSteel Design LRFD GuidesokainaNoch keine Bewertungen

- Strain in OtrsionDokument45 SeitenStrain in OtrsionrenebbNoch keine Bewertungen

- Chapter 2Dokument40 SeitenChapter 2IntanLeeyanaNoch keine Bewertungen

- Theory of PlasticityDokument10 SeitenTheory of Plasticitybabu1434100% (1)

- ME111 1.1 The Mechanical Design Process: 9/27/00 ME111 Lecture 1 1 9/27/00 ME111 Lecture 1 2Dokument9 SeitenME111 1.1 The Mechanical Design Process: 9/27/00 ME111 Lecture 1 1 9/27/00 ME111 Lecture 1 2Adam NortonNoch keine Bewertungen

- Simple Stresses in Machine PartsDokument38 SeitenSimple Stresses in Machine Partsiftikhar ahmedNoch keine Bewertungen

- Lecture 26: Plane Strain Bending of Strips: Dept. of Mechanical Engg., NIT CalicutDokument12 SeitenLecture 26: Plane Strain Bending of Strips: Dept. of Mechanical Engg., NIT CalicutprasannaNoch keine Bewertungen

- Prestressing in Combination of High Strength Steel and ConcreteDokument7 SeitenPrestressing in Combination of High Strength Steel and ConcreteEdzel RenomeronNoch keine Bewertungen

- Stresses and strains moduleDokument11 SeitenStresses and strains moduleEesha NairNoch keine Bewertungen

- 10.concepts of Force-Stress and Deformation-StrainDokument25 Seiten10.concepts of Force-Stress and Deformation-StrainaderancNoch keine Bewertungen

- Mechanical Properties Guide for MaterialsDokument55 SeitenMechanical Properties Guide for MaterialsbinoNoch keine Bewertungen

- Mech MatDokument11 SeitenMech MatDwie OktavianaNoch keine Bewertungen

- Axial Loading-Part 2Dokument20 SeitenAxial Loading-Part 2Alex BradleyNoch keine Bewertungen

- Lesson 24: Design and Coding: ObjectiveDokument5 SeitenLesson 24: Design and Coding: ObjectivedearsaswatNoch keine Bewertungen

- Lecture 21Dokument23 SeitenLecture 21dearsaswatNoch keine Bewertungen

- Lecture 22Dokument10 SeitenLecture 22dearsaswatNoch keine Bewertungen

- STRENGTH OF MATERIALS EXAMDokument4 SeitenSTRENGTH OF MATERIALS EXAMdearsaswatNoch keine Bewertungen

- Sub Module 1.2 2. Errors in MeasurementsDokument4 SeitenSub Module 1.2 2. Errors in MeasurementscaptainhassNoch keine Bewertungen

- Lecture 23Dokument4 SeitenLecture 23dearsaswatNoch keine Bewertungen

- Lesson 26: Introduction To E-Commerce: ObjectiveDokument3 SeitenLesson 26: Introduction To E-Commerce: ObjectivedearsaswatNoch keine Bewertungen

- Mechanical MeasurementsDokument3 SeitenMechanical MeasurementscaptainhassNoch keine Bewertungen

- Sub Module 1.6 6. Design of ExperimentsDokument16 SeitenSub Module 1.6 6. Design of ExperimentscaptainhassNoch keine Bewertungen

- Lesson 6: Value Chain Process: ObjectiveDokument2 SeitenLesson 6: Value Chain Process: ObjectivedearsaswatNoch keine Bewertungen

- Lecture 22Dokument6 SeitenLecture 22dearsaswatNoch keine Bewertungen

- Lecture 21Dokument3 SeitenLecture 21dearsaswatNoch keine Bewertungen

- Lecture 20Dokument4 SeitenLecture 20dearsaswatNoch keine Bewertungen

- Lesson 19: Organizational Goal Orientation: ObjectiveDokument4 SeitenLesson 19: Organizational Goal Orientation: ObjectivedearsaswatNoch keine Bewertungen

- Lecture 13Dokument4 SeitenLecture 13dearsaswatNoch keine Bewertungen

- Lesson 15: Functional Management: 48 11.302 © Copy Right: Rai UniversityDokument2 SeitenLesson 15: Functional Management: 48 11.302 © Copy Right: Rai UniversitydearsaswatNoch keine Bewertungen

- Lesson 7: Introduction To Computers: ObjectiveDokument3 SeitenLesson 7: Introduction To Computers: ObjectivedearsaswatNoch keine Bewertungen

- Lecture - 16 9.1 The Telecommunications Revolution: The Marriage of Computers and CommunicationsDokument13 SeitenLecture - 16 9.1 The Telecommunications Revolution: The Marriage of Computers and CommunicationsdearsaswatNoch keine Bewertungen

- Lesson 6: Value Chain Process: ObjectiveDokument2 SeitenLesson 6: Value Chain Process: ObjectivedearsaswatNoch keine Bewertungen

- Lesson 3: Sources and Components: ObjectiveDokument1 SeiteLesson 3: Sources and Components: ObjectivedearsaswatNoch keine Bewertungen

- Lesson 4: Organization and Information Systems: ObjectiveDokument6 SeitenLesson 4: Organization and Information Systems: ObjectivedearsaswatNoch keine Bewertungen

- Lecture 05Dokument4 SeitenLecture 05dearsaswatNoch keine Bewertungen

- Build Systems the Right Way with Lifecycles and AlternativesDokument9 SeitenBuild Systems the Right Way with Lifecycles and AlternativesdearsaswatNoch keine Bewertungen

- Lesson 2: System Framework: ObjectiveDokument3 SeitenLesson 2: System Framework: ObjectivedearsaswatNoch keine Bewertungen

- Unit - C: Building Information Systems in The Digital FirmDokument9 SeitenUnit - C: Building Information Systems in The Digital FirmdearsaswatNoch keine Bewertungen

- Organizing Data in Traditional and Database EnvironmentsDokument16 SeitenOrganizing Data in Traditional and Database EnvironmentsdearsaswatNoch keine Bewertungen

- Lecture - 21 11.3 System-Building Methodologies and ToolsDokument7 SeitenLecture - 21 11.3 System-Building Methodologies and ToolsdearsaswatNoch keine Bewertungen

- Lecture - 14 7.4 New Software Tools and Approaches: Object-Oriented ProgrammingDokument7 SeitenLecture - 14 7.4 New Software Tools and Approaches: Object-Oriented ProgrammingdearsaswatNoch keine Bewertungen

- Lecture - 8 4.3 Individual Models of Decision Making: The Rational ModelDokument6 SeitenLecture - 8 4.3 Individual Models of Decision Making: The Rational ModeldearsaswatNoch keine Bewertungen

- Lecture - 12 6.4 Secondary Storage: Magnetic Disk and TapeDokument8 SeitenLecture - 12 6.4 Secondary Storage: Magnetic Disk and TapedearsaswatNoch keine Bewertungen

- Steel Beam Design CalculationsDokument45 SeitenSteel Beam Design CalculationsOng George SammyNoch keine Bewertungen

- Chapter Two 2.1 Cyclic/Fatigue Loading of Structural MembersDokument28 SeitenChapter Two 2.1 Cyclic/Fatigue Loading of Structural MembersVignesh WaranNoch keine Bewertungen

- Failure Static LoadingDokument183 SeitenFailure Static LoadingoperationmanagerNoch keine Bewertungen

- Cavity Expansion in Rock Masses Obeying The Hoek-Brown Failure CriterionDokument15 SeitenCavity Expansion in Rock Masses Obeying The Hoek-Brown Failure CriterionAlexander ArdilesNoch keine Bewertungen

- Solid Mechanics ME 212 - Week 1 PDFDokument39 SeitenSolid Mechanics ME 212 - Week 1 PDFAlpha WolfNoch keine Bewertungen

- Geotechnik Blockprüfung - Module Description BGU50010Dokument5 SeitenGeotechnik Blockprüfung - Module Description BGU50010Devis CamiNoch keine Bewertungen

- Axially Loaded Compression MembersDokument19 SeitenAxially Loaded Compression MembersAnjielo AusaNoch keine Bewertungen

- Force and Torque MeasurementDokument26 SeitenForce and Torque MeasurementAndreea Diana GhitaNoch keine Bewertungen

- Seismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsDokument14 SeitenSeismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsMălíķ ĂsfęnđýårNoch keine Bewertungen

- CH 01 Simple Stresses and Strains VG 24Dokument40 SeitenCH 01 Simple Stresses and Strains VG 24Sivani SinghNoch keine Bewertungen

- Material Science Introduction - Demo Worksheet: InstructionDokument2 SeitenMaterial Science Introduction - Demo Worksheet: InstructionSalma FarooqNoch keine Bewertungen

- Asymmetric HeadgearDokument10 SeitenAsymmetric HeadgearAli HmoudNoch keine Bewertungen

- 2 StrainDokument10 Seiten2 StrainBOITIZON, Julius C.Noch keine Bewertungen

- Non-Linear FEM For Axisymmetric Torsion of Biphasic MaterialsDokument17 SeitenNon-Linear FEM For Axisymmetric Torsion of Biphasic MaterialsAhmed S. SharifNoch keine Bewertungen

- IPC-TM-650 Test Methods ManualDokument3 SeitenIPC-TM-650 Test Methods ManualRoman MiahNoch keine Bewertungen

- LSM Beam DesignDokument25 SeitenLSM Beam DesignPranavNoch keine Bewertungen

- Attachment M - John Fowler - AnnexXRevBDokument5 SeitenAttachment M - John Fowler - AnnexXRevBBùi Văn HợpNoch keine Bewertungen

- Beam size and elastic modulus for structural columns and beamsDokument1 SeiteBeam size and elastic modulus for structural columns and beamsnurNoch keine Bewertungen

- 05 01 0123 PDFDokument8 Seiten05 01 0123 PDFSinem Kocabaş ŞirikçiNoch keine Bewertungen

- Sa283c Stress-Strain CurveDokument7 SeitenSa283c Stress-Strain CurveAnonymous AtAGVssJNoch keine Bewertungen

- Two Dimensional and 3D LoadingDokument20 SeitenTwo Dimensional and 3D LoadingJanith100% (1)

- Solutions of Problem Set 5Dokument15 SeitenSolutions of Problem Set 5yasin yttNoch keine Bewertungen

- CH 11Dokument42 SeitenCH 11LeonardoMadeira11Noch keine Bewertungen