Beruflich Dokumente

Kultur Dokumente

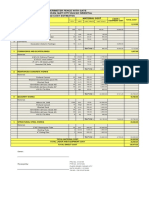

Specification Checklist For Steel and Concrete Coating

Hochgeladen von

sea_jazzOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Specification Checklist For Steel and Concrete Coating

Hochgeladen von

sea_jazzCopyright:

Verfügbare Formate

SSPCChecklistofItems CommonlyFoundin SpecificationsforCoating SteelandConcrete

SSPC: The Society for Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222-4656 Copyright 2011

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete

Aug. 2011

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete

NOTE: Use applicable portions of this document for each project, and add requirements not listed here as appropriate to produce a competent design. General contract considerations Coordinate with owners front-end documents (General Conditions, Additional General Conditions, Special Conditions, etc.) Define scope of project fully (Get detailed field conditions if maintenance work) Contract specifications (using CSI three-part Section format) GENERAL Scope of Project Areas to be coated and not to be coated Site Access and Storage Area Site Investigation Clause References (sometimes called Applicable Documents) SSPC PA 1 Shop, Field, and Maintenance Painting of Steel For coating concrete surfaces: SSPC-PA 7, Applying Thin Film Coatings to Concrete SSPC-TU 10, Procedures for Applying Thick Film Coatings and Surfacings Over Concrete Floors Surface preparation Others Precedence of Documents Definitions Submittals (pre-work)(Many of these continue during work) Contract errors, omissions, and other discrepancies, including conflicting requirements, ambiguous requirements Procedures for Corrective Action Project-specific Work Plan or Process Control Procedures (PCPs) Project-specific Health, safety, and environmental compliance plans Site access/security requirements Project-specific Confined space entry plans (permit required and nonpermit required) Procurement of necessary materials Procurement of necessary job site and support equipment Assigning the management team to the project Obtaining craft workers with the necessary skills

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete

Aug. 2011

Mobilization of all of the above Worker training and personal protective equipment (PPE) Inspection and test plan (ITP) (including forms with criteria for conformance and nonconformance) ITP Log to match requirement and schedules of other work procedures Qualifications Qualifications of the coating contractor Qualifications of certified protective coating specialist (PCS) Qualifications of a coating inspection company Qualifications of a quality control (QC) coating inspector Qualifications of individuals performing abrasive blasting, water jetting, coating application Qualifications of a certified industrial hygienist (CIH) Qualifications of a testing laboratory for coatings Qualifications of a testing laboratory for abrasives Certifications for materials used Regulatory requirements Field sampling requirements Pre-construction conference, coordination and progress meetings Manufacturers product data sheets for materials to be used Shelf-life of applicable materials Rules for shelf-life extension Manufacturers material safety data sheets for materials to be used Samples of specified liquid coatings Coating draw-down films (cured films of uniform thickness applied to cardboard or other substrates) Laboratory test results Certificates of product conformity to specification Requests for Information (RFI) Log Contract Change Order Log Submittal Log Daily production reports (including safety reports) Daily inspection and test reports (DIRs) Corrective Action Requests (CARs) Nonconforming Work Log Corrective Action Log Preventive Action Log Other reports that would provide meaningful data

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete

Aug. 2011

Submittals Required during Production All Logs Production, inspection, and other reports CARs Other reports or information affecting production or conformity to requirements PRODUCTS Coating materials and thinners (other than as specified by mfg.) Contrasting colors for multi-coat systems Abrasives Test Kits Amine blush testing Salt testing EXECUTION Deliver, Store, Mix, Apply, and Cure Coatings According to SSPC-PA 1 (for steel surfaces) or SSPC PA 7 or TU 10 for concrete surfaces) Equipment for Surface Preparation and Coating Application Kits and Equipment for Testing for Surface Cleanliness and Profile and Film Thickness Specified Types of Coating Materials Delivered and Their Verification Field mock-up (as part of verifying procedures during start-up particularly for coating of concrete) Acceptable Ambient Conditions Periods of control During surface preparation During coating application and initial curing (specify initial cure time) During other operation Parameters of control Air temperature Surface temperature Dew point/relative humidity Wind speed Surface contaminants Lighting for all work areas (as prescribed in SSPC-Guide 12) Blast Cleaning of Surfaces for Coating Application Desired results Allowable methods

SSPC Checklist of Items Commonly Found in Specifications for Coating Steel and Concrete

Aug. 2011

Ambient conditions for surface preparation Pre-cleaning of Surfaces for Painting Prior to Surface Preparation Profile shape/height/peak density Protection of areas not to be prepared Other Methods of Surface Preparation (e.g. Water jetting; Hand and Power Tool cleaning; Scarifying, etc.) Desired results Allowable methods Ambient conditions for surface preparation Pre-cleaning of Surfaces for Painting Prior to Surface Preparation Profile shape/height/peak density Protection of areas not to be prepared Coating Application Condition in container The ratio by volume of the components to combine Instruction for mixing components Amounts of thinner, if any, permitted Ambient conditions for application and curing (length of cure) Induction time at different temperatures Pot life at different temperatures Allowable application methods Stripe coating Protection of areas not to be coated Protection of painted surface during curing Initial cure period Recoat window Acceptable wet/dry film thickness range Repairs (how much allowable and special requirements) QC Inspection and Documentation Requirements Final inspection Punch List Clearing of Punch List Clearing of Nonconforming Work Log Clearing of Corrective Action Log Review of docs for completion/certification of documentation Warranty & correction period requirements/criteria Clean-up and proper disposal of wastes Clean up of site to condition at start of project

Das könnte Ihnen auch gefallen

- Standard Specification FOR Pipeline Internal CoatingDokument2 SeitenStandard Specification FOR Pipeline Internal CoatingRanjan KumarNoch keine Bewertungen

- Emulsion Paint ChecklistDokument2 SeitenEmulsion Paint Checklistmesmerize59Noch keine Bewertungen

- Inspection Check List 2Dokument34 SeitenInspection Check List 2r.devendranNoch keine Bewertungen

- 1-Frosio Chapter 1 Inspector Duties and BehaviourDokument84 Seiten1-Frosio Chapter 1 Inspector Duties and BehaviourtaiNoch keine Bewertungen

- STGPS N1 6 Painting SpecificationDokument18 SeitenSTGPS N1 6 Painting Specificationraluca_19735597Noch keine Bewertungen

- Polyurea Hot Spray Steel Surfaces Method StatementDokument9 SeitenPolyurea Hot Spray Steel Surfaces Method StatementGvsr SunnyNoch keine Bewertungen

- Contractor IOT Infrastructure & Energy Services LTDDokument38 SeitenContractor IOT Infrastructure & Energy Services LTDNaveen KurupNoch keine Bewertungen

- Long Question/ Narrative Question.: Define Pigment?Dokument3 SeitenLong Question/ Narrative Question.: Define Pigment?Hau LeNoch keine Bewertungen

- ChecklistDokument8 SeitenChecklistVenkatumeshNoch keine Bewertungen

- Daily Painting Inspection Report 08Dokument2 SeitenDaily Painting Inspection Report 08Oussama Ben AbbesNoch keine Bewertungen

- Application Guide Penguard MidcoatDokument6 SeitenApplication Guide Penguard Midcoatadeoye_okunoyeNoch keine Bewertungen

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDokument46 SeitenRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNoch keine Bewertungen

- Coating InterviewDokument37 SeitenCoating InterviewTASNEEM100% (2)

- Architectural Painting Works Ins ChecklistDokument2 SeitenArchitectural Painting Works Ins Checklistmunna100% (1)

- ICorr Insulation InspectorDokument31 SeitenICorr Insulation Inspector22238.spoNoch keine Bewertungen

- SP 18 Thoro Spot & Sweep 12-30-20Dokument7 SeitenSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiNoch keine Bewertungen

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDokument4 SeitenDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNoch keine Bewertungen

- CIP Work Experience FINALDokument2 SeitenCIP Work Experience FINALDeepak YadavNoch keine Bewertungen

- Inspection Thermal Spray WebinarDokument29 SeitenInspection Thermal Spray WebinarShriya Soni100% (1)

- Quallity Control JPCLDokument37 SeitenQuallity Control JPCLSerhan ÜnverNoch keine Bewertungen

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Dokument6 Seiten3855 ICorr Coating Inspector Assessment Guidelines 0821aliNoch keine Bewertungen

- PFP ProcedureDokument6 SeitenPFP ProcedureRamesh100% (1)

- Coating Method StatementDokument9 SeitenCoating Method StatementDaniel Martinez100% (2)

- Paint ApplicationDokument4 SeitenPaint ApplicationSteven FlynnNoch keine Bewertungen

- Visco-Elastic Coating MaterialDokument17 SeitenVisco-Elastic Coating Materialosmanmop100% (1)

- 1method Statement For Passivation and PicklingDokument6 Seiten1method Statement For Passivation and PicklinggatoNoch keine Bewertungen

- Coating Specification: 1. ScopeDokument4 SeitenCoating Specification: 1. ScopeThaiminh Vo100% (2)

- Painting of Structure Piping Equipment 22Dokument5 SeitenPainting of Structure Piping Equipment 22Saurabh Kumar VermaNoch keine Bewertungen

- Lead Supervising or 3rd Party Nace Peer Review/level 3 CertifiedDokument3 SeitenLead Supervising or 3rd Party Nace Peer Review/level 3 Certifiedapi-77735589Noch keine Bewertungen

- 6.PEB Painting Procedure (P0371) Rev.01Dokument22 Seiten6.PEB Painting Procedure (P0371) Rev.01MOHAMEDNoch keine Bewertungen

- William D. Corbett, KTA-Tator, Inc. Chair - SSPC Committee C.3.2 On Dry Film Thickness MeasurementDokument56 SeitenWilliam D. Corbett, KTA-Tator, Inc. Chair - SSPC Committee C.3.2 On Dry Film Thickness MeasurementvtjoselineNoch keine Bewertungen

- Salt TestDokument16 SeitenSalt Testم.ذكى فضل ذكى100% (1)

- Painting Procedure For CondenceDokument26 SeitenPainting Procedure For CondenceNamta GeorgeNoch keine Bewertungen

- Pull-Off Test Report - PUB Pedestrian Bridge ProjectDokument2 SeitenPull-Off Test Report - PUB Pedestrian Bridge ProjectErin Williams100% (2)

- 6 Sigma PaintDokument38 Seiten6 Sigma PaintAnonymous fvO1W3Noch keine Bewertungen

- Painting Maual For Power Sector ErectionDokument32 SeitenPainting Maual For Power Sector Erectionnagarathinam82Noch keine Bewertungen

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDokument5 SeitenG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Coating Inspector ResumeDokument4 SeitenCoating Inspector Resumetulasirao.nammiNoch keine Bewertungen

- 1.0 Description: Specifications For Coating Structural SteelDokument11 Seiten1.0 Description: Specifications For Coating Structural SteelCrni LabudNoch keine Bewertungen

- Hempel Brochure On Imo - PSPCDokument12 SeitenHempel Brochure On Imo - PSPCislimaNoch keine Bewertungen

- SSPC Pa 7 PDFDokument10 SeitenSSPC Pa 7 PDFkishorekumar.animuNoch keine Bewertungen

- Jotun DeveloperDokument7 SeitenJotun DeveloperAlex Kuvoric100% (1)

- Fenomastic Hygiene Emulsion SilkDokument4 SeitenFenomastic Hygiene Emulsion Silkمحمد عزتNoch keine Bewertungen

- Working Procedure For Coating Repair C4Dokument7 SeitenWorking Procedure For Coating Repair C4tuyen nguyenNoch keine Bewertungen

- Audit Checklist Blasting PaintingDokument4 SeitenAudit Checklist Blasting PaintingEyoh EffiongNoch keine Bewertungen

- CD # 0015 Corrosion Protection IDokument1 SeiteCD # 0015 Corrosion Protection IsimitzuNoch keine Bewertungen

- D6677Dokument2 SeitenD6677Robby DíazNoch keine Bewertungen

- Nace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceDokument2 SeitenNace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceNimish Pavan100% (1)

- Structured Method Statement For Concrete Repair - 2Dokument10 SeitenStructured Method Statement For Concrete Repair - 2m.umarNoch keine Bewertungen

- Blasting and Painting Procedure 1Dokument6 SeitenBlasting and Painting Procedure 1vishwas salunkheNoch keine Bewertungen

- Glossary of Paint Defect TermsDokument7 SeitenGlossary of Paint Defect Terms4romi89Noch keine Bewertungen

- QADokument21 SeitenQAms rooNoch keine Bewertungen

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDokument3 SeitenBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNoch keine Bewertungen

- Material Testing and Quality Assurance - Role of Resident EngineerDokument41 SeitenMaterial Testing and Quality Assurance - Role of Resident EngineermynalawalNoch keine Bewertungen

- SSPC New PDFDokument78 SeitenSSPC New PDFZal Dozer100% (3)

- 23sampling Methods and Quality Assurance PlanDokument34 Seiten23sampling Methods and Quality Assurance PlanSumit Rathi100% (1)

- Day 1.2 - Importance of Material TestingDokument77 SeitenDay 1.2 - Importance of Material Testingkingjames90Noch keine Bewertungen

- C Ti P Ti Coating Practices: International Association of Oil & Gas Producers Coatings Workshop June 10, 2008Dokument28 SeitenC Ti P Ti Coating Practices: International Association of Oil & Gas Producers Coatings Workshop June 10, 2008kelvinc256Noch keine Bewertungen

- Tender For Fabrication of Tanks For Tank Farm Phase 03Dokument6 SeitenTender For Fabrication of Tanks For Tank Farm Phase 03khansaleemNoch keine Bewertungen

- 04 Fab Install Stark Bogota 2019 8-5-19Dokument57 Seiten04 Fab Install Stark Bogota 2019 8-5-19DocimfernandezNoch keine Bewertungen

- 2018 01 05 - Dry Port Support RFP FINAL PDFDokument6 Seiten2018 01 05 - Dry Port Support RFP FINAL PDFsea_jazzNoch keine Bewertungen

- PI Schafer CMMIgranteesconf Paper PDFDokument4 SeitenPI Schafer CMMIgranteesconf Paper PDFsea_jazzNoch keine Bewertungen

- LetterDokument1 SeiteLettersea_jazzNoch keine Bewertungen

- Elastic Foundation Young Modulus For Soils - 1Dokument1 SeiteElastic Foundation Young Modulus For Soils - 1sea_jazzNoch keine Bewertungen

- Beam Design ManualDokument28 SeitenBeam Design ManualhangarrodNoch keine Bewertungen

- L09 153Dokument14 SeitenL09 153sea_jazzNoch keine Bewertungen

- Settlement of Shallow Foundations On Granular Soils PDFDokument233 SeitenSettlement of Shallow Foundations On Granular Soils PDFMUHAMMAD ALINoch keine Bewertungen

- Corrosion ProtectionDokument2 SeitenCorrosion Protectionsea_jazzNoch keine Bewertungen

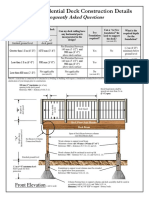

- Basic Deck Construction DetailsDokument3 SeitenBasic Deck Construction Detailssea_jazzNoch keine Bewertungen

- Draft: Finite Element IDokument73 SeitenDraft: Finite Element ISiavash KhademNoch keine Bewertungen

- ch4 Mechanical Properties of Wood PDFDokument46 Seitench4 Mechanical Properties of Wood PDFdan-gabiNoch keine Bewertungen

- 0354 46050305307MDokument14 Seiten0354 46050305307Msea_jazzNoch keine Bewertungen

- Neuberovo Pravilo PDFDokument21 SeitenNeuberovo Pravilo PDFMark JurichNoch keine Bewertungen

- Numerical Procedure For Ship Hydroelastic AnalysisDokument6 SeitenNumerical Procedure For Ship Hydroelastic Analysissea_jazzNoch keine Bewertungen

- Conversions of HSSDokument7 SeitenConversions of HSSsea_jazzNoch keine Bewertungen

- Shear Strength of High-Strength BoltsDokument61 SeitenShear Strength of High-Strength Boltsloox600Noch keine Bewertungen

- 25 01Dokument5 Seiten25 01Sopon SrirattanapiboonNoch keine Bewertungen

- Iabmas MadeoDokument8 SeitenIabmas Madeosea_jazzNoch keine Bewertungen

- Bolt Dimensions Clearances Manual of Steel Construction1990Dokument5 SeitenBolt Dimensions Clearances Manual of Steel Construction1990sea_jazzNoch keine Bewertungen

- L RFD Beam Load TablesDokument76 SeitenL RFD Beam Load TablesFederico.IoriNoch keine Bewertungen

- Non-Linear Static Push Over AnalysisDokument12 SeitenNon-Linear Static Push Over Analysismrnicus100% (1)

- Ce 479 Wood Design Nds 01 ConnectionsDokument53 SeitenCe 479 Wood Design Nds 01 Connectionssea_jazzNoch keine Bewertungen

- Awc NDS-2012Dokument200 SeitenAwc NDS-2012brianchen0671% (7)

- Pros and Cons of Pushover AnalysisDokument13 SeitenPros and Cons of Pushover AnalysisMrugesh Shah100% (1)

- WSS Welding Symbols Study Guide LFDokument88 SeitenWSS Welding Symbols Study Guide LFsea_jazz100% (3)

- Hacking Structural Analysis. Join The CrewDokument3 SeitenHacking Structural Analysis. Join The CrewLuis C. Pérez TatoNoch keine Bewertungen

- 223 STD Seismic Resistant Industrial Tanks SilosDokument74 Seiten223 STD Seismic Resistant Industrial Tanks Silossea_jazzNoch keine Bewertungen

- 223 STD Seismic Resistant Industrial Tanks SilosDokument74 Seiten223 STD Seismic Resistant Industrial Tanks Silossea_jazzNoch keine Bewertungen

- Welding Procedure PreparationDokument122 SeitenWelding Procedure Preparationthe_badass1234100% (21)

- Energy MethodsDokument5 SeitenEnergy MethodsNikkei Pfeiffer TadiliNoch keine Bewertungen

- IPR Meeting Commingling Project - Gate 1: Business Case PresentationDokument18 SeitenIPR Meeting Commingling Project - Gate 1: Business Case PresentationAnthony Hbk JerichoNoch keine Bewertungen

- Tsunami RXN 10-4Dokument5 SeitenTsunami RXN 10-4Ricca Valdez BaudinNoch keine Bewertungen

- Freedom SW 2000 Owners Guide (975-0528!01!01 - Rev-D)Dokument48 SeitenFreedom SW 2000 Owners Guide (975-0528!01!01 - Rev-D)MatthewNoch keine Bewertungen

- Is 3589Dokument19 SeitenIs 3589kishor.kokate60% (5)

- Materials 16 01374 v2Dokument11 SeitenMaterials 16 01374 v2Feyisa GuyeNoch keine Bewertungen

- Layout Room INDUSTRI FARMASIDokument1 SeiteLayout Room INDUSTRI FARMASIDwi MeliniaNoch keine Bewertungen

- Ador BookletDokument22 SeitenAdor Bookletgssrraju0% (1)

- CMT Lab ReportDokument3 SeitenCMT Lab ReportJohn Emerald GoloNoch keine Bewertungen

- Separator 01dyDokument44 SeitenSeparator 01dyFadhil KhalidNoch keine Bewertungen

- Materiales de Construcción CanaletasDokument40 SeitenMateriales de Construcción CanaletasErick Joel OcampoNoch keine Bewertungen

- Wrench ProjectDokument2 SeitenWrench Projectapi-246176233Noch keine Bewertungen

- E125-97 MT Ref PhotosDokument2 SeitenE125-97 MT Ref PhotosveluNoch keine Bewertungen

- KZCO AllcatalogDokument76 SeitenKZCO AllcatalogJaime SuaNoch keine Bewertungen

- ProctorCompactionTestforMaximumDryDensity 001Dokument23 SeitenProctorCompactionTestforMaximumDryDensity 001Raheel ADNANNoch keine Bewertungen

- CALOR EMAG Bag.1 PDFDokument10 SeitenCALOR EMAG Bag.1 PDFAditya AgasiNoch keine Bewertungen

- RPCP PDFDokument2 SeitenRPCP PDFmhafizanNoch keine Bewertungen

- Polymer: Huige Wei, Jiahua Zhu, Shijie Wu, Suying Wei, Zhanhu GuoDokument12 SeitenPolymer: Huige Wei, Jiahua Zhu, Shijie Wu, Suying Wei, Zhanhu GuoAlrayyan RashidNoch keine Bewertungen

- Prism Cryogenic Oxygen Generators: Reliable On-Site SupplyDokument4 SeitenPrism Cryogenic Oxygen Generators: Reliable On-Site SupplyEdwin RosasNoch keine Bewertungen

- CEP222 Chapter 2Dokument10 SeitenCEP222 Chapter 2Salve CatarrojaNoch keine Bewertungen

- General 2Dokument4 SeitenGeneral 2AnandNoch keine Bewertungen

- EstimateDokument1 SeiteEstimateAlemar Soriano MalintadNoch keine Bewertungen

- GPA Sampling Method (Scope, Definition, Principles, Safety)Dokument27 SeitenGPA Sampling Method (Scope, Definition, Principles, Safety)Candra Aditya Wiguna100% (2)

- Iodate and Iodine Speciation by LC-ICPMSDokument6 SeitenIodate and Iodine Speciation by LC-ICPMSShubhamNoch keine Bewertungen

- Argon Pure GasDokument1 SeiteArgon Pure GasAriyan AriyanNoch keine Bewertungen

- McQuay AWS User Manual EngDokument37 SeitenMcQuay AWS User Manual EngHermelindo Samuel Rabanales Cifuentes50% (2)

- Chapter 4 Part 1 Reaction Mechanism in Chain ReactionsDokument31 SeitenChapter 4 Part 1 Reaction Mechanism in Chain ReactionsMuhammadFaisalNoch keine Bewertungen

- Technical Manual 2011Dokument170 SeitenTechnical Manual 2011Aniie VaronaNoch keine Bewertungen

- BS 709Dokument17 SeitenBS 709vuthuy94Noch keine Bewertungen

- Riser Mounted Air Compressor: Electrical DevicesDokument12 SeitenRiser Mounted Air Compressor: Electrical DevicesChen MingliangNoch keine Bewertungen