Beruflich Dokumente

Kultur Dokumente

Lightning & Earthing Protection System Specifications

Hochgeladen von

Muhammad Ibad AlamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lightning & Earthing Protection System Specifications

Hochgeladen von

Muhammad Ibad AlamCopyright:

Verfügbare Formate

SECTION E-2 SPECIFICATIONS FOR LIGHTNING & EARTHING PROTECTION SYSTEM E2.

01 SCOPE OF WORK: The work consists of supplying, installing, testing & commissioning of all materials and services of the complete Lightning & Earthing Protection Systems as specified herein and / or stated on the Tender Drawings (UESI-ASM-E-18, 19 & 20) and in the Bill of Quantities (BOQ). The contractor shall discuss the Earthing Pits & Main Earthing Network Grid Running Trenches layout & the related work with the Amrelis Manager Electrical / Engineer at Dhabeji Site and coordinate at site with other services for exact route, location & position of Earthing Pits & Trenches, however not deviating the essence / standards / parameters & work as per the given BOQ & tender drawings. In the case of conflict, please consult the Electrical Consultant (M/S UESI) for resolution. Principal items of work are as following:

(a)

Installation of Lightning Arresters Air Terminations along with all accessories, auxiliaries (complete in all respect) at the roof tops of Main Plant Structure, Overhead Tank & Chimney and connected with copper strip (50 x 3 mm thick) grid / meshed network employing brazed connections. All the connections & joints are brazed through CAD / Exothermic Welding using appropriate powder & mould for perfect brazing. Materials as offered by M/S Furse - U.K or imported equivalent, would be acceptable. Making grid / mesh network of Copper Strip 50 x 3 mm thick at the roof tops of Main Plant Structure, Overhead Tank & Chimney. The down coming copper strips are further extending to the corresponding Earthing Pits, through CAD / Exothermic Welding using appropriate powder & mould for perfect brazing. Materials as offered by M/S Furse - U.K or imported equivalent, would be acceptable. Making Earthing Pits, 500 x 500 x 500 mm, with a drilled / bored hole having dimensions 100 mm x 10,000 mm deep (10 Meters deep) in the centre of every Earthing Pit. The Job should be complete in all respect along with all the accessories and auxiliaries including Earthing Electrode 17.2 mm x 3000mm length, Earthing Lead - 2 X 70 sq.mm bare copper wires, G.I Perforated Pipe 38 mm (1.5) x 7000 mm length, Earthing Termination / Test Point (ETP) 300 x 50 x 10 mm thick and as per the details given in the BOQ & drawings. Page-1

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

(b)

(c)

(d)

Making trench running at the ground, 500 x 500 mm deep, and burying Copper Strip, size 50 x 3 mm in the trench for connecting Earthing Pits with each other and as per given drawings. All the connections & joints are brazed through CAD / Exothermic Welding, using appropriate powder and mould for perfect brazing. Installation of Earthing Connection Points (ECPs) at appropriate locations, extending from the respective Earthing Pits Complete testing and commissioning of the installation.

(e)

(f)

If anything has been omitted or any items of work or material, usually furnished, which are necessary for the completion of the works as outlined herein before then such items of work must be and are hereby included in this section of the work. E2.02 WORK NOT INCLUDED:

(a)

Outgoing earthing connectivity of equipment onward Earthing Connection Points (ECPs), except when specifically noted otherwise. Provision of appropriate quantity & of specifications - Surge Protective Devices (SPDs). to be incorporated in the switchgear by Electrical Switchgear Consultant. Provision of appropriate quantity & of specifications Residual Current Devices for Earth Leakage Protection; to be incorporated in the switchgear by Electrical Switchgear Consultant.

(b)

(c)

E2.03 GENERAL: The Lightning & Earthing Protection Systems work shall be carried out in accordance with IEC 62305 Series of Standards & Codes of practice including protection against Physical Damage to Structure & Life Hazard. As per IEC 62305 series of Lightning Protection Standards and the statistical data available with IEC, Lightning Strokes / Flashes may lead to a maximum lightning current flow from 100,000 Amperes (100 KA) to 200,000 Amperes (200 KA) and even more, and these huge quantities of lightning currents are dissipated to ground within a few micro seconds. The extent of Lightning & Earthing Protection Systems of work, specified or shown on the tender drawings, is schematic & does not indicate the exact positions of the Lightning Arrestors / Air-Terminations, Earthing Pits, Trenches, conductor / copper strips connections / joints (types) etc. etc. Page-2

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

However, the contractor shall ensure that the system is complete in all respect, including all accessories & auxiliaries as intended by the specifications / BOQ & Tender Drawings. The Lightning Protection System shall comprise of: Air Terminations / Lightning Arresters & Copper Strips Mesh at the roof tops of Main Plant Structure, Overhead Tank & Chimney etc. and down coming (from roof top) copper strips that are further extending to the corresponding Earthing Pits on the ground. Materials as offered by M/S Furse U.K or imported equivalent, would be acceptable. The general earthing resistance requirements are such that the Lightning Protection Earthing System must have a resistance of less than 10 ohms, measured at a frequency, different from the power system frequency or multiple thereof. The Earthing Protection System shall comprise of: Earthing Pits (same are the part of Lightning Protection System as well) with a drilled / bored hole having solid copper Earthing electrode at the bottom of the drilled hole, Earthing leads, Earthing termination / test points (ETPs), Earthing Continuity Conductors ( Copper Strips 50 x 3 mm thick), Earthing Connection Points (ECPs) as well as Running Trenches having buried copper strips for connecting / looping Earthing Pits and all accessories & auxiliaries necessary for the satisfactory operation of the associated Electrical System. E2.04 MATERIALS:

(a)

All materials shall be in accordance with the type and manufacture described in the Bill of Quantities and/or shown on the relevant drawings. Where the Contractor desires to use material differing from those described, he shall obtain the approval of the Consultant in writing before tendering. Materials shall accord with the appropriate Pakistan and IEC Standard Specifications. The rights are reserved to inspect materials on site at reasonable times and to reject any material not complying with the specifications. The cost of any dismantling and re-erection of the installation occasioned by the removal of rejected materials shall be borne by the Contractor.

Page-3

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

(b)

(Items to be imported for use under this contract are listed hereunder. (Each bidder may submit his own list which may differ from the following provided the bidder can give justification for the proposed changes.) i) Copper Strips 50 x 3 mm thick, ETPs & ECPs, made of 99.9 % pure and Imported copper. Lightning Arresters Air Terminations along with all accessories, auxiliaries & complete in all respect. Materials as offered by M/S Furse U.K or imported equivalent, would be acceptable. Earthing Electrodes along with all accessories, auxiliaries & complete in all respect. Materials as offered by M/S Furse U.K or imported equivalent, would be acceptable. Brazed connections / joints through CAD / Exothermic Welding. Materials as offered by M/S Furse U.K or imported equivalent, would be acceptable. LIGHTNING & EARTHING PROTECTION SYSTEMS ITEMS MATERIAL & INSTALLATION DETAILS Air Termination (Lightning Arrestor) - 15 mm x 2000 mm Length Air Termination (Lightning Arrestor) shall comprise of copper rod 15 mm x 2000 mm Length, base, multi-point spikes - brazed on the top of the copper rod, and further including appropriate & suitable mounting arrangement over the copper strip mesh at the perlins of the roof top / ridge of the structure, perpendicular to x-axis or horizontal - axis. All the parts /sub-assemblies of the Air-Terminal must be made of 99.9 % pure copper. Moreover all the connections / joints / assemblies /sub-assemblies must be brazed through CAD / Exothermic Welding.

ii)

iii)

iv)

(c)

c-1

c-2

Roof top Copper Strips (50 x 3 mm thick) Mesh / Grid Network The roof-top copper strips (50 x 3 mm thick) mesh / grid network shall connect the Air Terminations / Lightning Arrestors with each Page-4

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

other and further provide various diversified current carrying paths for the lightning strokes / flashes (carrying huge lightning currents ) to reach the earthing electrodes / (earthing pits), to be dissipated in the earth mass. Air Terminals & the copper strip mesh at the perimeter of the roof-top shall be as close to the edges of the roof top / ridge structure, as practically possible. Moreover, Air-Terminals and the copper strip mesh, shall be installed on the perlins supporting the roof top, as the roof-top by itself, is just covered by 1 mm thick sheet which is not strong enough to hold Air-Terminals & the mesh. c-3 Down-Coming Copper Strips 50 x 3 mm thick (from roof-top) & extending to Earthing Pits for Lightning Protection System. The down-coming copper strips (50 x 3 mm thick) from the roof-top for Lightning Protection System & further extending to the corresponding Earthing Pits, shall be brazed through CAD / Exothermic Welding with the Steel structure (pillars) at 3 locations: top, middle and bottom ( bottom above PVC insulation) and further shall be saddled at each running meter. While running & connecting the down-coming copper strips with the items of the Lightning & Earthing Protection System, sharp bends / corners / turnings must be avoided using appropriate round bends / corners / turnings. The "Down coming copper strips" from the roof top of the "Main Plant Structure", O/H Water Tank, Chimney, must be insulated at least "100 KV, 1.2/50 micro seconds impulse wave insulation" using 3 mm thick PVC / Polyethylene Insulation up to a height of 2500 mm (2.5 meters) from finished floor level, to reduce touch potential threats for personnel.

c-4

Earthing Pit 500 x 500 x 500 mm deep Earthing pits having size: 500 X 500 X 500 mm deep (inside dimensions), shall be a cement concrete chamber, provided with a drilled / bored hole in the centre of the pit, having dimensions: 100 mm x 10,000 mm (10 meter) deep (in line with the Soil Resistivity Report provided by M/S Amreli Steels & as per its Page-5

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

recommendations for good conductivity), for carrying Earthing Electrode at the bottom of the bored/drilled hole. All Copper items / parts should be made of 99.9% Pure & imported copper. Earthing Pit work / job should be completed in all respect including all accessories, auxiliaries and as per Drawings: UESI-ASM-E-18, 19 & 20. The top of the Earthing Pit must be flushed with the finished floor level, where available & applicable, covered by a medium duty Cast Iron Cover & painted by "corrosion resistive" (anti-corrosive) paint, matching the Finished Flooring color. The earthing pit includes earthing electrode whose top-end, is connected / brazed through CAD / Exothermic welding by 2 x 70 sq. mm bare copper conductor wire to be connected with the Earthing Termination / Test Point (ETP), by using appropriate copper lugs to make removable connections of the earthing electrode for testing purposes. The 2 x 70 sq. mm bare copper conductor wire, (Earthing Lead) are further enclosed in a 38 mm (1.5 inch) x 7000 mm Length of Galvanized Iron Perforated Pipe, having cover on its top & a "T- connection" to extend copper wires to ETP, as shown in the drawing. The remaining space in the drilled / bored hole, inside & around the perforated G.I Pipe and around Earthing Electrode, must be filled by "sweet earth" and solidly compacted by watering to provide the least possible resistive path in the ground / earth. To reduce "Step Potential" threats for personnel, "GRAVEL" at the surface must be used, 150 mm deep and with a distance of 3000 mm around each Earthing Pit.

c-5

Solid Copper Earthing Electrode - 17.2 mm x 3000 mm Length Sloid Copper Earthing Electrode, rod type, having dimensions: 17.2 mm x 3000 mm Length, made of 99.9% pure & imported copper, with all accessories, auxiliaries & complete in all respect to be used as mentioned in item E-01 of BOQ relating to Earthing Pit. (Drwg: UESI- ASM-E-19).

Page-6

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

c-6

Earthing Lead 70 sq. mm Bare Copper Conductor Wire The earthing lead: 70 sq. mm bare copper conductor wire, shall connect the top end of the earthing electrode through brazed CAD / Exothermic Welding to the Earthing Termination / Test Point (ETP) via appropriate size of copper lugs to make the connections removable at ETP side, for testing purposes.

c-7

Earthing Termination / Test Point (ETP) SIZE: 300 x 50 x 10 mm Thick The Earthing Termination / Test Point (ETP), having dimensions: 300 x 50 x 10 mm thick, made of 99.9% pure & imported copper, to be installed in each earthing pit upon 2 x insulator supports. ETP shall provide connectivity to 2 x earthing lead through appropriate copper lugs, 2 x copper strips 50 x 3 mm thick, brazed through CAD / Exothermic welding to connect Earthing Connection Point (ECP) & further 2 x copper strips 50 x 3 mm thick, brazed through CAD / Exothermic welding, being the running Earth Continuity Copper Strips (ECC) as per the given tender drawings.

c-8

Earthing Continuity Copper Strips (ECC) 50 x 3 mm thick Earthing Continuity Copper Strips (ECC), having dimensions 50 x 3 mm thick, buried in a Running Trench, connecting / looping Earthing Pits through Earthing Termination / Test Point (ETP) & further connecting Earthing Connection Point (ECP) as per the given tender drawings. While running & connecting ECCs with the items of the Lightning & Earthing Protection System, sharp bends / corners / turnings must be avoided using appropriate round bends / corners / turnings.

c-9

Earthing Connection Point (ECP) SIZE: 400 x 100 x 10 mm Thick Earthing Connections Point (ECP), having dimensions: 400 x 100 x 10 mm thick, shall be provided & installed at suitable & appropriate locations to cater the requirements of "Earthing Connnectivity". The Earthing Connection Points (ECPs) should be made of 99.9 % pure & imported copper, having 14 outgoing connection holes of appropriate diameter for earthing connectivity. ECP should be installed / brazed with the structure / facility, at suitable / appropriate locations, 300 mm above the finished floor level. ECP Page-7

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

should be connected / Brazed by 2 x Copper Strips, having dimensions 50 x 3 mm thick, to Earthing Termination / Test Point(ETP) of each Earthing Pit for Structure (SP) & Electronic eqp. Pit (EP). The connections of the 2 x copper strips, (50 x 3 mm) at both the ends of ECP & ETP, are the brazed connections through CAD / Exothermic Welding. ECP should be complete in all respect including all the accessories & auxiliaries & as per drawing UESI-ASM-E-19.

c-10

Running Trench of size 500 x 500 mm deep running between Earthing Pits for Main Earthing Network Grid Connectivity as per given drawings. Main Earthing Network Grid of Copper Strips, 50 x 3 mm thick, connecting / looping Earthing Pits as per given drawings, shall be buried at least 500 mm below the natural ground level, in a running trench of size 500 x 500 mm deep, filled by sweet earth & compacted by watering.

c-11

All The Connections / Joints Brazed Through CAD / Exothermic Welding Except For Removable Connections All the connections / joints of the copper strips, connections of copper Strips between ETPs & ECPs, metallic / steel structure with the earting grid / mesh, lightning grid / mesh, lightning down-coming copper strips, lightning arresters / Air - Terminals, earthing pits, earthing electrodes, etc. shall be Brazed through CAD / Exothermic Welding as per IEC - 62305 Standards and practices, except for the "removable connections" for testing purposes, using appropriate "powder" and "mould" for perfect brazing: using materials as offered by M/S Furse - U.K or imported equivalent. The details of the joints & their corresponding moulds & powders required, as offered by M/S Furse U.K, are described in the BOQ.

c-12

3 mm thick PVC / Polyethylene Insulation on Lightning- Protection down-coming Copper Strips to reduce "Touch Potential" threat To reduce "Touch Potential" threats for personnel, the "down coming copper strips" (having size 50 x 3 mm thick) of Lightning Protection Page-8

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

System, from the roof top Tank, Chimney, shall be seconds impulse wave Polyethylene Insulation up the finished Floor Level.

of the "Main Plant Structure", O/H Water insulated at least "100 KV, 1.2/50 micro insulation" using 3 mm thick PVC / to a height of 2500 mm (2.5 meters) from

Page-9

UNITED ENGINEERING SERVICES INTERNATIONAL CONSULTING ENGINEERS

Das könnte Ihnen auch gefallen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Electrical BOQ150710Dokument11 SeitenElectrical BOQ150710Jaime Manalili LandinginNoch keine Bewertungen

- Selection of Main & Branch CB As Per NEC-210 (14.1.14)Dokument16 SeitenSelection of Main & Branch CB As Per NEC-210 (14.1.14)casaouis02Noch keine Bewertungen

- User's Guide: Group G Controller For Automatic & Non-Automatic Transfer SwitchesDokument40 SeitenUser's Guide: Group G Controller For Automatic & Non-Automatic Transfer Switchesangel aguilarNoch keine Bewertungen

- Calculate Street Lighting RequirementsDokument6 SeitenCalculate Street Lighting RequirementsRvNoch keine Bewertungen

- Process control modes and tuning methodsDokument23 SeitenProcess control modes and tuning methodsMuhammad Ibad AlamNoch keine Bewertungen

- CT Ratio Calculation as per IEC 60044-1Dokument13 SeitenCT Ratio Calculation as per IEC 60044-1Muhammad Ibad AlamNoch keine Bewertungen

- Cathodic Protection ReportDokument32 SeitenCathodic Protection ReportMuhammad Ibad Alam100% (1)

- Technical Data Sheets for Electrical WorksDokument36 SeitenTechnical Data Sheets for Electrical WorksVikas Dwivedi0% (1)

- Cable Low Voltage Specification PDFDokument12 SeitenCable Low Voltage Specification PDFAndreas OktoraNoch keine Bewertungen

- Cable Installation Notes - GeneralDokument6 SeitenCable Installation Notes - GeneralraghvendraNoch keine Bewertungen

- Boq ElectricalDokument22 SeitenBoq Electricaleng_hosNoch keine Bewertungen

- BS EvDokument2 SeitenBS EvPradeesh Vijayan (v.prathi)Noch keine Bewertungen

- Design Calculation For Electrical Earthing System: Client: Anrak Aluminium LimitedDokument9 SeitenDesign Calculation For Electrical Earthing System: Client: Anrak Aluminium Limitedparuchurivenkat5272100% (1)

- Touch Voltage - Ground Current (1.1.19)Dokument2 SeitenTouch Voltage - Ground Current (1.1.19)jiguparmar1516Noch keine Bewertungen

- SMS AREA LIGHTNING PROTECTION SPECIFICATIONS AND BOQDokument1 SeiteSMS AREA LIGHTNING PROTECTION SPECIFICATIONS AND BOQRuchir ChaturvediNoch keine Bewertungen

- Calculate Voltage Drop and Size of Electrical Cable For Following DataDokument5 SeitenCalculate Voltage Drop and Size of Electrical Cable For Following Datashibu danielNoch keine Bewertungen

- Specification 33 KV LineDokument18 SeitenSpecification 33 KV LineSatyaprasad NimmakayalaNoch keine Bewertungen

- Instrument Air System EssentialsDokument22 SeitenInstrument Air System Essentialsabhi_mohit2005100% (1)

- QA/QC Checklist - Installation of MDB Panel BoardsDokument6 SeitenQA/QC Checklist - Installation of MDB Panel Boardsehtesham100% (1)

- Cable MeggeringDokument12 SeitenCable MeggeringaeliusmanoNoch keine Bewertungen

- 5-Power & Control Cables PDFDokument11 Seiten5-Power & Control Cables PDFAnonymous ufMAGXcskMNoch keine Bewertungen

- Cable Pulling at E05 South InterconnectingDokument6 SeitenCable Pulling at E05 South InterconnectingHERWIN SEPTIYANNoch keine Bewertungen

- Installation MCC Room, E&I Rooms, and Battery RoomDokument9 SeitenInstallation MCC Room, E&I Rooms, and Battery RoomDario WicaksonoNoch keine Bewertungen

- Earthing WorksheetDokument5 SeitenEarthing Worksheetsry20780Noch keine Bewertungen

- 1.0 Cable Tray Technical Data SheetDokument2 Seiten1.0 Cable Tray Technical Data SheetRahul100% (1)

- Checklist For Erection of USSDokument3 SeitenChecklist For Erection of USSsasikumarNoch keine Bewertungen

- Earthing Calculation, Rev-5, (AS BUILT)Dokument7 SeitenEarthing Calculation, Rev-5, (AS BUILT)Mayank SharmaNoch keine Bewertungen

- Fall Protection Calculating Total Fall DistanceDokument1 SeiteFall Protection Calculating Total Fall DistancealphadingNoch keine Bewertungen

- Lightning CalculationsDokument48 SeitenLightning Calculationsbuntysurat83% (6)

- Earthing SystemDokument22 SeitenEarthing Systemashokparikh100% (2)

- Contractor QAP for HT Breaker PanelDokument1 SeiteContractor QAP for HT Breaker Panelmadhu_bedi12Noch keine Bewertungen

- Developing EV Charging Stations in VietnamDokument28 SeitenDeveloping EV Charging Stations in VietnamQuang Linh Lê100% (1)

- Calculate Minimum Size of Earthing Strip and WireDokument18 SeitenCalculate Minimum Size of Earthing Strip and Wirerushi_007Noch keine Bewertungen

- Earthing Method StatementDokument5 SeitenEarthing Method StatementMuhammad Saqib AsifNoch keine Bewertungen

- 11 KV RMU-Tech. Spec PDFDokument23 Seiten11 KV RMU-Tech. Spec PDFMohsin ElgondiNoch keine Bewertungen

- Underground Power Cable For AirportsDokument12 SeitenUnderground Power Cable For AirportsDevrim GürselNoch keine Bewertungen

- Methodology High MastDokument12 SeitenMethodology High MastAmis VenturesNoch keine Bewertungen

- Method of Statement Grounding System & Lightning ProtectionDokument7 SeitenMethod of Statement Grounding System & Lightning Protectionafm0% (1)

- Sandwich Bus Duct Specs for Power SystemDokument15 SeitenSandwich Bus Duct Specs for Power SystemONILEDA1970Noch keine Bewertungen

- Operations Flow Diagram - Lima RefineryDokument1 SeiteOperations Flow Diagram - Lima RefineryMuhammad Ibad Alam100% (1)

- Technology and Livelihood Education: Electrical Installation and MaintenanceDokument11 SeitenTechnology and Livelihood Education: Electrical Installation and MaintenanceAV Montes100% (1)

- Method Statement For Busduct System RevisedDokument16 SeitenMethod Statement For Busduct System Revisedhadi50% (2)

- XLPE Cable SpecificationDokument46 SeitenXLPE Cable Specificationjtwani100% (2)

- Block Flow Diagram of Lima PDFDokument1 SeiteBlock Flow Diagram of Lima PDFMuhammad Ibad AlamNoch keine Bewertungen

- Structural Lightning Protection Design ConsiderationsDokument5 SeitenStructural Lightning Protection Design ConsiderationsKhaldoon AlnashiNoch keine Bewertungen

- Actom Hve Ctb36 Outdoor Circuit Breakers Aug 2018 LRDokument6 SeitenActom Hve Ctb36 Outdoor Circuit Breakers Aug 2018 LRGary FortuinNoch keine Bewertungen

- Data Sheet for Power TransformerDokument3 SeitenData Sheet for Power TransformerMuhammad Ibad AlamNoch keine Bewertungen

- Iec 60027 Iec 60034 Iec 60038Dokument6 SeitenIec 60027 Iec 60034 Iec 60038Sabir NaseerNoch keine Bewertungen

- Electromechanical Work at 132kv SiteDokument14 SeitenElectromechanical Work at 132kv SitePius Odaba100% (1)

- Ei 1596Dokument33 SeitenEi 1596Muhammad Ibad Alam100% (2)

- CoP Fo Petroleum Road Tanker Vapour Collection Systems and Equipment Used in Unloading OperationsDokument29 SeitenCoP Fo Petroleum Road Tanker Vapour Collection Systems and Equipment Used in Unloading OperationsMuhammad Ibad AlamNoch keine Bewertungen

- Guidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFDokument89 SeitenGuidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFSwaroop Biswas100% (1)

- Worksheet On Magnetic Field Mapping RevisedDokument1 SeiteWorksheet On Magnetic Field Mapping RevisedglzrioNoch keine Bewertungen

- Distribution Board Schedule Db-L&P-Work Shop 1-4 TPN 10: 10A 10A 10A 10A 10A 10A 10A 10A 10A 10A 20A 20ADokument9 SeitenDistribution Board Schedule Db-L&P-Work Shop 1-4 TPN 10: 10A 10A 10A 10A 10A 10A 10A 10A 10A 10A 20A 20ANiveeth ChattergyNoch keine Bewertungen

- Cold Test Report 3Dokument1 SeiteCold Test Report 3Venkitesh PG100% (1)

- Tech. Specs. For 11 KV DP StructureDokument7 SeitenTech. Specs. For 11 KV DP StructureSaraswatapalitNoch keine Bewertungen

- Mohamed Moussa Elec CV 16Dokument3 SeitenMohamed Moussa Elec CV 16MohamedNoch keine Bewertungen

- DSR Electrical 2012Dokument78 SeitenDSR Electrical 2012জেত বন100% (2)

- 5 - SMDBDokument4 Seiten5 - SMDBKhyle Laurenz DuroNoch keine Bewertungen

- Tariff Metering PanelsDokument2 SeitenTariff Metering PanelsSaraswatapalitNoch keine Bewertungen

- Busway InstallationDokument20 SeitenBusway InstallationSufiyan KhedekarNoch keine Bewertungen

- 11kv 630a 25ka Outdoor VCB PanelDokument3 Seiten11kv 630a 25ka Outdoor VCB PanelSharafat AliNoch keine Bewertungen

- 33-11KV SUBSTATION BoQDokument37 Seiten33-11KV SUBSTATION BoQRicky ChangNoch keine Bewertungen

- QCS-2010 Section 21 Part 21 Lightning ProtectionDokument4 SeitenQCS-2010 Section 21 Part 21 Lightning Protectionbryanpastor106Noch keine Bewertungen

- Battery Bank CalculationDokument3 SeitenBattery Bank CalculationJoshua Cm100% (1)

- SIRIM - PS045003 - IEC60502-1 Power Cables With Extruded Solid Insulation (27-8-20) PDFDokument3 SeitenSIRIM - PS045003 - IEC60502-1 Power Cables With Extruded Solid Insulation (27-8-20) PDFanas Bie100% (2)

- BOQ Fordistribution ProjectDokument23 SeitenBOQ Fordistribution ProjectMohammad Jawad100% (1)

- 66 KV Single Core XLPE Power Cable PDFDokument11 Seiten66 KV Single Core XLPE Power Cable PDFRani VjNoch keine Bewertungen

- Calculation of Earthing - Thumb RuleDokument5 SeitenCalculation of Earthing - Thumb Ruleaamer6789Noch keine Bewertungen

- Lightnin Otection SystemDokument6 SeitenLightnin Otection Systemsajeevi piumikaNoch keine Bewertungen

- Electrical BOQ Plot C LPSDokument5 SeitenElectrical BOQ Plot C LPSAgrawal PrajaktaNoch keine Bewertungen

- SECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDokument8 SeitenSECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDenyNoch keine Bewertungen

- 0979 ERICO in Lightning ProtectionDokument6 Seiten0979 ERICO in Lightning ProtectionAndrei PantaNoch keine Bewertungen

- Hazard BeaconDokument6 SeitenHazard BeaconDevrim GürselNoch keine Bewertungen

- Visio-Airport ESD LogicDokument1 SeiteVisio-Airport ESD LogicMuhammad Ibad AlamNoch keine Bewertungen

- Compressor Gas Treatment System Wiring DrawingDokument6 SeitenCompressor Gas Treatment System Wiring DrawingMuhammad Ibad AlamNoch keine Bewertungen

- Caltex Kurnell refinery process flowDokument1 SeiteCaltex Kurnell refinery process flowMuhammad Ibad AlamNoch keine Bewertungen

- SKB Shutters Corp. Berhad ProfileDokument22 SeitenSKB Shutters Corp. Berhad ProfileMuhammad Ibad AlamNoch keine Bewertungen

- Block Flow Diagram of Refinery ValeroDokument1 SeiteBlock Flow Diagram of Refinery ValeroMuhammad Ibad AlamNoch keine Bewertungen

- Memphis Refinery ProcessDokument1 SeiteMemphis Refinery ProcessMuhammad Ibad AlamNoch keine Bewertungen

- Engineering Design Guideline Pump Rev3Dokument14 SeitenEngineering Design Guideline Pump Rev3hclsvw67% (3)

- 2548 DSE 005 R0 TransformerDokument4 Seiten2548 DSE 005 R0 TransformerMuhammad Ibad AlamNoch keine Bewertungen

- 00 Ec D 48660Dokument1 Seite00 Ec D 48660Muhammad Ibad AlamNoch keine Bewertungen

- Energy Crisis Report123Dokument16 SeitenEnergy Crisis Report123Muhammad Ibad AlamNoch keine Bewertungen

- Essential Pakistan Distribution Code OverviewDokument176 SeitenEssential Pakistan Distribution Code OverviewMuhammad RizwanNoch keine Bewertungen

- Report # 41 Rain SafetyDokument7 SeitenReport # 41 Rain SafetyMuhammad Ibad AlamNoch keine Bewertungen

- Inst Guide Profibus PADokument55 SeitenInst Guide Profibus PAMpho MathubaNoch keine Bewertungen

- Scot Pcs Control LogicDokument69 SeitenScot Pcs Control LogicMuhammad Ibad AlamNoch keine Bewertungen

- PSHL - Electrical PD DischargeDokument1 SeitePSHL - Electrical PD DischargeMuhammad Ibad AlamNoch keine Bewertungen

- GS130-9 (Specification of Shutdown Systems)Dokument19 SeitenGS130-9 (Specification of Shutdown Systems)Muhammad Ibad AlamNoch keine Bewertungen

- Elc Su 12.20Dokument8 SeitenElc Su 12.20Muhammad Ibad AlamNoch keine Bewertungen

- PIP PCCA001-Dec. 2004 Design of Combustible and Toxic Gas Detection Systems - UDokument10 SeitenPIP PCCA001-Dec. 2004 Design of Combustible and Toxic Gas Detection Systems - UMahathir Che ApNoch keine Bewertungen

- Anchor Bolt Design SHELL DEPDokument1 SeiteAnchor Bolt Design SHELL DEPMuhammad Ibad AlamNoch keine Bewertungen

- Elc Su 12.11Dokument30 SeitenElc Su 12.11Muhammad Ibad AlamNoch keine Bewertungen

- Seeb Vocational College Diploma CourceDokument2 SeitenSeeb Vocational College Diploma CourceSiva Agora KarthikeyanNoch keine Bewertungen

- Cadence Tutorial IIScDokument5 SeitenCadence Tutorial IIScCharanraj MohanNoch keine Bewertungen

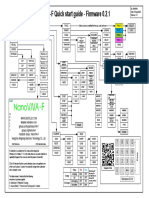

- Nanovna-F Quick Start Guide - Firmware 0.2.1: Home MenuDokument1 SeiteNanovna-F Quick Start Guide - Firmware 0.2.1: Home MenuKadir Mariño AbreuNoch keine Bewertungen

- Lab4 Thermal Relay-EngDokument4 SeitenLab4 Thermal Relay-EngRazvanTomaNoch keine Bewertungen

- Utc Ta7343apDokument5 SeitenUtc Ta7343apClaudiuMaxmiucNoch keine Bewertungen

- Mshengeli Issa H.150 323481421Dokument20 SeitenMshengeli Issa H.150 323481421roger damianNoch keine Bewertungen

- PMMCDokument16 SeitenPMMCRavi Shankar 31Noch keine Bewertungen

- Test Report Format - NSK5Dokument5 SeitenTest Report Format - NSK5Rsp SrinivasNoch keine Bewertungen

- Series RLC Circuit Voltage and Impedance AnalysisDokument8 SeitenSeries RLC Circuit Voltage and Impedance AnalysisJeffrey JimenezNoch keine Bewertungen

- Transformer Technical Data Sheet For The 1LAP016379Dokument1 SeiteTransformer Technical Data Sheet For The 1LAP016379alllim88Noch keine Bewertungen

- 3NP4070 0ca01Dokument5 Seiten3NP4070 0ca01Jorge Sanchez MuñozNoch keine Bewertungen

- CC-LINK Interface: SR83 Digital ControllerDokument24 SeitenCC-LINK Interface: SR83 Digital ControllerChristianNoch keine Bewertungen

- Fibre Optical Sources & DetectorsDokument17 SeitenFibre Optical Sources & DetectorsDIPAK VINAYAK SHIRBHATE88% (16)

- The "Strain-Gauge Thermocouple": A Novel Device For Simultaneous Strain and Temperature MeasurementDokument6 SeitenThe "Strain-Gauge Thermocouple": A Novel Device For Simultaneous Strain and Temperature MeasurementFrontiersNoch keine Bewertungen

- SEMIKRON Technical Explanation SKiiP4 F-Option EN 2017-08-30 Rev-02Dokument21 SeitenSEMIKRON Technical Explanation SKiiP4 F-Option EN 2017-08-30 Rev-02mastechNoch keine Bewertungen

- Moeller Sasy 60iDokument50 SeitenMoeller Sasy 60iOscar TorresNoch keine Bewertungen

- Sensors and Actuators SyllabusDokument14 SeitenSensors and Actuators SyllabusKeerthan R VarmaNoch keine Bewertungen

- EN RTU500 Modules V206Dokument77 SeitenEN RTU500 Modules V206Srinivasan SriniNoch keine Bewertungen

- Applied Physics Unit 3 Objective QuestionDokument12 SeitenApplied Physics Unit 3 Objective QuestionNitin YogeshNoch keine Bewertungen

- 29 TA4 FlexibleEarthDokument1 Seite29 TA4 FlexibleEarthvinoth sekarNoch keine Bewertungen

- Cable specifications for South Africa divisionDokument12 SeitenCable specifications for South Africa divisionDave CNoch keine Bewertungen

- Panasonic Car Stereo System CQ-CP134U PDFDokument16 SeitenPanasonic Car Stereo System CQ-CP134U PDFJuan Carlos SoHeNoch keine Bewertungen

- MAGMA2012 CommitteeDokument9 SeitenMAGMA2012 CommitteeTejaswi NisanthNoch keine Bewertungen

- 7300A User Manual HA176659ENG PDFDokument70 Seiten7300A User Manual HA176659ENG PDFGott PlankNoch keine Bewertungen

- Panasonic - SC-HTB770GN PDFDokument164 SeitenPanasonic - SC-HTB770GN PDFboroda2410100% (1)