Beruflich Dokumente

Kultur Dokumente

Path of Contact Calculation

Hochgeladen von

roberto_perraciniOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Path of Contact Calculation

Hochgeladen von

roberto_perraciniCopyright:

Verfügbare Formate

KISSsoft AG Uetzikon 4 8634 Hombrechtikon Switzerland

+41 55 254 20 50 +41 55 254 20 51 info@KISSsoft.AG www.KISSsoft.AG

Path of contact calculation KISSsoft 04-2010 1 Introduction

The tooth contact under load is an important verification of the real contact conditions of a gear pair and an important add-on to the strength calculation according to standards as ISO, AGMA or DIN. The contact analysis simulates the meshing of the two flanks over the complete meshing cycle and is therefore able to consider individual modifications on the flank at each meshing position. The tooth contact analysis is therefore mainly used to reduce noise which is caused by the effect of shock load at meshing entry due to elastic bending of the loaded teeth. It is further used to optimize load distribution by analyzing the effectiveness of gear profile modifications considering the misalignment of the gear axis due to shaft and bearing deformation under load.

Path of contact calculation KISSsoft 04-2010

1.1 Basic calculation method

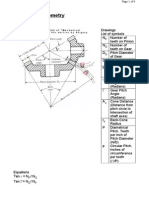

The tooth contact analysis simulates the meshing contact assuming a constant nominal torque. The calculation procedure has been defined by Peterson: For a given pinion rolling position (rotation angle 1) the corresponding gear rolling position 2 is determined with an iterative calculation (see figure 1). The calculation considers the local elastic deformation due to

Fig. 1: tooth contact analysis according to Peterson

several effects and the corresponding stiffnesss which appear under load: stiffness from bending and shear deformation cZ, stiffness from Hertzian flattening cH and bending stiffness of the tooth in gear body rim cRK. This calculation procedure is repeated for all the meshing cycle. Comparisons with FE calculations showed a very good correlation. The final stresses include the load increasing factors calculated by the standard, such as application factor KA, dynamic factor KV and load distribution factor Kin planetary gears or gear pairs. For the tooth root stress, also the gear rim factor YB according to ISO6336 is considered. Before KISSsoft Release 04-2010, also the load distribution factors KH , KH for Hertzian pressure resp. KF , KF for root stress was considered. This has been changed for the enhanced tooth contact analysis, please find the details below.

2 What is new in Version 04-2010 ?

With the KISSsoft Release 04-2010, the tooth contact analysis for cylindrical gears has improved significantly. In addition to the preceding releases, the stiffness model was extended to better take the load distribution in the width direction into account, which is a significant characteristic of helical gears, but also other effects are now considered, finalizing in the 3D display of results.

2.1 Coupling between the slices

For a tooth contact of helical gears, the meshing field is different to a spur gear. The contact lines for a spur gear are parallel to the root line, and herewith also the load distribution in length direction is uniform. The contact lines for a helical gear are diagonal over the tooth, which means the load is not uniformly distributed over the length of the tooth. Still the unloaded part of the tooth has a supporting effect and influences the deformation of the tooth as well.

Fig. 2: stiffness model according to Peterson and KISSsoft Release 04-2010

This supporting effect of the unloaded areas has to be considered for the contact analysis of helical gears. For this purpose, in KISSsoft 04-2010 the gear is in lengthwise direction divided in slices. The single slices are then connected between each other with the coupling stiffness c c so that a supporting effect between the slices can be considered (see figure 2).

cPet f (cZ , cRK )

cPet cZ cRK cH stiffness tooth root following Peterson stiffness from bending and shear deformation stiffness from deformation through rotation in the gear blank stiffness from Herztian flattening following Peterson

The coupling stiffness cC is defined as follows:

2 cC 0.04 Asec cPet

cC Asec

coupling stiffness Number of slices

The coupling stiffness is related to the contact stiffness and hence individual for each gear pair, and is verified for different gear types with FE calculations and other established software. The number of slices Asec depends on the accuracy setting which is defined from the user. However, the single coupling stiffness cC is defined in a way that the system coupling stiffness is independent of the number of slices and therewith also independent of the user settings. In figure 4, the same gear calculation is compared between the KISSsoft release 04-2010 and the previous release. It is a spur gear (helix angle = 0) with a larger face width for the pinion (b1=50mm) than for the gear (b2=44mm). The supporting effect of the unloaded face area outside the meshing contact causes an increased edge pressure within of the meshing contact. This effect can now be considered with the coupling stiffness between the slices. In the previous KISSsoft releases the forces remain constant (figure 4a), where as in the KISSsoft release 04-2010, the normal force at outer ends of meshing contact is increased (figure 4b). Note that figure 4a shows the pinion face width b2=50mm, whereas in figure 4b only the common face width b=44mm is displayed.

Fig. 4a: previous KISSsoft releases shows constant normal force (line load) over face width

Fig 4b: KISSsoft 04-2010 shows the increased normal force (line load) at edges of contact area

2.2 Decreased stiffness on the side borders of helical gears

For helical gears, the tooth may be cut by the cylindrical bodies (see figure 3), which results in reduced tooth thickness sred compared to a tooth that is not cut having a tooth thickness sn. Whenever force is applied to the tooth with reduced tooth thickness, it will result in higher deformation due to lower stiffness. This effect is considered with the reduced coupling stiffness cPet_border for the slices of teeth.

Fig. 3: decreased rigidity on the side borders

In KISSsoft 04-2010, the following formula is applied, which is also verified with FE calculation and other established software.

cPet _ border cPet 2

cPet_border cPet sred sn

sred sn

coupling stiffness for slices with reduced tooth thickness standard coupling stiffness reduced tooth thickness at border standard tooth thickness

In figure 5, the same gear calculation is compared between KISSsoft release 04-2010 and the previous release. It is a helical gear (helix angle =15) with the equal face width b=44mm. In the previous Releases the effect of reduced coupling stiffness at border wasnt considered, therefore the normal force (line load) at border isnt increased. In KISSsoft release 04-2010, the normal force at the start as well as end of contact is increased.

Fig. 5a: previous Releases dont show higher normal forces (line load) at ends

Fig 5b: KISSsoft 04-2010 shows higher normal forces (line load) at start and end of contact

2.3 Revised calculation of tooth stiffness of helical gears

For helical gears, the contact stiffness cPet following Peterson is calculated based on the effective tooth form in normal section. In earlier KISSsoft-versions the tooth form was based on the transverse section multiplied by the factor cos, which is a less accurate procedure. Therefore the results slightly differ between this and older releases. In figure 6, the same gear calculation is compared between KISSsoft release 04-2010 and the previous release. It is a helical gear (helix angle =15) with the equal face width b=44mm. In the KISSsoft release 04-2010, the tooth stiffness is slightly different to the previous KISSsoft release. Since the transmission error is strongly related to the stiffness, also the transmission error slightly differs too.

Fig. 6a: previous Releases calculate slightly higher tooth contact stiffness

Fig 6b: KISSsoft 04-2010 calculates slightly lower tooth contact stiffness

2.4 Load distribution factors not multiplied any more to stresses

In previous KISSsoft releases it was not possible to consider any unequal load distribution correctly since the slices were not coupled. Therefore the load distribution was added taking the factors KHKH as well as KFKF (ISO) and KM (AGMA) from the standards calculation. These were multiplied to the stresses from the tooth contact analysis. In KISSsoft 04-2010 these factors are no longer used. However, the displayed stresses are still multiplied with the application factor KA, dynamic factor KV and load distribution factor Kin planetary gears or gear pairs. In figure 7, the same gear calculation is compared between KISSsoft release 04-2010 and the previous release. It is a spur gear (helix angle =0) with the equal face width b=44mm. Its a overhang design, meaning the gear is outside the bearings. This results in a increased load distribution factor according from ISO standard calculation with KH =1.27 and KH=1.0. The tooth contact calculation is done without considering any misalignment of the gear axis, values for deviation error and inclination error are set as 0. In the KISSsoft release 04-2010, flank pressure and root stresses are lower compared to the previous release. For a realistic contact analysis the gear axis misalignments should defined with shaft and bearing calculations, i.e. from KISSsys.

Fig. 7a: previous releases consider load distribution factors in tooth contact analysis

Fig 7b: KISSsoft 04-2010 doesnt consider load distribution factors from Standard calculation

2.5 Calculation of Hertzian Pressure

The calculation of the Hertzian stress is based on the Hertzian law in the contact of two cylinders. This gives realistic results in most situations. However a problem is encountered when the contact is on a corner of the flank, i.e. corner at the tip diameter, corner at the beginning of a linear profile modification, corner at the beginning of an undercut. Then the radius of curvature becomes very small, which results in a high peak of Hertzian stress calculation. This is not a realistic issue, because the part of the flank near to the corner will be joined in the contact. An algorithm, checking the joining flank parts and increasing the radius of curvature is implemented. However, it may be that high peaks still remains. Then we recommend adding a realistic radius to the corners and using circular profile modifications instead of linear. In figure 8, the same gear calculation is compared between KISSsoft release 04-2010 and the previous release. It is a spur gear (helix angle =0) with the equal face width b=44mm. In fig. 8a there is no tip rounding applied whereas in fig. 8b there is a tip rounding 0.5mm. The pressure peaks are drastically reduced with the tip rounding.

Fig. 8a: high pressure peak due to no tip rounding

Fig 8b: much lower pressure with tip rounding 0.5mm

2.6 3D display

With KISSsoft release 04-2010 the graphical evaluation has been enhanced with 3D graphics. However, the 2D graphics remain as a good comparison to the previous releases. The 3D graphics show a 3 axis diagram, whereas the color indicates the stress level. In some cases there may be points where the stress data might be missing. In such cases the colors are interpolated directly between two neighboring stress data values. This may result in unequal color display. Figure 9 shows an example of this effect at start and end of contact.

Fig. 9: 3D presentation of stress level

Das könnte Ihnen auch gefallen

- KISSsoft - New Developements in Cylindrical Gear Calculation Oncoming Changes in ISO6336Dokument7 SeitenKISSsoft - New Developements in Cylindrical Gear Calculation Oncoming Changes in ISO6336lionel.barreNoch keine Bewertungen

- AGMA Technical PaperDokument14 SeitenAGMA Technical PaperLuis TestaNoch keine Bewertungen

- Asymmetric Cylindrical GearsDokument6 SeitenAsymmetric Cylindrical Gearsकृष्णकुमार दत्तात्रेय जोशीNoch keine Bewertungen

- Spur Gear DesignDokument4 SeitenSpur Gear DesignKB MambaNoch keine Bewertungen

- Face Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannDokument8 SeitenFace Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannosaniamecNoch keine Bewertungen

- Comparison Between Different Commercial Gear Tooth Contact Analysis Software PackagesDokument16 SeitenComparison Between Different Commercial Gear Tooth Contact Analysis Software PackagesAbhijeet DeshmukhNoch keine Bewertungen

- Spur Gear Design for Mechanical Strength and Surface ResistanceDokument6 SeitenSpur Gear Design for Mechanical Strength and Surface ResistanceANILNoch keine Bewertungen

- How Backlash Affects GearsDokument15 SeitenHow Backlash Affects GearsMohammad Ali TaghdiriNoch keine Bewertungen

- Application and Improvement of Face Load Factor Determination Based On Agma 927Dokument19 SeitenApplication and Improvement of Face Load Factor Determination Based On Agma 927Nursena SEVİNÇNoch keine Bewertungen

- Spur Gear Design Learn EngineeringDokument4 SeitenSpur Gear Design Learn EngineeringImran Sajid ShahidNoch keine Bewertungen

- Elastic Analysis of Load Distribution in Wide Faced Spur GearsDokument208 SeitenElastic Analysis of Load Distribution in Wide Faced Spur GearsJulian Steward100% (1)

- How retaining forces impact spindle bearing preloadDokument6 SeitenHow retaining forces impact spindle bearing preloadmurali036Noch keine Bewertungen

- Profile Shift of Involute Gears - Tec-ScienceDokument17 SeitenProfile Shift of Involute Gears - Tec-ScienceManoj SinghNoch keine Bewertungen

- Calculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMADokument9 SeitenCalculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMAretrospect1000Noch keine Bewertungen

- KissSoft Article GearAnalysisAndOptimization PDFDokument12 SeitenKissSoft Article GearAnalysisAndOptimization PDFeng13Noch keine Bewertungen

- Dynamic Load Analysis and Optimization of A Fracture-Split Connecting RodDokument11 SeitenDynamic Load Analysis and Optimization of A Fracture-Split Connecting RodRahul BadgujarNoch keine Bewertungen

- BevelDokument20 SeitenBevelOmer NadeemNoch keine Bewertungen

- CH 14Dokument13 SeitenCH 14mssaber77Noch keine Bewertungen

- Long Addendum Gears 1946Dokument15 SeitenLong Addendum Gears 1946Marco ViniciusNoch keine Bewertungen

- MECH 344/M Machine Element DesignDokument75 SeitenMECH 344/M Machine Element DesignlitonNoch keine Bewertungen

- Modern Shaft CalculationDokument8 SeitenModern Shaft CalculationNajaf HussainNoch keine Bewertungen

- Design and Structural Analysis of Spur Gear Using Various MaterialsDokument15 SeitenDesign and Structural Analysis of Spur Gear Using Various MaterialsprajeeshNoch keine Bewertungen

- Bending Load Capacity Enhancement Using Asymmetric Tooth ProfilesDokument7 SeitenBending Load Capacity Enhancement Using Asymmetric Tooth ProfilesJavier Antonio Cardenas OliverosNoch keine Bewertungen

- International Journal of Computational Engineering Research (IJCER)Dokument7 SeitenInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)Noch keine Bewertungen

- Technical NoteFunction of A WasherDokument8 SeitenTechnical NoteFunction of A Washerkirabalicemil4949Noch keine Bewertungen

- High Speed Gears-Design and Application by James R. PartridgeDokument10 SeitenHigh Speed Gears-Design and Application by James R. PartridgeAbbasAnsariNoch keine Bewertungen

- Spiral Bevel Gear - Calculation of StrenghtDokument28 SeitenSpiral Bevel Gear - Calculation of StrenghtCarlo_Filippin85% (13)

- BacklashDokument6 SeitenBacklashHarihar PanigrahiNoch keine Bewertungen

- App 014 Combining KISSsys FEMDokument8 SeitenApp 014 Combining KISSsys FEMalexNoch keine Bewertungen

- Modeling Bolted Connections in ANSYS: Bonded, Beam, Spring & Solid BoltsDokument7 SeitenModeling Bolted Connections in ANSYS: Bonded, Beam, Spring & Solid BoltsAlmir PendekNoch keine Bewertungen

- An Algorithm For Robust Gear Modifications DesignDokument16 SeitenAn Algorithm For Robust Gear Modifications DesignAbhijeet DeshmukhNoch keine Bewertungen

- Ijmet 07 05 023Dokument12 SeitenIjmet 07 05 023SANDEEP BUDANIANoch keine Bewertungen

- Planetary Gear SystemDokument11 SeitenPlanetary Gear SystemNikhil NairNoch keine Bewertungen

- Simpson Strong-Tie CFS Designer ManualDokument26 SeitenSimpson Strong-Tie CFS Designer Manualdnl_vicarsNoch keine Bewertungen

- ARB DesignDokument4 SeitenARB Designtamilselvan33Noch keine Bewertungen

- Part 1 - Endeavos InnovaDokument10 SeitenPart 1 - Endeavos InnovatarekNoch keine Bewertungen

- The Effects of Addendum Modification Coefficient On Tooth Stresses of Spur GearDokument8 SeitenThe Effects of Addendum Modification Coefficient On Tooth Stresses of Spur GearSezgin BayrakNoch keine Bewertungen

- AGMA FTM 05 Tooth Form Calculation EDokument13 SeitenAGMA FTM 05 Tooth Form Calculation Etropical0007Noch keine Bewertungen

- Fatigue Analysis of An Automotive Stabilizer BarDokument4 SeitenFatigue Analysis of An Automotive Stabilizer BarAbhay KhotNoch keine Bewertungen

- Introduction To Direct Gear DesignDokument15 SeitenIntroduction To Direct Gear DesignburaktuncerNoch keine Bewertungen

- Bevel ExplanationDokument4 SeitenBevel ExplanationVarun VaidyaNoch keine Bewertungen

- Thin Rims For Internal GearsDokument8 SeitenThin Rims For Internal GearsMass Giovani100% (1)

- Converção de Valores AGMA - ISO - ArtigoDokument8 SeitenConverção de Valores AGMA - ISO - ArtigoWagner AbreuNoch keine Bewertungen

- Isma2012 0731Dokument12 SeitenIsma2012 0731ranim najibNoch keine Bewertungen

- Design Analysis of Spur Gear With The Usage of The Advanced ComputerDokument6 SeitenDesign Analysis of Spur Gear With The Usage of The Advanced ComputerMohammed JimmyNoch keine Bewertungen

- Flyer Rolling Bearing AnalysisDokument4 SeitenFlyer Rolling Bearing AnalysisBikash Ranjan SahooNoch keine Bewertungen

- Effects of Profile Corrections On Peak-to-Peak Transmission ErrorDokument10 SeitenEffects of Profile Corrections On Peak-to-Peak Transmission ErrorcoroNoch keine Bewertungen

- 1 - C.J. Carter, C.J. Duncan - Recent Changes in U.S. Connection Design PracticeDokument8 Seiten1 - C.J. Carter, C.J. Duncan - Recent Changes in U.S. Connection Design Practiceb52raleighNoch keine Bewertungen

- Problem StatemenetDokument7 SeitenProblem StatemenetlitonNoch keine Bewertungen

- Specwise PDFDokument3 SeitenSpecwise PDFJuan Gutier CcNoch keine Bewertungen

- IADC/SPE 49495: Optimizing Bent Housing Angle in Steerable BHA Mohamed O. AI Attas, ADMA-OPCO, Abu Dhabi, UAEDokument6 SeitenIADC/SPE 49495: Optimizing Bent Housing Angle in Steerable BHA Mohamed O. AI Attas, ADMA-OPCO, Abu Dhabi, UAEsaeed65Noch keine Bewertungen

- Calculation of The Tooth Root Load Carrying Capacity of Beveloid GearsDokument10 SeitenCalculation of The Tooth Root Load Carrying Capacity of Beveloid GearsdineshkshirsagarNoch keine Bewertungen

- Luk Kolloquium en PDFDokument180 SeitenLuk Kolloquium en PDFDevakumarNoch keine Bewertungen

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisVon EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNoch keine Bewertungen

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsVon EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsBewertung: 4 von 5 Sternen4/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Planar Linkage Synthesis: A modern CAD based approachVon EverandPlanar Linkage Synthesis: A modern CAD based approachNoch keine Bewertungen

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- How To Inspect A GearboxDokument9 SeitenHow To Inspect A Gearboxroberto_perracini100% (1)

- API Roldanas e TamboresDokument5 SeitenAPI Roldanas e Tamboresroberto_perraciniNoch keine Bewertungen

- 1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,LrregularDokument3 Seiten1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,Lrregularroberto_perraciniNoch keine Bewertungen

- Keyed vs Keyless Connections: Torque, Backlash, and FrettingDokument3 SeitenKeyed vs Keyless Connections: Torque, Backlash, and Frettingroberto_perraciniNoch keine Bewertungen

- Macro PittingDokument1 SeiteMacro Pittingroberto_perraciniNoch keine Bewertungen

- Vibration Analysis For GearsDokument5 SeitenVibration Analysis For GearsJaime Berry100% (1)

- AteDokument3 SeitenAteroberto_perraciniNoch keine Bewertungen

- Ameri DriveDokument1 SeiteAmeri Driveroberto_perraciniNoch keine Bewertungen

- CarbDokument84 SeitenCarbJurun_BidanshiNoch keine Bewertungen

- General Design Principles For BearingsDokument8 SeitenGeneral Design Principles For Bearingsmehdi7891Noch keine Bewertungen

- VTBS-P-01-019 en 201008 Produktuebersicht Bildschirm PDFDokument20 SeitenVTBS-P-01-019 en 201008 Produktuebersicht Bildschirm PDFroberto_perraciniNoch keine Bewertungen

- Plastic DeformationDokument1 SeitePlastic Deformationroberto_perraciniNoch keine Bewertungen

- THE POWER OF EMOTIONAL GEARBOXESDokument22 SeitenTHE POWER OF EMOTIONAL GEARBOXESroberto_perraciniNoch keine Bewertungen

- Ball Mill Gearbox Case History - BCEASE 2016Dokument43 SeitenBall Mill Gearbox Case History - BCEASE 2016roberto_perraciniNoch keine Bewertungen

- Gearbox Design PrinciplesDokument20 SeitenGearbox Design Principlesschumiizz2best100% (2)

- Gear Couplings PDFDokument8 SeitenGear Couplings PDFroberto_perraciniNoch keine Bewertungen

- Brittle FractureDokument2 SeitenBrittle Fractureroberto_perraciniNoch keine Bewertungen

- PA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZDokument1 SeitePA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZroberto_perraciniNoch keine Bewertungen

- Lubrication Tips Part 1Dokument2 SeitenLubrication Tips Part 1roberto_perraciniNoch keine Bewertungen

- Lubrication Tips Part 2Dokument2 SeitenLubrication Tips Part 2roberto_perraciniNoch keine Bewertungen

- Ductile FractureDokument1 SeiteDuctile Fractureroberto_perraciniNoch keine Bewertungen

- Mixed Mode FractureDokument1 SeiteMixed Mode Fractureroberto_perraciniNoch keine Bewertungen

- Brittle Fracture PDFDokument2 SeitenBrittle Fracture PDFroberto_perraciniNoch keine Bewertungen

- Mu48 Rebite de Repuxo Pop Padrao Din 7337 Tipo A Sim Iso 15983Dokument1 SeiteMu48 Rebite de Repuxo Pop Padrao Din 7337 Tipo A Sim Iso 15983roberto_perraciniNoch keine Bewertungen

- Mu48 Rebite de Repuxo Pop Padrao Din 7337 Tipo A Sim Iso 15983Dokument1 SeiteMu48 Rebite de Repuxo Pop Padrao Din 7337 Tipo A Sim Iso 15983roberto_perraciniNoch keine Bewertungen

- Tas 4006 enDokument2 SeitenTas 4006 enroberto_perraciniNoch keine Bewertungen

- 3015.1 DK torque transmission bush specificationsDokument2 Seiten3015.1 DK torque transmission bush specificationsroberto_perraciniNoch keine Bewertungen

- Tas 8006 enDokument3 SeitenTas 8006 enroberto_perraciniNoch keine Bewertungen

- Tas 3012 enDokument2 SeitenTas 3012 enroberto_perraciniNoch keine Bewertungen

- MU05 Rosca Metrica Grossa TecemDokument1 SeiteMU05 Rosca Metrica Grossa Tecemroberto_perraciniNoch keine Bewertungen

- Chapter 2 - Waveguide PDFDokument38 SeitenChapter 2 - Waveguide PDFHiroshi RayNoch keine Bewertungen

- Exam Primer McqsDokument25 SeitenExam Primer Mcqsjohn eric100% (1)

- 1st Year Important Questions 2019 - 2020Dokument3 Seiten1st Year Important Questions 2019 - 2020Lohith CharyNoch keine Bewertungen

- AISC-LRFD93 Untuk Perencanaan Stuktur Baja Dengan SAP2000Dokument30 SeitenAISC-LRFD93 Untuk Perencanaan Stuktur Baja Dengan SAP2000irbar.darmansyah.alwi100% (2)

- Charged ParticlesDokument19 SeitenCharged Particlesjonan_evansNoch keine Bewertungen

- FEA Lab Manual for SV College of EngineeringDokument139 SeitenFEA Lab Manual for SV College of Engineeringडॉ. कनिष्क शर्माNoch keine Bewertungen

- Distillation: Enthalpy Concentration Methods (HX) Diagram or Ponchon Savarit MethodDokument9 SeitenDistillation: Enthalpy Concentration Methods (HX) Diagram or Ponchon Savarit MethodRose Dane Escobedo DiestaNoch keine Bewertungen

- LC OscillationDokument20 SeitenLC Oscillationaditya66605Noch keine Bewertungen

- Skema Fizik SPM Trial Perak 2009Dokument16 SeitenSkema Fizik SPM Trial Perak 2009fizmie100% (2)

- Thermal Science and Engineering Progress: SciencedirectDokument22 SeitenThermal Science and Engineering Progress: Sciencedirect조기현Noch keine Bewertungen

- Cambridge International AS & A Level Chemistry Workbook Roger Norris, Mike Wooster (2020)Dokument365 SeitenCambridge International AS & A Level Chemistry Workbook Roger Norris, Mike Wooster (2020)APURVA YADAV100% (1)

- Shielding of Power CablesDokument4 SeitenShielding of Power Cablespmaniamp100% (1)

- How To Convert Celsius To FahrenheitDokument1 SeiteHow To Convert Celsius To FahrenheitLV Martin0% (1)

- EE213 Applied Electrical Engineering Course OverviewDokument18 SeitenEE213 Applied Electrical Engineering Course OverviewElbert VonVerimNoch keine Bewertungen

- Quantum Mechanics ch5 - 2Dokument5 SeitenQuantum Mechanics ch5 - 2alex61937Noch keine Bewertungen

- Questions of MRI - True FalseDokument2 SeitenQuestions of MRI - True FalseHoang Dinh MinhNoch keine Bewertungen

- MicromagnetsDokument5 SeitenMicromagnetsTa BarNoch keine Bewertungen

- Significant Figures, Scientific Notation and Metric PrefixesDokument3 SeitenSignificant Figures, Scientific Notation and Metric PrefixesmphoNoch keine Bewertungen

- General Chemistry 2 Kinetic Molecular Model of Solids and LiquidsDokument3 SeitenGeneral Chemistry 2 Kinetic Molecular Model of Solids and LiquidsJohnmark RaquiñoNoch keine Bewertungen

- Experiment 4: Conditions For Equilibrium Laboratory ReportDokument6 SeitenExperiment 4: Conditions For Equilibrium Laboratory ReportNathaniel Soriano BaluyutNoch keine Bewertungen

- Design of a submerged slide gate structureDokument11 SeitenDesign of a submerged slide gate structurealiNoch keine Bewertungen

- Fa 2 Brood 3Dokument8 SeitenFa 2 Brood 3LanceDavidNoch keine Bewertungen

- Tutorial #3 #ProblemsDokument5 SeitenTutorial #3 #ProblemsAisha AbuzgaiaNoch keine Bewertungen

- Waves Transfer EnergyDokument40 SeitenWaves Transfer EnergyGellirose S. Bantayan100% (1)

- Industrial and Measurement Applications of LasersDokument7 SeitenIndustrial and Measurement Applications of LasersShaik RoshanNoch keine Bewertungen

- Chemical Engineering MathematicsDokument103 SeitenChemical Engineering MathematicsRyan NurisalNoch keine Bewertungen

- 1st Year Formula SheetDokument14 Seiten1st Year Formula SheetSaim SultanNoch keine Bewertungen

- Chapter 4 PDFDokument47 SeitenChapter 4 PDFAdolfo ElizondoNoch keine Bewertungen

- Flow Around Cylinder With CirculationDokument27 SeitenFlow Around Cylinder With CirculationchandwanivinayNoch keine Bewertungen

- Shell and Tube Heat ExchangerDokument31 SeitenShell and Tube Heat ExchangerDhiyyah Mardhiyyah100% (1)